Development of Safety Plan to Improve OHS (Occupational Health

and Safety) Performance for Construction of Dam Supporting

Infrastructure based on WBS (Work Breakdown Structure)

Aprilia Dhiya Ulhaq, Yusuf Latief and Rossy Armyn Machfudiyanto

Department of Civil Engineering, Universitas Indonesia, Jakarta, Indonesia

Keywords:

Safety Plan, Risk Identification, Dams, Access Roads, Bridges, Tunnels, Dodge Channel, OHS Performance.

Abstract:

Of all existing construction projects such as buildings, roads, dams, irrigation channels, bridges and tunnels,

Dam is one of the construction projects that has the highest probability of a workplace accident in the world.

By developing a safety plan based on the use of WBS (Work Breakdown Structure) that has been standardized

as an object in this research to obtain risks that have an impact on workplace accidents, it is expected to reduce

the level of workplace accidents that occur. This study aims to develop a safety plan to reduce the level of

workplace accidents as one indicator of OHS (Occupational Health and Safety) performance using qualitative

methods. The results of this study are sources of risk and risk that are classified as high which have potential

hazards and have an influence on OHS performance on the components of the Road Access and Bridges as

well as Tunnels and Dodge Channels. In addition, a safety plan document will be developed based on the

RK3K PU 05 / PRT / M / 2014 format and refers to the high risks that have been identified based on the WBS

to achieve improved OHS performance by reducing the rate of workplace accidents.

1 INTRODUCTION

Dams are buildings in the form of land, stones, con-

crete, or stone pairs that are built in addition to hold-

ing and storing water, can also be built to hold and ac-

commodate mine waste (tailings) or to collect mud so

that reservoirs are formed (PP No. 37 of 2010). In the

2014-2019 period, dam projects in Indonesia will be

carried out on a large scale. Indonesian government is

currently keen to realize this infrastructure (Kausarian

et al., ). Given a large number of stakeholders / parties

involved in the construction process, then in its plan-

ning, a standard that can be used by various parties

that carry out its construction needs to be used. The

standard was created in a systematic form in the form

of WBS (Work Breakdown Structure) that has been

studied by (Hidayah et al., 2018). The existence of

this WBS standard will present uniform requirements

in the estimation, monitoring and control (PMBOK,

2017).

According to (Hidayah et al., 2018) Standard Dam

WBS consists of 8 supporting infrastructure / subpro-

ject jobs in naming the level at the WBS, namely:

Preparation, Access Roads and Bridges, Cofferdam,

Tunnels and Dodge Channel, Main Dam, Spillway,

Intakes, and other public facilities work. The lowest

level on the WBS will present a series of detailed ac-

tivities on the project. Each predetermined WBS level

brings the WBS to a more complex level of activity, in

which case activities are strongly affected by risk and

risk will have an impact on the safety planning (Elsye

and Latief, 2018). This plan is an attempt to prevent

the occurrence of undesirable things that can lead to

workplace accidents (Maengga, 2015).

Based on the 2014 Data and Information Center of

the Indonesian Ministry of Health, every job always

contains potential hazard risks in the form of work ac-

cidents where the amount of potential depends on the

type of production, technology used, materials used,

spatial planning and building environment as well as

the quality of management and implementing staff.

Of all the existing construction projects, the dam is

a construction project with the highest work accident

rate in the world. ICOLD since 1965 conducted stud-

ies until 1973, there were at least 236 accidents of

various types of dams caused by various things and

76 accidents caused by design and 41 caused by con-

struction (Asiyanto, 2011).

Workplace accidents can be prevented if all parties

involved in construction projects start from the high-

est level such as reaching the lowest level such as the

workers paying attention to and prioritizing OHS (Oc-

258

Ulhaq, A., Latief, Y. and Machfudiyanto, R.

Development of Safety Plan to Improve OHS (Occupational Health and Safety) Performance for Construction of Dam Supporting Infrastructure based on WBS (Work Breakdown Structure).

DOI: 10.5220/0009186502580267

In Proceedings of the Second International Conference on Science, Engineering and Technology (ICoSET 2019), pages 258-267

ISBN: 978-989-758-463-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

cupational Health and Safety) aspects in each stage of

the construction work carried out by creating a haz-

ard handling strategy. Strategies for handling occu-

pational hazards in construction can remove poten-

tial hazards, further investigation of hazards that often

occur and can produce a safety plan on construction

projects (Albert, 2014). Therefore, it is necessary to

develop a safety plan with a WBS (Work Breakdown

Structure) as a tool that will be used to compile the

category and urgency of project risk assessment as a

systematic risk system based on its source (Mhetre

et al., 2016).

2 RESEARCH OBJECTIVES

The objective of this study is:

• To Identify sources of high potential hazard risk

that affect OHS performance indicators (work-

place accidents) at Access Road and Bridge

Works and Tunnel and Evacuation Channels from

Dam WBS (RQ1)

• To develop a risk-based safety plan from WBS

Dam for Access and Bridge Road Works and Tun-

nel and Dodge Channels (RQ2)

3 LITERATURE REVIEW

3.1 Work Breakdown Structure (WBS)

in Dam Construction

The WBS (Work Breakdown Structure) is a hier-

archical decomposition of the entire scope of work

that must be done by the project team to achieve

project objectives and create the necessary work re-

sults, where each level decrease shows a more de-

tailed definition (Institute, 2017).

Based on (Hidayah et al., 2018), the WBS Stan-

dard for dam construction projects for each subpro-

ject consists of 4 levels. Dam projects can be divided

into 8 (eight) work subprojects, namely Preparation,

Access Roads and Bridges, Cofferdam, Tunnels and

Dodge Channel, Main Dam, Spillway, Intakes, and

other public facilities work. The following is an ex-

ample of Standard WBS Identification in tunnel and

dodge channel construction:

• Level 1 is the name of the project (dam subproject:

tunnel and dodge channel)

• Level 2 is the Work Section (dewatering, soil, sup-

port and protection, concrete, drilling, and grout-

ing)

• Level 3 is the Sub Work Section (for a sub work

section of support and protection there are support

and protection for open excavation work and sup-

porting work for tunnel excavation)

• Level 4 is the Work Package (for work package of

support and protection for open excavation work

consisting of a shortcrete wire mesh protection

package, grouted anchor protection, masonry pro-

tection, and dolken wood protection)

• Alternative Methods / Design between Level 4

and Level 5

• Level 5 is an activity which is a derivative of a

work package

• Level 6 is resources such as material, equipment,

and labor resources

3.2 Risk Management

Risk is a variation in terms of what might happen

(Fisk, 1997). Risk is considered a negative term, but

in the engineering construction industry, managing

risks that arise is very necessary and carried out in

a structured manner, knowledge of risk management

that can nullify and minimize the risk of occurring in

construction projects (Mhetre et al., 2016). Risks are

threats to life, property, or financial impacts due to the

dangers that occur (Duffield and Trigunarsyah, 1999).

Risk management is all series of activities related

to risk, namely planning, assessment, handling, and

monitoring (Kerzner, 2001). According to risk as-

sessment carried out with 2 methods namely qualita-

tive analysis and quantitative analysis (Mhetre et al.,

2016). The qualitative analysis focuses more on de-

termining priority risks, identifying risks, seeing their

impact on projects and relying on experts as a compar-

ison, while quantitative analysis is more on statistical

calculations (Institute, 2017). This study uses qual-

itative risk analysis with a probability / Impact Risk

Rating Matrix that is referenced by PMBOK because

the results of validated questionnaires to experts are

based on priority risk assessments using probabilities,

impacts and other influential factors.

Risk handling (RR) can be categorized into 4 cat-

egories, namely: Avoid / V, Mitigation / M, Transfer

/ T, and Accept / A (Labombang, 2011). According

to (Mhetre et al., 2016) Avoid is done by reducing all

causes of risk, Mitigation is done to reduce the possi-

bility or impact of risk, Transfer by transferring risk

to other parties to be responsible for the management

and if it occurs, Accept is done when it is impossible

to reduce or take advantage of risk.

Development of Safety Plan to Improve OHS (Occupational Health and Safety) Performance for Construction of Dam Supporting

Infrastructure based on WBS (Work Breakdown Structure)

259

3.3 Concept of OHS or Safety

Performance

3.3.1 Definition of OHS or Safety Performance

Based on OHSAS 18001: 2007 Clause 3.15, OHS

(Occupational Health and Safety) Performance is a

measurable result of managing an organization’s OHS

risk, with a note:

• OHS performance measurement includes a mea-

surement of control effectiveness implemented by

the organization.

• In the context of the OHS management system,

the results can be measured compared to the orga-

nization’s OHS policy, the objectives of the OHS,

and the OHS performance requirements

3.3.2 OHS or Safety Performance Indicators

According to (Wu et al., 2015) and (Lu et al., 2016)

Indicators of safety performance consist of 6 things,

namely:

• Safety awareness, the safety awareness of a con-

struction project is the awareness of all stakehold-

ers from the leadership to the workers

• Safety costs, Safety Costs must be part of the

investment that is measured and carried out in

SMK3 which includes training, incentives, and

salaries of safety supervisors.

• Accident Level, Safety documentation of con-

struction projects is an element of awareness and

security of construction project performance and

can be considered as a measure for performance

evaluation

• Productivity, Safety, and productivity are the most

important requirements in improving the perfor-

mance of construction projects

• Management of self-discipline, to ensure con-

struction safety, the company has good control of

all aspects, such as security objectives, mecha-

nism for construction assessment procedures and

resource mobilization

• Performance Measurement, Companies can iden-

tify deficiencies in occupational health perfor-

mance according to previous historical knowl-

edge, and then make a quick and effective re-

sponse.

According to (Garza et al., 1998) measurement of

work safety performance can be viewed from 5 as-

pects, namely:

• Injury frequency rate

• Injury severity rate

• Average days change per disabling injury

• Project accident cost figures

• Number of incidents of work accidents

3.4 Safety Plan Concept in

Construction Projects

3.4.1 Definition of Safety Plan

The safety plan is a plan document that contains prac-

tical safety that can help companies avoid potential

hazards and can control them in the best way when in

these hazard conditions (Elsye and Latief, 2018). In

projects carried out by the Ministry of Public Works,

the Safety Plan is known as RK3K or OHS Contract

Plan.

RK3K is a complete document of the plan for the

implementation of the Management System of OHS

(SMK3) in the PU Sector and is a unit with the con-

tract document of a construction work made by the

service provider and approved by service users and

subsequently used as a means of interaction between

service providers and service users in implementing

Management System of OHS (SMK3) of the PU (The

Ministry of Public Works) field. In the standard safety

plan, the document created is a document for the oper-

ational safety issues by covering hazard identification,

risk assessment, and mitigation steps and conditions

that must be met to maintain the level of safety.

3.4.2 Safety Plan Format

The ministry of manpower as a stakeholder develops a

safety program indicates the variable (Machfudiyanto

et al., 2018). Based on the format stated in govern-

ment regulations PU 05 / PRT / M / 2014, this docu-

ment consists of several parts, namely:

• OHS Policy

• OHS Organization

• OHS Planning

– Hazard Identification, Risk Assessment, Pri-

ority Scale, Safety Risk Control, Responsible

Person

– Compliance with laws and regulations and

other requirements

– OHS Objectives and Programs

• OHS Operational Control

• Examination and Evaluation of OHS Performance

• OHS Performance Review

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

260

All the parts mentioned above already have their

respective writing formats.

4 METHODOLOGY

This research was conducted with a qualitative ap-

proach to answer the research objectives. Surveys and

discussions were carried out using structured research

instruments in the form of questionnaires to experts

from dam work with more than 10 years of experi-

ence. The flow of research can be seen from the fol-

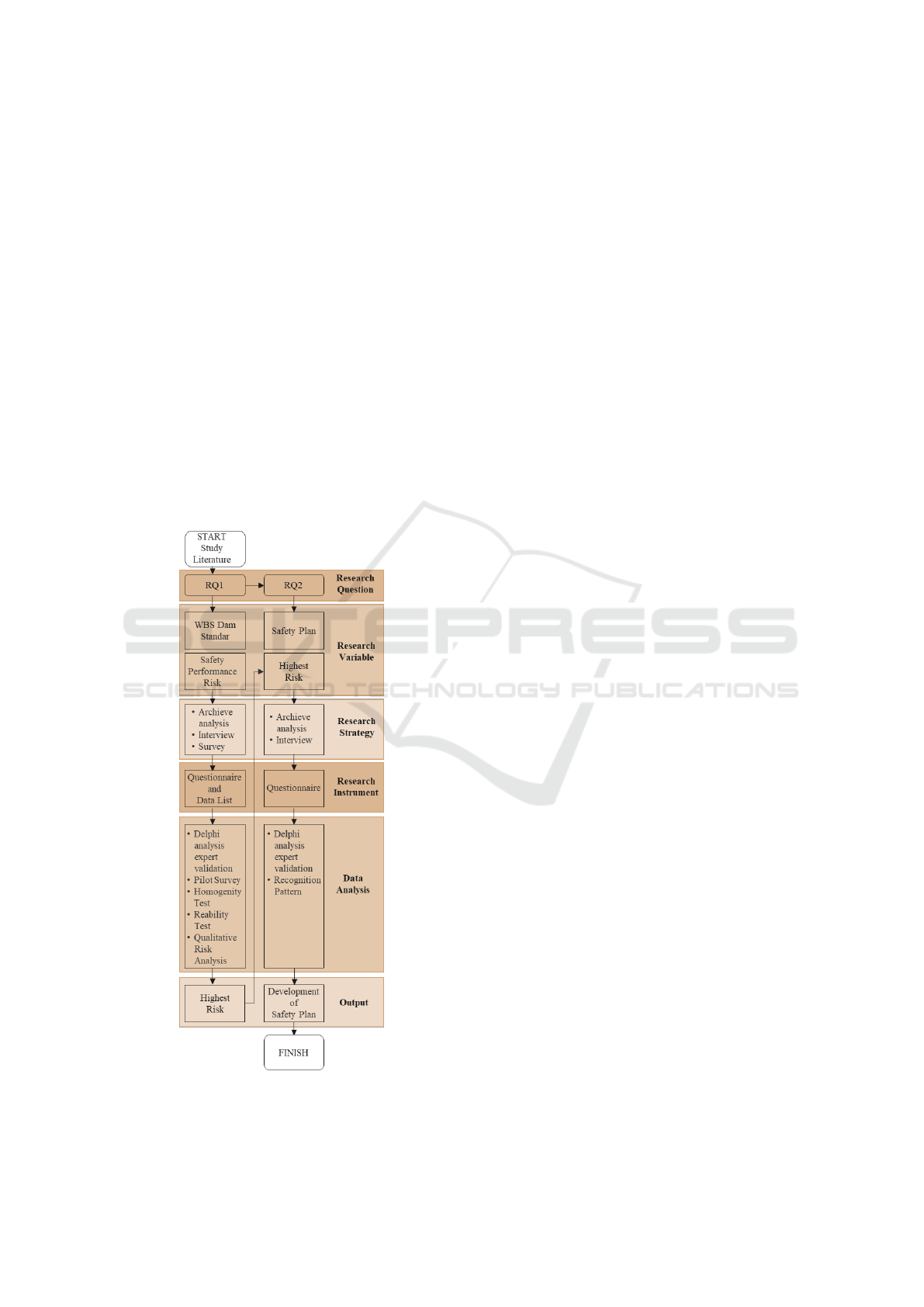

lowing picture

Figure 1: The research flow diagram

5 RESULT AND DISCUSSION

5.1 To Answer RQ1

5.1.1 Risks Affecting OHS Performance

Indicators

Potentially hazardous risk identification is carried out

for each activity of each work package derived from

the results of a literature study taking into account the

detailed methods and resources of the Standard Dam

WBS (Work Breakdown Structure) for the work of ac-

cess and bridge roads and tunnel and duct ducts. From

the results of identification of these risks 507 risks that

have the potential to be hazardous and affect the OHS

(Occupational Health and Safety) performance indi-

cators are the accident rates.

The results of risk identification are then verified,

clarified, and validated for content and contract by ex-

perts. This strategy is carried out with a discussion

with experts related to whether the risks include po-

tentially dangerous risk factors, relevant or not with

their activities and whether there are additional risks

that have not been included.

The results of the discussion found 323 risks af-

fecting the OHS performance indicators, namely the

level of accidents in the access and bridge road sub-

projects and 312 risks for tunnel and evacuation sub-

projects from the dam WBS. Due to the number of

repetitions of the same risk due to repetition of the

same activity, the recalculation of the risk is carried

out. To obtain 160 risks in the access road and bridge

subprojects and 125 risks of tunnel and dodge subpro-

jects.

Then a pilot survey is conducted to the respondent

to find out whether all the risks that have been identi-

fied previously can be understood by everyone in the

project environment.

5.1.2 Risk Assessment

Risk evaluation of a project depends on the probabil-

ity of occurrence (frequency) and its impact (Duffield

and Trigunarsyah, 1999).

FR = FxD (1)

Risk evaluation which is then called risk level

analysis (FR) is a multiplication between frequency

(F) and impact (D) which in this study was obtained

from the distribution of questionnaires with a likeli-

hood scale of 1-5. The following are indicators of the

scale:

Development of Safety Plan to Improve OHS (Occupational Health and Safety) Performance for Construction of Dam Supporting

Infrastructure based on WBS (Work Breakdown Structure)

261

Table 1: Frequency Scale Indicator (F).

Scale Criteria Indicators

1 Very Low Very unlikely to occur

2 Low It is less likely to occur

3 Moderate Pretty likely to occur

4 High May occur

5 Very High Very possible to occur

Table 2: Impact Scale Limit (D).

Scale

Severity/Loss/Impact Indicator

Person Property

1

Does not cause labor

to be injured

Do not cause

interference to

vehicles or heavy

equipment or

surrounding facilities

or cause physical care

for at least 15 minutes

2

The workers are

lightly injured

(enough first aid

treatment or clinic)

and can continue to

work

Causes minimal

disruption to vehicles

or heavy equipment

but does not cause

work to be hampered

4

Workers are severely

injured to disability

of functions or organs

and need treatment

outside the project

location (clinic or

hospital) 2x24 Hours

Facilities and

equipment were

severely damaged,

requiring 1-7 days of

recovery

5

Workers experience

permanent disability

or die

Facilities and

equipment were

severely damaged,

requiring more than 7

days of recovery

From the likelihood scale, the weighting will be

carried out on the PMBOK scale. The following is

the weighting:

Table 3: Weighting Frequency and Impact.

Value Criteria F Weight

F

Criteria D Weight

D

1 Very Low 0,1 No effect 0,05

2 Low 0,3 Less influ-

ential

0,1

3 Moderate 0,5 Pretty In-

fluential

0,2

4 High 0,7 Influential 0,4

5 Very High 0,9 Very influ-

ential

0,8

The weighting when multiplied to obtain FR val-

ues will result in the FR (risk level analysis) category

range as follows:

Table 4: Risk Category.

Risk Score Risk Level

Analysis

Steps for

Handling

(FR)

0.18 - 0.72 High Risk Reduced risk is

carried out to a

lower place

0,06 – 0,17 Moderate

Risk

Correction

steps are

needed in a

certain period

0.01 - 0.05 Low Risk Repair steps

whenever

possible

After the calculation is done, 17 of the highest

risks are obtained as shown in table 5.

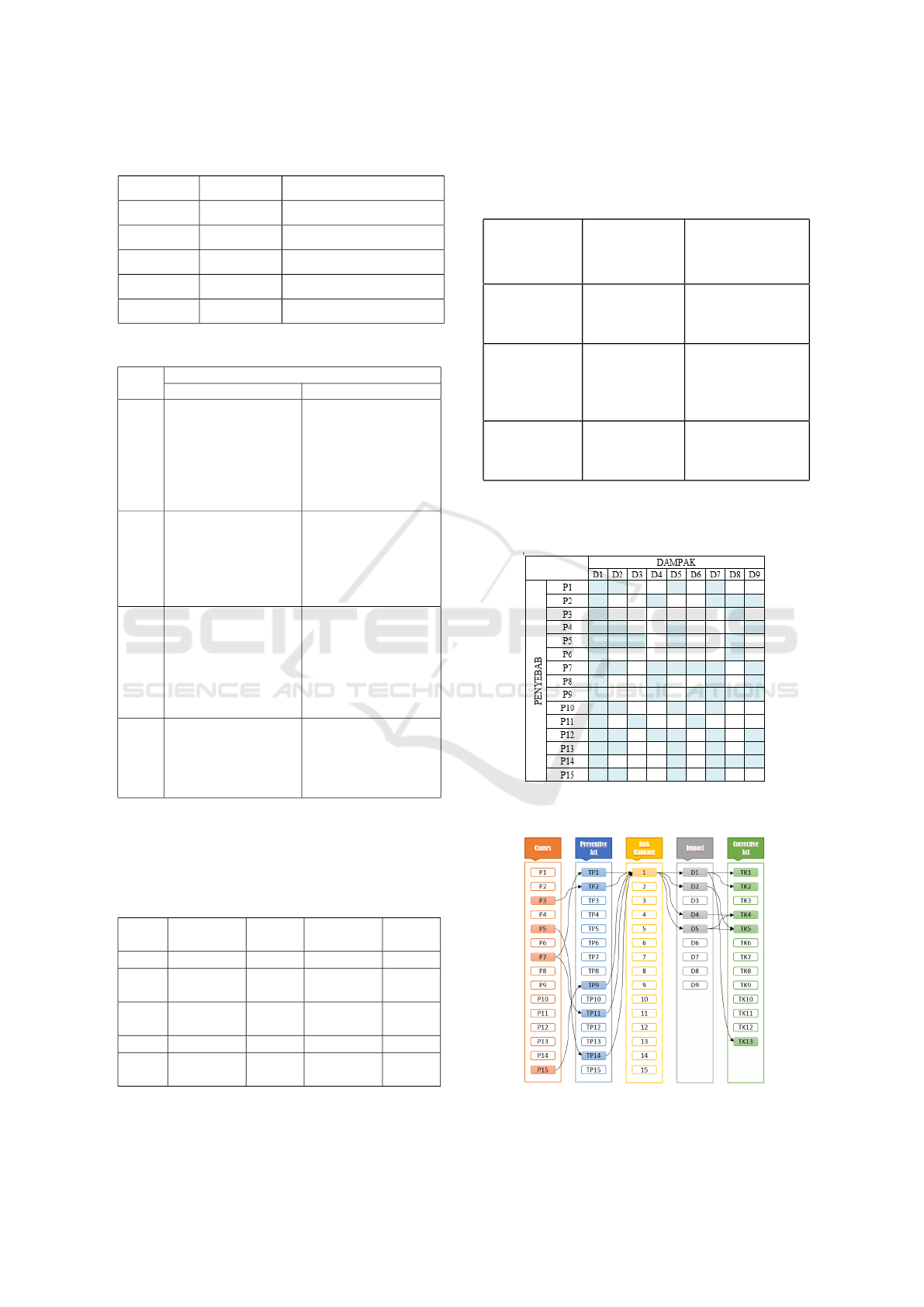

Figure 2: Risk Causes and Impact Matrix.

Figure 3: Recognition Pattern for Highest Risk.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

262

Table 5: The Highest Risk That Affects OHS Performance; Subprojects: Tunnel and Dodge Channels.

Risk Rank Risk Score Activities Work Package

An explosion

occurred due to

missfire during

drilling

1

0,2611

Installation of Explosives (Drilling) Stone Drilling

Closed Excavation / Tunnel

2 0,2580 Drilling Rockbolt Protection

Lack of oxygen

5 0, 2176

Making an Air Ventilation System

(Suction and Blowing)

Closed Excavation / Tunnel

excavation work Excavation

Stone Drilling

Stone Retaining Wall

Protection

Dolken Wood Retaining Wall

Protection

Being crushed or

exposed to blast-

ing debris

15 0,1814 Stone Blasting

Stone Drilling

Closed Excavaton / Tunnel

5.2 To Answer RQ2

Before developing the RK3K/safety plan document,

it is necessary to know the causes and impacts of the

risks that occur so that a risk response can be found

that will be used in the development of RK3K.

5.2.1 Causes and Effects of Risk

According to experts during the discussion, in the

construction of the Dam, in general, can be sepa-

rated into 2 work, namely preparation and main work.

Work that is generally included in the main work in

dam construction is work that requires special meth-

ods in its implementation such as excavation, em-

bankment, concrete placing, blasting, formwork in-

stallation. While other works just use simple meth-

ods.

Of all the causes it has been concluded that there

are 15 causes of risk that produce 9 different impacts

which can be seen from the table below.

In activities classified as preparation work, the

causes of risk in the project are usually caused by

P1, P3, P4, P5, P6, while the activities classified as

main work are caused by causes caused by prepara-

tory work and added by P2, P7, P8, P9, P10. It proves

that an error occurred in the design or inappropriate

construction (Kausarian et al., 2018).

Then an analysis of causes and impacts is illus-

trated through a matrix to find the root of the problem

and the impact of each risk on OHS (Occupational

Health and Safety) performance. The analysis can be

seen in figure 2. From the matrix below it can be seen

that the same impact can be caused by more than one

cause. For example, impact 1 (D1), which is injury,

wound, or death can be caused by all causes.

5.2.2 Risk Response

Risk response is a handling action taken against the

risks that may occur (Labombang, 2011). Based on

the analysis of the causes and effects of high risk as

stated in Table 5, it was concluded that there were

15 preventive measures and 13 corrective actions that

could be taken.

Of all the causes, the impact of preventive and

corrective actions was analyzed using the recognition

pattern at the highest risk shown in table 5. The recog-

nition pattern can be seen from figure below.

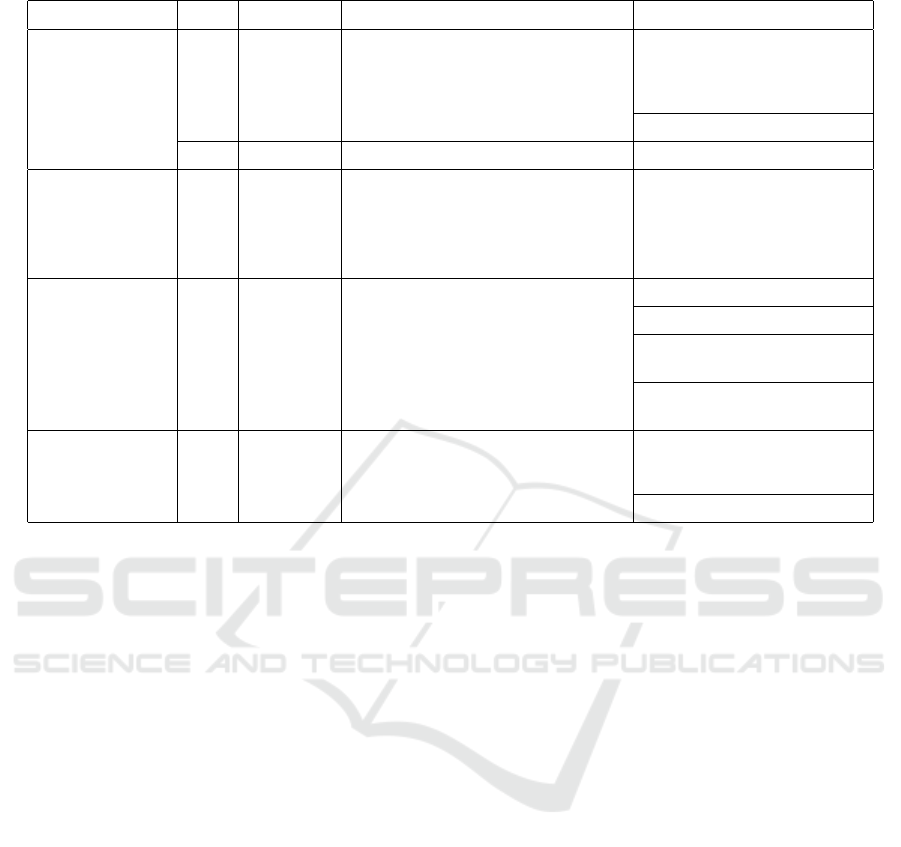

5.2.3 Development of the Safety Plan

From the results of discussions with experts, the

RK3K/safety plan document whose the general for-

mat had been submitted previously was carried out in

section C.1 which has been arranged in a table format

Development of Safety Plan to Improve OHS (Occupational Health and Safety) Performance for Construction of Dam Supporting

Infrastructure based on WBS (Work Breakdown Structure)

263

Table 6: The Highest Risk That Affects OHS Performance; Subprojects: Acces and Bridge Road.

Risk Rank Risk Score Activities Work Package

Workers are hit

by piles during

lifting / erecting

3 0,2290 Steel Pole Designing Structural Steel Piles

7 0,2100 Drafting of Wood Piles

Wood Piles

14 0,1893

11 0,1987 Design of Prefabricated Concrete

Piles

Pre- fabricated Concrete Piles

4 0,2195 Placing the girder on the bearing pad Erection using the double

crane method

Falling from a

height

6 0,2113

Reinforcement Abutment / Column / Pier

Head (Concrete Cast Insitu)

Expansion Joint

Bearing Pad Elastomer Bearing Pad

Tower crane

collapsed due to

overload

8 0,2022 Installation of Concrete Drainage

Precast Box Culvert

Concrete Drainage Precast

Box Culvert

Precast concrete

befalls workers

9 0,2020 U-Ditch Precast Concrete Drainage

Installation

U-Ditch Precast Concrete

Drainage

10 0,1990 Installation of Concrete Drainage

Precast Box Culvert

Concrete Drainage Podcast

Box Culvert

Workers are

buried in land

during excava-

tion work

12 0,1925 Mechanic Excavation Ordinary Land

Excavation

Soft Stone Excavation

Stone Drilling

Paved Pavement Excavation

Excavation of Concrete

Pavement

Structure Excavation

Broken Sling

Crane

13 0,1906 Installation of Concrete Drainage

Precast Box Culvert

Concrete Drainage Precast

Box Culvert

Table 7: Effect of Risk Affecting OHS Performance Indicators (Work Accidents)

Code Effect Affected Subjects

D1 Injury, Wound, Death

Labor and Community

D2 Raises doubts for other workers

D3 Feel uncomfortable living around the project area Society

D4 The project stopped temporarily Projects

D5 Labor and equipment are idle or unproductive Projects

D6 The results of construction are too late to use Company

D7 Nearby equipment and facilities are damaged Company

D8 Got a bad company image Company

D9 Construction failure Company

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

264

Table 8: Causes of Risk Affecting OHS Performance Indicators (Work Accidents)

Code Cause

P1 Human Error (Workers are tired, unhealthy, or negligent)

P2 Do not carry out the correct work safety procedures for each job

P3 Using Personal Protective Equipment (PPE) that is incomplete or not used at all

P4 Do not carry out the Toolbox meeting / Safety Briefing / Safety Morning Talk (SMT) before starting work

every day

P5 Lack or absence of OHS signs or safety lines

P6 Do not do House Keeping or 5R (Compact, Neat, Clean, Care, Diligent)

P7 Missing or not following Work Instruction (WI)

P8 There is no safety plan document or safety plan that does not refer to field conditions

P9 Errors in planning and doing work methods (incorrect or not on target)

P10 Work supervision or safety patrol is not carried out routinely or according to procedures

P11 Do not anticipate conditions (weather or hydrology) in the project location that affect the work

P12 The equipment used does not meet the standard specifications

P13 There is no quality control or checking the specifications of the material or tool used

P14 Material and tool checking is not carried out under applicable procedures

P15 The appointment of workers is not selected or not through the right process so that workers are less competent

in their field

Table 9: Preventive Action

Code Preventive Action RR

TP1 Carry out the Toolbox meeting / Safety Briefing / Safety Morning Talk (SMT) before starting work

every day

M

TP2 Using a complete Personal Protective Equipment (PPE) M

TP3 Give and take training or coaching work methods M

TP4 Socialization to the public regarding the control of hazards that can be caused by the project M

TP5 Conduct maximum control of hazards by conducting routine and comprehensive supervision regard-

ing work safety programs

M

TP6 Arrange Job safety analysis before doing work M

TP7 Make comprehensive construction safety regulations M

TP8 Ensure that the worker is healthy before working M

TP9 Use worker that has a certificate or a specialist at his job and has experience M

TP10 Carry out Quality Assurance to ensure material specifications or tools according to standards M

TP11 Make Work Instruction (WI) for work methods that are easily understood by workers M

TP12 Plan a work safety program before the project starts M

TP13 Reviewing real conditions in the field in determining the safety plan before the project starts M

TP14 Use OHS warning signs or safety lines and barricades M

TP15 Perform workplace or housekeeping cleaning or 5R (Compact, Neat, Clean, Care, Diligent) M

from goverment regulations PU 05 / PRT / M / 2014

shown in figure 4.

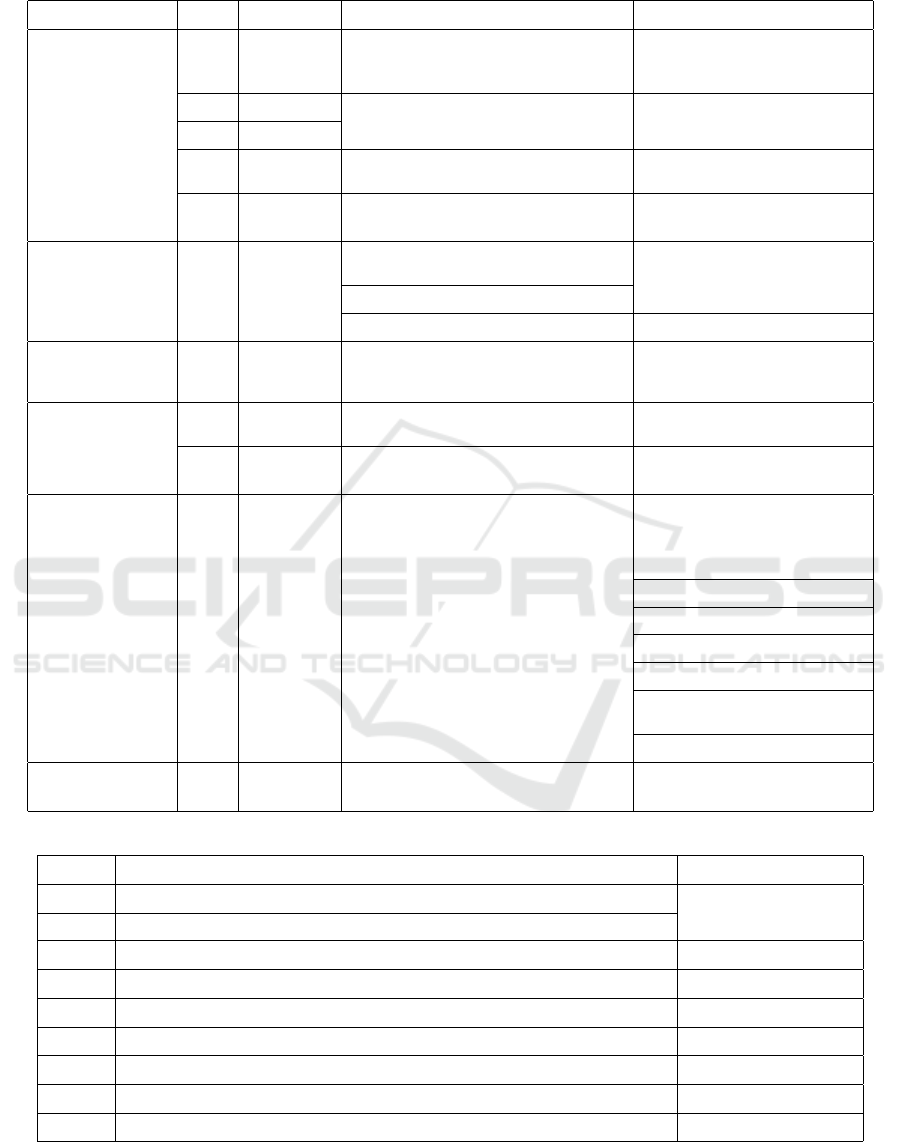

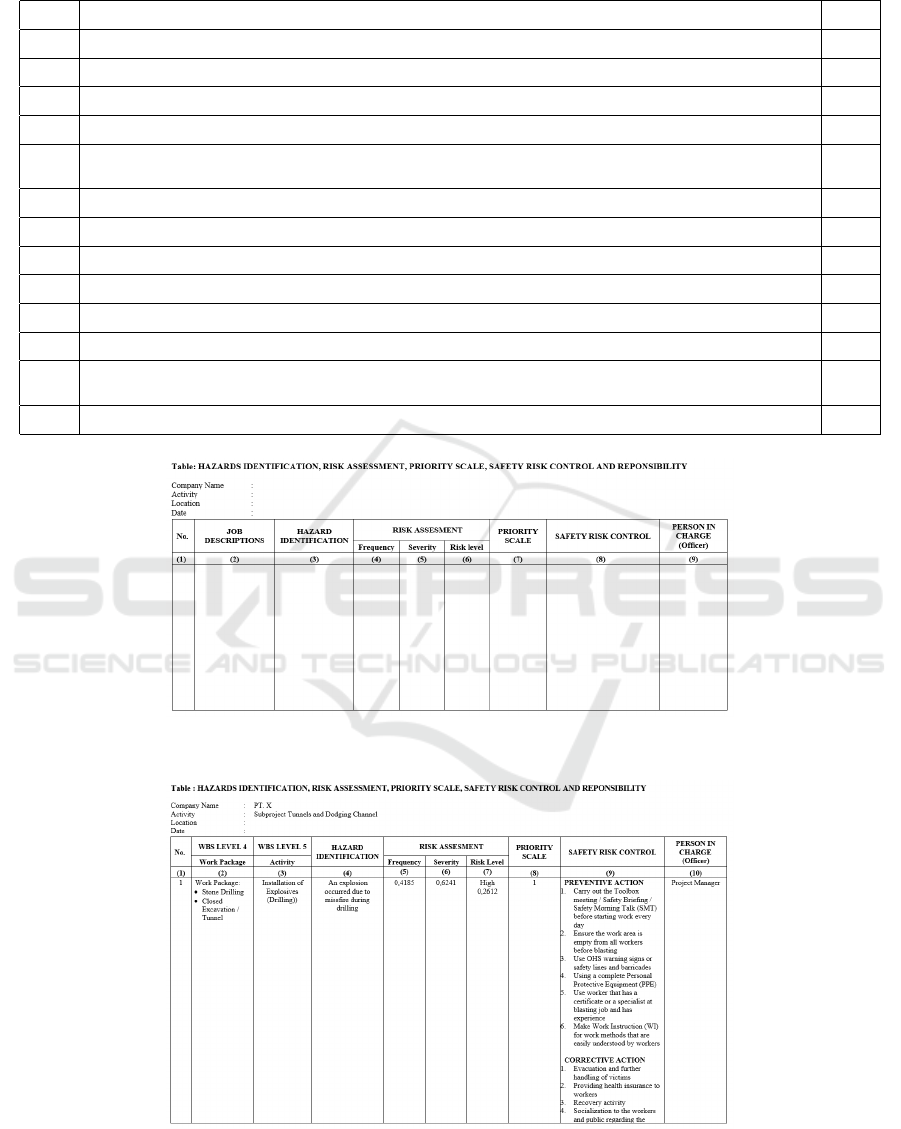

The results of the development shown in figure 5,

carried out are by detailing the job descriptions di-

vided into 2, namely work packages (level 4 WBS/

Work Breakdown Structure) and activities (level 5

WBS) and in the risk control column detailed with

preventive actions and corrective actions for construc-

tion work. So it can be seen an example of the de-

velopment of section C.1 in the image below for the

highest risk.

Development of Safety Plan to Improve OHS (Occupational Health and Safety) Performance for Construction of Dam Supporting

Infrastructure based on WBS (Work Breakdown Structure)

265

Table 10: Corrective action

Code Corrective action RR

TK1 Evacuation and further handling of victims A

TK2 Providing health insurance to workers T

TK3 Socialization to the public regarding the control of hazards that can be caused by the project A

TK4 Recovery activity A

TK5 Conduct OHS socialization to workers both in the form of safety talk, safety induction, and toolbox

meeting

A

TK6 Use experts when making a safety plan A

TK7 Increase learning lessons for specifications of types and methods of work A

TK8 Make and carry out a safety plan / safety procedure for the method of work to be carried out A

TK9 Reviewing real conditions in the field in determining the safety plan before the project starts A

TK10 Replace tools according to specifications needed and according to standards A

TK11 Change workers with more competent and experienced people V

TK12 Carry out the Toolbox meeting / Safety Briefing / Safety Morning Talk (SMT) before starting work

every day

A

TK13 Conduct training to be responsive to risk that is going to be a disaster A

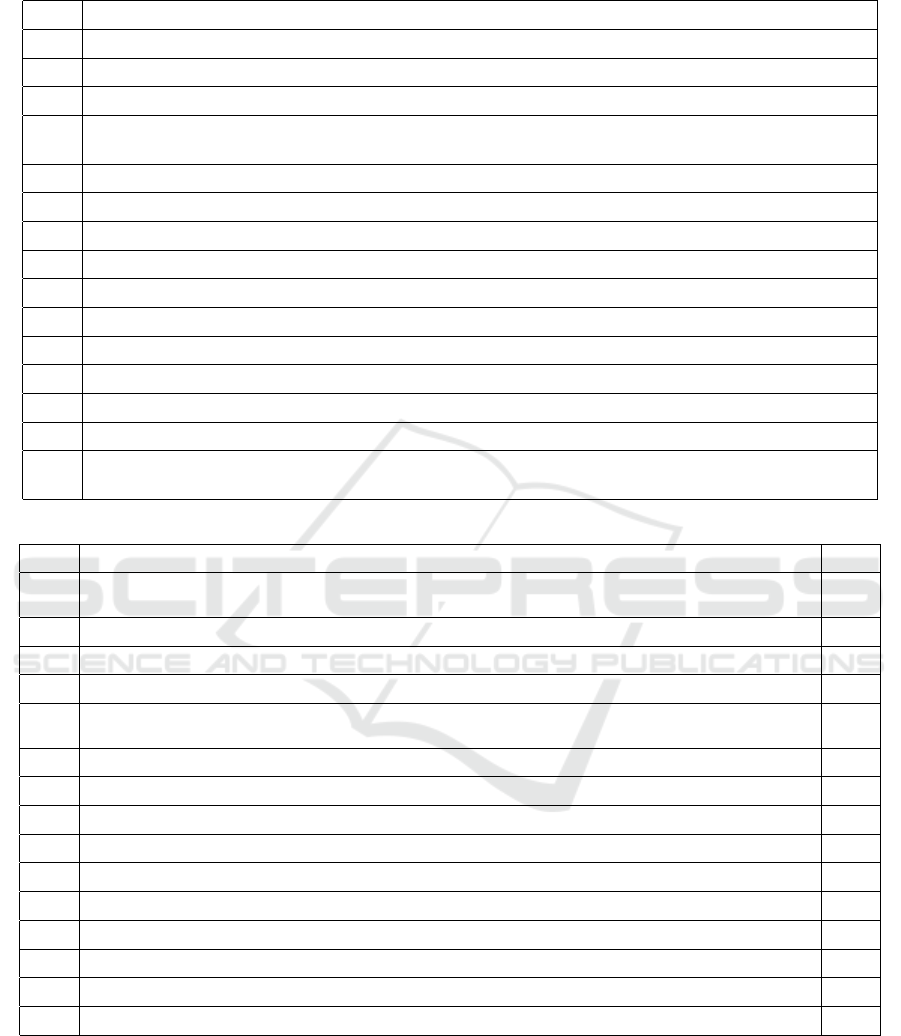

Figure 4: Table C.1 Hazard Identification, Risk Assessment, Priority Scale, Safety Risk Control, Responsible Person format

from goverment regulations PU 05 / PRT / M / 2014.

Figure 5: The results of the development table C.1 Hazard Identification, Risk Assessment, Priority Scale, Safety Risk Control,

Responsible for the Highest Risk of Tunnel Subprojects and Dodge Channels.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

266

6 CONCLUSION

Based on the process carried out to develop a safety

plan, it can be concluded that 10 high risks in the ac-

cess and bridge road subprojects and 5 high risks in

the tunnel and dodge subprojects on the dam project

can be seen from table 5.

By using the highest risk, the development of a

safety plan was developed from the RK3K PU 05 /

PRT / M / 2014 document. The results of the devel-

opment carried out are by detailing the job descrip-

tions WBS (Work Breakdown Structure) divided into

2, namely work packages (level 4 WBS) and activities

(level 5 WBS) and in the risk control column detailed

with preventive actions and corrective actions for con-

struction work.

ACKNOWLEDGEMENTS

The authors would like to thank the financial support

provided by Universitas Indonesia through PITTA

B funding scheme under grant number NKB –

0803/UN2.R3.1/HKP.05.00/2019 managed by Direc-

torate for Research and Public Services (DRPM) Uni-

versitas Indonesia.

REFERENCES

Albert, A. (2014). Emerging Strategies for Construction

Safety & Health Hazard Recognition. Journal of

Safety, Health & Environmental Research.

Asiyanto (2011). Metode Konstruksi Bendungan. UI Press,

Depok.

Duffield, C. and Trigunarsyah, B. (1999). Project Manage-

ment Conception to Completion. Engineering Educa-

tion Australia. (EEA). Australia.

Elsye, V. and Latief, Y. (2018). Development of work break-

down structure (WBS) standard for producing the risk

based structural work safety plan. MATEC Web Con-

ferences, 147.

Fisk, E. R. (1997). Construction Project Administration

Fifth Edition. Prentice Hall.

Garza, D. L., M., J., Hancher, D. E., and Decker, L. (1998).

Analysis of Safety Indicators in Construction. Journal

of Construction Engineering and Management 124.

Hidayah, D. N., Latief, Y., and Riantini, L. S. (2018). 2nd

Nommensen International Conference on Technology

and Engineering. IOP Publishing.

Institute, P. M. (2017). A Guide To The Project Management

Of Body Of Knowledge 6th Edition. Project Manage-

ment Institute, Newtown Square.

Kausarian, H., Batara., P., E., D. B., Suryadi, A., and Lubis,

M. Z. (2018). Geological mapping and assessment

for measurement the electric grid transmission lines in

west sumatera area. Indonesia. Internasional Journal

on Advanced Science Engineering Information Tech-

nology, Vol, 8(3):856–862.

Kausarian, H., Sumantyo, J. T. S., Putra, D. B. E., Suryadi,

A., and Gevisioner. 2018. Image processing of alos

palsar satellite data, small unmanned aerial vehicle

(UAV), and field measurement of land deformation. In-

ternational Journal of Advances in Intelligent Infor-

matics, Vol, 4(2):132–141.

Kerzner, H. (2001). Project Management Seventh Edition.

Canada: John Wiley & Sond.

Labombang, M. (2011). Risk management in construction

project. Journal Smart Technology, Vol 9, No. 1, 1:39–

46.

Lu, M., Cheung, C. M., Li, H., and Hsu, S. C. (2016).

Understanding the relationship between safety invest-

ment and safety performance of construction projects

through agent-based modeling. Accident Analysis and

Prevention.

Machfudiyanto, R. A., Latief, Y., Suraji, A., and Soeharso,

S. Y. (2018). Improvement of Policies and Institutional

in Developing Safety Culture in The Construction In-

dustry to Improve The Maturity Level, Safety Perfor-

mance, and Project Performance in Indonesia. Inter-

nasional Journal of Civil Engineering and Technology

(IJCIET) Vol 9, Issue 10.

Maengga, P. (2015). Analisa Faktor yang Berpengaruh Ter-

hadap Konsep Safety In Design pada Tahap Peren-

canaan untuk Meningkatkan Kinerja Keselamatan

Kerja Pelaksanaan Proyek Konstruksi. Depok: libUI.

Mhetre, K., Konnur, B. A., and Landage, A. B. (2016). Risk

Management in Construction Industry. Internasional

Journal of Engineering Research Vol 5.

Wu, X., Liu, Q., Zhang, L., Skibniewski, M. J., and Wang,

Y. (2015). Prospective Safety Performance Evaluation

On Construction Sites. Accident Analysis and Preven-

tion.

Development of Safety Plan to Improve OHS (Occupational Health and Safety) Performance for Construction of Dam Supporting

Infrastructure based on WBS (Work Breakdown Structure)

267