Analysis of Voltage and Electric Current in a Web-based Solar Power

Plant

Riza Hadi Saputra, A. M. Miftahul Huda, Ain Sahara, Yohanes Robinson Deky Rohie

Sekolah Tinggi Teknologi Minyak dan Gas Bumi, East Borneo, Indonesia

Keywords: Solar Power Plant, Arduino Uno, Voltage, Current, GSM SIM800L

Abstract: Solar Power Plant utilizes solar energy into electricity. Important data generated from electrical energy can

be in the form of voltage and current where measurements are made by a multimeter in which its measurement

results cannot be done remotely and stored automatically. Therefore, it is necessary to design a tool that can

measure voltage and current from electrical energy over long distances in which its value can be automatically

stored in a database and displayed on the website. This system is built from GSM SIM800L as a data sender,

Arduino Uno as a data processor, Voltage Sensor as a voltage sensor, and ACS712-30A as a current sensor.

If the manual measurement is used as a reference, the level of accuracy of measurements on currents is 30%;

while, if the automatic measurement as a reference is used, it is 45%. In addition, if the manual measurement

is used as a reference in voltage measurements, the level of accuracy is 2%; while, if the automatic

measurement is used as a reference, it is 2%. Which is the lower the level of accuracy, the better the value;

on the contrary, the greater the level of accuracy, the worse the value?

1 INTRODUCTION

Solar Power Plant utilizes solar energy into electricity

where this type of power plant will never run out; it is

a power plant in which its main component is sunlight

that can always be renewable (Reatti, Kazimierczuk,

Catelani, & Ciani, 2017). In addition to solar power

as the main component, of course, there are several

other components used to support the conversion of

solar energy into electrical energy. Some components

commonly used include solar panels to capture solar

energy and convert it to electrical energy, the battery

as a storage place for electrical energy generated, the

inverter is used to convert current from DC to AC,

and several supporting cables for the installation of

the Solar Power Plant components so that it can work

well (Gurung et al., 2017).

When solar energy is converted to electrical

energy, we can measure the electrical energy obtained

through a multimeter (Unger et al., 2014). Usually,

the main thing that is measured in electrical energy is

the voltage and current generated. Because the

electrical energy produced will run continuously to

get data through the values that have been recorded

from observations of the power plant. Important data

that can be obtained include the amount of voltage

obtained and the current entering the battery or

battery (Mehne & Nowak, 2018).

From this background, a device that can display

data of voltage and current is made, the

communication of which data can be done wirelessly,

because so far the voltage and current measurements

made using a multimeter are limited to the length of

the multimeter cable that makes the measurements

must be made on the area to be measured (Adhya,

Saha, Das, Jana, & Saha, 2016). One of the options to

replace it is using GPRS as its data communication.

The advantage of the GPRS signal is its long-range

distance with a note that as long as there is a GPRS

signal in the area, then the data communication can

still be done and can run well. Therefore, GPRS

signals are used as data communication for devices

that will be built using Arduino Uno. Arduino Uno

functions to measure and retrieve data from electrical

energy obtained from solar power plants, and the

existing data is then sent by GSM SIM800L and will

be automatically stored in an already available

database. Furthermore, data that has been stored in a

database can be displayed on the website, and the data

can be seen at any time via the internet (Desima,

Ramli, Ramdani, & Rahman, 2018).

Saputra, R., Huda, A., Sahara, A. and Rohie, Y.

Analysis of Voltage and Electric Current in a Web-based Solar Power Plant.

DOI: 10.5220/0009444601910199

In Proceedings of the 1st International Conference on Industrial Technology (ICONIT 2019), pages 191-199

ISBN: 978-989-758-434-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

191

2 METHODOLOGY

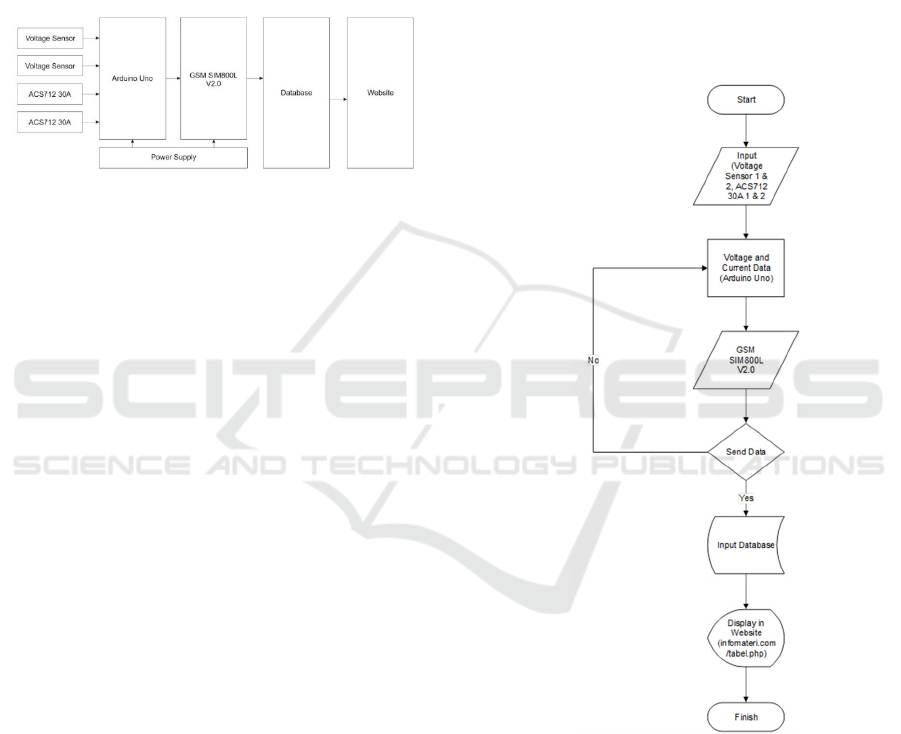

A series of block diagrams is one of the most

important parts of the design of an instrument. From

the block diagram, it can be seen the working

principle of the whole circuit. So that the whole series

of block diagrams will produce a system that can

function as the working principle of the design of an

instrument. The block diagram design can be seen in

Figure 1.

Figure 1: Block Diagram

a. Arduino Uno

Used for the calculation process and pin-

gathering place of the sensor, which will then

be inserted a script that will be able to calculate

the desired output value.

b. GSM SIM800L V2.0

As a tool used to send data to databases on the

internet.

c. Voltage Sensor

As a tool used to obtain the value of the voltage

of an electronic device that is powered by

electricity.

d. ACS712-30A

As a tool used to get the current value of a load.

e. Resistor

It is an electronic component that has two pins

and is designed to regulate electrical voltage

and electric current. The resistor in the device

to be built is used as a voltage divider that

serves to reduce the voltage from the voltage

source to be measured.

f. Breadboard/PCB

Used to install components and connect

electronic components with other electronic

components.

g. Power Supply

To convert AC into DC which is then converted

into power or energy needed by the

components

h. Cable

Used to connect electronic components

through pins on components.

i. Antenna

An electrical device that can convert an

electrical signal into electromagnetic waves

and then emit it into free space or vice versa,

namely capture electromagnetic waves from

free space and convert it into electrical signals.

j. Laptop

Used to add, delete, and edit program

languages that are used to send program

languages to Arduino devices.

k. USB Cable

As a connecting device between Arduino and

laptops.

Figure 2 shows a flowchart of research that has

been done.

Figure 2: Research Flowchart

It is designing a device that can send the results of

voltage and current measurements using a voltage

sensor and an ACS712-30A sensor where the voltage

and current values are sent to the database and

displayed on the website. The data that has been

obtained will be sent via GSM SIM800L V2.0

(Septiana, 2018). Sending the value obtained to the

database uses the GPRS network that has been set on

Arduino Uno will make the values occur continuously

to the database. On the website page, there are several

ICONIT 2019 - International Conference on Industrial Technology

192

columns namely the voltage column, the current

column, the voltage usage column, the time column

and the date column; where the last two columns are

automatically created when the value is stored in the

database(Moghimi, Bennett, Leskarac, Stegen, & Lu,

2016).

3 RESULT AND DISCUSSION

3.1 Instrument Design Result

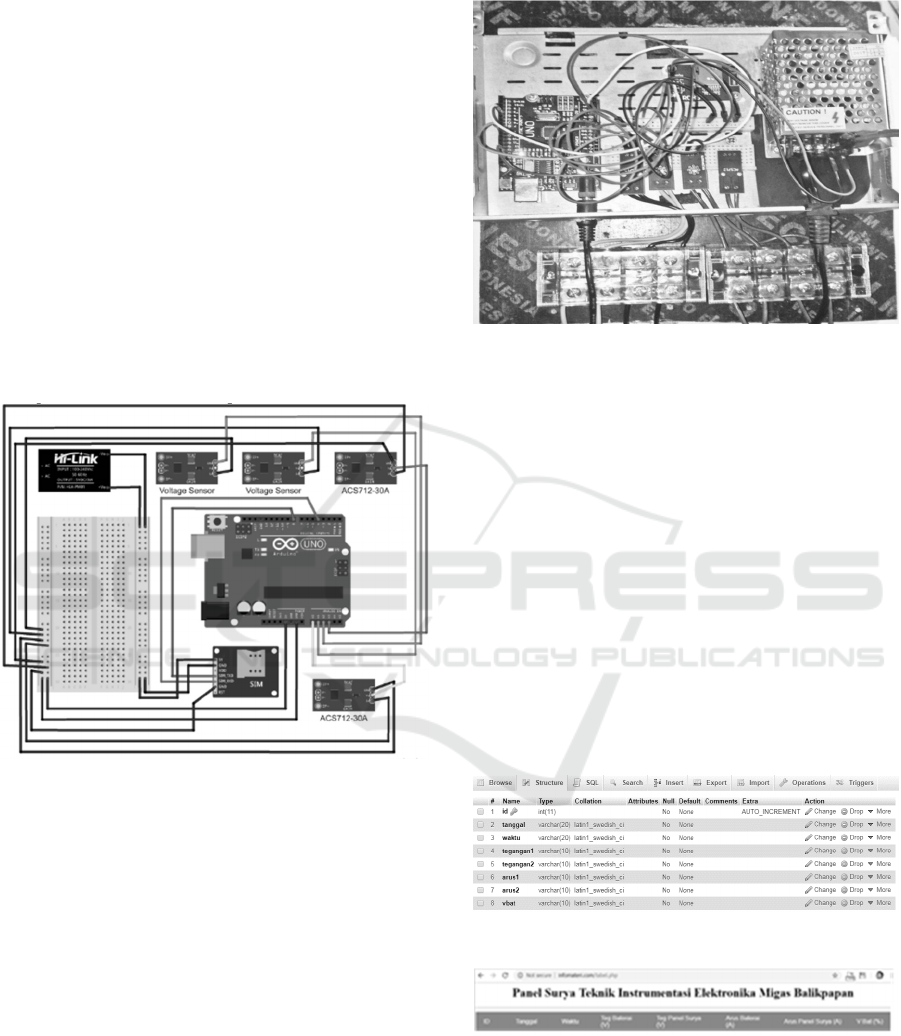

The design of this tool uses a Voltage Sensor and

ACS712-30A to get the measured voltage and current

value, and the main component for data

communication is the GSM SIM800L V2.0 module,

which will be set to send the measurement results to

the database (Turahyo, 2017). Figure 3 shows the

design of a wireless data acquisition instrument.

Figure 3: Design of a Wireless Data Acquisition Instrument

Figure 3 shows a power supply with a 5VDC

voltage and 3A current to run the GSM SIM800L

V2.0 module. On the voltage sensor, there are three

pins, namely signal pins (S), plus pins (+) and minus

pins (-). At the end of the voltage sensor, there are two

wires to connect to the voltage source, which was

measured. For the current sensor, ACS712-30A uses

three pins on ACS712-30A, namely VCC pin, OUT

pin and GND pin. At the other end, there are two

wires connected to the load to measure the current.

The voltage sensor and ACS712-30A are assembled

on a breadboard that has been installed on the chassis.

Figure 4 shows an instrument that has been

created from the results of the design. Almost all pins

of the component are connected to Arduino Uno.

Arduino Uno sends the processed data through pin

four, which is received by GSM SIM800L V2.0. The

data that has been processed is sent to the database by

GSM SIM 800L V2.0 through the GPRS network.

Figure 4: Instrument created from the research design

3.2 Results of Design in Database and

Website

After the tool has been completed, as seen in Figure

4, the next step is to set the website to be used in this

study. The first step is to open a browser on a laptop

and then enter the database by filling in an existing

username and password (Abidin, Jusoh, James, Al

Junid, & Mohd Yassin, 2015). Select the database,

then select the table that has been saved in the

database. Figure 5 shows the names of the columns

made in the table named table tb_tes in the database.

In addition to the columns in the database, there is

also a list of columns on the website that has been

created and have been uploaded at

http://infomateri.com/tabel.php, as shown in Figure

6.

Figure 5: Names of columns in the database

Figure 6: Column that has been made

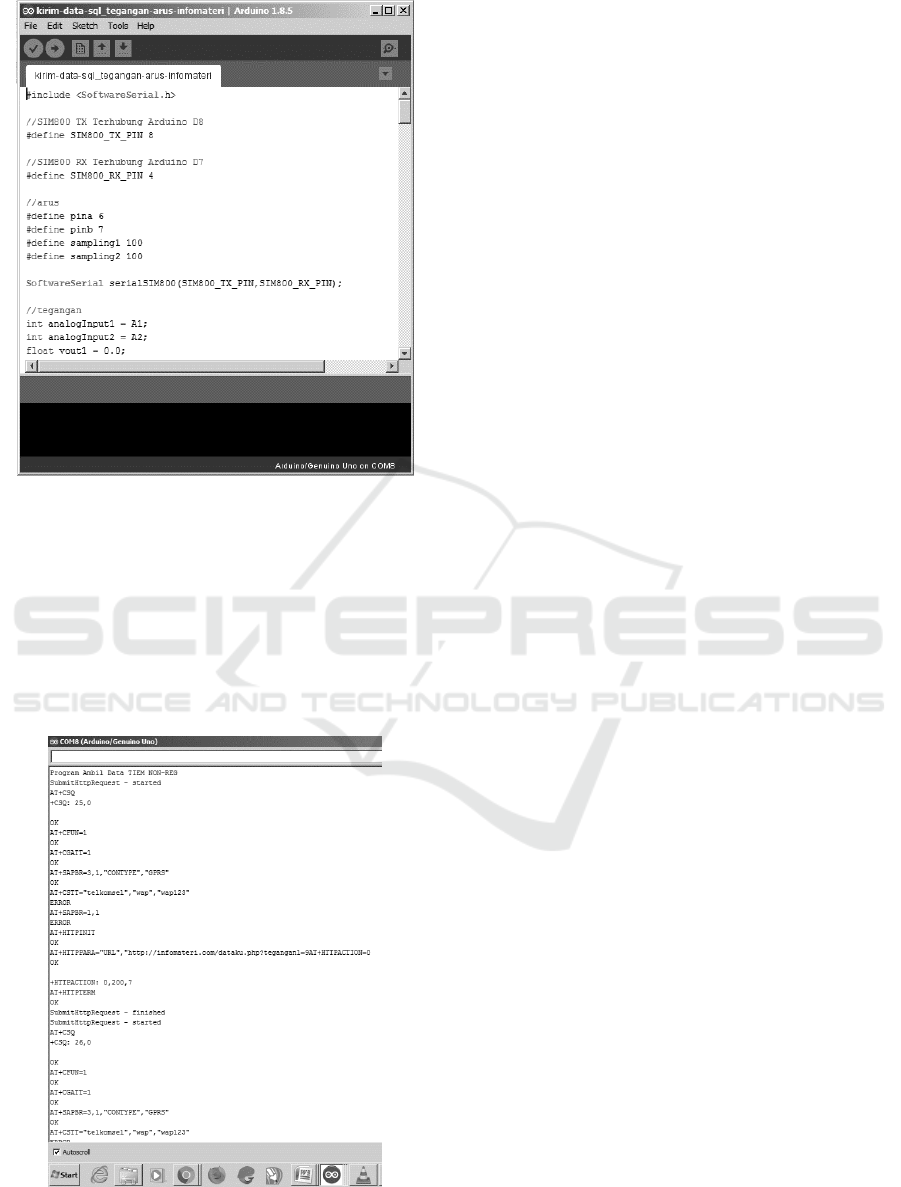

After the database and tables on the website have

been completed, the next step is to send the created

program to Arduino Uno. Figure 7 shows the Arduino

Uno source code that has been created to connect the

Arduino Uno with the database.

Analysis of Voltage and Electric Current in a Web-based Solar Power Plant

193

Figure 7: Source Code for Arduino Uno Connection to

Database

When the program has been successfully sent to

Arduino Uno, we can monitor the results of programs

that have been made through the Serial Monitor in the

Arduino IDE application. Besides, this application

can also see the course of programs that we have

made. Figure 8 shows the Serial Monitor results of a

successful connection between Arduino Uno and the

database.

Figure 8: Results of the Connection between Arduino Uno

and the Database

The following is a detailed explanation of the

source code in Figure 8.

a. TIEM NON-REG Data Download Program

The title when the program is first to run

b. Submit HTTP request - started

Program markers can run

c. AT+CSQ

Check the signal quality of the provider of the

SIM Card used

d. AT+CFUN=1

Prepare the function of the module, which has

value 1, where value 1 means “full

functionality," and the power taken is the

highest level.

e. AT+CGATT=1

The command is used to attach or disconnect

the device to the domain package service,

where command 1 is to activate the attachment.

f. AT+SAPBR=3,1,“CONTYPE”,“GPRS”

As a bearer regulator for IP-based applications,

where number 3 is the bearer parameter setting,

and number 1 is the identification of the

bearer’s profile. “CONTYPE” means a type of

internet connection, and “GPRS” means the

type of connection used.

g. AT+CSTT=“Telkomsel”,“wap”,“wap123”

To start setting APN, username, and password

on the SIM Card that is used. Since the service

used is Telkomsel, then the APN, username and

password settings follow Telkomsel settings

h. AT+SAPBR=1,1

Bearer settings, where the first 1 value to open

the bearer and the second 1 value to connect the

bearer.

i. AT+HTTPINIT

To initialize or activate the HTTP service, this

command must be used first before using the

HTTP service

j. AT+HTTPPARA=“URL”,“http://infomateri.c

om/dataku.php?tegangan”.

Set HTTP parameters and to regulate sending

data to the URL address on the website

k. AT+HTTPACTION=0

Delivering HTTP parameters that have been set

up, where the value 0 gives a command with

the POST Method, which means sending data

or values directly to the action to be contained,

without displaying the URL.

l. AT+HTTPTERM

Terminate the HTTP service

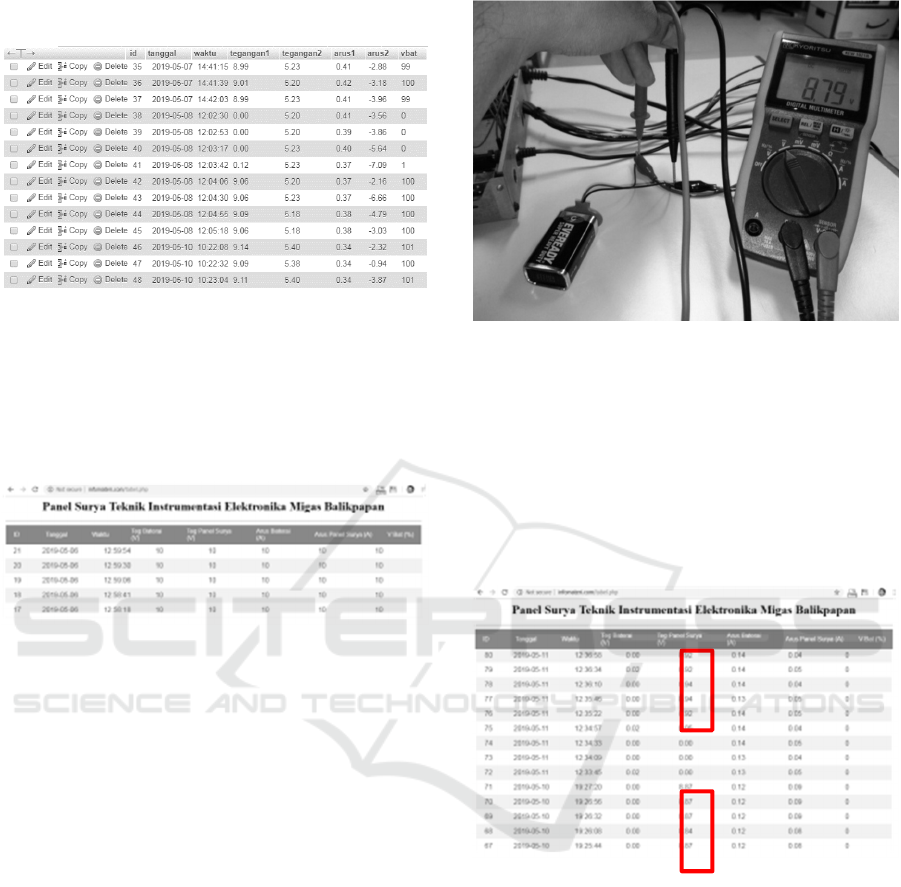

When the program successfully runs and sends

data, the table in the database will enter the data sent

ICONIT 2019 - International Conference on Industrial Technology

194

from GSM SIM800L V2.0. Figure 9 shows data that

has been successfully sent and stored in a database.

Figure 9: Data has been successfully sent to the database

When the data has been inputted to the database,

the data on the website will be automatically updated.

The data stored on the website can be seen at

http://infomateri.com/tabel.php. Figure 10 shows the

display of data on the website.

Figure 10: Data display on the website

In Figure 10, the incoming data is in the form of

Teg 1 (V) for voltage measurement 1, Teg 2 (V) for

voltage measurement 2, Current 1 (A) for current

measurement 1, Current 2 (A) for current

measurement 2 and V Bat (%)for the percentage of

battery conditions.

3.3 Measurement Tests on 9VDC

Batteries

This test was done to compare the value displayed on

the website with the value measured using a

multimeter. This started with a 9VDC battery as a

trial sample. The battery used is connected to a

voltage sensor. The first thing to do is to measure the

voltage value on the battery using a multimeter with

the voltage measurement result obtained is 8.79VDC.

Figure 11 shows the 9VDC Battery Voltage

Measurement.

Figure 11: 9VDC Battery Voltage Measurement

After the measurement using a multimeter, the

next step is to measure through a device that has been

made. The trick is to connect the battery to the voltage

sensor to calculate the voltage obtained. After all the

tools are installed, it needs to wait for 1 minute, and

the measurement results can be seen on the website

on http://infomateri.com/tabel.php. Figure 12 shows

a 9VDC battery data display.

Figure 12: 9VDC Battery Data Display

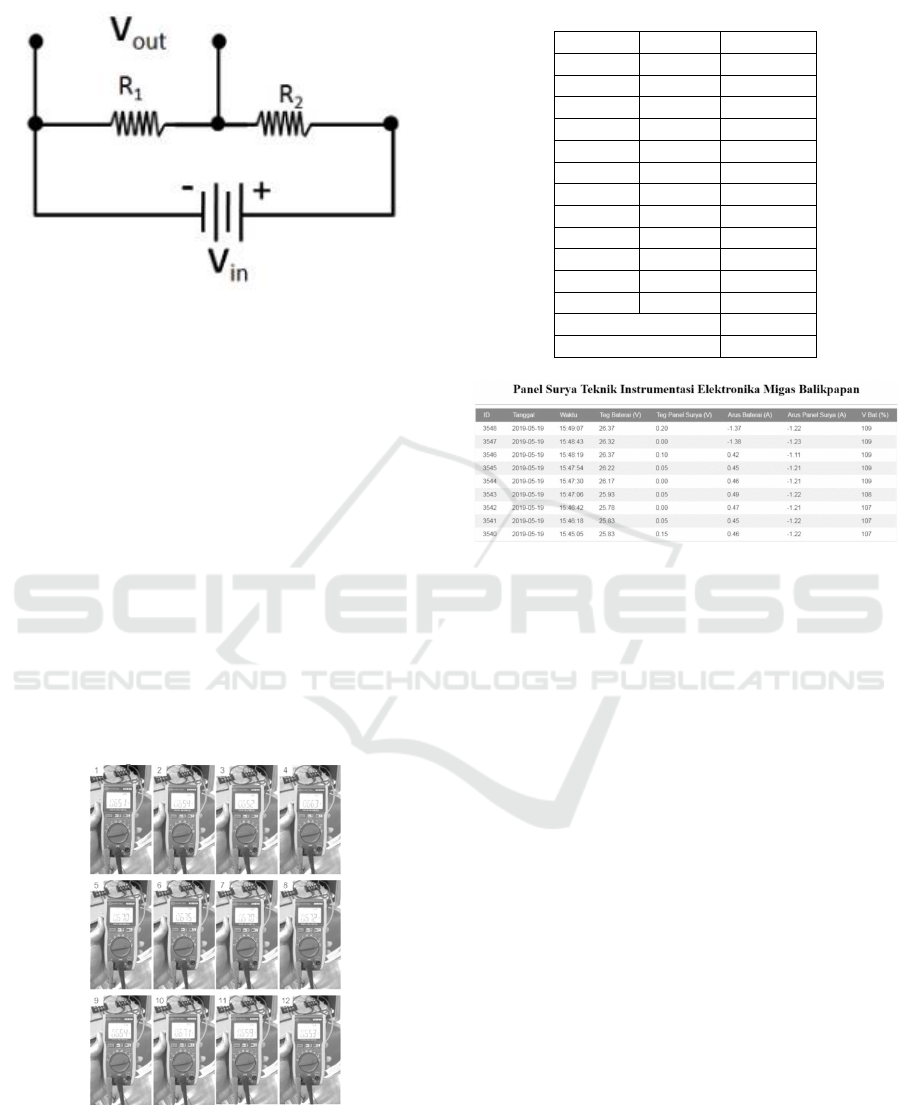

3.4 Voltage Divider

Because the voltage obtained from the solar panel is

in the range of 28-40 VDC and the voltage sensor can

only measure a maximum of 25 VDC, a voltage

divider is made using a resistor to avoid the value

entered into the voltage sensor exceeding 25 VDC. A

voltage divider is a simple circuit that converts large

voltages into smaller voltages. It functions to divide

the input voltage into one or several output voltages

needed by other components in the circuit. Using two

or more resistors and input voltage, a simple voltage

divider circuit can be made. Figure 13 shows an

example of a voltage divider that has been made.

Analysis of Voltage and Electric Current in a Web-based Solar Power Plant

195

Figure 13: Voltage Divider

3.5 Deviation

In statistics and probabilities, the standard deviation

is the most common measure of statistical

distribution. In short, this method measures the values

of scattered data so that the values that have been

scattered can be seen whether close to the original or

not. In this study, the standard deviation is used to see

whether the values on the website are similar to those

on the multimeter.

3.5.1 Battery Current without Solar Power

Plant

Figure 14 shows the acquisition of battery current

data without solar panels taken 12 times. Meanwhile,

Figure 15 shows the display of battery current data

without a solar power plant on the website.

Figure 14: Battery Current Data Acquisition without Solar

power plant

Table 1: Standard Deviation of Battery Current Data

without Solar Panels

Sample Seconds Value (A)

1 0 0.651

2 2 0.654

3 4 0.652

4 6 0.663

5 8 0.670

6 10 0.675

7 12 0.670

8 14 0.672

9 16 0.664

10 18 0.671

11 20 0.659

12 22 0.653

Average 0.663

Standard Deviation 0.009

Figure 15: Data Display of Battery Current without Solar

power plant

It can be seen in Figures 14 and 15 that the

difference from the average value and the results on

the website is 0.19 A, and the deviation distance is

plus or minus 0.009 from the average value that can

be seen in Table 1. Therefore, the results of

comparison with multimeters towards the

measurements which are displayed on the web page

are not within the standard deviation range.

3.5.2 Battery Current with Solar Power

Plant

Figure 16 shows the acquisition of battery current

data with solar panels taken 12 times. Meanwhile,

Figure 17 shows the display of battery current data

with the solar power plant on the website.

ICONIT 2019 - International Conference on Industrial Technology

196

Figure 16: Battery Current Data Acquisition with Solar

power plant

Table 2: Standard Deviation of Battery Current Data with

Solar Panels

Sample Seconds Value (A)

1 0 -1.447

2 2 -1.398

3 4 -1.379

4 6 -1.411

5 8 -1.426

6 10 -1.431

7 12 -1.436

8 14 -1.411

9 16 -1.454

10 18 -1.430

11 20 -1.421

12 22 -1.409

Average -1.421

Standard Deviation 0.021

Figure 17: Data Displays of Battery Current with Solar

power plant

Figures 16 and 17 show that the difference from

the average value and the results on the website is

0.17 A, and the deviation distance is plus or minus

0.021 from the average value that can be seen in Table

2. Therefore, the results of comparison with

multimeters towards measurements which is

displayed on the web page are not within the standard

deviation range.

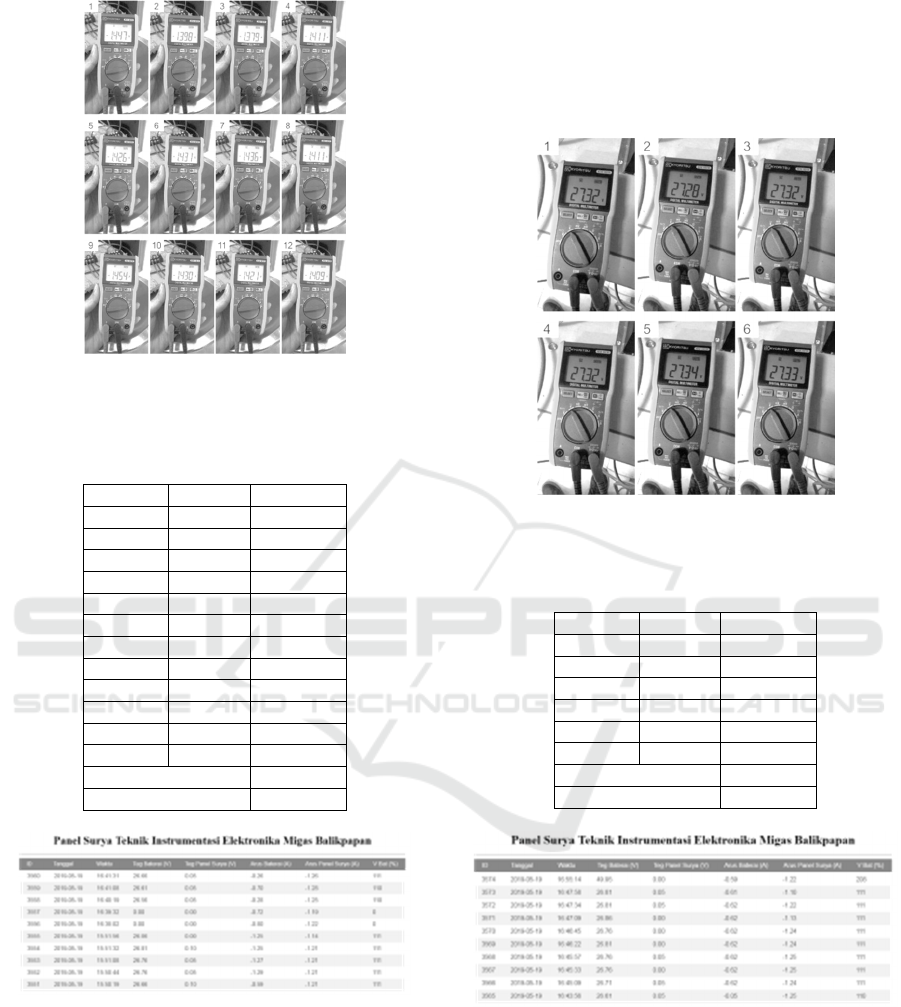

3.5.3 Battery Voltage with Solar power

plant

Figure 18 shows the battery voltage data taken six

times, while Figure 19 is a display of battery voltage

data that is on the website.

Figure 18: Battery Voltage Data Acquisition with Solar

power plant

Table 3: Standard Deviation of Battery Voltage Data with

Solar Panels

Sample Seconds Value (A)

1 0 27.32

2 5 27.28

3 10 27.32

4 15 27.32

5 20 27.34

6 25 27.33

Average 27.32

Standard Deviation 0.02

Figure 19: Display Data Battery Voltage with Solar power

plant

It can be seen in Figure 18 and 17 that the

difference from the average value and the results on

the website is 0.56VDC, while the standard deviation

distance is plus or minus 0.02 from the average value

that can be seen in Table 2. Therefore, the results of

comparison with multimeters towards the

Analysis of Voltage and Electric Current in a Web-based Solar Power Plant

197

measurements which is displayed on the web page are

not within the deviation range.

4 ANALYSIS

Comparison of data obtained on battery currents

without solar panels, battery currents with solar

panels and voltage on the battery against the

multimeter has not shown the appropriate result, and

there is a significant difference in value, where the

constraints that occur due to the elaboration and

definition of the programming language made are

incorrect. Therefore, there are still differences in the

value produced.

If the manual measurement is used as a reference,

the level of accuracy of measurements on currents is

30%; while, if the automatic measurement is used as

a reference, it is 45%. In voltage measurements, if the

manual measurement is used as a reference, the level

of accuracy is 2%; while, if the automatic

measurement is used as a reference, it is 2%. In this

case, the lower the level of accuracy, the better the

value, while, if the greater the level of accuracy, the

value is worse.

Manual and automatic data acquisition has

advantages and disadvantages. The advantage of

manual data acquisition is to be able to carry out

measurements directly and be able to do physical

checking on the tool and directly take action if there

is damage on the tool; meanwhile, its disadvantages

include that data recorded is easily damaged, and

recorded errors can occur in data collection. The

advantage of automatic data acquisition is that data

can be used together; data security is guaranteed; data

can be accessed anywhere via the internet and can

analyze data faster. Meanwhile, its disadvantages are

that it takes skilled personnel in managing data and

measurement results that are not accurate when

compared to measurements using a multimeter.

5 CONCLUSIONS

Voltage and current gauges can send data to databases

through the internet and can be built using GSM

SIM800L and GPRS as data communication. Data

communication occurs during the measurement

process in a simplex manner. The results of the

current measurement with the multimeter measuring

instrument can be said to be almost the same, the

value that comes out is the result of the processing of

the programming language that is made where the

output is very dependent on the translation and

definition of the programming language. In current

data without solar power plant case, if the manual

measurement is used as a reference, the level of

accuracy of measurements on currents is 30%, while

if the automatic measurement as a reference is used,

it is 45%. In current data with solar power plant case,

if the manual measurement is used as a reference, the

level of accuracy of measurements on currents is

12%, while if the automatic measurement as a

reference is used, it is 13%.In voltage measurements,

if the manual measurement is used as a reference, the

level of accuracy is 2%; while, if the automatic

measurement is used as a reference, it is 2%. In this

case, the lower the level of accuracy, the better the

value; while, the greater the level of accuracy, the

value is worse.

ACKNOWLEDGMENTS

I would like to thank God Almighty because of his

blessing, and this tool can be completed. I would also

say thank to our parents who have provided support,

and prayers for all of us, and for all those whose

names cannot be mentioned one by one. I would also

like to thank the campus community who provided

support, laboratory facilities for the manufacture of

this tool.

REFERENCES

Abidin, A. F. Z., Jusoh, M. H., James, E., Al Junid, S. A.

M., & Mohd Yassin, A. I. (2015). Real-Time Remote

Monitoring with Data Acquisition System. IOP

Conference Series: Materials Science and Engineering,

99(1). https://doi.org/10.1088/1757-899X/99/1/012011

Adhya, S., Saha, D., Das, A., Jana, J., & Saha, H. (2016).

An IoT based smart solar photovoltaic remote

monitoring and control unit. 2016 2nd International

Conference on Control, Instrumentation, Energy and

Communication, CIEC 2016, 432–436.

https://doi.org/10.1109/CIEC.2016.7513793

Desima, M. A., Ramli, P., Ramdani, D. F., & Rahman, S.

(2018). Alarm system to detect the location of IOT-

based public vehicle accidents. 3rd International

Conference on Computing, Engineering, and Design,

ICCED 2017, 2018-March, 1–5.

https://doi.org/10.1109/CED.2017.8308118

Gurung, A., Chen, K., Khan, R., Abdulkarim, S. S.,

Varnekar, G., Pathak, R., … Qiao, Q. (2017). Highly

Efficient Perovskite Solar power plant Photocharging

of Lithium Ion Battery Using DC–DC Booster.

Advanced Energy Materials, 7(11), 1602105.

https://doi.org/10.1002/aenm.201602105

ICONIT 2019 - International Conference on Industrial Technology

198

Mehne, J., & Nowak, W. (2018). Predicting the battery core

temperature: Explanatory power of measurement

quantities under different uncertainty scenarios. Journal

of Energy Storage, 18, 476–484.

https://doi.org/10.1016/j.est.2018.06.001

Moghimi, M., Bennett, C., Leskarac, D., Stegen, S., & Lu,

J. (2016). Communication architecture and data

acquisition for experimental MicroGrid installations.

Asia-Pacific Power and Energy Engineering

Conference, APPEEC, 2016-Janua.

https://doi.org/10.1109/APPEEC.2015.7380917

Reatti, A., Kazimierczuk, M. K., Catelani, M., & Ciani, L.

(2017). Monitoring and field data acquisition system

for hybrid static concentrator plant. Measurement:

Journal of the International Measurement

Confederation, 98, 384–392.

https://doi.org/10.1016/j.measurement.2015.06.022

Septiana, Y. (2018). Design of prototype decision support

system for flood detection based on ultrasonic sensor.

MATEC Web of Conferences, 197.

https://doi.org/10.1051/matecconf/201819703017

Turahyo, N. (2017). Implementasi Sinusoidal Pulse Width

Modulation Pada Inverter Satu Fase Berbasis Lookup

Table Menggunakan Mikrokontroler 16-Bit.

Semnastek, (November), 1–2. Retrieved from

https://jurnal.umj.ac.id/index.php/semnastek/article/vi

ew/2035

Unger, E. L., Hoke, E. T., Bailie, C. D., Nguyen, W. H.,

Bowring, A. R., Heumüller, T., … McGehee, M. D.

(2014). Hysteresis and transient behavior in current-

voltage measurements of hybrid-perovskite absorber

solar power plant. Energy and Environmental Science,

7(11), 3690–3698. https://doi.org/10.1039/c4ee02465f

Analysis of Voltage and Electric Current in a Web-based Solar Power Plant

199