HPMC Inhibit Mannitol Re-crystallization in Air-dried Liposome

Formulations

Raditya Weka Nugraheni

1,2*,

Helmy Yusuf

2

, Dwi Setyawan

2

1

Department of Pharmacy, Faculty of Health Sciences, University of Muhammadiyah Malang Jalan Bendungan Sutami 188

A Malang 65145, East Java, Indonesia

2

Department of Pharmaceutics, Faculty of Pharmacy, Universitas Airlangga, Jalan Mulyorejo Surabaya 60115, East Java,

Indonesia

Keywords: Liposome, Air-Drying, Mannitol, HPMC, Crystallizations

Abstract: Liposome defined as a spherical vesicle, which is formed when phospholipids are being hydrated with an

aqueous environment. This study investigated the role of HPMC to inhibit mannitol crystallization in the air-

dried liposome formulation. HPMC has been used in solid dispersion to prevent crystallization drugs. The

mannitol and HPMC were included in the developed formulations with four different ratios and air-dried at

40ºC for 120 h. Liposome was composed of SPC:DDA: Chol (9:3:1 in molar ratio). XRD data showed

crystalline-forming properties as a function of mannitol and HPMC ratio. The formula with the highest

mannitol: HPMC ratio (4:1) showed the most apparent crystallinity, while the lowest proportion (2:3)

indicated amorphous solid. DTA analysis found that the following formula showed a broad endothermic peak

at 150-170ºC, indicating amorphous solid. SEM data supported these results where no crystalline structure

was observed in the latter formulation. The rest formula showed partially amorphous and partially crystalline.

It can be concluded that the incorporation of HPMC as a dispersion matrix potentially inhibits crystal

formation in the developed formulation

1 INTRODUCTION

Liposome was defined as a spherical vesicle, which is

formed when phospholipids are being hydrated with

an aqueous environment (Kaur, 2011). Liposome,

which is widely used in drug delivery, is well known

for its versatility for delivering both hydrophilic and

lipophilic agents(Çağdaş, Sezer, & Bucak, 2014;

Chen, Han, Cai, & Tang, 2010). Research on

producing liposomes into solid materials has been

conducted extensively since solid liposome has more

advantages in terms of stability compared to the

liposome in water suspension. Decreasing molecular

mobility in a solid-state may decrease chemical

degradation, which leads to physical instability

(Mohammed, Bramwell, Coombes, & Perrie, 2006).

However, dehydration could also be detrimental

for the liposome since removing water from the

system will cause the vesicle structure to collapse. To

prevent this, compounds that are rich in hydroxyl

group are employed to interact with the phosphate

head, thus replacing the water molecules during

drying (Franks, 2007; Ingvarsson, Yang, Nielsen,

Rantanen, & Foged, 2011). Mannitol is an alcoholic

sugar that is widely used in the drying process of the

liposome. However, mannitol is easily re-crystallized

and potentially damaging bi-layer the membrane (Li

et al., 2016).

We tried to address the problem by employing

hydroxypropylmethylcellulose

(HPMC) as a

dispersing matrix, which will help to suppress the re-

crystallization of mannitol (Kiew, Cheow, &

Hadinoto, 2015). HPMC is a cellulose-derived

polymer that methylated and hydroxy-propylated

(Rowe, 2009). It is widely used as bioadhesive

material, a controlled release agent, a dispersion

agent, and an increasing viscosity agent. To produce

a stable liposome vesicle, we used a combination of

soy phosphatidylcholine (SPC) as principal lipid

constituent, bromide salt of dimethyl

dioctadecyl

ammonium (DDAB) which is cationic, and

cholesterol (Patent No. US20150079156 A1, 2015).

We observed the effects of mannitol in

combination with HPMC as a dispersing matrix in

different ratios on the physical characteristics of the

solid dried products. Powder X-Ray Diffraction

228

Nugraheni, R., Yusuf, H. and Setyawan, D.

HPMC Inhibit Mannitol Re-crystallization in Air-dried Liposome Formulations.

DOI: 10.5220/0009130502280232

In Proceedings of the 2nd Health Science International Conference (HSIC 2019), pages 228-232

ISBN: 978-989-758-462-6

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

(PXRD), and Differential Scanning Calorimetry

(DSC) were used to investigate the properties of the

products. The procedures of physical characterization

were conducted according to our previous work

(Yusuf, 2013).

2 METHODS

Materials

The lipid phase for liposome formulation was

Dimethyl-Dioctadecylammonium (Sigma Aldrich,

Singapore) and Soy Phosphatidylcholine (Lipoid

GmBh, Germany), and cholesterol (Sigma-Aldrich,

Singapore). The use of cholesterol was to enhance

liposomal membrane stability. The protectant used in

this research was Mannitol (Sigma-Aldrich,

Singapore), a poly-alcohol compound. Hydroxy-

propyl-methyl-cellulose (Shin-Etsu, Japan) was

selected as a dispersion matrix to increase physical

stability of the products in terms of increasing the

total mass of the products. Methanol (E. Merck) was

chosen to dissolve all of the lipid phases in the

liposomal ingredients. All materials used were of

analytical grade.

Research Procedure

The technique for liposome formula preparation was

thin-film hydration methods in which the lipid phase

solution was evaporated and hydrated using water

medium. The lipid phase was dissolved in methanol

proportionally SPC:DDA: Cholesterol = 9:3:1.

The thin-film, which was formed after the

evaporation using a rotary evaporator (Büchi,

Germany) for 60 minutes hydrated with a solution of

mannitol in various concentrations that had

previously warmed to facilitate miscibility. Had been

done at 50°C for 10 minutes, the appearance of white

liquid suspension indicate the formation of liposomal

suspension. Liposome suspension sonicated for 5

minutes to produce a smaller vesicle size. HPMC

powder was weighed

according to Table 1, and

dispersed in 5 mL purified water to form HPMC gel.

Liposome suspension was combined into HPMC

gel and stirred until a homogeneous mixture achieved

and portioned into vials

for air-drying. The

temperature and time of the air-drying was 40°C for

72 hours.

Table 1: The composition of Mannitol and HPMC in the

Formula

Formula

Mannitol

Weight (g)

HPMC

Weight (g)

Mannitol:

HPMC

FMO1 0,250 0,125 2:1

FMO2 0,500 0,125 4:1

FMO3 0,250 0,375 2:3

FMO4 0,500 0,375 3:4

Differential Thermal Analysis (DTA)

The thermal profiles of the solid samples were

analyzed using DTA instrument (Mettler Toledo,

Switzerland). The sample is put into aluminum

crucibles and scanned from 30°-300°C at a heating

rate of 10°C/min.

X-Ray Diffraction Analysis (XRD)

The crystallinity of the dried products analyzed using

Powder X-Ray Diffraction Instrument (Phillips

X'Pert PRO PANalytical, Netherlands). The samples

inserted into the sample holder and flatten. The

condition of analysis waa using Cu metal target and

Kα filter. The voltage and current were 40 kV and 40

mA, performed at room temperature, in a range of 2Ɵ

of 5-40°.

Scanning Electron Microscopy (SEM)

A small amount of the samples was dispersed and

glued onto 25 mm diameter sample holder. The

samples were sputter-coated with 5 nm layer of Au-

Pd (Gold-Palladium). The observation was completed

using 500 and 1000 magnitude.

3 RESULTS AND DISCUSSION

The formulations profile was partially amorphous.

The results could be seen from the presence of broad

peaks in the temperature range 96-116 for FMO1,

FMO2, and FMO3, which correspond to endothermic

transition temperatures for HPMC. The results show

that some of the material has been incorporated to

form amorphous solid dispersions and is the expected

profile of the product because it indicated the success

of the vitrification mechanism in maintaining the

physical stability of the dry liposome (Ingvarsson et

al., 2011).

HPMC Inhibit Mannitol Re-crystallization in Air-dried Liposome Formulations

229

Table 2: Endothermic peak list in DTA thermogram

T1 (˚C) ΔH1 (J/g) T2 (˚C) ΔH2 (J/g) T3 (˚C) ΔH3 (J/g)

SPC 99.54 284.49

DDAB 90.18 145.50

Cholesterol 149.31 79.8

Mannitol 168.3 190

HPMC 88.37 169.95

FMO1 116.3 17.4 166.5 72.2

FMO2 96.7 10.7 157.4 9.50 172.5 113.0

FMO3 100.3 32.1 157.5 11.4 171.8 48.7

FMO4 160.3 62.3

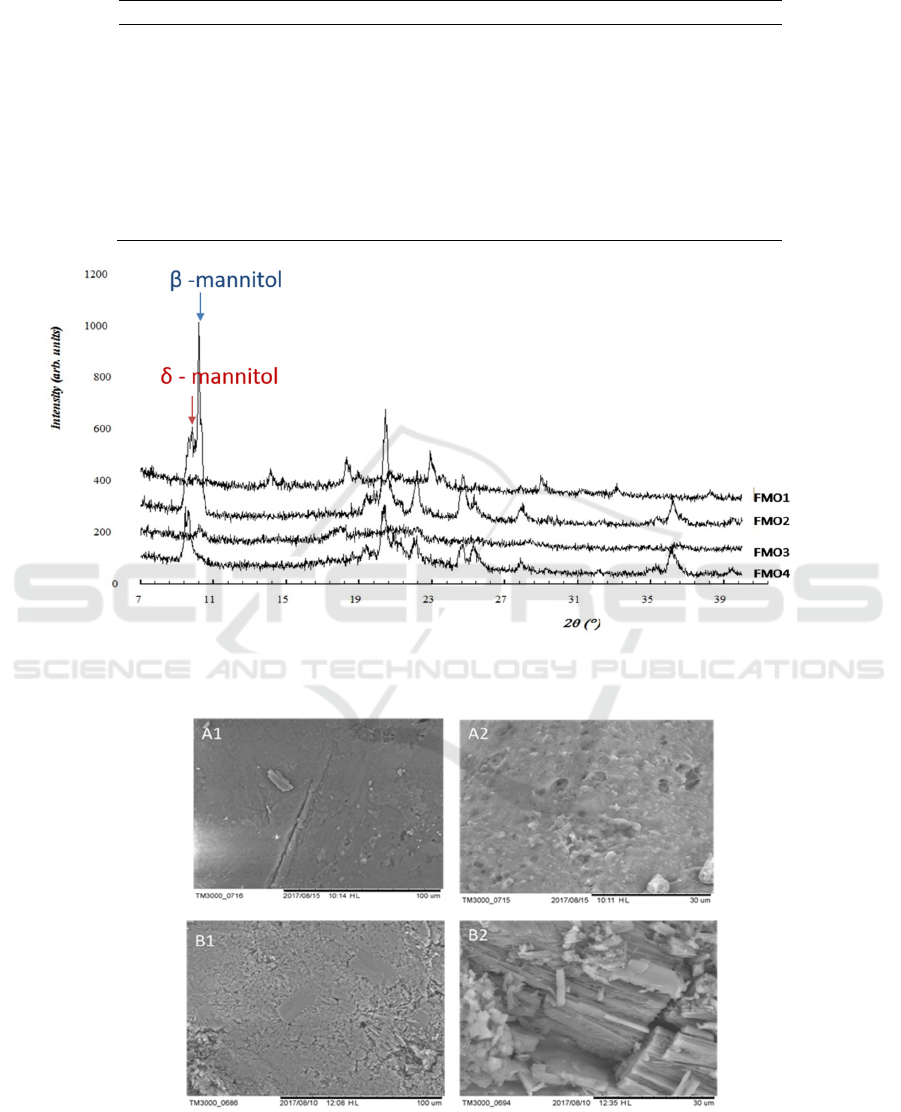

Figure 2: The X-ray diffractogram profile of air-dried liposome formulation with mannitol in combination with HPMC in a

different ratio, according to table 1.

Figure 3: Morphology of liposome formulation characterized by SEM. A1 and A2 were FMO3, while B1 and B2 were FMO4.

HSIC 2019 - The Health Science International Conference

230

However, there are still sharp peaks that may

correlate with mannitol transition temperatures. The

results of the thermal analysis showed that there were

new peaks (listed in Table 2) different from the

original substances. Mannitol is a material which has

different morphological phases (polymorphism), β-

and δ-mannitol polymorph had endothermic peaks in

157˚ and 167˚ Celsius, respectively (Barreneche, Gil,

Sheth, Inés Fernández, & Cabeza, 2013). The peak of

pure mannitol was observed in 168.3˚C, indicating δ-

mannitol existence; no other peak was observed.

However, observations of thermal analysis of the

formulations showed two peaks that existed together

in FMO2 and FMO3. From this data, we could

conclude that β-mannitol was formed during the

formulations processes as there was no raw material

which had endothermic peaks at such temperature.

Interestingly, only β-mannitol observed in FMO1,

and only δ-mannitol was found in FMO4. The

difference between the FMO1 and FMO4 formulas is

in the ratio of the weight of mannitol: HPMC, which

are 2:1 and 3:4, respectively. Mannitol levels in

FMO1 are higher than HPMC, so the shape of the

delta mannitol, which has existed since the beginning,

is relatively unchanged. Whereas in FMO3, the

HPMC ratio is higher than that of mannitol; this is

what might trigger the shift from delta to beta

mannitol. High HPMC ratios also occur in FMO3, but

in this formula, the amorphous form dominates, as

evidenced by the relatively high endothermic

enthalpy at 100.3 (ΔH1=32,1 J/g). The differences in

endothermic enthalpies of the peaks indicating

different energy levels of thermodynamic transitions

in the formulations. These results will be confirmed

using the crystallinity profile from X-Ray powder

diffraction.

The X-Ray diffractogram results showed that

FMO3 was an amorphous form, characterized by the

absence of intensive crystalline peaks (Kiew et al.,

2015). Nevertheless, the sharp peak of mannitol

detected from the formulas FMO2 and FMO4.

According to the previous investigations, the

characteristic peaks of β-mannitol was 10.56° and

14.71°, the α-mannitol was 13.79°, and δ-mannitol

was 9.57° (Vanhoorne et al., 2016). In FMO2, it is

confirmed that there is a mixture of β- and δ-mannitol

all at once. The results show that the difference in the

ratio of mannitol: HPMC in the formula is very

influential on the phase behavior even though

although the process is carried out uniformly.

Morphological analysis with SEM instruments

also supports the DTA and XRD examination. The

FMO3 formula is known to provide an amorphous

and porous surface image, while FMO4 on the same

scale shows a high crystallinity (Haque & Roos,

2005). As a carrier for dry liposomes, the FMO3

profile is preferrable because liposomes can be

incorporated and protected during the drying process

(Nugraheni, Setyawan, & Yusuf, 2017).

4 CONCLUSIONS

The incorporation of HPMC as a dispersion matrix

potentially inhibits crystal formation in the developed

formulation, especially in FMO3, which is the most

suitable carrier for air-dried liposome compared to the

other formulations.

REFERENCES

Barreneche, C., Gil, A., Sheth, F., Inés Fernández, A., &

Cabeza, L. F. (2013). Effect of d-mannitol

polymorphism in its thermal energy storage capacity

when it is used as PCM. Solar Energy, 94, 344–351.

https://doi.org/10.1016/j.solener.2013.05.023

Çağdaş, M., Sezer, A. D., & Bucak, S. (2014). Liposomes

as Potential Drug Carrier Systems for Drug Delivery. In

A. D. Sezer (Ed.), Application of Nanotechnology in

Drug Delivery. Retrieved from

http://www.intechopen.com/books/application-of-

nanotechnology-in-drug-delivery/liposomes-as-

potential-drug-carrier-systems-for-drug-delivery

Chen, C., Han, D., Cai, C., & Tang, X. (2010). An overview

of liposome lyophilization and its future potential.

Journal of Controlled Release, 142(3), 299–311.

https://doi.org/10.1016/j.jconrel.2009.10.024

Franks, F. (2007). Freeze-drying of pharmaceuticals and

biopharmaceuticals: Principles and practice.

Cambridge: Royal Society of Chemistry.

Haque, Md. K. & Roos, Y. H. (2005). Crystallization and

X-ray diffraction of spray-dried and freeze-dried

amorphous lactose. Carbohydrate Research, 340(2),

293–301. https://doi.org/10.1016/j.carres.2004.11.026

Ingvarsson, P. T., Yang, M., Nielsen, H. M., Rantanen, J.,

& Foged, C. (2011). Stabilization of liposomes during

drying. Expert Opinion on Drug Delivery, 8(3), 375–

388. https://doi.org/10.1517/17425247.2011.553219

Kaur, R. (2011). Liposomes: Formulation and

characterisation as contrast agents and as vaccine

delivery systems (Ph.D., Aston University). Retrieved

from http://eprints.aston.ac.uk/15820/

Kett, V., Yusuf, H., McCarthy, H., & Chen, K. H. (2015).

Patent No. US20150079156 A1. Retrieved from

http://www.google.ch/patents/US20150079156

Kiew, T. Y., Cheow, W. S., & Hadinoto, K. (2015).

Preserving the supersaturation generation capability of

amorphous drug-polysaccharide nanoparticle complex

after freeze drying. International Journal of

HPMC Inhibit Mannitol Re-crystallization in Air-dried Liposome Formulations

231

Pharmaceutics, 484(1–2), 115–123.

https://doi.org/10.1016/j.ijpharm.2015.02.057

Li, J., Hu, M., Xu, H., Yu, X., Ye, F., Wang, K., … Zhang,

D. (2016). Influence of type and proportion of

lyoprotectants on lyophilized ginsenoside Rg3

liposomes. Journal of Pharmacy and Pharmacology,

68(1), 1–13. https://doi.org/10.1111/jphp.12489

Mohammed, A. R., Bramwell, V. W., Coombes, A. G. A.,

& Perrie, Y. (2006). Lyophilisation and sterilisation of

liposomal vaccines to produce stable and sterile

products. Methods, 40(1), 30–38.

https://doi.org/10.1016/j.ymeth.2006.05.025

Nugraheni, R. W., Setyawan, D., & Yusuf, H. (2017).

Physical Characteristics of Liposomal Formulation

Dispersed in HPMC Matrix and Freeze-Dried Using

Maltodextrin and Mannitol as Lyoprotectant.

Pharmaceutical Sciences, 23(4), 285–292.

https://doi.org/10.15171/PS.2017.42

Rowe, R. C. (Ed.). (2009). Handbook of pharmaceutical

excipients (6. ed). London: APhA, (PhP)

Pharmaceutical Press.

Vanhoorne, V., Van Bockstal, P.-J., Van Snick, B., Peeters,

E., Monteyne, T., Gomes, P., … Vervaet, C. (2016).

Continuous manufacturing of delta mannitol by cospray

drying with PVP. International Journal of

Pharmaceutics, 501(1–2), 139–147.

https://doi.org/10.1016/j.ijpharm.2016.02.001

Yusuf, H. (2013). THE DEVELOPMENT OF FREEZE-

DRIED LIPOSOME FORMULATIONS AS VACCINE

DELIVERY SYSTEMS (Ph. D. Thesis). Queen’s

University Belfast, Belfast.

HSIC 2019 - The Health Science International Conference

232