Construction Design and Performance of Dry Leaf Shredder with

Vertical Rotation for Compost Fertilizer

Syawaldi

Department of Mechanical Engineering, Universitas Islam Riau, Pekanbaru, Indonesia

Keywords:

Machine, Leaf , Crusher, disposal

Abstract:

One of the large private universities (PTS) in Riau Province is known as Universitas Islam Riau (UIR). UIR

is a large university and has extensive land infrastructure that is planted with a variety of green plants such

as trees and flowers. These trees have encountered many problems, namely producing leaf litter and causing

problems. Lots of leaf litter is collected and disposed of at the final disposal site. Some can be processed

into compost manually and some are burned. In the composting process, the processing time is too long, so it

is necessary to design a construction machine for crushing dry leaves. This machine consists of an inlet and

outlet, a tube made of drums, a five-level shredder and with an electric motor. From the results of the design of

the construction size length 60 cm width 60 cm and height 100 cm made of angle iron L profile size 40 x 40 x

4 cm with a power of

1

2

HP and 1400 rpm motor drive rotation. From the results of engine performance tests,

the production capacity of 40 kg/hr in the form of final process chips size of 5-10 mm and 92% efficiency.

From the results of this machine design can accelerate the process of making compost and can be used by

students in developing the entrepreneurship unit of the Faculty of Engineering students.

1 INTRODUCTION

One of the private Universitas Islam Riau (UIR). UIR

is the oldest university in Riau Province. In addition,

the university has large land and green land. So that

many found in the rubbish foliage. This garbage is a

problem that is collected every day by campus clean-

liness. This the garbage is disposed of at the final

disposal site. Some can be processed into fertilizer

manually and some are burned. So the waste has not

been used much for the more efficient once such as

compost.

The use of waste from leaves can be used as com-

post, known as leaf compost. This can be a good and

creative solution so that the campus becomes clean,

it also empowers the community and students to be-

come Student Entrepreneurship Enterprises. (Setyan-

ingsih et al., 2017).

As for organic waste such as fallen leaves, waste

from agricultural residues, garbage from kitchen veg-

etables, and other types of organic waste. Can be pro-

cessed by the community itself into compost, which

will certainly provide more benefits to the commu-

nity and students (Nasution et al., 2013; Yamin et al.,

2008). One of the processing must use technology

to speed up work. This technology has also been and

many are made in the form of chopped /flake. Besides

technology also helps the composting process (Hande

& Deshpande, 2014; Kumar & Kumar, 2015).

In managing traditionally destroying leaves and

organic waste by the community, there are those who

do it by manually storing up the tones. Traditional

management requires large labor and long time. The

design of a leaf chopper in increasing the business of

making compost. The special garbage shredder for

the leaves has not been sold in the market. Existing

machines are made in multi-use so that the price of

the machine is quite expensive. In addition, the re-

search into the manufacture of dry leaf shredder has

been carefully studied by several researchers (Hande

et al., 2015). In addition, research on the manufacture

of dry leaf shredder has been studied thoroughly by

several researchers (Nithyananth et al., 2014).

The purpose of this study is to design a shredder

to form flakes / fine grains to facilitate and speed up

the process of making compost. Besides that, from

the design results in the form of leaf crusher in or-

der to build a compost processing center in the En-

trepreneurship Unit of the Faculty of Engineering,

Universitas Islam Riau.

Syawaldi, .

Construction Design and Performance of Dry Leaf Shredder with Vertical Rotation for Compost Fertilizer.

DOI: 10.5220/0009129601090113

In Proceedings of the Second International Conference on Science, Engineering and Technology (ICoSET 2019), pages 109-113

ISBN: 978-989-758-463-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

109

2 LITERATURE REVIEW

Garbage from the campus field or yard is generally

rubbish from leaves (organic waste). Where waste is

managed properly will get high benefits. Waste from

leaves is very good to be used as compost fertilizer.

Compost will be able to fertilize the agricultural area

in the form of land acquisition (Budihardjo, 2006;

Sulistyorini, 2005).

The leave are of the leaves are burned by the com-

munity, which also causes air pollution. The man-

agement of these leaves if done properly through an

appropriate process will have a positive impact in the

form of compost (Nasution et al., 2013; Setyaningsih

et al., 2017). The management process is by con-

structing a technology to destroy leaves. The results

of the work process of the machine depends on the

results of the design (Nwakaire et al., 2011). Much

research has been done on the design and construc-

tion of machinery related to demolition (Hassan et al.,

2009). In the process of crushing the engine compo-

nents are needed to produce power.(Nwakaire et al.,

2011). Power can be determined by the following

equation:

Power,P = work done/second

= work done/time

= (Force x distance)/time

= Force x velocity

P = F.V (1)

Where, P = Power (Nms

−1

), F = Force of crushing

(N), and Velocity is , V = r.ω (m/s).

Force required to thresh the leaf is given by

F = m.ω2.r (2)

Where F is the force needed to chop leaves in con-

tainers, m is the mass of the chopper, ω the angular

velocity on the shaft with equation 2.π. N / 60, where

n is the round per minute. Power on the shaft can be

F.ω.r. For the motor drive, the electric motor is de-

termined based on the power contained in the shaft.

(Suga et al., 2004). The relation of the pulley to the

one driven through the driving force is:

N

1

D

1

= N

2

D

2

(3)

Where N

1

is the driving speed, the driven N

2

speed, D

1

the drive pulley diameter and D

2

are the

driven pulley diameters. The mass weight (m) of pul-

leys in the shaft can be determined,

m = ρv (4)

where ρ pulle density and v are pulley volume.

Pulley weight,

W p = ρ × (π.d

2

/4) × l

p

(5)

Where d is the pulley diameter and lp pulley length.

If the pull on the pull side and the slack side of the

pulley are F

1

and F

2

respectively, then the magnitude

of the tensile is effective (F

e

),

F

e

= F

1

− F

2

(6)

T

s

p (torque on the shaft) is:

T

sp

= F × r (7)

where F force works counting leaves, this is the

same as torque (T

s

) in the system.

T

s

= F × r (8)

Where T

m

(motor torque) = F × r

where

T

s

= T

m

(9)

Power required,

P

m

= ω.T

m

(10)

Tensile is effective F

e

is

F

e

= P

m

/(ω.r) (11)

MT (torque moment) = (F

1

− F

2

) r

1

. The power

transferred to the belt is:

P = (F

1

− F

2

).V (12)

Where, V (Velocity)

V = (π.D.n)/60 (13)

Also

F

1

/F

2

= exp(µ θ) (14)

Where θ the contact angle of the belt on the driv-

ing pulley groove, and µ is the real friction coefficient

between the belt and pulley, the dry surface µ = 0.3.

The magnitude of the contact angle on the drive belt

is ;

θ = 180 − (57(D

1

− D

2

)/C) (15)

Determining the pulley length is as follows,

L = 2C + π/2(D + d) + 1/4C(D − d)

2

(16)

The minimum diameter of the shaft can be deter-

mined:

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

110

d

3

= [(5,1/τ

a

)K

t

C

b

T ]

1/3

(17)

Where d is the shaft diameter, K

t

collision correc-

tion factor (1.0) if the load is applied subtly (1.0-1.5)

if there are a few surprises and collisions and (1.5-3.0)

if the load is subjected to a shock or a large collision.

If indeed it is expected that usage will occur with a

flexible load, it can be considered the use of the C

b

factor (1.2-2.3). For general use on a shaft with a

strength marked with a permit voltage τa are:

τ

a

(kg/mm

2

) = σB/(S f

1

xS f

2

) (18)

Where :

S f

1

(6,0)

S f

2

(1,3-3,0)

is safety factor.

The leaf chopping machine is tested to determine

the effectiveness of the equipment performance in its

use with respect to engine performance. One of the

performance carried out is the production ability of

Q

T

= W

T

/t

T

, where W

T

is the weight of the process

and t

T

is the process work time in units (kg/hr)

3 MATERIALS AND METHODS

3.1 Design Considerations

The method used in the construction design consists

of:

• Field survey

• Coordination with related institutions and the

cleanliness of the field at Riau Islamic University.

• Coordination with student entrepreneurship units.

3.2 Calculating Design

The spin speed of the dry leaf chopper knife is 1866

revolution per minute (rpm), with a counter force of

13.05 Newton is blades, angular velocity (ω) 195.3

radians per second.

3.3 Description of Machine Parts

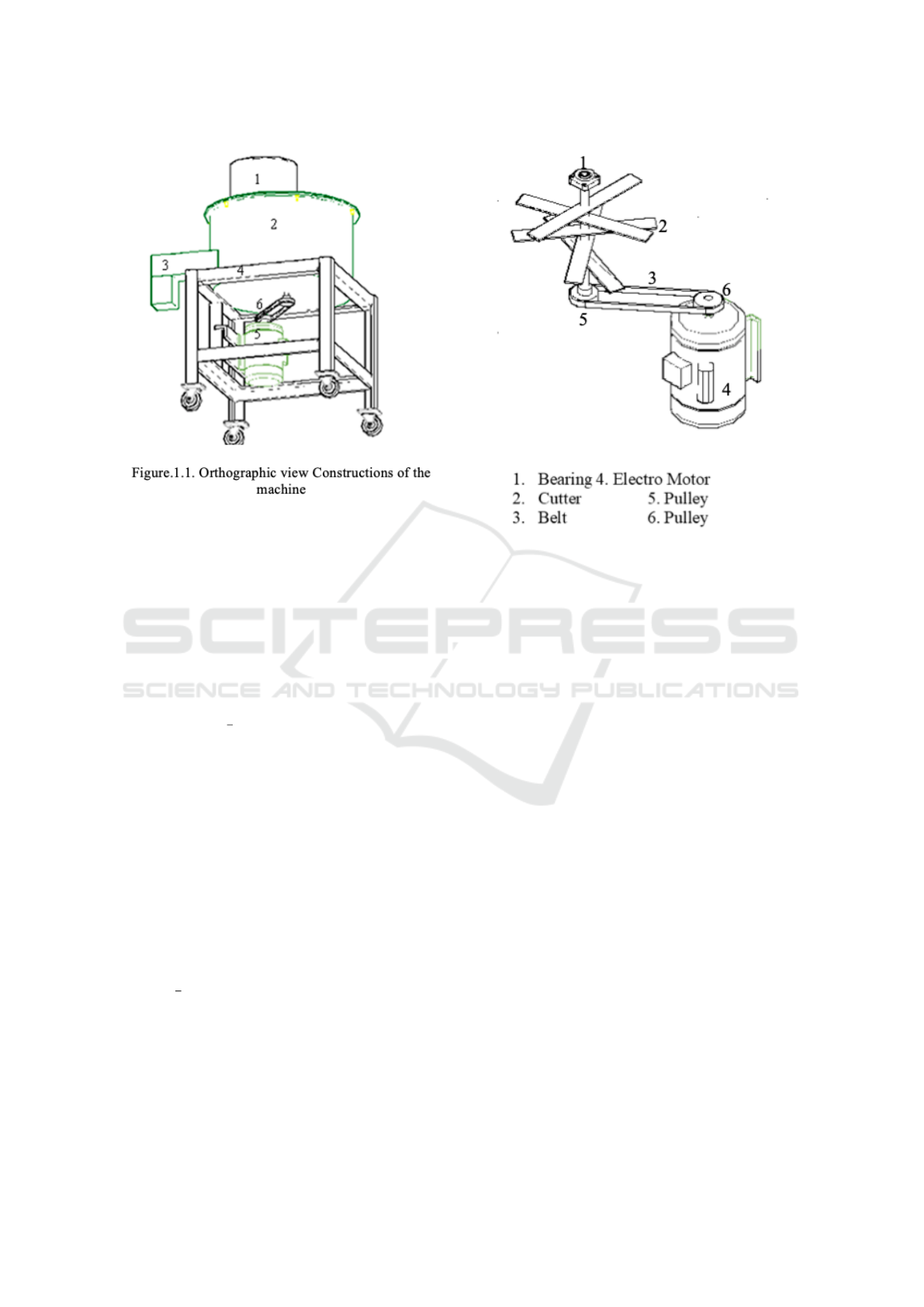

In the figure 1.1. explained that some machine and

construction parts of the design.

• The Main Frame

The main frame work functions as a buffer for

components or machine elements that work. This

counter frame is made of structural steel with a

size (60 mm x 60 mm x 100 mm) and a right an-

gle iron profile (40 mm x 40 mm x 4 mm).

• The Hopper

The hopper function is where the channel en-

ters the leaves into the drum for the destruc-

tion/enumeration process. Where this carriage has

a diameter of 27.5 mm and a height of 25 mm

which is made of carbon steel while being shaped

sheet plate with a thickness of 2 mm. The position

of the design hopper is placed at the top of the tub.

• The Screen

The Screen located inside serves to filter or sep-

arate granules and debris from the results of enu-

meration by the chopper knife. The results will

come out through the outlet in fine grains and with

a size of 5-10 mm.

• The Outlet

The outlet is designed as a place to exit the results

of the leaves counting. Where the design is made

of steel plate sheets with a size of 2mm thick.

• Shaft Design

Shaft is a very important element in machine

movement in moving power and rotation. Usually

on installed shafts such as gears, pulleys, sprocket

and other engine elements. The shaft is made

from ST 37 Steel with a length of 65 cm and a

diameter of 19 mm and is mounted on the middle

side of a leaf chopping tool using a bearing. The

bottom and middle end of the bearing is attached

and the upper end of the blade is attached on po-

sition vertical.

• The Cutter

The knife is a machine element for chopping

leaves. The design of this knife is used as many

as 5 (five) levels (as shown in figure 2). The blade

material is made of steel plate from the spring of

the vehicle. This knife is connected by welding

and in the middle is given a hole to insert the shaft

and locked.

• The Pulley

– Drive Pulley, The drive pulley is enabled to

continue the 1400 rotation per minute and the

power of the

1

2

HP Electric motor drive. Where

is the size of the pulley diameter of the 75 mm

drive made of aluminum.

– Movable pulleys, The driven pulley is used to

rotate the shaft to chop leaves of leaves. In the

pulley there is a rotation of 1400 rpm to 1866

rpm with a diameter of 100 mm and made of

aluminum.

– The Bearings Bearings are the main parts of the

engine component. It functions as a rotating

and stationary shaft position. From the results

Construction Design and Performance of Dry Leaf Shredder with Vertical Rotation for Compost Fertilizer

111

Figure 1: Orthographic view Constructions of the machine

of the design the bearing has a hole diameter of

19 mm. Where these bearings are mounted on

the bottom of the engine shells.

– The Prime Mover The starting drive functions

to divide the power and rotation to the shaft,

which is moved through the pulley. The power

and rotation of the machine are used to cut leaf

leaves to produce products in the form of fine

grains and flakes. The drive used is an Electric

motor with

1

2

hp and 1400 rpm.

– The Transmission System The transmission

system on the leaf counter machine consists

of an Electric motor as a driver, drive pulleys,

driven pulleys, v-belts and shafts. The aim is

to regulate the distribution of power and rota-

tion needed in the process of counting leaves.

Transmission system as shown in Figure 1.2.

4 DESIGN CALCULATION AND

RESULTS

Machines designed using drives are electric mo-

tors with

1

2

HP power and 1400 rpm rotation. Where

the rotation is changed from 1400 rpm to 1866 rev-

olution per minute. The average rotational speed of

the engine shaft is 1866 rpm, then the results of other

engine components with a shaft size of 19 mm, shaft

mass and blade is 2.5 kg, with a length of 65 cm, on

the shaft there are 5 level crushing blades with size

with crushing force 24,5 N.

Figure 2: Orthographic view Constructions of the machine

5 PERFORMANCE TEST

Based on the results of testing the design of dried fo-

liage leaf chopper, the production capacity of 40 kg

/ day with flake-shaped size of 5 to 10 mm and effi-

ciency of 92% is obtained. In addition there is also

vibration in the construction due to the absence of a

balance of force between the contraction and the ro-

tating force on the shaft. In addition, the results of the

enumeration work process production capacity is still

low. Based on the results of testing the design of a

dry leaf chopper machine using 5 levels/10 knives, a

production capacity of 40 kg/hr in the form of flakes

measuring 5 to 10 mm and 92% efficiency. This is

compared to a machine that is almost similar to us-

ing a chopper as many as 40 knives (Akbar, 2015).

Besides that, the corn thresher can efficient of 79.3%

(Chuan-udom et al., 2013).

6 CONCLUSION

From the results above, the design of the dried foliage

leaf enumeration machine has been successfully made

and tested as the central need of the Student Business

Unit at the Universitas Islam Riau and the commu-

nity of making compost fertilizer. Where this ma-

chine is easy to use and carry because it has wheels.

In addition, usage can be arranged for approximately

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

112

8 hours/day. Electricity saving is only 350 watts.

REFERENCES

Akbar, K. (2015). Rancang Bangun Mesin Pencacah Sam-

pah Organik (PROSES PEMBUATAN). PhD thesis,

Politeknik Negeri Sriwijaya.

Budihardjo, M. A. (2006). Studi potensi pengomposan

sampah kota sebagai salah satu alternatif pengelolaan

sampah di tpa dengan mengunakan aktivator em4 (ef-

fective microorganism). Jurnal Presipitasi, 1(1), 25–

30.

Chuan-udom, S. et al. (2013). Operating factors of

thai threshers affecting corn shelling losses. Songk-

lanakarin Journal of Science and Technology, 35(1),

63–67.

Hande, A. S. & Deshpande, A. (2014). Methodology for

design & fabrication of portable organic waste chop-

ping machine to obtain compost-a review. Interna-

tional Journal for Innovative Research in Science &

Technology, 1(7), 1–4.

Hande, A. S., Padole, V., Hande, A. S., & Padole, V. (2015).

Design & fabrication of portable organic waste chop-

ping machine to obtain compost. International Jour-

nal, 2, 1–8.

Hassan, A. B., Abolarin, M. S., Olugboji, O. A., Ugwuoke,

I. C., et al. (2009). The design and construction of

maize threshing machine. Au JT, 12(3), 199–206.

Kumar, I. S. & Kumar, H. (2015). Design and development

of agricultural waste shredder machine. International

Journal of Innovative Science, Engineering & Tech-

nology, 2(10), 164–172.

Nasution, F. J., Mawarni, L., & Meiriani, M. (2013). Ap-

likasi pupuk organik padat dan cair dari kulit pisang

kepok untuk pertumbuhan dan produksi sawi (brassica

juncea l.). AGROEKOTEKNOLOGI, 2(3).

Nithyananth, S., Samuel, L., Mathew, N., & Suraj, S.

(2014). Design of waste shredder machine. Interna-

tional Journal of Engineering Research and Applica-

tions, 4, 487–491.

Nwakaire, J., Ugwuishiwu, B., & Ohagwu, C. (2011).

Design, construction, and performance analysis of a

maize thresher for rural dweller. Nigerian Journal of

Technology, 30(2), 49–54.

Setyaningsih, E., Astuti, D. S., & Astuti, R. (2017). Kom-

pos daun solusi kreatif pengendali limbah. Bioeksper-

imen: Jurnal Penelitian Biologi, 3(2), 45–51.

Suga, K.-S., Perencanaan, D., & Mesin, P. E. (2004). Pt

pradnyaparamita.

Sulistyorini, L. (2005). Pengelolaan sampah dengan cara

menjadikannya kompos. Jurnal Kesehatan Lingkun-

gan, 2(1).

Yamin, M., Satyadarma, D., & Naipospos, P. (2008). Peran-

cangan mesin pencacah sampah type crusher. In Pro-

ceeding, Seminar Ilmiah Nasional Komputer dan Sis-

tem Intelijen (KOMMIT 2008): Gunadarma Univer-

sity.

Construction Design and Performance of Dry Leaf Shredder with Vertical Rotation for Compost Fertilizer

113