A Simulation Study of Downhole Water Sink Guidelines Plot Application

using Real Field Data

Praditya Nugraha

Universitas Papua, Sorong, West Papua

Keywords:

Downhole Water Sink, Simulation Study, Guidelines Plot, Water Coning.

Abstract:

One solution for water coning problem is Downhole Water Sink (DWS) system. A dual completion system

is used to produce the oil perforated zone and the water separated zone separately. Pressure drawdown in the

water zone is used to oppose pressure drawdown in the oil zone so the water-oil contact is remained stable

and prevents the water coning. A DWS guideline plot proposed by Marhaendrajana and Alliyah is used as a

basis in application of DWS by using real field data. This research aimed to apply the DWS guideline plot

to get the benefit of DWS which is controlling the water coning problem. A geological reservoir model has

been upscaled and history-matched into a representative dynamic reservoir model used in this study. The

simulation is conducted by applying 5 scenarios in DWS application considering the number of active wells

and the variation of flow rate in this reservoir. DWS guideline plot and its application using real field data gave

good results in increasing oil recovery with some concern related with the amount of water produced in water

perforated zone. The best scenario which is using DWS in high and medium rate wells group gave 16.24%

recovery factor.

1 INTRODUCTION

Water almost always co-exist with our desired fluids

in a reservoir, therefore, it is expected to produce

a certain amount of water during production. The

amount of water produced is usually referred to as

the water cut. The highwater cut will lower the oil

production rate and increase the water treatment cost.

This problem arises in a water drive reservoir and

water injection in waterflooding operations. Water

which has higher mobility than oil tends to bypass the

oil flow and cause water coning. A lot of research

has been conducted on studying critical production

rates and water breakthrough time to control water

coning (Chaperon et al., 1986; Abass et al., 1988;

Høyland et al., 1989). On the other hand, economical

production rates also need to be considered when

production rates are limited. Downhole water sink

(DWS) was introduced for controlling water coning

without limiting the oil production rate below its

critical rate (Wojtanowicz et al., 1991).

This paper presents a simulation study of DWS

guideline application using real field data. The basic

concept of DWS and its guideline will be covered

briefly. Then, the field data and some assumptions

used are presented before the result is summarized.

2 DOWNHOLE WATER SINK

TECHNOLOGY

One technology to overcome water coning problem

is Downhole Water Sink technology (DWS). DWS

is a dual completion application technology where

the oil zone and water zone are produced separately.

This concept was proposed by Wojnatowicz in

1991 (Wojtanowicz et al., 1991) and then called

as Downhole Water Sink for the first time in

1997 (Shirman and Wojtanowicz, 1997). An equal

pressure drawdown is created in water perforated

zone to prevent water coning and to create a stable

oil-water contact, so oil can be produced from

the top perforation while water is produced from

the bottom completion. Astutik (2006) has listed

several studies that showed the DWS application

successfully worked to preventwater coning and

increase oil production without water breakthrough.

Those studies included numerical studies and field

application. However, most of those studies were

focused on comparing DWS with conventional

completion technique.

Marhaendrajana and Alliyah proposed a guideline

for DWS design (Marhaendrajana, Sukarno, and

Alliyah, 2008) which incorporates parameter

Nugraha, P.

A Simulation Study of Downhole Water Sink Guidelines Plot Application using Real Field Data.

DOI: 10.5220/0009065500310034

In Proceedings of the Second International Conference on Science, Engineering and Technology (ICoSET 2019), pages 31-34

ISBN: 978-989-758-463-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

31

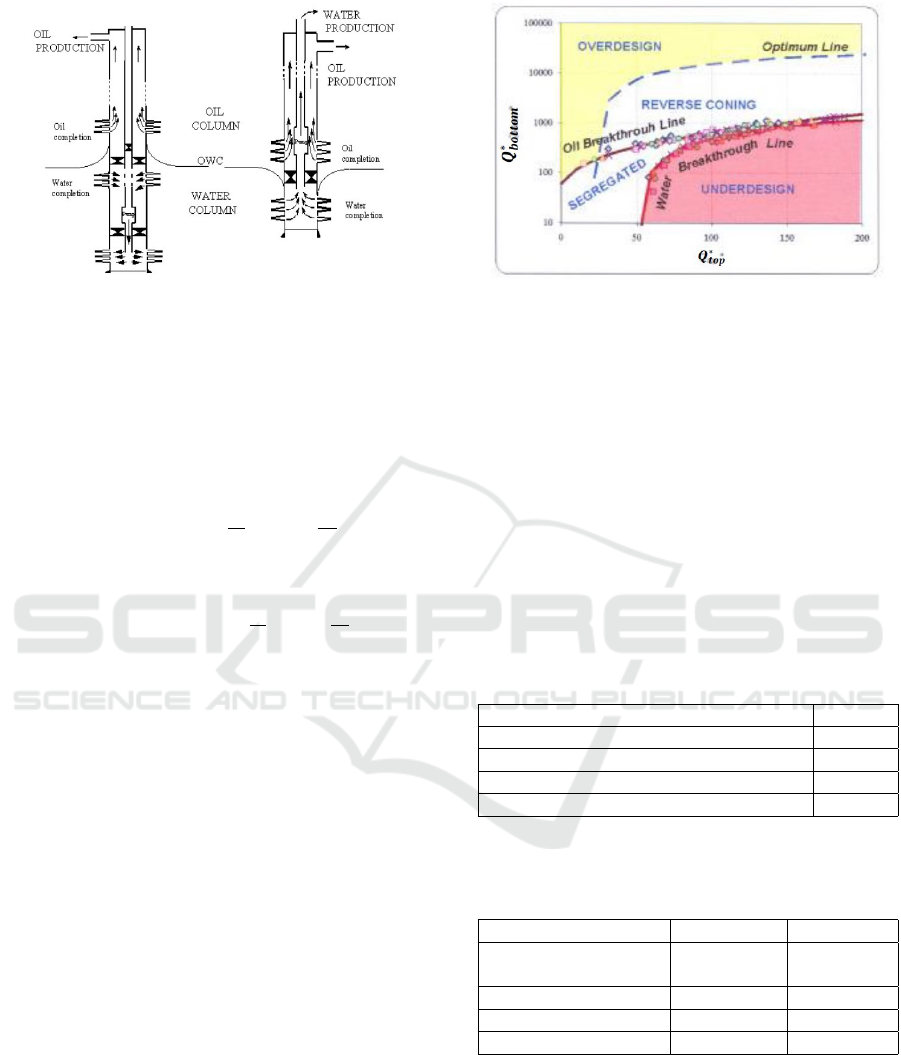

Figure 1: Schematic of Downhole water sink (taken from

(Wojtanowicz, 2006)). A. DWS water drainage-injection.

B. DWS water drainage-production.

affecting water coning such as permeability

anisotrophy (k

v

/k

h

)and perforation interval (h

p

/h

o

).

Where Qtop* and Qbottom* are respectively :

Q

∗

top

= Q

top

+

10

α1

k

v

k

h

α2

h

p

h

o

α3

(1)

Q

∗

bottom

= Q

bottom

+

10

β1

k

v

k

h

β2

h

p

h

o

β3

(2)

Where : α1=2.401433, α2=0.518346, α3=1.283428;

and β1=3.227316, β2=0.842945, β3=1.567493.

The preferable condition is where instead of water

coning, the oil coning happened or called as reverse

coning. The segregated and reverse coning phase

in the DWS guideline plot become the guideline to

determine the production rate in the oil zone (Qtop)

and the water zone (Qbottom).

3 SIMULATION AND FIELD

DATA

The simulation and field data used are from a

Jurassic reservoir in China (Huawei et al., 2013).

A reservoir dynamic model has been upscaled from

geological model and well history-matched with its

production history data. The model was built using

PETREL and run using ECLIPSE. Production history

data showed that water production rose rapidly and

become a major problem. This reservoir has 4 major

layers (Y71, Y81, Y82, and Y91) with an average

permeability of 100 mD and average porosity 14.5%.

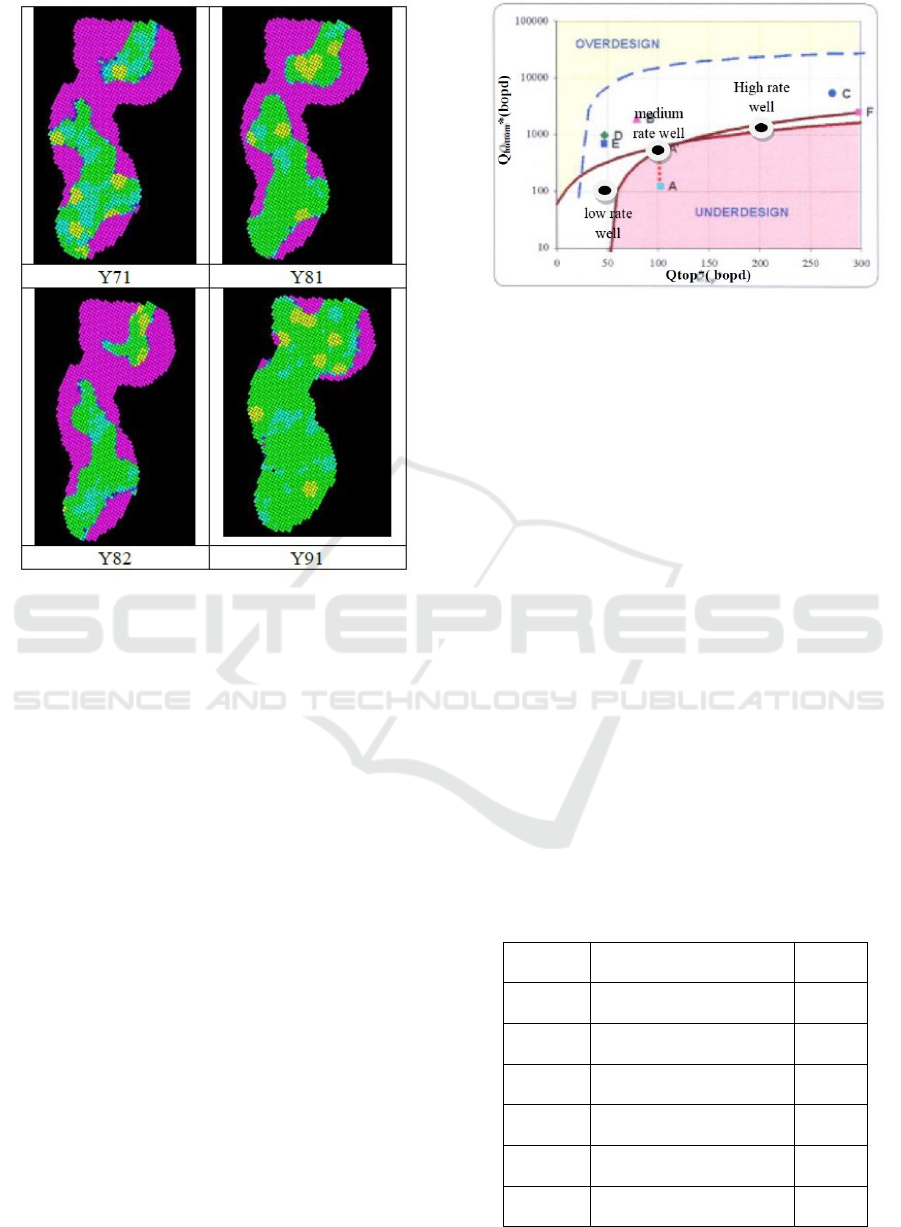

Figure 2: DWS Guideline Plot (taken from

(Marhaendrajana et al., 2008).

Table 1 and Table 2 summarized the reservoir and

oil properties.

In this reservoir there are 81 vertical wells and 1

horizontal well. At the end of history matching 12

wells are converted to be water injector wells. 15

years of production years is used as the basis for the

development strategy.

The oil recovery factor at the end of history

matching is 7.26%. From Figure 3, the remaining oil

saturation for each layer is still quite high which is 0.6

inthe green color region.

Table 1: Rock Properties (taken from Huawei et.al., 2013).

Rock Characteristics

Porosity, % 14.5

Horizontal permeability, millidarcy (mD) 100

Kv/Kh 0.1

Compressibility, 1/bar 0.00055

Table 2: Fluid Properties (taken from Huawei et.al., 2013).

Oil Water

Density, kg/m3

14.5

1000

(32.15

◦

API)

Viscosity, cp 8.88 0.5494

FVF 1.13 1.014

Compressibility, 1/bar 4.16 x 10-5

At first, it was needed to optimize the water

injection scheme to maintain reservoir pressure

above the bubble point pressure while increasing the

recovery factor (RF). The optimization resulted in

recovery factor of 14.94%. The optimized water

injection case will be used as our base case in

implementing DWS.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

32

Figure 3: Remaining oil saturation at the end of history

matching (So initial for development).

4 DWS GUIDELINE PLOT

APPLICATION

For employing DWS concept in the reservoir

simulation, a well with DWS is two wells in the same

location with different perforation intervals. One

perforation will perforate the oil zone while the other

one will perforate the water zone in the same well.

The production rate for the water zone is higher than

in the oil zone to keep a good Oil-Water Contact

(OWC) in straight line or to make the oil and water

in segregated phase.

In applying the DWS technology, the wells

are sorted into three groups. High rate wells

(production rate > 15 m

3

/day), medium rate wells

(production rate between 10-15 m

3

/day), low rate

wells (production rate < 10 m

3

/day). There are 5

cases conducted in this simulation study to evaluate

which case gives the highest recovery factor. The

operation condition for DWS (Qtop and Qbottom)

are determined by 3 chosen operation conditions for

each sorted group of different production rate (high,

medium, and low).

High – Qtop* = 200bopd, Qbottom* = 1000bopd

Medium – Qtop* = 100bopd, Qbottom* = 800bopd

Figure 4: DWS Operation condition for each group

well.(modified from Marhaendrajana, Sukarno, and

Alliyah, 2008).

Low – Qtop* = 50bopd, Qbottom* = 100bopd

For Case 1, 8 wells from high rate wells group were

using DWS with Qtop = 30 m3/day and Qbottom =

160 m3/day.

For Case 2, 5 wells from medium rate wells

group were using DWS with Qtop = 15 m3/day and

Qbottom = 80 m3/day.

For Case 3, 10 wells from low rate wells group

were using DWS with Qtop = 8 m3/day and Qbottom

= 30 m3/day.

For Case 4, DWS was implemented in high rate

wells and medium rate wells and did nothing for the

low rate wells.

For Case 5, DWS was implemented in each group

of well, high rate, medium rate and low rate.

Qtop and Qbottom used in each group wells were

calculated from the DWS guideline plot. The values

also have been converted from SIunit (International

System of unit) in reservoir data unit (China using SI

unit) into field unit in DWS guideline plot. After the

simulation, the results are presented in Table 3.

Table 3: Simulation Study Results.

Case Scenario RF

(%)

Base

case

Optimized Water

Injection

14.94

Case 1 Base case + DWS high

rate

15.37

Case 2 Base case + DWS

medium rate

15.23

Case 3 Base case + DWS low

rate

14.66

Case 4 Base case + DWS high

and medium rate

16.24

Case 5 Base case + DWS high,

medium and low rate

16.15

A Simulation Study of Downhole Water Sink Guidelines Plot Application using Real Field Data

33

From the results, case 4 gave the highest recovery

factor with only DWS application in high and medium

rate. This shows that DWS application in low

rate wells did not give significant water drainage

in reducing water coning. These results correlate

with DWS operation condition for the low group

rate which is located at segregated zone (Figure

4). Segregated inflow production can only be

achieved for a relatively low flow rate. In the field

operations, reverse coning has been used mostly

in the reversed coning mode of DWS production

(Shirman and Wojtanowicz, 1997). While on other

hand, the preferred oil coning provides additional

constrain in terms of water treatment capacity

as the more water will produce in conjunction

with higher water production rate in water zone.

DWS water drainage-injection mode can be used to

overcome this excess water problem (Figure 1A.)

The water drainage was pumped into water zone

below the water drainage perforated zone. This

approach has already been applied in real fields such

as Greater Burgan Field (Al-Fadhli et al., 2019)

and North Kuwait (Anthony and Al-Mosaileekh,

2016). But in general, the DWS guideline plot

provide a good approximate operating condition

in DWS application.In its application, the Qtop*

and Qbottom* can be optimizedfor each well with

different production rates. The grouped production

rates are used to simplify the simulation considering

the number of wells in this field. Production rate

should be a screening criterion in DWS application.

An adequate flow rate is needed to operate DWS in

reverse coning region to optimize the benefit of DWS.

5 CONCLUSIONS

From this study, we observe that DWS guideline

plot gave good approximate operation condition in

terms of production rate in oil zone (Qtop) and

water zone (Qbottom). Grouped production rate

wells can be used to simplify the implementation of

DWS application as different production rate need

different DWS operation condition. Reverse coning

region is the preferred operation condition for DWS

application. Screening of production rate is needed

to make sure DWS application in reverse coning

operation region. In DWS application,economic

evaluation is needed to make sure the incremental

oil production can cover the investment of additional

water treatment capacity as more water will be

produced. DWS water drainage-injection mode can

be used as alternative to overcome excessive water

production.

ACKNOWLEDGMENTS

This work is partially from the author’s Master

Thesis at Institut Teknologi Bandung (ITB). The

author also would like to thank Dr.AmegaYasutra

from ITB for his guidance, Prof. Ning Zhengfu

from China University of Petroleum-Beijing (CUPB)

for providingthe data used in this study andhis PhD

students in helping author understanding the data.

REFERENCES

Abass, H., Bass, D., et al. (1988). The critical production

rate in water-coning system. In Permian Basin Oil

and Gas Recovery Conference. Society of Petroleum

Engineers.

Al-Fadhli, W., Kurma, R., Kovyazin, D., and Muhammad,

Y. (2019). Modeling and simulation to produce thin

layers of remaining oil using downhole water sink

technique for improved oil recovery. a case study in

greater burgan field.

Anthony, E. and Al-Mosaileekh, S. (2016). Downhole water

sink technology improves recovery and rates from

strong water drive reservoirs in north kuwait – a pilot

case study.

Astutik, W. (2007). A study of down-hole water sink (dws)

technology - optimum dws design in vertical well

considering reservoir parameters.

Chaperon, I. et al. (1986). Theoretical study of coning

toward horizontal and vertical wells in anisotropic

formations: subcritical and critical rates. In SPE

annual technical conference and exhibition. Society

of Petroleum Engineers.

Høyland, L. A., Papatzacos, P., Skjaeveland, S. M., et al.

(1989). Critical rate for water coning: correlation

and analytical solution. SPE Reservoir engineering,

4(04):495–502.

Huawei, Z. et al. (2013). Pengyang Jurassic Oilfield :

Fine Reservoir Description Reservoir Study. Reseacrh

Report, China University of Petroleum-Beijing.

Marhaendrajana, T., Sukarno, P., Alliyah, I., Geologi,

H., Buniayu, S. B. T. K., Di Daerah, S. P.

S. K., and Cilacap, J. T. (2008). Oil production

enhancement using bottom-hole water sink: A

guideline for optimum design application. Proceeding

for Simposium Nasional & Kongres IX Ikatan Ahli

Teknik Perminyakan Indonesia (IATMI), Jakarta,

pages 15–17.

Shirman, E. and Wojtanowicz, A. (1997). Water

coning reversal using downhole water sink-theory and

experimental study.

Wojtanowicz, A., Xu, H., Bassiouni, Z., et al. (1991).

Oilwell coning control using dual completion with

tailpipe water sink. In SPE Production Operations

Symposium. Society of Petroleum Engineers.

Wojtanowicz, A. K. (2006). Down-hole water sink

technology for water coning control in wells.

Wiertnictwo, Nafta, Gaz, 23(1):575–586.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

34