The Impact of Additively Coal Fly Ash toward Compressive Strength

and Shear Bond Strength in Drilling Cement G Class

Novrianti, Dori Winaldi and Muhammad Ridho Efras

Department of Petroleum Engineering , Universitas Islam Riau, Pekanbaru, Indonesia

Keywords:

Fly Ash, Pozzolan, Compressive Strength, Shear Bond Strength, Hydraulic Press.

Abstract:

The successful of cementing process in petroleum is indicated by the strength value consisting of the compres-

sive stress value and the shear bond strength value. The value of compressive strength permitted in drilling

is 500 psi while for shear bond strength is 100 psi. To increase the strength of cement is done by adding

pozzolanic additives. One alternative pozzolan that can be used and derived from inorganic waste is coal fly

ash. Indonesia has reserves of around 38.9 billion tons of coal with annual production reaching 435 million

tons, resulting in a large amount of coal fly ash. The silica contained in coal fly ash is pozzolan which can

increase the strength of cement and can reduce costs because it does not need to use additives from industry

and can also reduce environmental pollution from fly ash. This study was conducted to determine the value of

compressive strength and shear bond strength by using coal fly ash additives with variations in concentrations

of 2.5%, 5%, 7.5%, 10%, 12.5% and 15% by weight of cement (BWOC). Making cement suspension samples

is done by mixing water, bentonite, polypropylene glycol, CaCl2, and coal fly ash softens the mixer, then it is

poured in a mold and left in the water bath. The residence is carried out for 24 hours with temperature 60

0

C.

Compressive strength and shear bond strength test can be done by utilizing hydraulic pressure. The addition

of coal ash can increase the strength of cement. The optimal compressive strength and shear bond strength is

obtained on 7.5% BWOC additively ash coal with the value of compressive strength obtained is 1680.39 psi

and the shear bond strength is 138.88 psi.

1 INTRODUCTION

Coal is one of the energy sources in Indonesia with

estimated reserves of 38.9 billion tons (Suwandi and

Suyartono, 2001) Coal is used as a steam power plant

(SPP). Coal burning in SPP on the one hand provides

benefits for energy availability but on the other hand

can have a negative impact because it causes pollu-

tants that can pollute the environment and the health

impacts of the population (Finahari et al., 2007).

Burning coal from the boiler will produce waste

in the form of fly ash and bottom ash (Suarnita,

2011). It contains silica which can increase the

strength of drilling cement which consists of com-

pressive strength and shear bond structure, where the

strength of drilling cement is very influential on the

success of oil and gas well drilling operations.

Compressive strength is the strength for handling

the pressures from the formation and casing, while

the shear bond strength is the strength for holding

the weight of casing (Prasetyo and Lisantono, 2017).

Compressive strength withstands pressures in the hor-

izontal direction and cement strength shear bonds re-

sist pressure from the vertical direction (Samura et al.,

2018).

Coal fly ash has pozzolanic properties which

contain reactive silica which can reduce free lime

(Ca(OH)

2

) (Salain, 2015). The result of this reaction

results in a bond of calcium silica hydrate (C – S – H)

which is the nature of cement (Safitri and Djumari,

2010).

Utilizing fly ash on cement has been done fre-

quently. fly ash is gained by coal-burning and burn-

ing palm oil. The use of fly ash varies in number but

is usually used ¡25% (Roskos et al., 2011). In addi-

tion, fly ash can be used as a substitute for cement for

concrete compressive strength. In research (Ervianto

et al., 2016) the optimum compressive strength is ob-

tained by 7.5% fly ash.

This research aims to determine the impact of coal

fly ash on the strength of drilling cement. It was cho-

sen in this study because the amount is widely avail-

able and can reduce pollutant waste which can pollute

the environment. This research was also conducted

114

Novrianti, ., Winaldi, D. and Efras, M.

The Impact of Additively Coal Fly Ash toward Compressive Strength and Shear Bond Strength in Drilling Cement G Class.

DOI: 10.5220/0009129801140119

In Proceedings of the Second International Conference on Science, Engineering and Technology (ICoSET 2019), pages 114-119

ISBN: 978-989-758-463-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

to determine the composition of optimal coal fly ash

which will produce the value of compressive stress

and shear bond optimum structure.

2 RESEARCH AND

METHODOLOGY

This research was conducted at the Petroleum Engi-

neering Drilling Laboratory of the Islamic University

of Riau. The first step that must be prepared before

conducting this research is the preparation of tools

and materials, the main material of this research is

coal fly ash obtained from the SPP Makmur Sejahtera

Wisesa in South Kalimantan.

Fly ash coal contains a chemical composition of

silica oxide (SiO

2

) 74.20%, iron oxide (

2

O

3

) 14.40%

and aluminum oxide (AL

2

O

3

) 5.70% can be used as a

mixture of cement since it is pozzolanic. Pozzolan

which consists of silica and aluminum which react

chemically with calcium hydroxide at ordinary tem-

peratures forms compounds that are cementitious or

binding (Dembovska et al., 2017). The chemical com-

position of coal fly ash can be seen in the table 1, be-

low:

Table 1: Coal Chemical Composition of Fly Ash.

Chemical Composition (%)

SiO

2

74.20

Al

2

O

3

5.70

Fe

2

O

3

14.40

C

a

O 2.40

M

g

O 2.03

K

2

O 0.260

a

2O 0.06

T

i

O2 0.47

P

2

O

5

0.051

M

n3

0

4

0.160

SO

3

-

Source: (Haryanti, 2014)

In addition to coal fly ash the materials used

in this study are cement, water, bentonite, Calcium

cloride (CaCl

2

), Polypropolin e Glycol (PPG). While

the equipment used is Digital Lead, Constant Speed

Mixer, Water Bath Temperature Controller, sample

mold and Hydraulic Press.

Fly ash sample preparation refers to ASTM C 117-

03 where Fly ash coal is filtered with filter numbers

200 mesh (Theodorus et al., 2008). So that when the

stirring process can be mixed with other ingredients.

Then, the next step is to make cement samples based

on IS : 9013 – 1978 Where in this study the sample

made consisted of basic cement without fly ash and

basic cement using fly ash with concentration 2.5%,

5%, 7.5%, 10%, 12.5% and 15% as found in table 2.

Cement powder with bentonite additives, CaCl2, and

Coal fly ash is mixed in dry conditions, while water is

mixed with PPG.

The mixture of water and PPG was stirred in a

mixture with a speed of 4000 rpm after which the ce-

ment mixture was also put into a mixer and stirred at

a speed of 1200 rpm for 3 minutes. The sample was

then poured into a mold and wrapped using aluminum

foil. Compressive Strenght and Shear Bond Strenght

are tested within temperature of 60

0

C.

The equations used to calculate compressive

strength and shear bond strength are as follows:

CS = K × P(

A1

A2

)

Where:

CS = Cement Compressive Strength, psi

K = Coe f f icient f actor, f unction o f high

comparison (h) toward diameter (d)

P = Maximum loading, psi

A1 = Cross section o f block bearing, inch

2

A2 = Sur f ace area o f cement samples, inch

2

The equation used to calculate Shear bond Strength :

SBS = K × P(

A1

π × D × h

)

Where:

SBS = Shear bond strength o f cement, psi

K = Factor Coe f f icient, a f unction o f the ratio

o f the height(h) to diameter(d)

P = Maximum loading, psi

A1 = Cross section o f block bearing, inch

2

d = Inner diameter o f sample casing (cement),

inch

Testing of compressive strength and shear bond

strength test is carried out by using hydraulic press

according to SNI03-1974-1990 standards.The values

of compressive strength and shear bond strength that

have obtained were inputted in the minitab of soft-

ware to determine correlation and regression analysis.

The Impact of Additively Coal Fly Ash toward Compressive Strength and Shear Bond Strength in Drilling Cement G Class

115

Table 2: Composition of drilling cement samples

No Sample Cement Suspension Compo-

sition

1 S0 Cement (C)

2 S1 C + 2.5 Coal fly ash

3 S2 C + 5 Coal fly ash

4 S3 C + 7.5 Coal fly ash

5 S4 C + 10 Coal fly ash

6 S5 C + 12.5 Coal fly ash

7 S6 C + 15 Coal fly ash

3 RESULTS AND DISCUSSION

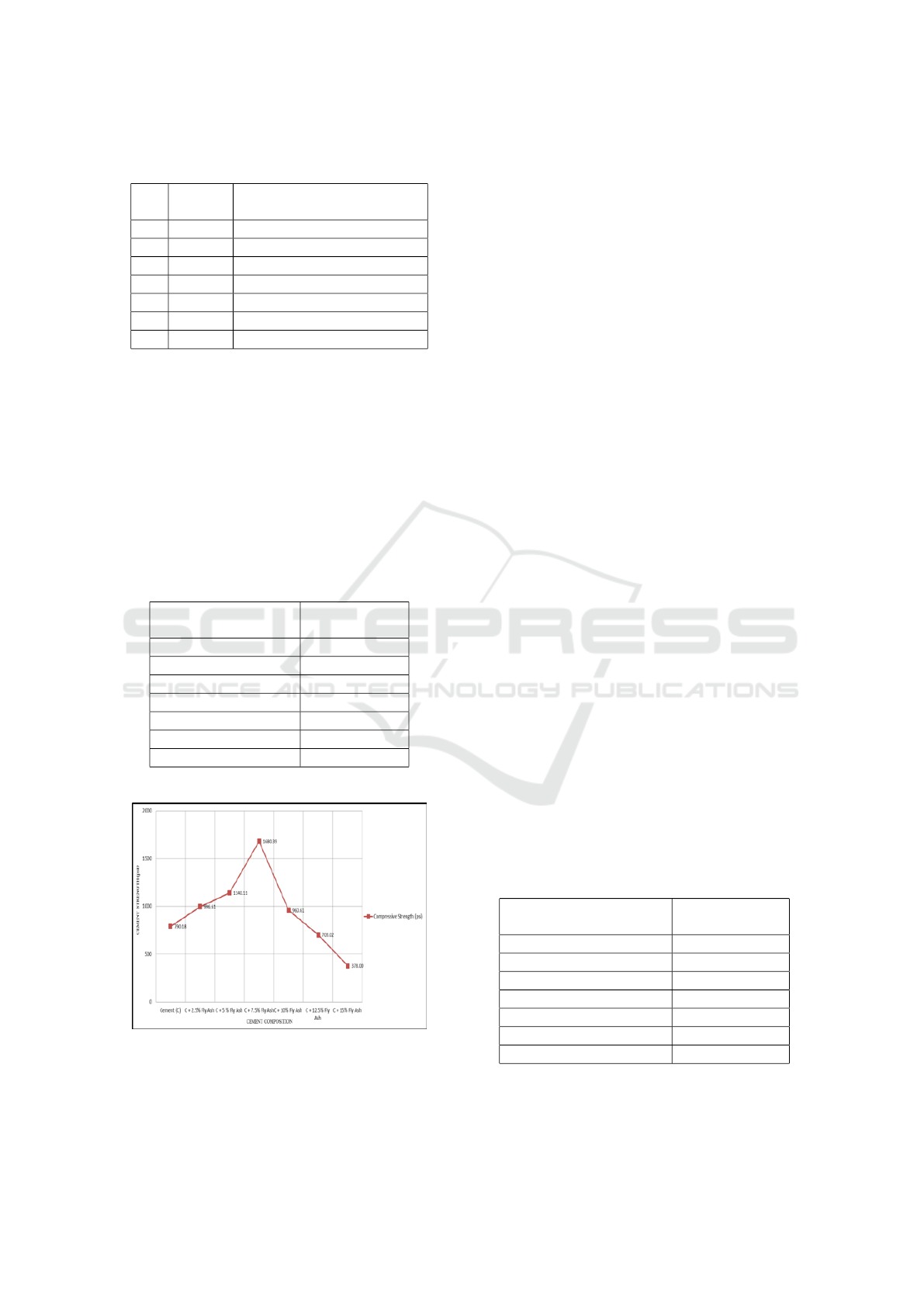

3.1 Compressive Strength

Testing of compressive strength on basic cement and

cement that added to the concentration of fly ash coal

consisting of concentration 2.5%, 5%, 7.5%, 10%,

12.5% and 15% bwoc can be seen in the Table 3 and

Figure 1 below:

Table 3: Calculation results of the value of Basic Cement

compressive strength plus coal fly ash

Cement Suspension

(CS) Composition

Value CS (psi)

Cement (C) 790.11

C + 2.5 Coal fly ash 996.61

C + 5 Coal fly ash 1140.11

C + 7.5 Coal fly ash 1680.39

C + 10 Coal fly ash 960.61

C + 12.5 Coal fly ash 703.02

C + 15 Coal fly ash 378.00

Figure 1: Value of Compressive Strength

Figure 1 shows coal fly ash affects the compres-

sive strength value. Where the composition of coal fly

ash within the concentration of 2,5%, 5% and 7.5%

increases the value of the compressive drilling cement

structure. However, the addition of fly ashcoal at a

concentration of 10%, 12.5% and 15% causes a de-

crease in the value of compressive strength, the opti-

mum compressive strength value is obtained within a

concentration of 7.5% is the concentration that pro-

duces.

The improvement in the value of compressive

strength in coal fly ash is caused by fly ash being

one of the pozzolanic ingredients (ASTM, 2001). Ac-

cording to Salain (Salain, 2015) with the presence of

pozzolanic properties on fly ash containing reactive

silica, it can function to reduce free lime (Ca(OH)2).

The result of this reaction results in a bond of cal-

cium silica hydrate (C – S – H) which is the nature

of cement. With composition C – S – H the right

strength of cement will increase (Safitri and Djumari,

2010). While the decrease in the value of compressive

strength ash coal in concentrations above 10% is due

to imperfect pozzolanic reactions. This is because the

higher the concentration of coal fly ash, the less the

amount of cement, so the amount of tricalcium sil-

icate (C3S) and dicalcium silicate (C2S) which is a

compound that is responsible for the strength of ce-

ment decreases and the bonding power does not run

perfectly (Munir, 2008). According to Safitri & Dju-

mari (Safitri and Djumari, 2010). The addition of a

lot of coal fly ash will cause many silica elements that

cannot react with calcium. So the bond C – S – H

imperfect results in a low grade of cement strength.

3.2 Shear Bond Strength

Shear Bond Strength testing was done on the base ce-

ment and cement added with the concentration of fly

ash coal consisting of the addition of fly ash coal as

much as 2.5%, 5%, 7.5%, 10%, 12.5% and 15% bwoc

and the results can be seen in table 4 and figure 2 be-

low:

Table 4: Results Calculation of shear bond strength of Basic

Cement plus coal Fly Ash

Cement Suspension

Composition

Value SBS (psi)

Cement (C) 92.58

C + 2.5 Coal fly ash 98.20

C + 5 Coal fly ash 112.42

C + 7.5 Coal fly ash 138.48

C + 10 Coal fly ash 133.95

C + 12.5 Coal fly ash 120.09

C + 15 Coal fly ash 94.18

In figure 2 shows that the addition of coal fly ash

also affects the value of the drilling cement shear

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

116

Figure 2: Value of Shear Bond Strength.

bond structure. As the compressive stress test results,

the results of the BPD shear test test also show the

same results where the addition of coal fly ash at a

concentration of 2.5%, 5%, and 7.5% increases the

drilling cement shear bond value while increasing the

concentration of coal fly ash with a concentration of

10%, 12.5% and 15% cause a decrease in the value of

drilling cement shear bond structure. Therefore, it can

be concluded that the 7.5% of coal fly ash concentra-

tion can produce the optimum shear bond value.

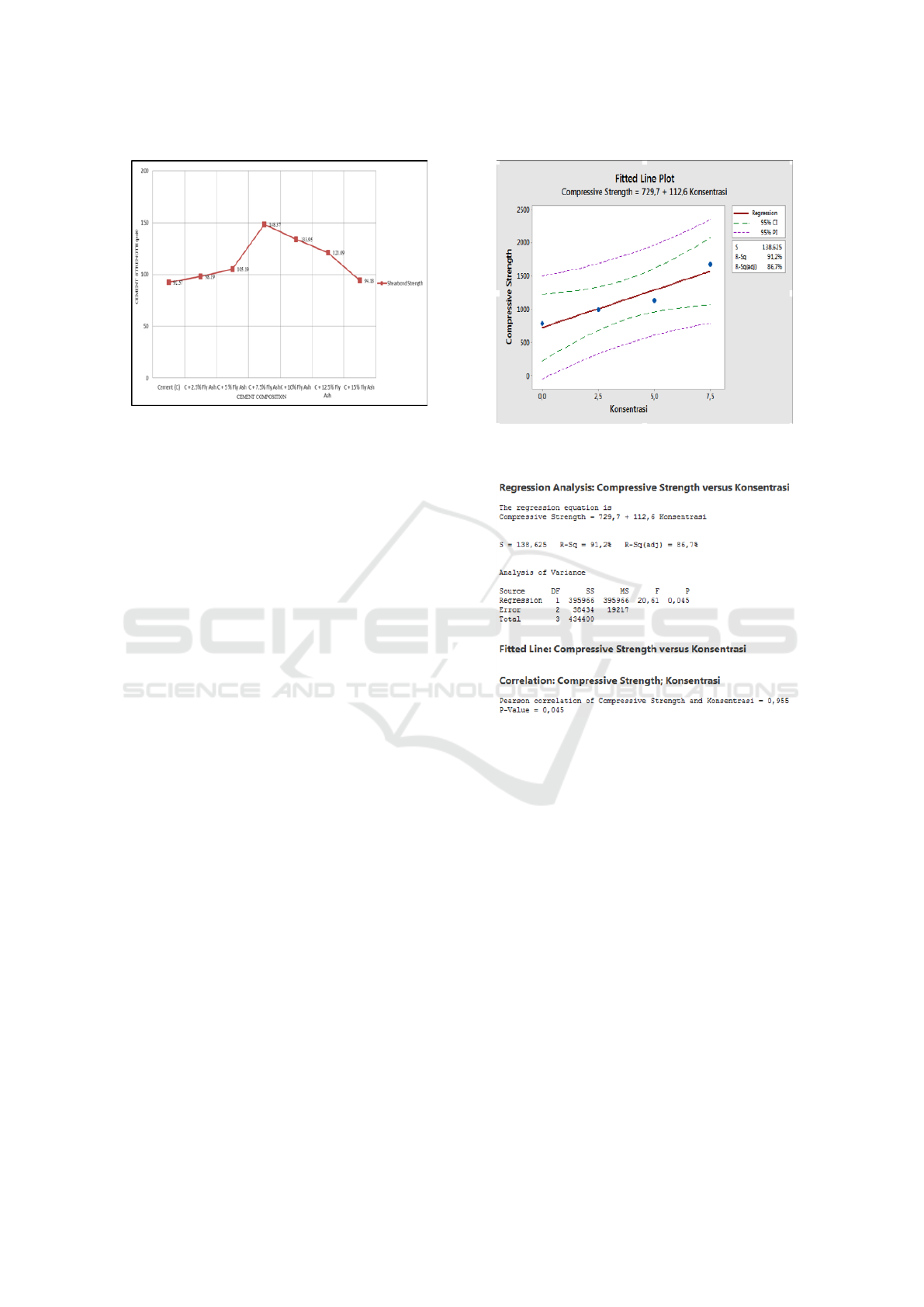

3.3 Regression Analysis and

Correlation between Test

Parameters against Concentration

3.3.1 Compressive Strength against

Concentration 0-7.5% of Coal Fly Ash

The concentrations used in this study were 0, 2.5%,

5%, 7.5%, 10%, 12.5% and 15% coal fly ash. From

the concentration testing, regression testing and cor-

relation to the results of compressive strength were

carried out. The following are the results of regres-

sion analysis and correlation on 0- 7.5% of coal fly

ash concentrations against compressive strength.

Judging from the software output above in the

analysis of variance, the p-value is 0.045, which

means that it is smaller than the value of the signifi-

cant criteria used by the evidence level of 95% so that

the α value is 5% or 0.05. In the probability value ap-

proach (p-value) if the value of probability (p-value)

is smaller or equal to the level of significance (α) then

the zero hypothesis is accepted. But if the probability

value is greater than the significance level, the zero

hypothesis is rejected (Gio et al., 2016). Value of p-

value is 0.045 which means smaller than the signifi-

Figure 3: Fitted Line Plot Versus Compressive Strength

Concentration.

Figure 4: Regression Analysis compressive strength versus

concentration.

cance value (α) which means that the linear regression

model meets the linearity criteria.

Value of R-sq (adj) obtained is 86.7% which

means that the compressive strength variable can be

explained by 86.7% by the concentration variable.

The remaining 14.3% is explained by other variables

other than concentration. The equation obtained is

compressive strength = 729.7 + 112.6 concentration

means that an increase of 1 concentration has a posi-

tive effect on compressive strength of 112.6.

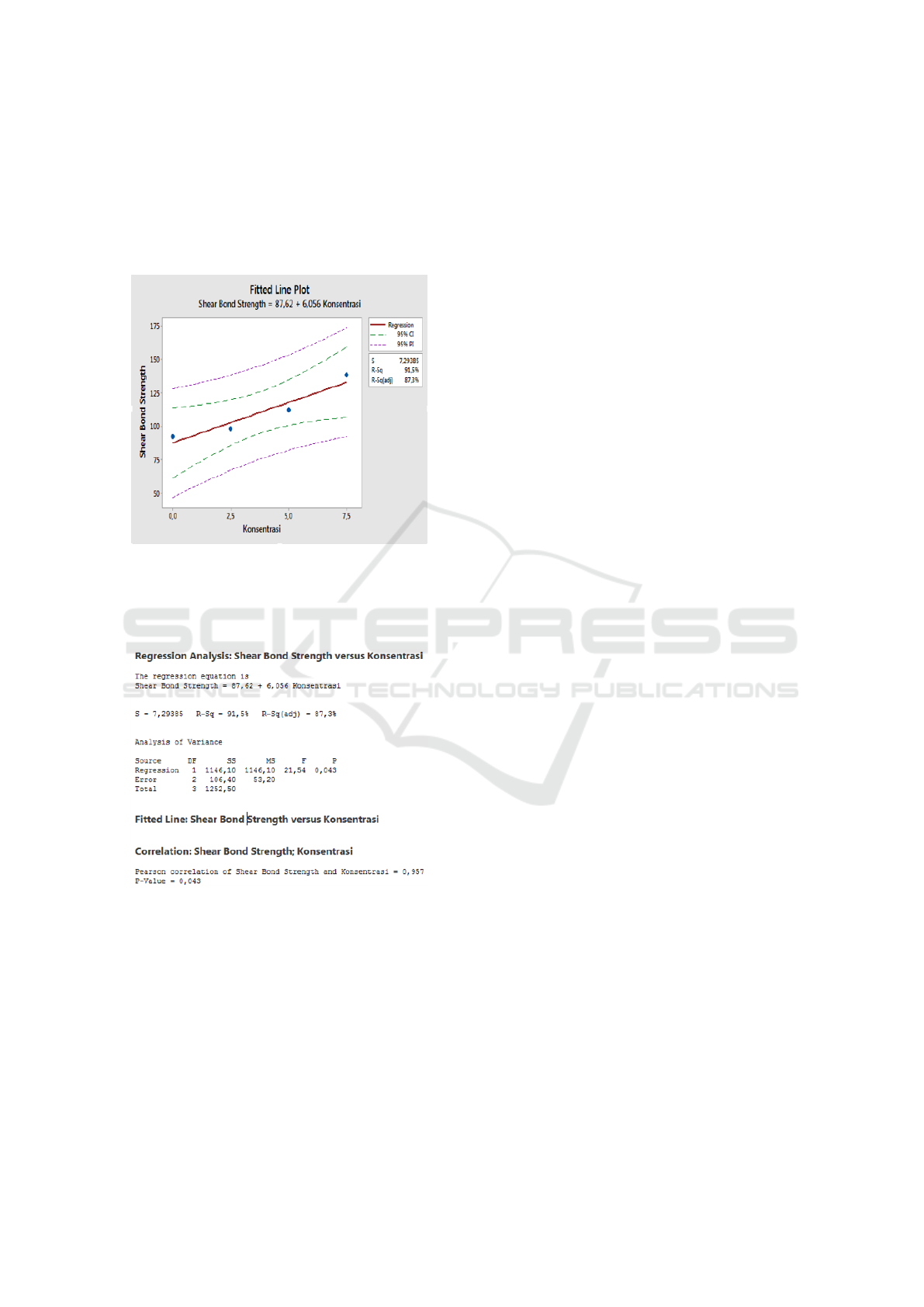

3.3.2 Shear Bond Strength against

Concentrations of 0- 7.5% Coal Fly Ash

The following are the results of regression analysis

and correlation on concentrations of 0-7.5% coal fly

ash against shear bond strength. Judging from the

software output above in the analysis of variance, a

significance value or p is obtained which is equal to

The Impact of Additively Coal Fly Ash toward Compressive Strength and Shear Bond Strength in Drilling Cement G Class

117

0.043, which means that it is smaller than the signifi-

cant criterion value, which is used a confidence level

of 95% or 0.05. This means that the value of the P-

value smaller than 0.05 indicates that the linear re-

gression model meets the linearity criteria.

Figure 5: Regression Analysis Shear Bond strength versus

concentration.

Figure 6: Regression Analysis Shear bond strength versus

concentration.

Then get the value of R-sq (adj) 87.3%, which

means that the variable shear bond strength can be ex-

plained by 87.3% by the concentration variable. The

remaining 13.7% is explained by other variables other

than concentration. The equation obtained was shear

bond strength = 87.62 + 6.056 concentration, mean-

ing that the increase in 1 concentration gave a positive

effect on the shear bond strength which was equal to

6.056.

4 CONCLUSIONS

Addition of coal fly ash has an effect on the value of

compressive strength and shear bond drilling cement

structure. Based on the results of the research the

value of optimum compressive strength was obtained

at a variation of 7.5% concentration of 1680.39 Psi.

The optimum shear bond strength value was also ob-

tained at a variation of 7.5% concentration of 138.48

Psi. From the results of laboratory tests using Minitab

software for concentrations of 0-7.5% coal fly ash

the compressive strength equation = 729.7 + 112.6

concentrations was obtained, the correlation value of

0.995, P-value 0.045. The value of the linear regres-

sion results for shear bond strength with a concen-

tration of 0-7.5% found that the shear bond strength

equation = 87.62 + 6.056 concentrations, the correla-

tion value of 0.957, P-value 0.043.

ACKNOWLEDGEMENTS

Thank you to the Petroleum Engineering Study Pro-

gram drilling laboratory, Faculty of Engineering, the

Islamic University of Riau which has provided time

and opportunity to conduct research.

REFERENCES

ASTM, C. (2001). 618 (2001). Standard specification for

coal fly ash and raw or calcined natural pozzolan for

use as a mineral admixture in concrete. Annual Book

of ASTM Standards, 4:310–313.

Dembovska, L., Bajare, D., Pundiene, I., and Vitola, L.

(2017). Effect of pozzolanic additives on the strength

development of high performance concrete. Procedia

Engineering, 172:202–210.

Ervianto, M., Saleh, F., and Prayuda, H. (2016). Kuat tekan

beton mutu tinggi menggunakan bahan tambah abut

terbang (fly ash) dan zat adiktif (bestmittel). Sinergi:

Jurnal Teknik Mercu Buana, 20(3):199–206.

Finahari, I. N., Salimy, D. H., and Susiati, H. (2007). Gas

c02 dan polutan radioaktif dari pltu batubara. Jurnal

Pengembangan Energi Nuklir, 9(1).

Gio, P. U. et al. (2016). Belajar olah data dengan spss,

minitab, r, microsoft excel, eviews, lisrel, amos, dan

smartpls.

Haryanti, N. H. (2014). Uji abu terbang pltu asam asam

sebagai bahan pembuatan bata ringan. Jurnal Fisika

FLUX, 11:127–137.

Munir, M. (2008). Pemanfaatan abu batubara (fly ash)

untuk hollow block yang bermutu dan aman bagi

lingkungan. PhD thesis, program Pascasarjana Uni-

versitas Diponegoro.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

118

Prasetyo, A. M. A. and Lisantono, A. (2017). Compressive

and shear bond strength of oil well cement with cal-

cium carbonate and silica fume. Jurnal Teknik Sipil,

13(4):255–259.

Roskos, C., Cross, D., Berry, M., and Stephens, J. (2011).

Identification and verification of self–cementing fly

ash binders for ‘green’concrete. In proceedings of the

2011 world of coal ash (WOCA) conference—May 9–

12, 2011 in Denver CO, USA.

Safitri, E. and Djumari, D. (2010). Kajian teknis dan

ekonomis pemanfaatan limbah batu bara (fly ash) pada

produksi paving block. Media Teknik Sipil, 9(1):36–

39.

Salain, I. m. A. K. (2015). Perekat Berupa Campuran Se-

men Portland Tipe I. Prosiding Seminar Nasional

Teknik Sipil 1 (SeNaTS 1), 1(April):113–118.

Samura, L. et al. (2018). Pengujian compressive strength

dan thickening time pada semen pemboran kelas g

dengan penambahan additif retader. Petro, 6(2):49–

54.

Suarnita, I. W. (2011). Kuat tekan beton dengan aditif fly

ash ex. pltu mpanau tavaeli. SMARTek, 9(1).

Suwandi and Suyartono (2001). Hidup dengan batubara

(dari kebijakan hingga pemanfaatan).

Theodorus, A., Sugeng, B., Suratman, I., and Hermawan,

R. (2008). Kajian efektifitas semen dan fly ash dalam

campuran soil cement memakai tanah lempung dan

pasir pulau timor. Journal of Civil Engineering,

15(2):69–84.

The Impact of Additively Coal Fly Ash toward Compressive Strength and Shear Bond Strength in Drilling Cement G Class

119