PID Controller Design for Solar Tracking System

Marwan

1

, Muhammad Anshar

2

1

Electrical Engineering Department Polytechnic State of Ujung Pandang Makassar Indonesia

2

Mechanical Engineering Department Polytechnic State of Ujung Pandang Makassar Indonesia

Keywords: Control; design; PID; solar; tracking.

Abstract: The aim of this research is to design solar tracking in order to orientate the solar panel to the maximum

radiation at all times. In the present work, designing of an optimum proportional-integral-derivative (PID)

controller is used to control a dual axis solar tracker system, namely: rotation and elevation. To obtain the

optimum result, two kinds of testing were conducted, namely, testing of mechanical design and PID

parameters. As a result, the mechanical testing indicated that this system can work properly based on the

parameters input. Similar to the PID testing, the response of PID set point with set position rotation and

elevation according to the parameters input. In addition, this research was conducted in an electrical power

system Laboratory in the State Polytechnic of Ujung Pandang, Makassar, Indonesia.

1 INTRODUCTION

Renewable energy is a significant factor in solving

the energy problems of the world. Renewable

energy, such as solar energy, will be consistently

cheaper than fossil fuels. Applying renewable

energy to overcome the lack of electricity sources is

cheaper than connected electricity from the utility.

According to (Kåberger, 2018) renewable electricity

is now starting to replace fossil fuels in other sectors

as the principal low cost factor. Supporting the

development of renewable energy technology can

reduce their costs through economies of scale

(Foster et al., 2017).

Renewable energy technology is a cleaner source

than fossil energy technology. It has brought impact

to the environmental side. The renewable energy

technology has a lower environmental impact than

fossil energy technology. According to (A.K.Akella,

R.P.Saini, & M.P.Sharma, 2009) fossil energy sources

are effective drivers to develop an economy for a

society, however at the same time it can damage

the environment and human health. In addition,

renewable energy is an effective alternative for

reducing air pollution and preventing resources

depletion (C.Cosmi et al., 2003).

Some examples of renewable energy are: solar

energy, wind energy and hydropower. Solar energy

is an effective way keep the environment healthy as

it does not produce water or air pollution. The

authors in (A.H.Almasoud & M.Gandayh, 2015)

argue that the cost of solar energy is cheaper than

fossil fuels when the indirect cost created by fossil

fuel generation includes health and environmental

costs.

In China, the cost of solar power delivery to the

large cities is around 20 $c/kWh (Labordena &

Lilliestam, 2015). Similarly, in USA, the cost of

solar energy ranges from 18 to 23 ¢/kWh, with the

expectation that it will decrease to 5–10 ¢/kWh by

2015 (A.H.Almasoud & M.Gandayh, 2015). In

addition, the cost of renewable energy including

solar and wind energy is approximately $0.326 per

kWh in South Korea (Park & Kwon, 2016).

However, the energy cost for solar energy in Indonesia

ranges from US$ 0.145 – 0.25/kWh (Hamdi, 2019).

Conversely,, applying solar energy in Indonesia has

not been optimized. Some factors have been

influenced by policy, location and technology.

Improving technology to optimize solar energy has

been required to get maximum power, particularly

developing technology to get maximum power from

the sun. Current technology only puts the

photovoltaic cells on roofs. However, it is not

effective in the afternoon or in the morning.

Controlling solar tracking is needed to get optimum

result from the sun. Solar tracking assists to

minimize the angle of incidence. Solar trackers

create more electricity than stationary counterparts

72

Marwan, . and Anshar, M.

PID Controller Design for Solar Tracking System.

DOI: 10.5220/0009431400720077

In Proceedings of the International Conferences on Information System and Technology (CONRIST 2019), pages 72-77

ISBN: 978-989-758-453-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

due to increased direct exposure to solar rays. On the

other hand, solar trackers are slightly more

expensive than stationary counterparts, due to the

more complex technology and moving parts necessary

for their operation.

Solar tracking systems are the best potential methods

for solar power collection (Zheng, Zheng, Ji, & Niu,

2019). According to (Kim & Cho, 2019) in order to

operate most efficiently, solar tracking systems must

be installed to achieved an optimal tilt of solar

panels. Solar tracking is a type of technical

performance to achieve solar radiation by tracking

the position of the sun accurately, considering

various climate changes (Hyuna, Taehoon, &

LeeMinhyun, 2019).

A PID controller is a smart control to manage the

tracking system of the sun. This method was

developed to get an accurate position of the tracking

system. PID is a control loop mechanism employing

feedback that is widely used in industrial control

systems and a variety of other applications requiring

continuously modulated control.

2 LITERATURE REVIEW

Some researchers have been investigated strategies

to control sun tracking, for example, the solar central

receiver developed by (Hu, Shen, & Yao, 2018) to

define the tracking formula of the sun tracking

strategy by using the coordinate rotation

transformation method. The simulated result

illustrated this method can improve the

concentration efficiency of solar central receiver.

Other researchers have developed a sun tracking

design in Tunisia for a solar parabolic (Skouri, Ali,

Bouadila, Salah, & Nasrallah, 2016). To design a

new solar parabolic, the parameters of solar

radiation and angle values were required to operate

in more efficient and feasible ways. In addition,

according to (Singh, Kumar, Gehlot, & Pachauri,

2018) the efficiency of the photovoltaic system can

then be achieved by managing the tracking position

of the sun. In this study, the solar tracking was

developed by Programmable Logic Control (PLC),

microcontroller and Field Programmable Gate Array

(FPGA). The microcontroller applied according to

the capacity and location has installed the solar

tracking. The PLC is designed to assess the

economic aspects.

A new concept of solar detection was developed by

(Away & M.Ikhsan, 2017). This study described

solar detection sensor by using a dual-axis sun

tracking system. This design compares with other

previous types, consequently, this sensor has a high

quantity, accuracy and effectiveness, as shown in

other research (Sinha & S.S.Chandel, 2016). It has

developed two axes tracking compared with all

tracking systems and fixed tilted photovoltaic

system. The result of the research indicated that the

horizontal axis generates 4.8 %-26.2 9% more

energy per year than the existing fixed tilt photovoltaic

system. This methodology has been improved and

recommended to apply in any location in the world.

However, none of these methods have been

mentioned above applied solar tracking by using a

PID controller.

A study of the PID controller has been illustrated in

some references in (M.Mosaad, A.Attia, &

Y.Abdelaziz, 2019; Pradhan, Majhi, KuPradhan, &

Pati, 2018). Author in (B.Rabaoui, H.Hamdi,

Braiek, & M.Rodrigues, 2019) considers the design

of reconfigurable PID fault tolerant for a tracking

controller. This method was developed to reduce the

conservatism of previous methods with more

parameters designed so as to minimize their

disadvantages and to give better control loop

performances, especially in terms of the accuracy

and speed of trajectory tracking even when a fault

occurs. However, the result of this research was not

similar to this project. This project was designed to

manage the solar tracking to be effective and smart

and to accurately measure the position of the sun.

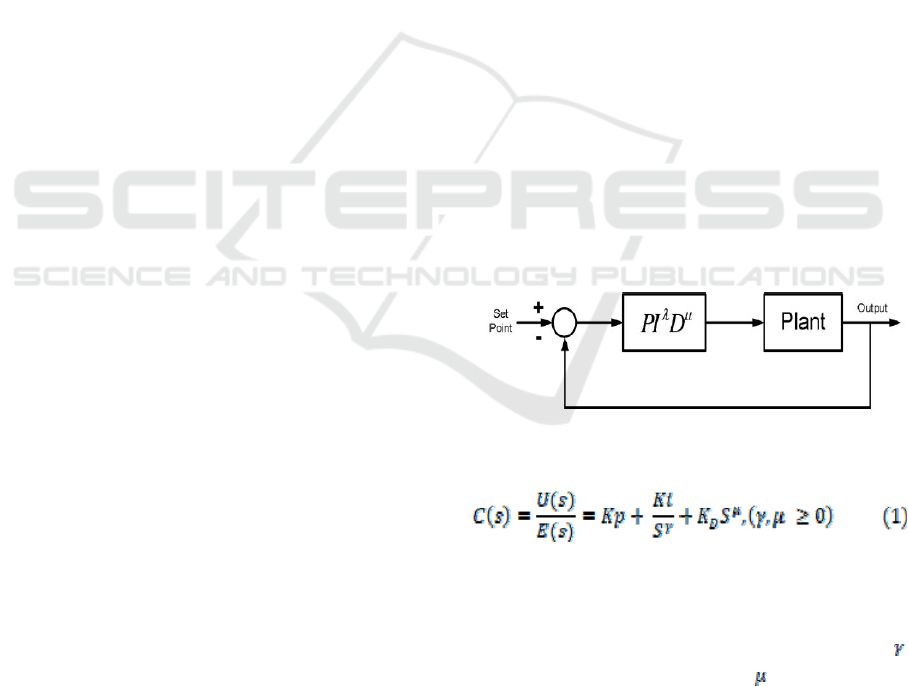

Figure 1 illustrates the general block diagram of PID

controller:

Figure 1: General Block Diagram of PID controller

(Shah & Agashe, 2016).

where, C(s) is the controller output, U(s) is the

control signal, E(s) is the error signal, K P is the

proportional constant gain, K I is the integration

constant gain, K D is the derivative constant gain,

is the order of integration, and

is the order of

differentiator (Away & M.Ikhsan, 2017).

PID Controller Design for Solar Tracking System

73

3 RESEARCH METHODOLOGY

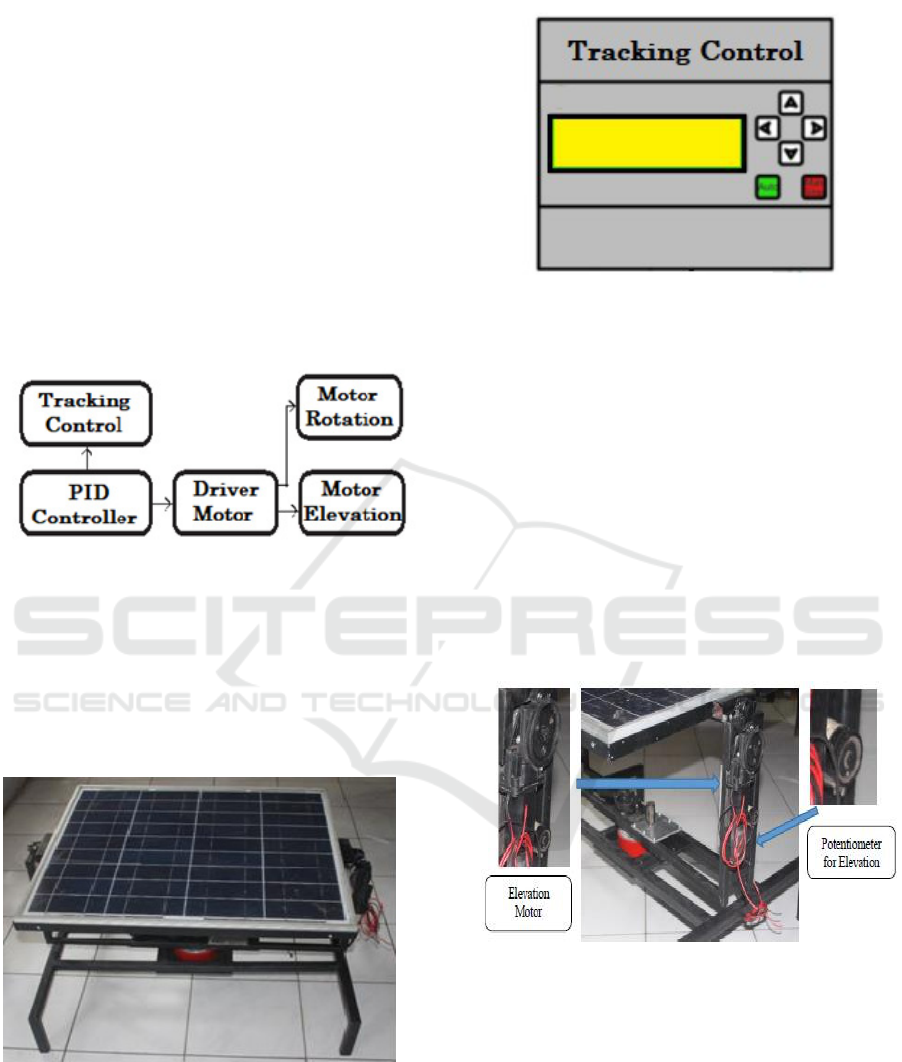

To describe the operational process and make it

easier to understand the design, Figure 2 (below)

illustrates the block diagram of solar tracking.

Tracking control connected to the PID controller to

manage the position of solar cells. The PID

controller is used in this research as this control

accurately receives the output. The PID controller

connects to the driver motor to arrange the position

required according to the command from the

tracking control. Motor rotation and elevation were

needed to manage the position of solar cell.

Figure 2: Block Diagram for solar Tracking

Figure 3 (below) indicated the mechanical design of

solar tracking. To simplify, solar panels are only put

above the framework. Consequently, it is easy for

the solar panel to perform rotation and elevation

style. In addition, the sun can directly face the solar

tracking without any inside resistance.

Figure 3: Mechanical Design for solar Tracking

Figure 4: Tracking Control Box

Figure 4 illustrates the tracking control of this

design. The function of tracking control is to manage

the position of the tracking system. This design allows

the consumer to arrange the position of the solar

panel. In this research, auto and manual settings

were developed to assist consumers to achieve

optimum results. Some options were provided in this

design, namely: upper and bottom, left and right. The

green and red buttons are for ‘run’ and ‘stop’.

Figure 5 (below) illustrates the mechanical design of

solar tracking for elevation motor. The function of

elevation motor is to assist this system to elevate the

position. Elevation motor was required when the

command from tracking control asked to elevate the

position of the solar panels.

Figure 5: Mechanical Design of Solar tracking-

elevation motor.

Figure 6 (below) illustrated the mechanical design of

solar tracking for the rotation motor. As previously

shown, the rotation motor was needed when the

command from the tracking control asked to rotate the

position of solar panels.

CONRIST 2019 - International Conferences on Information System and Technology

74

Figure 6: Mechanical Design of Solar tracking-

rotation motor.

4 RESULT AND ANALYSIS

4.1 Testing of Mechanical Design

Figure 7 (below) illustrates the result of mechanical

testing for the standard elevation. This position was

selected as the solar panel directly faces towards the

sun.

Figure 7: Standard Position of elevation

Figure 8 (below) illustrates the position of solar

panel -30

o

C from standard elevation. Based on this

Figure, the elevation position is 30

o

C clockwise

from standard elevation. To get this position, the

consumer only sets up by tracking control.

Figure 8: Position of solar panel with -30

o

C from

standard elevation

Figure 9 (below) illustrates the result of mechanical

testing for standard rotation. The position of

standard rotation was 90

o

C. To simplify, this

position was selected as the standard rotation. There

are some examples of the position that was

conducted in this research. However, only 30

o

C was

illustrated as an example to represent that the

rotation function was worked properly, as illustrated

in Figure 10.

Figure 9: Standard Position of rotation

PID Controller Design for Solar Tracking System

75

Figure 10: Position of solar panel with -30

o

C from

standard rotation

4.2 Testing of PID Parameters

To operate this system, there are two kinds of

settings provided: manual and auto. To investigate

whether this system was working properly, the

manual setting was chosen for the case study. To

control under the PID method, the values of Kp, Ki

and Kd were required to analyze this system. In this

research, the parameters of Kp, Ki and Kd were 20,

5 and 10, respectively.

Figure 11: Response of PID set point

Testing of PID parameters aims to recognize that the

PID control gives a response according to a given

angle. The graphic response of PID is when the set

point of rotation and elevation were 10

o

. As a result,

response time was 4 seconds, as illustrated in Figure

11 above.

Figure 12: Response of PID set point

Figure 12 illustrates the response of PID set point with

set position rotation were 20

o

for rotation and

elevation. Similar to the previously method, the

response time to get this position is 2 second. Based

on the Figure above indicated that the PID

parameters give a response accurately (see Figure

12). However, only graphic respond PID for rotation

was unprecise, as illustrated in Figure 11.

5 CONCLUSIONS

This research illustrates the design of a sun tracking

system by a PID controller. In order to orientate the

solar panel to the maximum radiation at all times,

this system is designed with dual axis control, such as:

rotation and elevation. According to the mechanical

test, the function of rotation and elevation can

work properly based on the parameters input. In

addition, the PID parameters give a response

precisely based on the parameters input.

Consequently, the solar tracking can recognize the

position of the sun more accurately.

ACKNOWLEDGEMENTS

The authors would like to take this opportunity to

thank the Ministry of Education and Culture of the

CONRIST 2019 - International Conferences on Information System and Technology

76

Republic of Indonesia and Polytechnic State of

Ujung Pandang Makassar Indonesia.

REFERENCES

A.H.Almasoud, & M.Gandayh, H. 2015. Future of solar

energy in Saudi Arabia. Journal of King Saud University

- Engineering Sciences, 27(2), 153-157.

A.K.Akella, R.P.Saini, & M.P.Sharma. 2009. Social,

economical and environmental impacts of renewable

energy systems. Renewable Energy, 34(2), 390-396.

Away, Y., & M.Ikhsan. 2017. Dual-axis sun tracker sensor

based on tetrahedron geometry. Automation in

Construction, 73, 175-183.

B.Rabaoui, H.Hamdi, Braiek, N. B., & M.Rodrigues.

2019. A reconfigurable PID fault tolerant tracking

controller design for LPV systems. ISA Transactions, xx,

xx.

C.Cosmi, M.Macchiato, L.Mangiamele, G.Marmo,

F.Pietrapertosa, & M.Salvia. 2003. Environmental and

economic effects of renewable energy sources use on

a local case study. Energy policy, 31(5), 443-457.

Foster, E., Contestabile, M., Blazquez, J., Manzano, B.,

Workman, M., & Shah, N. 2017. The unstudied barriers

to widespread renewable energy deployment: Fossil fuel

price responses. Energy policy, 103, 258-264.

Hamdi, E. (2019). Indonesia’s Solar Policies:

Designed to Fail? Retrieved from

Hu, Y., Shen, H., & Yao, Y. 2018. A novel sun- tracking and

target-aiming method to improve the concentration

efficiency of solar central receiver systems. Renewable

Energy, 120, 98-113.

Hyuna, K., Taehoon, H., & LeeMinhyun. 2019.

Technical performance analysis of the smart solar

photovoltaic blinds based on the solar tracking methods

considering the climate factors. Energy and Buildings,

190,

34-48.

Kåberger, T. 2018. Progress of renewable electricity

replacing fossil fuels. Global Energy Interconnection,

1(1), 84-52.

Kim, K.-H., & Cho, S.-B. 2019. An efficient concentrative

photovoltaic solar system with Bayesian selection of

optimal solar tracking algorithms. Applied Soft

Computing, 83, 105618.

Labordena, M., & Lilliestam, J. (2015). Cost and

transmission requirements for reliable solar

electricity from deserts in China and the United States

Paper presented at the European Geosciences Union

General Assembly 2015, EGU Division Energy,

Resources & Environment, ERE Switzerland

M.Mosaad, A., A.Attia, M., & Y.Abdelaziz, A.

2019. Whale optimization algorithm to tune PID and PIDA

controllers on AVR system. Ain Shams Engineering

Journal, xx, 1-13.

Park, E., & Kwon, S. J. 2016. Towards a Sustainable Island:

Independent optimal renewable power generation

systems at Gadeokdo Island in South Korea.

Sustainable Cities and Society, 23, 114-118.

Pradhan, R., Majhi, S. K., KuPradhan, J., & Pati, B.

B. 2018. Antlion optimizer tuned PID controller based on

Bode ideal transfer function for automobile cruise control

system. Journal of Industrial Information Integration, 9,

45-52.

Shah, P., & Agashe, S. 2016. Review of fractional

PID controller. Mechatronics, 38, 29-41. Singh, R., Kumar,

S., Gehlot, A., & Pachauri, R.

2018. An imperative role of sun trackers in photovoltaic

technology: A review. Renewable and Sustainable

Energy Reviews, 82, 3263-3278.

Sinha, S., & S.S.Chandel. 2016. Analysis of fixed tilt and

sun tracking photovoltaic–micro wind based hybrid

power systems. Energy Conversion and Management,

115, 265-

275.

Skouri, S., Ali, A. B. H., Bouadila, S., Salah, M. B.,

& Nasrallah, S. B. 2016. Design and construction of sun

tracking systems for solar parabolic concentrator

displacement. Renewable and Sustainable Energy

Reviews, 60, 1419-1429.

Zheng, T., Zheng, F., Ji, X. R. X., & Niu, K. 2019.

A novel ultralight dish system based on a three-extensible-

rod solar tracker. Solar Energy, 193, 335-359.

PID Controller Design for Solar Tracking System

77