Experimental Use of Natural Yeast (Sourdough) as a Replacement of

Conventional Yeast in the Making of Artisan (Homemade) Bread

Betari Azani and Zeilla Nailurrahmi

Sekolah Tinggi Pariwisata NHI Bandung, Indonesia

Keywords: Bakery, bread, sourdough, bread development agent

Abstract: As one of the staple foods consumed by humans, bread is food that can be easily made at home. In making

bread, we need a developer made from yeast where the yeast can convert sugar into carbon dioxide (CO2)

so that it can expand the bread. Today the lifestyle and consumption of Indonesian people in general

increasingly want to consume foods that are natural, healthy and nutritious. Therefore, the development of

bread by utilizing lactic acid bacteria as a source or starter that has the same developer ability as

conventional yeast needs to be done in order to suppress the growth of mold Rhizopus sp that can cause

damage to the bread and can extend the storage period of bread and more importantly is to provide complete

nutrition to consumers. Sourdough or levain is the oldest form of yeast which is a natural bread

development agent that can be used for making healthier home-based bread. Based on the results of our

experiment, the results of using sourdough as compared to conventional yeast are the similarities in color

when exiting the oven, which is golden brown, chewy texture with larger cavities, and also a longer shelf

life. In addition, the benefits of using sourdough can also be seen in terms of the efficiency of the time of

making bread. So from the use of sourdough, a home-based bread product is obtained that is almost similar

to conventional yeast bread, with better nutrition and is free of preservatives and additional coloring.

1 INTRODUCTION

Bread is one of the staple foods consumed by

humans since the ancient times. In making bread, we

need a developer made from yeast. Bread yeast is a

spore culture of a type of yeast that grows and

ferments sugar in the dough (Afrianti, 2013). Yeast

is needed in the fermentation process in making

bread that can convert sugar into carbon dioxide

(CO2), so that it can expand bread.

In addition to developing bread, yeast can also

ripen and smooth gluten so that the dough can

capture the CO2 gas produced by bread. Yeast can

also help the formation of aromas and flavors in

making bread. The use of yeast in making bread

does not function as a preservative so that the bread

has a limited shelf life of only three days (Rumeus

and Turtoi, 2013).

Yeast itself can increase antinutrient substances

namely phytic acid so that the nutrients in bread

cannot be absorbed optimally (Yousif and Faid,

2014). This is contrary to the lifestyle and

consumption of Indonesian people today who

increasingly want to consume foods that are natural,

healthy and nutritious. Therefore, the development

of bread by utilizing lactic acid bacteria (BAL) as a

source or starter that has the same developer ability

as conventional yeast needs to be done in order to

suppress the growth of mold Rhizopus sp that can

cause damage to the bread and can extend the

storage period of bread and more more important is

to provide complete nutrition to consumers.

One type of lactic acid (BAL) or commonly

referred to as a starter that can be used as an

ingredient in making bread is a sourdough starter.

Sourdough or levain (in france) is the oldest form of

yeast which is a natural bread development agent

that is believed by many people to be first created by

the Egyptians (Couch, 2016), containing microflora

such as BAL and yeast. Until the discovery of

commercial yeast in the nineteenth century,

sourdough was the only method of bread

development. In 1910, the use of traditional

sourdough sources was much less used because

bread made using commercial yeast was much faster

and easier, and produced more consistent products.

The positive quality of sourdough bread is

unfortunately ignored because of the speed and

Azani, B. and Nailurrahmi, Z.

Experimental Use of Natural Yeast (Sourdough) as a Replacement of Conventional Yeast in the Making of Artisan (Homemade) Bread.

DOI: 10.5220/0009366500510055

In Proceedings of the 1st NHI Tourism Forum (NTF 2019) - Enhancing Innovation in Gastronomic for Millennials, pages 51-55

ISBN: 978-989-758-495-4

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

51

consistency offered by commercial yeast (Couch,

2016).

According to Corsetti and Settanni (Corsetti and

Settani, 2007), BAL contained in a sourdough starter

are Leuconostoc, Weissella, Pediococcus,

Lactococcus, Enterococcus, Streptococcus and

Lactobacillus. However, the Lactobacillus strain still

dominates sourdough. These microbes in sourdough

play a role in the process of acidifying and

developing bread (Corsetti and Settani, 2007).

Research conducted by Gocmen et al. (Gocmen

et al., 2007)

and Thiele et al. (Thiele et al., 2002)

produced a conclusion that the application of

sourdough to

wheat bread produced several effects,

including yeast, acidification, improved dough

properties, flavor of bread, texture, firmness and

delayed staling, increased

resistance to microbial

spoilage and increased availability of nutrients

and

fiber. In addition, it has been noted that when

sourdough is added, there is a change in the

fundamental rheological properties of the wheat

dough, making it soft, less elastic and easily formed

(Crowley et al., 2002).

The results of bread made using sourdough itself

has advantages that can improve taste and aroma,

improve nutrition, bind water content, improve

texture and extend the shelf life of bread naturally.

This is because BAL, yeast, and endogenous

enzymes found in sourdough are able to hydrolyze

carbohydrates, phenolic compounds, lipids, and

proteins. Lipid metabolism during fermentation

takes place increasing the activity of antioxidants,

anticonductors, and some flavor-forming compounds

thereby increasing the shelf life of bread to be

doubled or more (Czerny and Schieberle, 2002).

The increasing number of consumer demand for

foods that are more natural, tastier and healthier, has

made the use of sourdough primers again popularly

applied to bread making in bakeries and

conventional bread producers in recent years (Thiele

et al., 2002). Therefore it is necessary to conduct

research on good developers and provide many

nutrients and other benefits in making bread. So this

makes the basis why the authors are interested in

making a research on the use of sourdough primers

in making bread for daily consumption that is

healthier, easier, and cheaper.

The aim of this study is to gain a better

understanding of sourdough starter as a substitute of

conventional yeast on the making of artisan (home-

made) bread as a healthier option for daily

consumption. The benefit of this research is to know

how much influence the sourdough starter is giving

on the production of artisan bread, and to know how

the sourdough starter is performing in term of flavor,

aroma, texture, and the shelf life of the bread itself

compared to the usage of conventional yeast.

2 MATERIALS AND METHODS

2.1 Sourdough Starter

Sourdough starter production only requires two

ingredients, namely flour and water. Starter

production is not limited to the use of wheat flour,

because other types of flour used including rice, rye,

spelled, barley, and spinach can be used (Couch,

2016)

High-protein wheat flour (Cakra Kembar

Premium) was used to make this sourdough starter.

The starter was stored in a covered glass container

on a room temperature at 25°C. The duration of this

experimemt is 2 weeks, the starter was feed once a

day with 100mL spring water (Amidis) and 100g of

wheat flour then mixed. The starter was fully

activated by numerous feedings and close

temperature monitoring.

The initial step taken when making this

sourdough starter is to make sure the glass bottle to

be used is really clean so it is not contaminated.

Then mix the flour and water into a glass jar with the

same ratio using a ratio of 1:1, stirring until evenly

mixed. Then keep the glass jar in a dark and warm

place. Leave the glass jar in the closed position for

24 hours. Feed the yeast every 24 hours or once a

day, remove half of the mixture from the glass jar

and then replace it with a mixture of new ait and

flour. This treatment is carried out until the 5th day

of fermentation.

2.2 Conventional Yeast

Conventional yeast or baker’s yeast is a commercial

preparation consisting of dried cells of one or more

strains of the fungus Saccharomyces cerevisiae.

Bakers use yeast as a leavening agent in the rising of

dough for baking. A secondary contribution of yeast

to bread is flavouring and aroma. Bakers yeast was

produced in a high volume and low value, with 1574

x 106 kg being produced per annum on a global

scale (O’Shea, 2005). Baker’s yeast is marketed in

two ways, either as compressed cakes or as a dry

powder, however there is also a saleable

intermediate of the process known as ‘cream yeast’.

Now a days, baker’s yeast is a product of

biochemical, microbiological, technical knowledge

and experience. Biochemistry has led to an insight

NTF 2019 - The NHI Tourism Forum

52

into the fermentation process; microbiology has

made it possible to breed new and better strains of

yeast and to develop better techniques for

sterilization and disinfection. Advanced technologies

have led to the large scale production of yeast with a

high degree of automation and process control,

giving commercial yeast of consistent quality and

activity at an economic price. By feeding on sugars

from the starch in flour, yeast produces carbon

dioxide. This gas expands the gluten proteins in the

flour and causes the dough to rise, this process of

bread making being the most commonly associated

with yeast.

2.3 Preparation of Sourdough Starter

Thirty-six hours prior to using the starter to make

dough, the starter was fully activated by removing

40 g of the culture from the glass container and

mixing with 40mL of spring water (Amidis) and 40g

of high-protein wheat flour. During this 36-hour

activation process the mixture was covered loosely

and kept at room temperature, 21°C, between each

feeding. After 12 hours the mixture was fed for a

second time with 120mL of spring water and 120 g

of bread flour. The third feeding was 8 hours later

with 360 ml of water and 360 g of bread flour, and

the fourth feeding was 8 hours after the third and

required 1080 mL of water and 1080 g of bread

flour. At this point the culture was active and

doubled in size in less than 8 hours.

2.4 Bread Making using Sourdough

Starter

To conduct this research, researchers made a

Baguette bread product made using Instant Yeast

and Sourdough Starter so that it can be seen through

a comparison after the bread is cooked.

Food for bacteria and yeast consists of an evenly

mixed mixture, based on weight, flour and water that

is put into the starter. To keep the sourdough starter

active at room temperature, microorganisms must be

fed regularly every 12 or 24 hours depending on the

type of flour and the maturity of the source. When

making new starter, for example, it is recommended

to feed them every 12 hours for at least the first three

days. To activate an inactive starter, the process can

take between 1 and 3 days. Often the starter is

produced in large mason jars that are lightly covered

with cloth such as nets or cheesecloth when being

activated at room temperature. This unclosed

environment allows microorganisms to breathe.

After the starter is active and mature, in at least

two weeks, it is ready to produce a sourdough bread.

On making the bread itself requires ingredients:

220g wheat flour (Cakra Kembar Premium),

plus extra for dusting

125g water

1/2tsp. sea salt

121g sourdough starter

Instructions:

Combine all ingredients in a mixing bowl and

mix well.

Sprinkle just a couple of tablespoons of flour

onto a work surface and knead the dough

slightly. It should be a little sticky; avoid

adding too much flour to it while kneading.

Form the dough into a ball and cut in half.

Form each half into a long baguette

shape. Place the formed baguettes onto a

baguette pan or a greased cookie sheet.

Cover lightly with a damp towel and let rise

until double in size in a warm place, 3-6 hours.

Preheat oven to 220°C. Bake baguettes 15 - 25

minutes, or until golden-brown.

Remove to a cooling rack for at least 20

minutes and serve.

2.5 Bread Making using Conventional

Yeast

On making the bread using conventional yeast

requires ingredients :

383g wheat flour (Cakra Kembar Premium),

plus extra for dusting

284g water

2g instant yeast

1tsp salt

The first stage of making is to mix all the dry

ingredients, bread flour, salt into a large bowl and

stir. Make a well in the middle of the flour mixture,

then add the yeast in the middle, mix. Add cold

water, little by little, while stirring. Knead the

mixture until it is smooth. After it is smooth, cover

the bowl with plastic wrap and let it rise to twice the

volume. Divide the dough into 4 equal portions, and

shape each into a long loaf (about 15 inches in

diameter and 1 1/2 inches), with a pointed tip. Place

the bread on a flour-wrapped towel, cover with an

oiled plastic wrap, and let it rise for 30 to 45

minutes. Sprinkle with flour, and make 4 long cuts

down each with a knife, razor, or sharp blade. The

bread is ready to bake.

Experimental Use of Natural Yeast (Sourdough) as a Replacement of Conventional Yeast in the Making of Artisan (Homemade) Bread

53

3 ANALYSIS REPORT

3.1 Time Efficiency

Time spent on preparing each bread dough and

fermentation.

3.2 Baking Time

The maximum length of baking time each bread

sample was baked in a temperature of around 205°C

to 220°C until each bread is ready to serve (golden

brown in color).

3.3 Color

Caracterization of the color on each bread sample

after being baked and made.

3.4 Flavor

Caracterization of the flavor on each bread sample

after being baked and made.

3.5 Texture

Caracterization of the texture on each bread sample

after being baked and made.

3.6 Shelfing Time

The maximum length of storage time each bread

sample was stored in a closed state at room

temperature for several times until it changes in

terms of texture or visualization.

4 RESULTS AND DISCUSSION

4.1 Time Efficiency

By using sourdough, stirring the dough will be faster

because the yeast is already in the starter, so that

when the sourdough mixing process does not need to

use additional yeast again. In addition, the first

development fermentation is faster because there are

already some active yeasts and final proofing is also

faster. While the drawback is that it takes quite a

long time in making this sourdough starter.

Conventional yeast requires a longer time for the

fermentation process, thus the use of conventional

yeast is more efficient in its use because it does not

need to be made first.

4.2 Baking Time

In terms of baking time, each bread sample was

baked for 15 - 25 minutes in a temperature of around

220°C until golden brown.

4.3 Color

In terms of the color, both breads that uses

conventional yeast and sourdough are both golden

brown when exiting the oven.

4.4 Flavor

The more time dough takes to rise, the more flavor

will be in the final loaf of bread. Sourdough bread

has a slightly sour taste because sourdough itself is

an artificial yeast that produces lactic acid bacteria

(BAL) which is dominated by Lactobacillus strains.

While for the bread with conventional yeast does

not have a sour taste. Dough made with conventional

yeast rise very quickly, this make the bread sample

made with conventional yeast doesn’t have as much

flavor. This is why other ingredients, like oil, butter,

sugar, or honey, are often used in recipes calling for

instant yeast.

4.5 Texture

In terms of the texture, both bread have crunchy

cured on the outside and rather chewy in the inside.

The differences from both breads are sourdough

bread is more resilient, has a larger cavity also much

more softer and moist compared to bread that uses

instant yeast. While for the bread using conventional

yeast comes with smaller spreaded cavity and drier

inside.

4.6 Shelfing Time

Then in terms of storage / shelfing time, sourdough

bread have a longer shelfing time (5 days) when

stored in a closed state at room temperature until it

become harder and bread that uses instant yeast

more quickly becomes harder than sourdough bread

when stored in a closed state at room temperature (3

days).

NTF 2019 - The NHI Tourism Forum

54

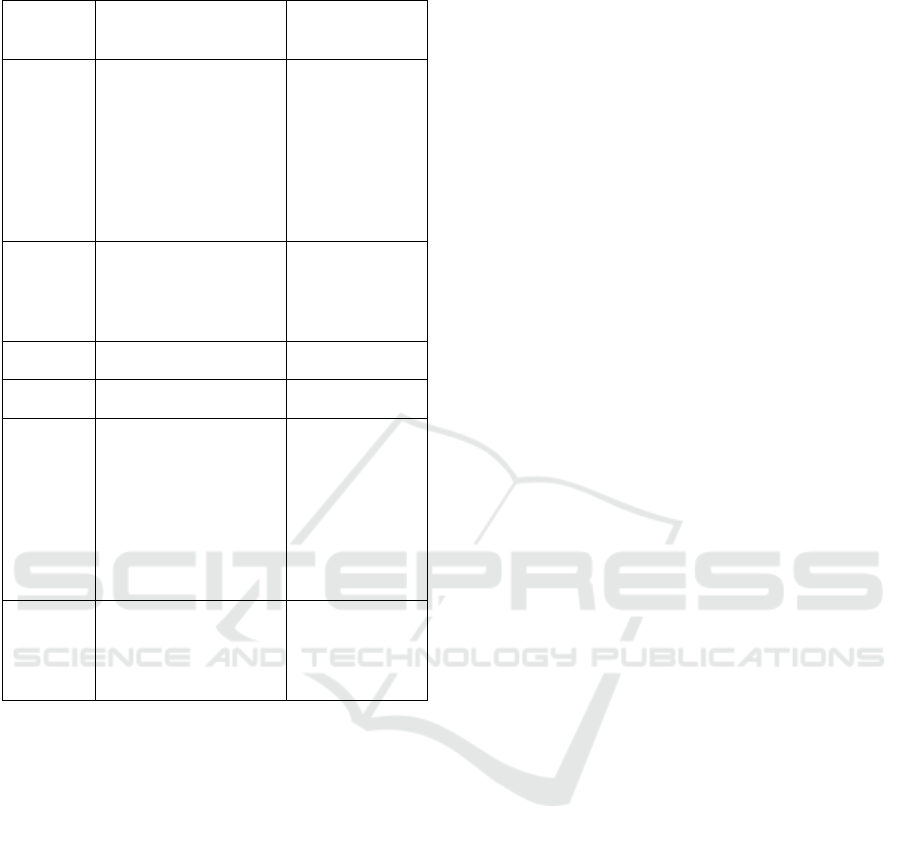

Table 1: Result of The Experiment

Conventional Yeast Sourdough

Starter

Time

Efficiency

It takes a shorter time in

the bread fermentation

process, and faster in

preparation of making

dough.

Longer time in

fermentation

process, takes

time and

patience in

making the

sourdough

starter.

Baking

Time

15 - 20 minutes in a

temperature of around

220°C until golden

b

rown

15-25 minutes in

total until it

reaches golden

b

rown color.

Color Golden brown Golden brown

Flavor Plain Sourish

Texture Crunchy at the outside

with a soft and chewy

texture in the inside.

Small spreading

cavaties, drier body.

Crunchy at the

outside with a

soft and chewy

texture in the

inside. Larger

spreading

cavities, moist

and softer body.

Shelfing

Time

3 days in room

temperature until the

bread hardens

5 days in room

temperature until

the bread

hardens

5 CONCLUSION

From the above results it might be concluded that

there are weaknesses and strengths of using

sourdough as a source of bread development. It

tastes much better, more fragrant and more moist. Its

softness level also seems stable even though it's been

days compared to commercial yeast. In addition,

sourdough can last for years if properly maintained,

fed with regular drinking and drinking to stay alive.

Sourdoughfermentation process is relatively long.

That is why the resulting bread becomes more

delicious, easy to digest the stomach, and soft and

moist. Thus, bread using sourdough is more healthy

than bread using conventional yeast.

From this research the authors recommend using

sourdough starter instead of conventional yeast to

used in making bread. Sourdough has better taste

and texture compared to conventional yeast,

sourdough also uses beneficial microorganisms that

come from natural ingredients, not from artificial

yeast. Naturally fermented bread will be a lot more

healthy because there are no artificial additives.

From this research, it can be developed further as

a reference for further research on the nutritional

content of sourdough sources and also the

production of sourdough sources using other media

besides water and flour.

REFERENCES

Afrianti, L. H., Teknologi Pengawetan Pangan, Alfabeta,

Bandung, 2013.

Rumeus, I., and M. Turtoi, Influence of sourdough use on

rope spoilage of wheat bread, Journal of

Agroalimentary Processes and Technologies, 2013,

19(1), pp. 94-98.

Yousif, M. R. G., and S. M. Faid, Effect of Using

Different Types of Yeasts on the Quality of Egyptian

Balady Bread, Journal of American Science, 2014, 10

(2), pp. 100-109.

Couch, G. W., Effect of Sourdough Fermentation

Parameters on Bread Properties, All Theses, 2016,

2581.

Corsetti, A., and L. Settani, Lactobacilli in Sourdough

Fermentation, Food Research International, 2007, 40,

pp. 539-558.

Gocmen, D., O. Gurbuz., A. Yildirim, K. A. F. Dagdelen,

and I. Sahin, The effects of wheat sourdough on gluten

patterns, dough rheology, and bread properties,

European Food Research and Technology, 2007, 225,

pp. 821-830.

Thiele, C., M. G. Gänzle, and R. F. Vogel, Contribution of

Sourdough Lactobacilli, Yeast, and Cereal Enzymes to

the Generation of Amino Acids in Dough Relevant for

Bread Flavor, Cereal Chemistry Journal, 2002, 79(1),

pp. 45–51.

Crowley, P., T. Schober, C. Clarke, and E. Arendt, The

effect of storage time on textural and crumb grain

characteristics of sourdough wheat bread, European

Food Research and Technology, 2002, 214(6), pp.

489–496.

Czerny, M., and P. Schieberle, Important Aroma

Compounds in Freshly Ground Fermentation, Food

Microbiology, 2002, 37 (0), pp. 2 -10.

O’Shea, D., Industrial Bioprocessing - Module Notes

[online] Available from: www.dcu.ie/-oshead/BE401,

2005 [accessed 14 Oct 2019]

Experimental Use of Natural Yeast (Sourdough) as a Replacement of Conventional Yeast in the Making of Artisan (Homemade) Bread

55