Antimicrobial Properties of [2-(Acryloyloxy)Ethyl]-Trimethyl

Ammonium Chloride and Maleic Anhydride Surface

Grafted-Cotton Fibers

Hazna Sartiva

1

, Diana Adnanda Nasution

2

and Basuki Wirjosentono

2*

1

Postgraduate Chemistry Study Program, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1 Kampus USU, Medan, Indonesia

2

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Jl. Bioteknologi

No. 1, Medan 20155, Indonesia

Keywords: Cotton Cellulose, Surface Modification, Aspergillus Niger, Staphylococcus Aureus, Antimicrobial Fibres.

Abstract: Antimicrobial compound of [2-(acryloyloxy)ethyl]-trimethyl ammonium chloride (AETAC) can be bound

into polymer backbones to produce various antimicrobial polymeric materials. In this work, cotton cellulose

(CCell) fibres was modified in a laboratory scale reflux-reactor for 2 hours in toluene (TL) as solvent with

addition of maleic anhydride (MA). TL solution of antimicrobial compound of AETAC and

ammoniumpersulphate (NH

4

)

2

S

2

O

8

) as initiator was added dropwise and the reflux was further continued

for 2 hours. The reaction mixture with optimum weight ratio (CCell/MA/AETAC: 100/20/20) was then

cooled down, filtered and wash thoroughly using distilled water and dried in oven vacum to constant weight

at 80

o

C. The AETAC/MA-modified Cellulose (AETAC/MA-g-CCell) was then characterised using infrared

spectroscopy (FTIR) for chemical structure identification of the reaction products. Antimicrobial properties

of the modified cellulose was tested using: Aspergillus niger and Staphylococcus aureus. Results of FTIR

spectra of the AETAC/MA-g-CCell after exhaustive Soxhlet extraction in toluene still showed stable

absorption peak of AETAC/MA carbonyl group (>C=O) at 1736 cm

-1

and dissapearance of bond absorption

peak of acryloyl group (>C=C<) at 1470 cm

-1

. The AETAC/MA-modified cotton cellulose showed marginal

antimicrobial activity against Aspergillus niger, however the modified cellulose showed excellent

antimicrobial activity against Staphylococcus aureus.

1 INTRODUCTION

Cotton being globally distributed across Asia, North

America and Western Africa. According to data

from the International Cotton Advisory Committee

in 2015 more than 80 countries around the world

plant cotton, mostly in Asia and America. More than

half of the clothes people wear are made of cotton

fiber, because it is can used to make a soft-textile

(Yanjun, 2019).

One of the problems in the use of natural fiber-

based textile product such as cotton is the growth of

insect and microorganism, such as bateria and fungi.

Natural fiber such as cellulosic and protein-based

ones are more danger because of the chemical bonds

that may easily be broken down by microorganism.

Cotton fabrics are suitable matrices for the growth of

fungi, particularly Aspergillus niger. Some studies

have been worked by gamma irradiation for

inactivation of Aspergillus niger in aged cotton

(Donna, 2019).

Cellulose has three ractive hydroxyl group per

anhydroglucose repeating unit that form and inter-

and intramoleculer hydrogen bonds. These bonds

strongly influence chemical reactivity of cellulose

(Wasilla, 2010). Modified cotton cellulose was

studied widely as antimicrobial agent. The monomer

(3-acrylamidopropyl) trimethylammonium chloride

was used to treat a cotton fibers by grafting

copolymerization. Antimicrobial properties was run

by transferring oxidative chlorine to their cells and

then further oxidizing the cellular systems and

causing the expiration of cells (Ying, 2014).

Besides that compound, there was also

[2(acryloyloxy)ethyl]-trimethyl ammonium chloride

(AETAC) used as antimicrobial agent. In previous

work, researcher studied chemical modification of

Sartiva, H., Nasution, D. and Wirjosentono, B.

Antimicrobial Properties of [2-(Acryloyloxy)Ethyl]-Trimethyl Ammonium Chloride and Maleic Anhydride Surface Grafted-Cotton Fibers.

DOI: 10.5220/0008934103190323

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 319-323

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

319

wool fabrics in order to get antimicrobial textile.

Anionic sulphonate groups were introduced onto a

wool fibre surface by grafting with polystyrene

sulphonate, which enabled binding of cationic

quaternized chitosan by ionic bonding. A bioactive

quaternary ammonium polymer, poly[2-

acryloyloxy)ethyl]trimethylammonium chloride, was

grafted onto chitosan to enhance chitosan's limited

antimicrobial activity (Hasan, 2015).

In this work, we studied about modified cotton

cellulose (CCell) fibres in a laboratory scale.

AETAC/MA grafting onto cotton cellulose was run

by ammonium Persulphate as initiator. It was

characterized using infrared spectroscopy (FTIR)

and scanning electron microscope (SEM) for

chemical structure. Antimicrobial properties of

modified cotton were investigated using Aspergillus

niger and Staphylococcus aureus. The expected

outcome of this work is obtaining new antimicrobial

cotton cellulose.

2 MATERIALS AND METHODS

2.1 Materials

Cotton cellulose was obtained from fabric cotton.

Toluene, maleic anhydride, ammonium persulphate

(NH

4

)

2

S

2

O

8

), aceton, PDA (Potatoes dextrose agar),

NA (Nutrient agar), DMSO, Aspergillus niger and

Staphylococcus aureus.

2.2 Methods

Cotton cellulose (10,0 g) was carried out in toluene

solution and refluxed for two hours with addition of

maleic anhydride (MA) at 60-70

o

C. Thereafter, the

solution was filtered, washed with acetone and dried

to obtain modified cellulase. Toluene solution of

antimicrobial compound of AETAC and ammonium

persulphate (NH

4

)

2

S

2

O

8

) as initiator was added

dropwise and the reflux was further continued for 2

hours. The reaction mixture with optimum weight

ratio (CCell/MA/AETAC: 100/20/20) was then

cooled down, filtered and wash thoroughly using

acetone and dried in oven vacuum to constant

weight at 60

o

C. The AETAC/MA-modified

Cellulose (AETAC/MA-g-CCell) was then

characterized using infrared spectroscopy (FTIR)

and scanning electron microscope (SEM) for

chemical structure identification of the reaction

products.

2.3 Antimicrobial Activity

Antimicrobial activity of modified cotton cellulose

was investigated against two differential microbe

names Aspergillus niger and Staphylococcus aureus

bacteria by agar disc diffusion method. In this

method, the antibacterial activity of AETAC/MA-

modified cotton cellulose against Aspergillus niger

manifested using PDA (Potatoes Dextrose Agar)

medium solid agar petri dish and against

Staphylococcus aureus bacteria using NA (Nutrient

Agar). The sample were sterilized by autoclaving at

115

o

C for 30 minutes, thereafter, placing on

Aspergillus niger and Staphylococcus aureus agar

plates and incubating for 24 h at 37

o

C. AETAC/MA-

modified cotton cellulose sample were cut about 5

mm on each side. The inhibition zones were

measured.

3 RESULTS AND DISCUSSION

3.1 Synthesis and Characterization of

AETAC/MA-g-Ccell

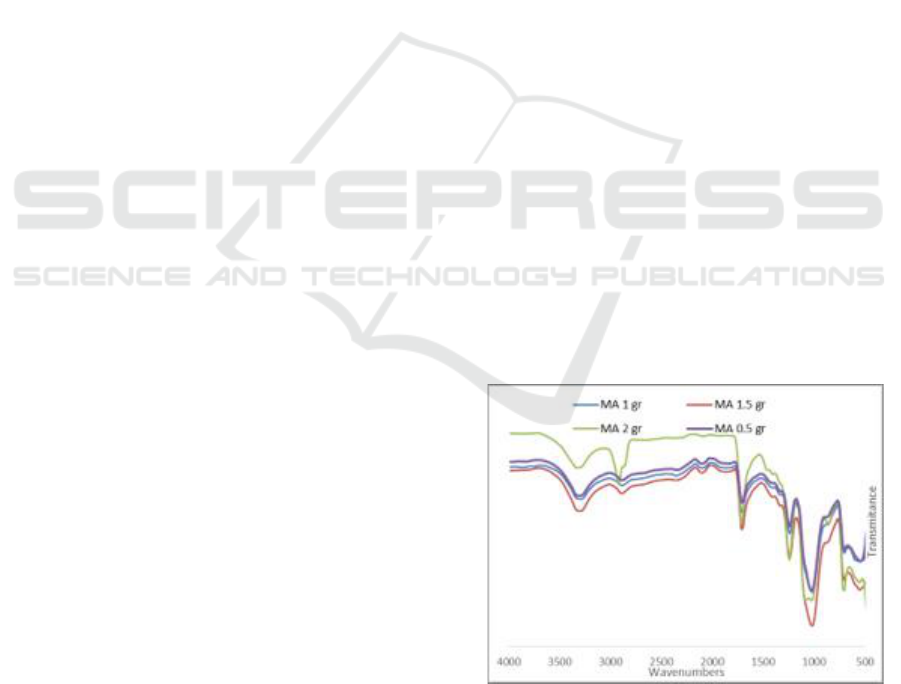

The FTIR spectra were used to analyze the bonding

between cellulose and AETAC/MA. The broad peak

at 3326 cm

-1

was due to stretching of hydroxyl (-

OH) groups, it is assigned to the cellulose structure.

(Ling et al, 2018) In this section, cotton cellulose

was modified by addition of 0.5, 1, 1.5, or 2 gram

maleic anhydride under the same reaction

conditions. The optimum condition was additional of

2 gram of maleic anhydride (Figure 1).

Figure 1: FTIR spectra of MA-g-Ccell.

This optimum condition was obtained by

comparing the absorption peaks between C-C-O

stretching around the number of waves 1242.94 cm

-1

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

320

and C = O stretching around the wave number

1709.05 cm

-1

with a consecutive value of 0.2399;

0.2460; 0.2325; 0.4493 for the addition of maleic

anhydride 0.5; 1 1.5 to 2 grams.

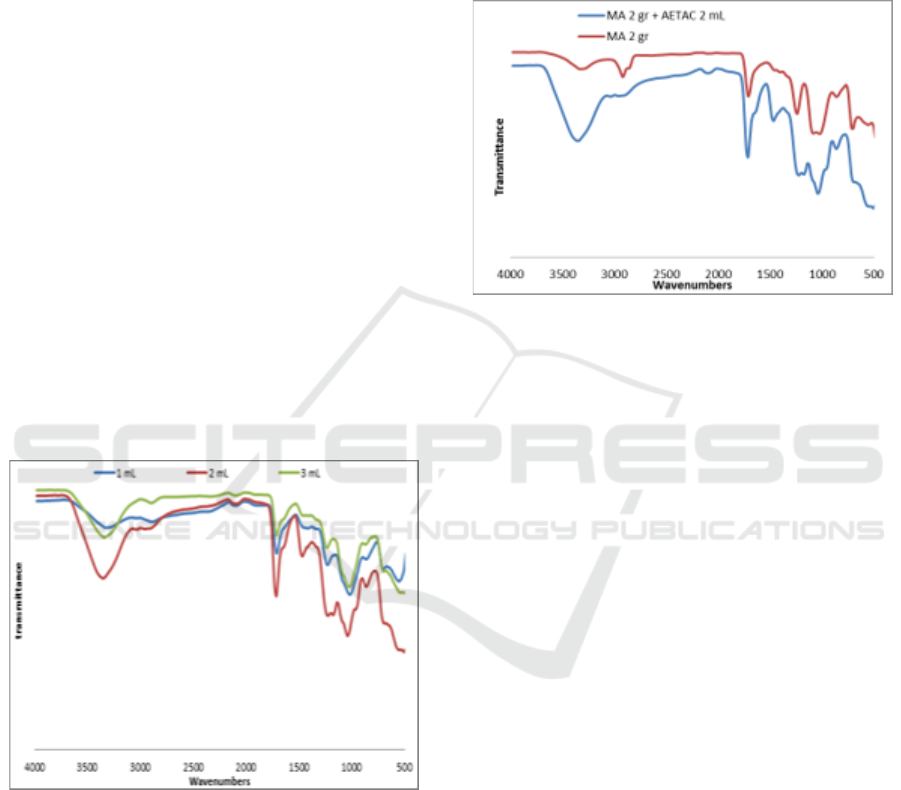

After the addition of Maleic Anhydride and

followed by reflux for 2 hours, then the sample was

dried in the oven with a temperature of 60

o

C. The

dried sample was added by ammonium Persulphate

as the initiator, where this compound would

produces radical compounds of cellulose cotton that

has been grafted using Maleic Anhydride. Then the

addition of AETAC [2-(Acryloyloxy) ethyl]-

trimethyl ammonium chloride as an antimicrobial

compound. The added AETAC volumes are 1, 2 and

3 mL. Optimum condition was achieved in addition

of 2 mL AETAC, this can be seen from the highest

absorption in the number of waves 1717.36 cm

-1

. In

the addition of 3 mL AETAC obtained the

absorption intensity of its smaller function group, it

was likely because AETAC was added too much, so

that there was a clotting on the specimen and

causing a smaller grafting condition. It can be seen

from the resulting dry sample having clumps of

cotton cellulose due to too much volume of AETAC

addedThe figure below shows the functional groups

of AETAC / MA-g-Cell with optimum conditions at

the addition of 2 mL AETAC.

Figure 2: FTIR spectra of AETAC/MA-g-Ccell.

The graft AETAC/MA onto cotton cellulose

were synthesized by using ammonium Persulphate

(APS) as initiator. Persulphate ion initiate free

radical sites on the cellulose. The mechanism by

which the initiator ion react with cellulose materials

has been widely studied (Hassan, 2015).

Comparable between FTIR spectrum of MA-g-Ccell

and AETAC/MA-g-Ccell were shown in Figure 2.

Absorption occurred at ~1717 cm

-1

(C=O stretching

vibration of the ester group) and disappearance of

bond absorption peak of acryloyl group (>C=C<) at

1470 cm

-1

suggested that AETAC and MA have

been successfully grafted onto cellulose backbone

(Ling, 2018). Factors affecting graft including

initiator concentration, monomer concentration and

reaction time have been well investigated (Bledzki,

1997).

Figure 3: FTIR spectra of MA-g-Ccell and AETAC/MA-

g-Ccell.

Free OH stretching vibrations (no hydrogen

bonds) have occurred in the 3700-3500 cm

-1

region

while absorption of the OH bound hydrogen band

has been seen in the 3450 - 3200 cm

-1

region as a

rather strong and wide band. Therefore, based on

data obtained from the table, only hydrogen bonds

occured.

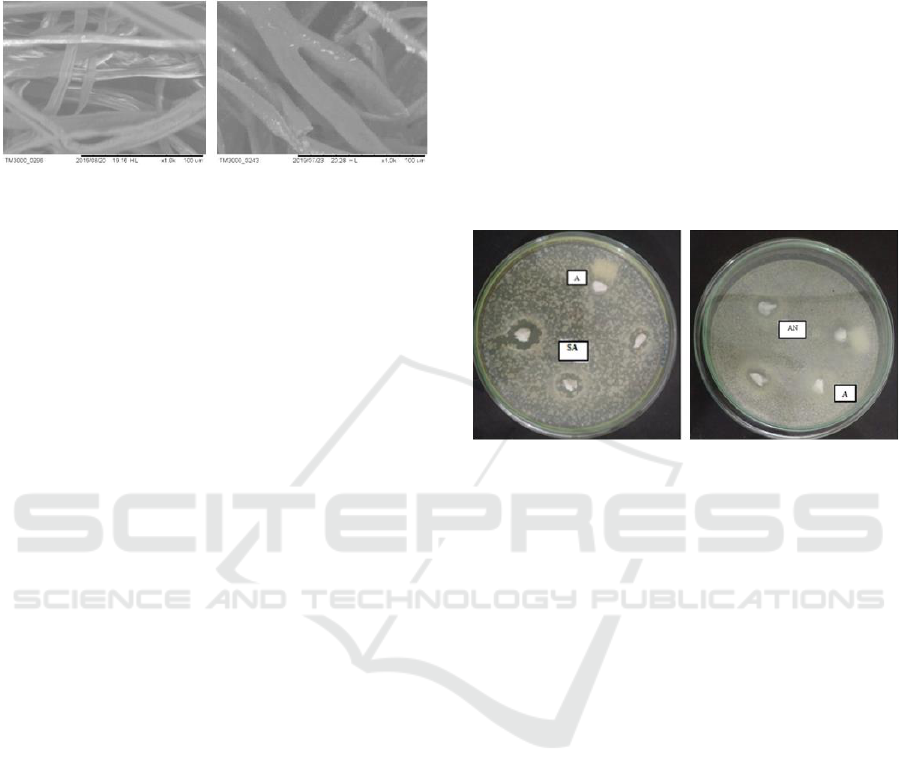

The results of the SEM analysis could provide

information about the shape and surface changes of

a sample being tested. If there has been a change in a

sample in the form of for example curves, fractures,

and structural changes, the material tends to

experience energy changes. Changed energy can be

emitted, reflected and absorbed and converted into

electron waves that can be captured and read the

results on SEM photographs.One potential challenge

is the modification of cotton cellulose to see the

morphology and structure of the fiber, which can

destroy the physical properties and integrity of the

structure.

The surface morphology of untreated cellulose

and AETAC/MA-modified cotton cellulose were

shown in Figure 3. By comparing the two images,

almost no major changes in the morfology of sample

surfaces could be observed. The surfaces of both

samples were flat and smooth, on which natural

structure (Liduo, 2019). The morphology of

modified cotton cellulose is more flat than fabric

cotton fibre. Esterification reaction of grafting

process were not destroying the fibre. The results

indicated the modification process was efficient and

Antimicrobial Properties of [2-(Acryloyloxy)Ethyl]-Trimethyl Ammonium Chloride and Maleic Anhydride Surface Grafted-Cotton Fibers

321

did not cause any damage to cotton fbre

microstructure. The image below shows a SEM

photo of commercial cotton and modified with the

antimicrobial component of AETAC.

Figure 4: SEM image of (a) untreated cellulose and (b)

AETAC/MA-modified cotton cellulose.

3.2 Antimicrobial Properties

Based on the Ministry of Trade of the Republic of

Indonesia that the fungus that can live on used

clothing is Aspergillus sp and Candida sp.

Aspergillus sp found in nature as saprophytes, grows

in tropical areas with high humidity. Types of

Aspergillus sp that can cause disease in humans are

Aspergillus flavus and Aspergillus niger, all of

which are transmitted by inhalation transmission.In

the antimicrobial activity test conducted to

determine the inhibition of the antimicrobial

component of AETAC against the fungus

Aspergillus niger and Staphylococcus aureus

bacteria. Bacteria and molds were rejuvenated first,

then microbial suspensions were made. The

modified surface cotton was moistened using

DMSO, performed three times with unmodified as

standard. After incubating for 24 hours for bacteria

and 48 hours for fungi, a zone of inhibition was

indicated which indicates the antimicrobial

inhibition of modified cotton. The difference in

incubation time between fungi and bacteria was

caused by differences in the growth rate of both,

where the bacteria in this test have a faster growth

rate compared to fungi so that the zone of inhibition

of the fungus has not been seen after 24 hours and

can be clearly observed after 48 hours of incubation.

Below was a picture of an antimicrobial test against

the fungus Aspergillus niger (AN) and the bacterium

Staphylococcus aureus (SA) with A as the standard

of unmodified cotton.

Evaluation of antimicrobial properties done by

inoculating Aspergillus niger and Staphylococcus

aureus on agar plate. The zone of inhibition or

regions where the growth of the microbial was

inhibited around the samples were measured by

investigating radius of the zone. The AETAC/MA-

modified cotton cellulose showed excellent

antimicrobial activity against Staphylococcus aureus

and Aspergillus niger. The results are shown in

Figure 4, AETAC/MA-modified cotton cellulose

produce large zone of inhibition against Aspergillus

niger after 48 hours incubation and produce zone of

inhibition against Staphylococcus aureus after 24

hours. The average radius of “Zone of Inhibition”

for AETAC/MA-modified cotton cellulose were 9.5

mm for Aspergillus niger and 12.3 mm for

Staphylococcus aureus. Below is a figure of an

antimicrobial test against the fungus Aspergillus

niger (AN) and the bacterium Staphylococcus

aureus (SA) with A as the standard of unmodified

cotton.

Figure 5: Representing of “Zone of Inhibition” for

Staphylococcus aureus (SA) and Aspergillus niger (AN)

with A is untreated cotton cellulose.

4 CONCLUSIONS

In this work, [2-(acryloyloxy)ethyl]-trimethyl

ammonium chloride (AETAC) and maleic anhydride

were grafted on cotton cellulose surface for

changing the properties of cotton. FTIR spectra of

the AETAC/MA-g-CCell after exhaustive Soxhlet

extraction showed stable absorption peak of

AETAC/MA carbonyl group (>C=O) at 1736 cm

-1

and disappearance of bond absorption peak of

acryloyl group (>C=C<) at 1470 cm

-1

. SEM images

showed that the surfaces of both samples were flat

and smooth, on which natural structure. The results

indicated the modification process was efficient and

did not cause any damage to cotton fibre

microstructure. The resulting material showed

excellent antimicrobial activity against

Staphylococcus aureus and Aspergillus niger.

ACKNOWLEDGEMENTS

The authors would like to thank to the Higher

Education Directorate, Ministry of Research,

Technology and Higher Education for granting the

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

322

research fund to carry out this works through:

“Penelitian Tesis Magister, DRPM RISTEKDIKTI

2019 of Universitas Sumatera Utara”.

REFERENCES

Bledzki, A. K, Gassan, J., 1997. Natural fibre reinforce

plastics, Handbook of engineering polymeric

materials, Marcel Dekker Publishers, New York.

Donna, U. Chito, F,. Mylene, C., 2019. Gamma irradiation

for the inactivation of Aspergillus niger in aged cotton

fabris. Rad. Phy. Chem. 165 108399.

Hassan, M., 2015. Binding of a quaternary ammonium

polymer-grafted-chitosan onto a chemically modified

wool fabric surface: Assessment of mechanical,

antibacterial and antifungal properties. RSC Adv. 5,

35497–35505.

Liduo, R., Hongchen, L., Bijia, W., 2019. Durable

antibacterial and hydrophobic cotton fabrics utilizing

enamine bonds. J. Carb. Pol. 01.103.

Ling, Z., Hui, H., Mei-chun, L., 2018. Enhancing

mechanical properties of poly(lactic acid) through its

in-situ crosslinking with maleic anhydride-modified

cellulose nanocrystals from cottonseed hulls. Ind.

Corp. Prod. 112 449-459.

Wassila, D., Djamila, G., Atika, O., 2010. Preparation and

biological characterization of cellulose graft

copolymers. J. Biochem. Eng. 48 187-194.

Yanjun, Z., Hezhong, D., 2019. Yield and Fiber Quality of

Cotton. Agri. Sci.

Ying, L. Yin, R., Xuehong, 2014. Antimicrobial cotton

containing N-halamine and quaternary ammonium

group by grafting copolymerization. Appl. Surf. Sci.

296 231-236.

Antimicrobial Properties of [2-(Acryloyloxy)Ethyl]-Trimethyl Ammonium Chloride and Maleic Anhydride Surface Grafted-Cotton Fibers

323