Separation of Crude Oil and Its Derivatives Spilled in Seawater by using

Cobalt Ferrite Oxide

Mohammed A. Samba

1

, Ibrahim Ali Amar

2

, Musa Abuadabba

1

, Mohammed A. ALfroji

1

, Zainab M.

Salih

1

and Tomi Erfando

3

1

Department of Oil and Gas , Faculty of Energy and Mining Engineering, Sebha University, Sebha, Libya

2

Department of Chemistry, Faculty of Science, Sebha University, Sebha, Libya

3

Department of Petroleum, Universitas Islam Riau, Pekanbaru, Indonesia

eng.zainabmohammed27@gmail.com, tomierfando@eng.uir.ac.id

Keywords:

Magnetic Cobalt Ferrite Oxide Nanoparticles, Oil Spills, Sea Water.

Abstract:

Oil spills can cause a wide range of impacts in the marine environment and are often portrayed by the media

as ’environmental disasters’ with dire consequences predicted for the survival of marine flora and fauna. The

purpose of this paper is to study the possibility of using spinel oxide (CFO) as an oil absorbent material

with the aim of removing crude oil and its derivatives from aqueous solutions. Spinel oxide from cobalt

ferrite nanoparticles with formula CoFe2O4 (CFO) was prepared by sol-gel method. Functional groups were

also identified on the surface of the oxide using the infrared spectrum (FTIR). In addition, crude oil and its

derivatives were diagnosed using FTIR, and the density and viscosity of crude oil and its derivatives at 15

◦

C temperature. In this study, three samples of seawater were used from different Libyan regions (Gemens

Seawater, Abo Sitta Port, Elbrega Anchorage), and Two samples of crude oil were used from different Libyan

fields (Light, Medium). The samples of crude oil used at three different concentrations (0.01g, 0.03g, 0.05g).

However, the oil removal was calculated for different scenarios as gm / gm and as percentage. The oil removal

capabilities of the prepared absorbent were found to be 10.966 2.3651 g/g to 4.5426 ± 0.113 g/g, 31.8333 ±

5.324 g/g to 7.02053 ± 1.1271, 14.7333 ± 3.1988 g/g to 6.01 ± 0.1287 g/g, 47.1033 ± 6.0222 g/g to 9.2122

± 2.8177, 10.8833 ± 2.1840 g/g to 4.5786 ± 0.1921 g/g, 42.96 ± 1.4046 g/g to 10.5020 ± 1.3172 g/g for

Gemmens Seawater (light oil), Gemmens Seawater (medium oil), Port Abu Sitta (light oil), Port Abu Sitta

(meduim oil), Elbrega Anchorage (light oil) and Elbrega Anchorage (medium oil), respectively. The results

suggest that the prepared magnetic nanoparticles can be used as absorbent materials for removing oil spills

from sea water especially at medium oil.

1 INTRODUCTION

Environmental pollution is the pollution of air, land

and water in many ways. There are several reasons

for environmental pollution, such as from agricul-

ture and industry. Environmental pollution has dras-

tically changed the air, water and terrestrial ecosys-

tems as a result of the industrial revolution in Europe,

North America and China in the 19th century. More-

over, different types of toxic gases and different forms

of carbon components were produced from factories,

transport, and energy sectors has resulted in different

changes in the global climate and weather patterns,

and become a source of contamination of land, as well

as the ocean environment where the average temper-

ature and acidity are increasing. In addition, many

other chemicals like fertilizers used in the agricultural

industry also contribute to the pollution of the seas

over vast areas (Fartoosi and M., 2013).

Oil spills can have devastating effects on water-

ways and oceans. In the oil it is the polycyclic aro-

matic hydrocarbons (PAHs) that cause most of the

toxicity for human life, but the physical nature of oil,

i.e. the stickiness is a major problem for a number of

organisms such as birds. Spills of oil has a numerous

negative impacts both short and long term, resulting

in economic and financial losses. Also, the recover-

ing and clean-up processes are very costly; see for

example cases such as the clean-up from the Exxon

Valdes or the Deep Water Horizon (Fartoosi and M.,

2013). Oil spills could be removed through many

methods such as mechanical, chemical and treatment

Samba, M., Amar, I., Abuadabba, M., Alfroji, M., Salih, Z. and Erfando, T.

Separation of Crude Oil and Its Derivatives Spilled in Seawater by using Cobalt Ferrite Oxide.

DOI: 10.5220/0009146901750181

In Proceedings of the Second International Conference on Science, Engineering and Technology (ICoSET 2019), pages 175-181

ISBN: 978-989-758-463-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

175

by burning in situ, this study will include a part of the

chemical methods spinel oxide nanoparticles (mag-

netic spinal compounds).

1.1 Magnetic Spinel Compounds

The mixed transition elements of the general formula

AB2O4 are called spinel’s. These oxides take their

name from spinel metal (MgAl2O4). A is a binary

ion (Fe

2

+, Co

2

+, Ni

2

+, Zn

2

+, Mg

2

+, etc.), while B

is a trivalent ion (Fe

3

+, Co

3

+, Cr

3

+, Al

3

+, Mn

3

+, etc. ) (Smart, ). Spinel oxides are among the

most important magnetic nanomaterial’s. Spinel fer-

rite, SF Magnetic nanoparticles are spinel oxides con-

taining tri-iron ions. These oxides have the general

formula M

2

+ Fe

3

+ O

4

(Where M

2

+ represents Mn

2

+, Fe

2

+, Co

2

+, Ni

2

+, Zn

2

+, Mg

2

+ etc.). These

oxides have distinct chemical and physical properties

(Reddy, 2016). Excellent magnetic properties, Large

surface area, its surface has a large number of effec-

tive sites, high chemical stability, easy to prepare and

convert to the desired shape (Smart, ; Gomez-Pastora

et al., ).

Spinel oxides has wide applications in several

fields including: gas sensors, magnetic devices, wa-

ter purification, medicine, catalysts, recharging bat-

teries and ammonia production by electric stimulation

(Amar, 2014), as shown in figure 1.

In the field of water treatment, spinel nano-

magnetic nanoparticles on the list of materials can

be used as absorbent materials, because it can be re-

moved quickly and easily from the solution after ab-

sorption using an external magnetic field, after sepa-

rating the pollutants can be removed and reused sev-

eral times, Water Purification.

2 MATERIALS AND CHEMICALS

CoFe

2

O

4

were used in this study. Seawater three sam-

ples were used after routine testing and distilled water.

Light and Medium crude oil were also used with (den-

sity: 0.8245, API: 40, viscosity: 5.6136 and Boris

3.5915 @ 25

◦

C and @ 37.5

◦

C, Sp.Gr @ 60/60Fo

:0.8249) for light. While the (density: 0.8368, API:

37.5, viscosity: 19.5970 and Boris 9.7102 @ 25

◦

C and @ 37.5

◦

C, Sp.Gr @ 60/60 Fo:0.8372) for

medium.

2.1 Cobalt Ferrite Oxide Nanoparticle

Particles (CoFe

2

O

4

)

The magnetic spinal Cobalt ferrite oxide powder was

prepared 10 gm from magnetic spinal Nanoparticle

Figure 1: Some applications of spinel ferrite oxides (Amar,

2014)

formula CFO )COFe

2

O

4

(by Sol-gel method (Amar

et al., 2018), and The required quantities of cobalt

nitrate (12.4041g) and iron nitrate (34.4369g) were

weighed, Then add it in a small amount of distilled

water. Then add citric acid in amount of (36.8486g)

and EDTA in amount of (37.34g) as complication fac-

tors, the ammonia solution (NH

3

.H

2

O) was added to

pH control to 6, The solution was then evaporated us-

ing an electric heater with the solution moving contin-

uously by a magnetic mold to distribute heat. And by

continuously heating and stirring solution (mixture)

to thick black gel, the magnetic stirrer was then re-

moved and the gel left on the electric burner com-

pletely burned and turned into a solid component

(ash), The component was milled solid obtained and

placed in ceramic seals and burned in the air in the

furnace at 600

◦

C for 2 hours to remove the remaining

organic compounds and obtain a pure phase of pow-

der (Cobalt ferrite oxide), which will later be used as a

maze material to remove the blue methylene dye from

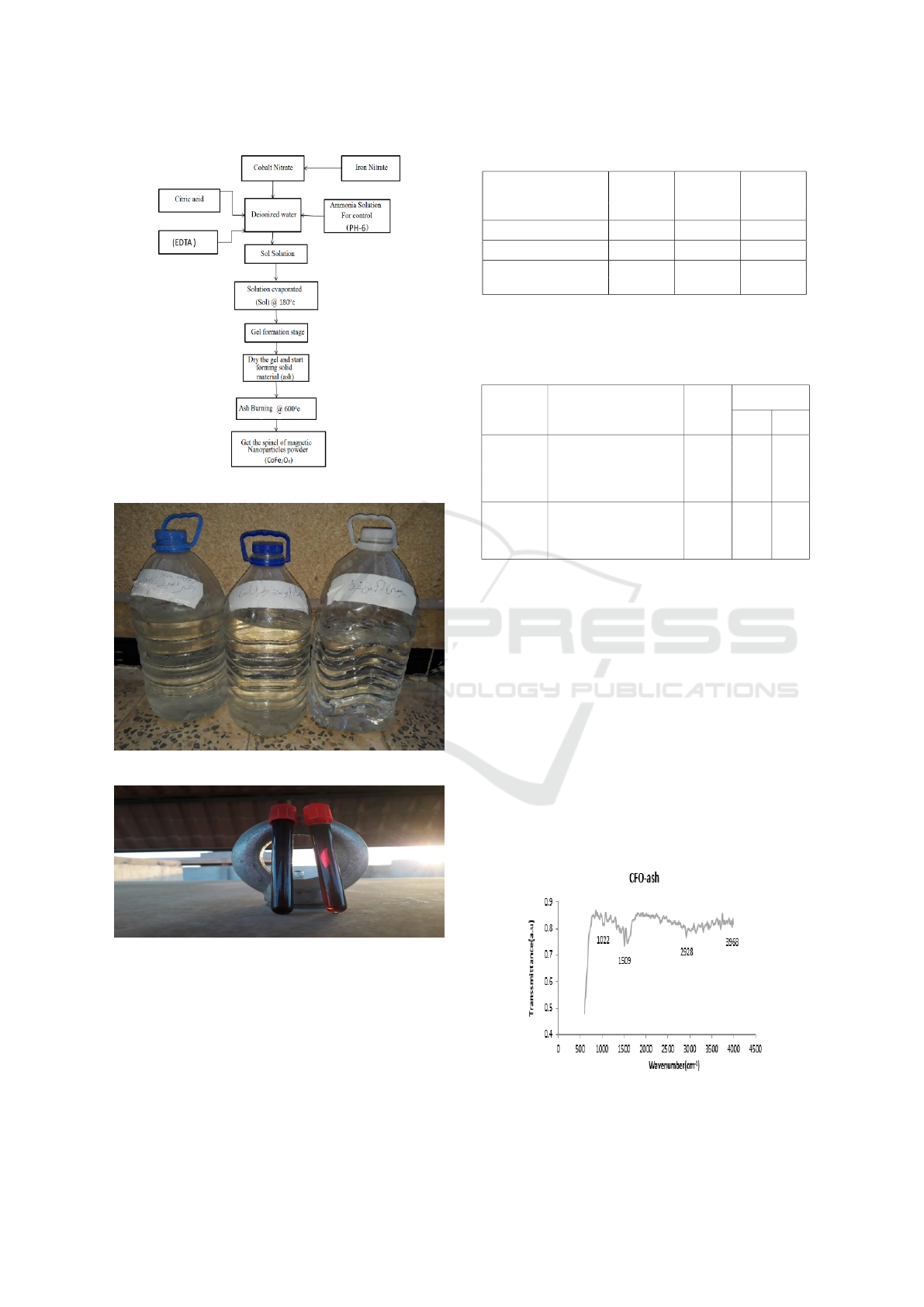

its solutions water. Figure 2 Shows the procures to

prepare the spinal oxide (Scheffe et al., 2011; Scheffe

et al., 2013).

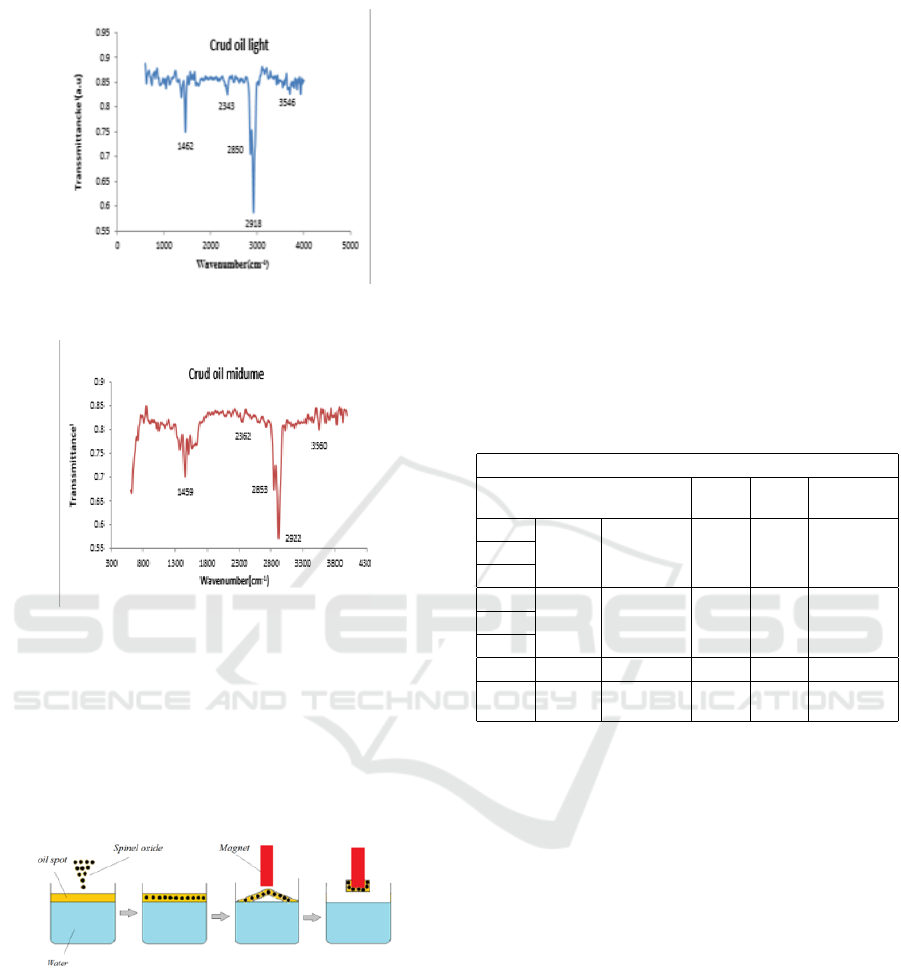

2.2 Sea Water and Crude Oil

Three samples of seawater were obtained from dif-

ferent parts of Libya, Tripoli, Benghazi and Al Brega

as shown in the figure 3. The parameters of seawa-

ter were calculated at the Faculty of Science Univer-

sity of Sebha, as shown in Table 1. Two samples of

crude oil were collected from different fields of Libya

(Light, Medium) As shown in the figure 4, Crude oil

properties were calculated at the Tripoli Petroleum

Research Center as shown in table 2.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

176

Figure 2: Steps of Preparation Spinal oxide

Figure 3: Shows seawater samples that used in this study

Figure 4: Shows oil samples that used in this study

3 RESULTS AND DISCUSSION

3.1 FTIR Result

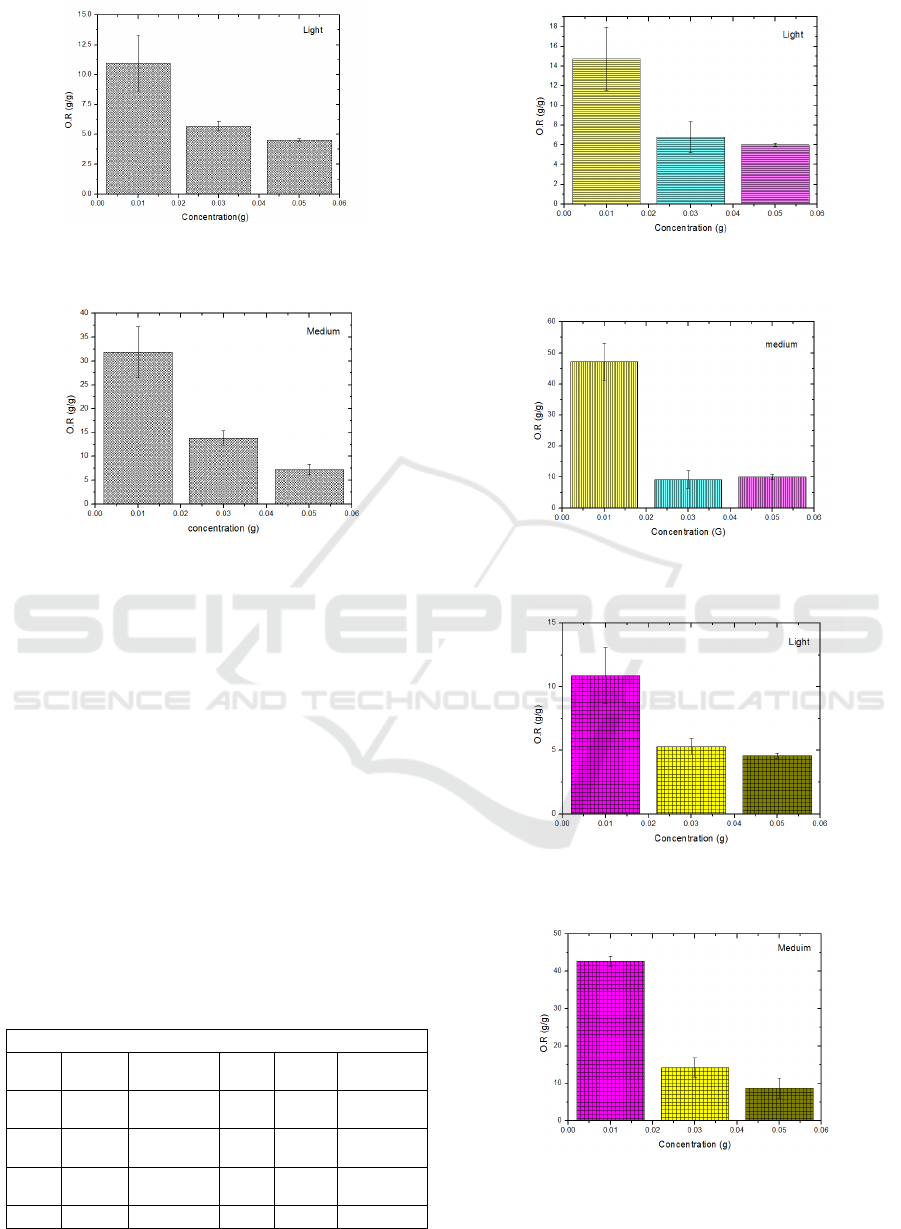

Functional groups on the surface of the spinel oxide

prepared by the sol-gel method and then identified us-

ing the infrared absorption spectrum (FTIR). The car-

Table 1: The Properties of seawater for three samples

Type

Marsa Sea

Gmines

Mina

Abo-seta

al-Briga /Benghazi /Tripoli

Conductivity (mc/cm) 183.9 186.7 180.7

pH 7.34 7.9 7.52

Salinity

1222810 1314210 1132110

(ppm)

Where:

MC/CM = Milli Cemence/Centimeter

Ppm = Pond per Million

Table 2: The Properties of Crude Oil.

Test Method TestDescription Unit

Result

X- field X-field

ASTM D 5002 Density @ 15

◦

CSp.Gr 60/60FAPI g/cc////

0.8368 0.8245

0.8372 0.8249

37.5 40

ASTM D 445

K.Viscosity@25

◦

C m 19.597 5.6136

K.Viscosity@

37.8

◦

C

m

2

/s 9.7102 3.5915

Where:

ASTM = American Society for Testing And Material.

K.Viscocity = Kinematic Viscocity Sp.Gr = Specific

Gravity

bon nanotube (CFO) oxide after burning the ash com-

pounds in preparation in air at 600

◦

C for two hours.

Figure 5 shows the FTTR results for Nanoparticles,

it is clearly seen that there are bundles of the termi-

nals at 3968 cm

-1

and 2928 cm

-1

; these packets can

be attributed to the Co-O and Fe-O bonds, respec-

tively. These specialty packs are characteristic of all

spinel oxides. Figure 6 and figure 7 have shown the

FTTR results for different oil type, where the range of

wavenumber from 600 to 4000 cm

-1

.

Figure 5: FTIR results for nanoparticles

Separation of Crude Oil and Its Derivatives Spilled in Seawater by using Cobalt Ferrite Oxide

177

Figure 6: FTIR Results for light oil.

Figure 7: FTIR Results for medium oil.

3.2 Results of Oil Removal as

gram/gram g/g

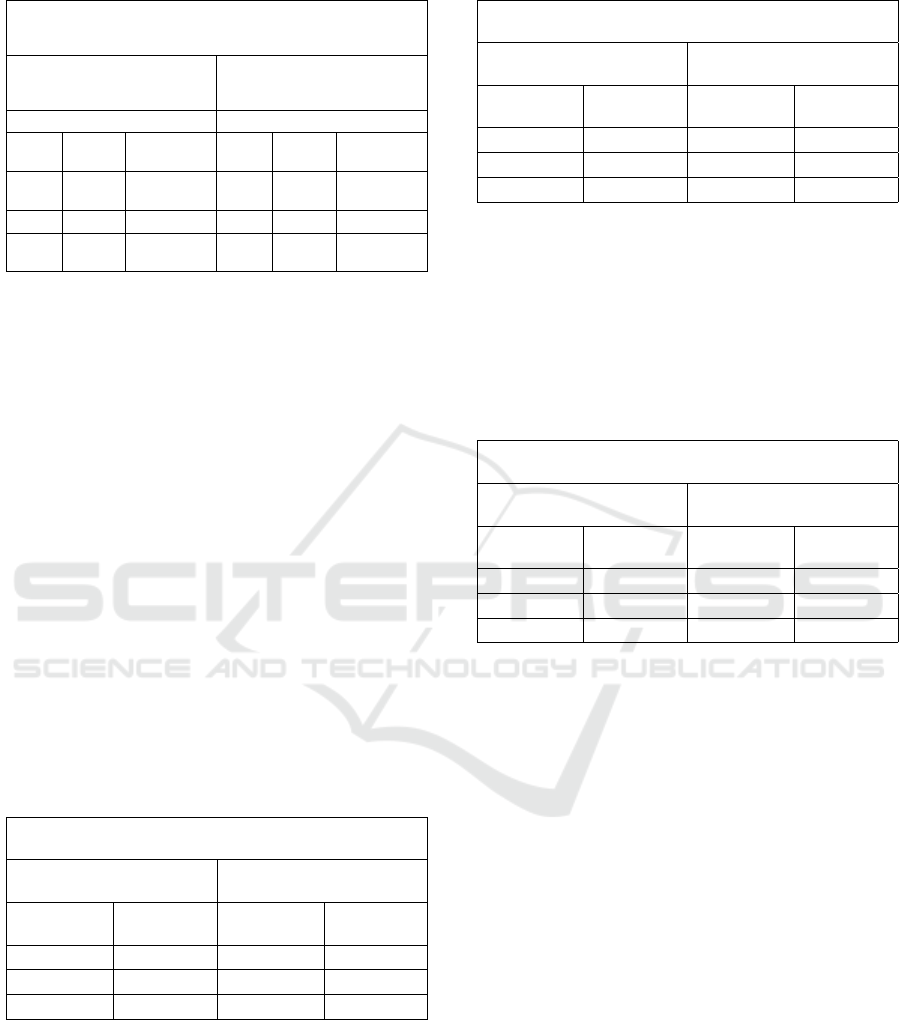

The technique of remove the oil from the sea water a

by using magnetic rod has shown in the figure 8.

Figure 8: Shows the step of removal oil spot from water

surface (Amar et al., 2019)

The following equation for calculating the oil re-

moved:

OR = (m2 − m1)/m1 (1)

Where:

OR=Oil Removal (gm/gm).

m1= Concentration of the spinal (gm).

m2= The weight of the spinal and oil (gm).

3.2.1 Gemmens Seawater

Figure 9,10 and table 3 display the gravimetric oil re-

moval (OR, g/g) or the oil absorption capacity of the

tested oily samples (light and medium) of Gemmens

Seawater as a function of absorbent amount. As can

be seen, in all cases the gravimetric oil removal of

Gemmens Seawater decrease with the increase in the

amount of the adsorbent from 0.01 to 0.05 g. In the

case of light oil (Figure 9), the OR decreased from

10.966 ± 2.3651 g/g to 4.5426 ± 0.113 g/g as the

amount of absorbent material. For the medium oil, the

OR was about 31.8333 ± 5.324 g/g at the absorbent

amount of 0.01 g and reached a value of 7.02053 ±

1.1271 g/g when the absorbent amount increased to

0.05 g (Figure 10).

Table 3: The Properties of Crude Oil.

Gemmens

Meduim Light

O.R

Concentrate

Sd O.R

Concentrate

Sd

31.8333 0.01 2.36 10.966 0.01

5.324

1.5565 13.8388 0.03 0.3967 5.6955 0.03

1.1271 7.2053 0.05 0.113 4.5426 0.05

Where:

OR=Oil Removal.

Sd=Standard Devition.

3.2.2 Port Abu Sitta

Figure 11,12 and table 4 display the gravimetric oil

removal (OR, g/g) or the oil absorption capacity of

the tested oily samples (light and medium) of Port

Abu Sitta Seawater as a function of absorbent amount.

As can be seen, not all cases the gravimetric oil re-

moval of Abu Sitta Seawater decrease with the in-

crease in the amount of the adsorbent from 0.01 to

0.05 g. In the case of light oil (Figure 11), the OR de-

creased from 14.7333 ± 3.1988 g/g to 6.01 ± 0.1287

g/g as the amount of absorbent material. For the

medium oil, the OR was about 47.1033 ± 6.0222 g/g

at the absorbent amount of 0.01 g and reached a value

of 9.2122 ± 2.8177 when the absorbent amount in-

creased to 0.03 g, while 10.0593 ± 0.8987 g/g when

the absorbent amount increased to 0.05 g (Figure 12).

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

178

Figure 9: Shows The Crude Oil (Light) Concentration, Oil

Removal Gemmens

Figure 10: Shows the Crude Oil (Medium) Concentration,

Oil Removal Gemmens

3.2.3 Elbrega Anchorage

Figure 13,14 and table 4 display the gravimetric oil re-

moval (OR, g/g) or the oil absorption capacity of the

tested oily samples (light and medium) of Elbrega An-

chorage Seawater as a function of absorbent amount.

As can be seen, in all cases the gravimetric oil re-

moval of Elbrega Anchorage Seawater decrease with

the increase in the amount of the adsorbent from 0.01

to 0.05 g. In the case of light oil (Figure 13), the OR

decreased from 10.8833 ± 2.1840 g/g to 4.5786 ±

0.1921 g/g as the amount of absorbent material. For

the medium oil, the OR was about 42.96 ± 1.4046 g/g

at the absorbent amount of 0.01 g and reached a value

of 10.5020 ± 1.3172 g/g when the absorbent amount

increased to 0.05 g (Figure 14).

Table 4: The Properties of Crude Oil.

PORT ABU SITTA

Medium Light

Sd O.R Concentrate Sd O.R Concentrate

6.0222 47.1033 0.01 3.1988 14.7333 0.01

2.8177 9.2122 0.03 1.598 6.8199 0.03

0.8987 10.0593 0.05 0.1287 6.01 0.05

Figure 11: Shows the Crude Oil (Light) Concentration, Oil

Removal Port Abu sitta

Figure 12: Shows the crude oil (medium) concentration, oil

removal port Abu sitta

Figure 13: Shows the crude oil (light) concentration, oil

removal Elbrega Anchorage

Figure 14: Shows the crude oil (medium) concentration, oil

removal Elbrega Anchorage

Separation of Crude Oil and Its Derivatives Spilled in Seawater by using Cobalt Ferrite Oxide

179

Table 5: The Properties of Crude Oil.

Elbrega Anchorage

Medium Light

Sd O.R Concentrate Sd O.R Concentrate

1.4046 42.69 0.01 2.184 10.8833 0.01

2.5788 14.2086 0.03 0.6217 5.3132 0.03

1.3172 10.502 0.05 0.1921 4.5786 0.05

3.3 Results of Oil Removal as

Percentage

The following equation for calculating the percent-

age:

Remaining = ((Woil +Powder)−W removal)/(Woil +Powder)

(2)

OilRemovalPercentage = (1 − Remaining) ∗ 100 (3)

3.3.1 Gemmens Seawater

The highest percentage of oil removal was (52.73%)

at the powder concentration (0.05gm) during the light

oil, when using the medium oil, the highest oil re-

moval percentage was (79.43%) at the powder con-

centration(0.03gm) as shown in the table 6.

Table 6: Shows the Oil Removal Percentage of Gemmens

Seawater

Gemmens

Light Medium

Concentration Percentage % Concentration Percentage %

0.01 24.65 0.01 60.92

0.03 33.74 0.03 79.43

0.05 52.73 0.05 65.09

3.3.2 Port Abu Sitta

When we use the light oil was the highest removed

(66.69%), It was when the powder concentration

(0.05gm), When using the medium oil was the highest

removal rate (91.1%), It was when the powder con-

centration (0.05gm) as shown in the table 7.

Table 7: Shows the oil removal percentage of Abu Sitta port

Port Abu Sitta

Light Medium

Concentration Percentage % Concentration Percentage %

0.01 32.41 0.01 89.25

0.03 46.41 0.03 54.81

0.05 66.69 0.05 91.1

3.3.3 Elbrega Anchorage

The light oil was the highest removed about (53.08%),

It was when the powder concentration (0.05gm),

When using the medium oil was the highest removal

rate (93.1%), It was when the powder concentration

(0.05 gm) as shown in the table 8.

Table 8: Shows the oil removal percentage of Abu Sitta port

Port Abu Sitta

Light Medium

Concentration Percentage % Concentration Percentage %

0.01 25.17 0.01 82.79

0.03 37.47 0.03 80.92

0.05 53.08 0.05 93.1

4 CONCLUSION

The properties of iron oxide were studied and func-

tional groups were identified using the infrared spec-

trum. Two types of oil samples (Light and Medium)

were used as water pollutants model. Within the ab-

sorbent amount of 0.01 to 0.05 g, the gravimetric

oil removal capabilities were between the 24.5% to

93.1%. The obtained results suggest that Cobalt Fer-

rite Oxide Nanoparticle might be promising absorbent

materials and can be used for oil-spill cleanup from

Sea water specially for medium oil.

• The material must be milled enough to avoid

falling into the bottom of the test.

• High-density raw materials must be heated when

aggregated in cold temperatures.

• Apply experiments in large vessels for easy han-

dling with magnets and to contribute to the suc-

cess of the experiment.

• A medium-sized absorbent should be used for

easy handling with the addition of oil.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

180

REFERENCES

Amar, I. A. (2014). et al (2014). Electrochemical synthesis

of ammonia from N 2 and H 2 O based on (Li, Na, K)

2 CO 3Ce 0. 8 Gd 0. 18 Ca 0, 8(18).

Amar, I. A. et al. (2018). Synthesis and Characterization of

Magnetic CoFe1. 9Cr0.

Amar, I. A. et al. (2019). Oil spill removal from wa-

ter by absorption on zinc-doped cobalt ferrite mag-

netic nanoparticles. Advanced Journal of Chemistry-

Section A (Theoretical, Engineering and Applied

Chemistry), pages 266–385):.

Fartoosi, A. and M., F. (2013). The impact of maritime

oil pollution in the marine environment: case study

of maritime oil pollution in the navigational channel

of Shatt Al-Arab.

Gomez-Pastora, J. et al. (2014).

Reddy, D. H. K. (2016). Spinel ferrite magnetic adsor-

bents: alternative future materials for water purifica-

tion? Coordination Chemistry Reviews.

Scheffe, J. R., Allendorf, M. D., Coker, E. N., Jacobs,

B. W., McDaniel, A. H., and Weimer, A. W. (2011).

Hydrogen production via chemical looping redox cy-

cles using atomic layer deposition-synthesized iron

oxide and cobalt ferrites. Chemistry of Materials,

23(8):2030–2038.

Scheffe, J. R., McDaniel, A. H., Allendorf, M. D., and

Weimer, A. W. (2013). Kinetics and mechanism of

solar-thermochemical h 2 production by oxidation of

a cobalt ferrite–zirconia composite. Energy & Envi-

ronmental Science, 6(3):963–973.

Smart, L. E. Solid state chemistry: an introduction. Third

Edition.

Separation of Crude Oil and Its Derivatives Spilled in Seawater by using Cobalt Ferrite Oxide

181