Preparation and Characteristics of Polyvinyl Alcohol-based Hydroel

Containing Natural Microbentonite

Mawarani Manullang

1

, Diana Adnanda Nasution

2

and Basuki Wirjosentono

2*

1

Postgraduate Chemistry Study Program, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1 Kampus USU, Medan, Indonesia

2

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Jl. Bioteknologi

No. 1, Medan 20155, Indonesia

Keywords: Polyvinylalcohol, Natural Microbentonite, Acrylicacid, Interpenetrating-hydrogels.

Abstract: In this work, polyvinylalcohol (PVA)-based interpenetrating-hydrogels containing natural microbentonite

(NMB) were prepared in a bench scale reflux-reactor using water as solvent in an optimized condition in the

presence of constant compositions of acrylicacid (AA) and N,N’-methylenebisacryamide (MBA) as

comono-mers as well as ammoniumpersulphate [(NH

4

)

2

S

2

O

8

, APS] as initiator. Results of interpenetrating-

hydrogels, with various loadings of NMB (2, 5, 10 and 15%) were moulded and cooled to form film

specimens, and then characterized for their properties. First of all, their mechanical properties and chemical

structure were measured using tensile testing (ASTM D882) and infrared spectroscopy (FTIR), then their

thermal properties were analysed using differential scanning calorimetry (DSC), and their morphological

properties were tested using scanning electron microscopy (SEM). Results showed that optimum

composition weight ratio of PVA/AA/NMB/MBA/APS = 60/40/10/1/0.5 enhanced highest tensile modulus

of the interpenetrating-hydrogel microcomposites 25% in compare to its neat hydrogel counterpart. FTIR

analysis of the film speci-mens after exhaustive extraction in n-hexane still contained stable AA-carbonyl

(C=O) peak at 1725 cm

-1

. Thermal properties of the optimized composition of the hydrogel showed slight

improved of thermal stability (decomposition temperature increase from 280 – 285

o

C). Morphological

properties of the interpenetrating-hydrogel microcomposite also showed finely distributed of the microfiller,

which is responsible for its improved mechanical and thermal properties. It is recommended that the

interpenetrating-hydrogels can be further developed for application as biomedical materials.

1 INTRODUCTION

Along with the increasing industry in Indonesia, all

the raw material needs derived from rock materials

also increase, one of which is bentonite. Bentonite is

a type of clay whose availability is very abundant in

Indonesia. Indonesia has a source of local raw ma-

terials based on natural polymer hydrogels, namely

bentonite. The potential of bentonite in Indonesia is

quite large and spread in several locations, namely

the island of Java and Sumatra. one of them in the

Province of Nanggroe Aceh Darussalam which is

located on the western tip of the island of Sumatra.

In this area the source of bentonite is still not widely

processed by the government and industry. Benton-

ite used as filler was first made into bentonite nano-

particles using the coprecipitation method. Hydrogel

is a hydrophilic polymer network that is cross-linked

and has the capacity to expand (swelling) by ab-

sorbing water or biological fluids but is insoluble

due to crosslinking. Hydrogel from poly (acrylic

acid) -ko-polyvinyl alcohol can be synthesized from

cranic acid and polyvinyl alcohol using gamma

irradiation (Nesa, 2017). This is indicated by an

increase in absorption (Erizal, 1998). The ability of a

hydrogel to absorb water that is insoluble in water is

indicated by the presence of cross connective tissue

when ex-posed to water will form a three-

dimensional mac-romolecular network (Zohuriaan-

Mehr, 2008).

Cross-linking in bentonite can improve the char-

acteristics of bentonites such as solubility in water,

or organic solvents, bacteriostatic effects, chelating

ability and complexing. Processing with N, N

dengan-methylene bisacrylamide (MBA) acrylic

acid as a crosslinker is expected to bind natural

Manullang, M., Nasution, D. and Wirjosentono, B.

Preparation and Characteristics of Polyvinyl Alcohol-based Hydroel Containing Natural Microbentonite.

DOI: 10.5220/0008928103010304

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 301-304

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

301

nanobentonite added in the interpenetration net-work

of the formed polyvinylalkyton-polyacrylate

hydrogel polymer. Polyvinylalkohol (PVA) is an

environmentally friendly polymer that is widely

used as a medical polymer, including: soft lenses,

absorbents, wound dressings, drug carriers, cosmet-

ics, and so on. PVA applications as absorbents are

hampered by their low mechanical properties so they

are easily destroyed, especially if applied in

excessive water medium (Kobayashi et al.,2008).

2 MATERIALS AND METHODS

2.1 Materials

Bentonite. Other reagents are commercially

available. Acrylic acid (AA) and Ammonium

Persulfate (APS) are used as initiators of

polymerization, Poly-vinylalkohol (PVA), N, N'-

methylenbisacrylamide (MBA).

2.2 Preparation PVA 10%

Technical PVA is weighed as much as 10 grams,

then dissolved into 100 mL of distilled water, steri-

lized and heated at 90°C for ± 3 hours until dis-

solved.

2.3 Making Bionanocomposite

Hydro-gel Interpenetration

The reflux device is equipped with a 250 mL 4 neck

flask, mechanical stirrer, condenser and

thermometer. Entered 6 mL aquadest, added

nanobentonite with a variation of weight 0; 0.2; 0.4;

0.6 and 0.8 and heated the mixture at 60

o

C with a

water bath and stirred constantly until it turns into a

sticky solution like a transparent paste. Enter 10%

PVA solution with variations of 1 ml, 2 ml, 4 ml, 6

ml and 8 ml into the reaction flask. Put 7 ml AA

with 0.04 g N, N'-metilenbisakrilamida (MBA) into

the reaction flask. After bubbling, nitrogen gas is

poured for 30 minutes. 0.05 g of Ammonium

Persulfat (APS) was added into the reaction flask

with a mechanical stirrer. The reaction mixture

temperature is raised to 60

o

C and the reaction is

maintained for 1 hour. Soaked with ethanol products

Which is produced for 24 hours. Dried in the oven

for 24 hours at 60

o

C.

2.4 Characterization

2.4.1 Analysis of FTIR

FTIR analysis was used to determine the functional

groups found in graphene oxide. Then the sample is

prepared in liquid form (suspension), then the sam-

ple is dropped between two KBr plates to make a

thin film. Then the plate is placed on the sample to

be passed by infrared light. FTIR analysis using the

Prestige-21 IR device was carried out in the wave

number range 4500-450 cm

-1

.

2.4.2 Morphological Analysis with SEM

The microscopic observation process using SEM

was carried out on the sample fault surface. Then

after the sample is cleaned with a blower, the sample

is coated with gold and palladium in a machine that

presses 1492 x 10

-2

atm, the sample is then put into a

room (vacuum evaporator) with a pressure of 0.2

Torr using the JSM-35 C Shimadzu machine .

Furthermore, the sample is irradiated with a 20 kV

electron beam in a special room so that the sample

emits secondary electrons and electrons which are

bounced can be detected by the Scientor detector

which is amplified by an electrical circuit that causes

a 4 minute Cathode Ray Tube (CRT) to appear.

Then the 400 Armstrong coating is inserted into the

Chamber specimen to be carried out by removing

secondary electrons and the detectors can be

detected by the detector. The shooting results can be

adjusted to the desired magnification for shooting.

2.4.3 Test the Percentage of Water

Absorption

Testing the percentage of water absorption was car-

ried out by determining the percent swelling ratio by

measuring the initial weight (Wd) of the sample

which was then immersed in distilled water for 24

hours. use filter paper and measure the final weight

again (Ws). Measuring the percentage of water

absorption in the hydrogel can be determined by the

following formula:

Where:

Degree of cross tie (%) =

𝑊𝑎

Wb

𝑥 100% (1)

Wa = weight of dry hydrogel after soaking

Wb = weight of dry hydrogel before immersion.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

302

3 RESULTS AND DISCUSSION

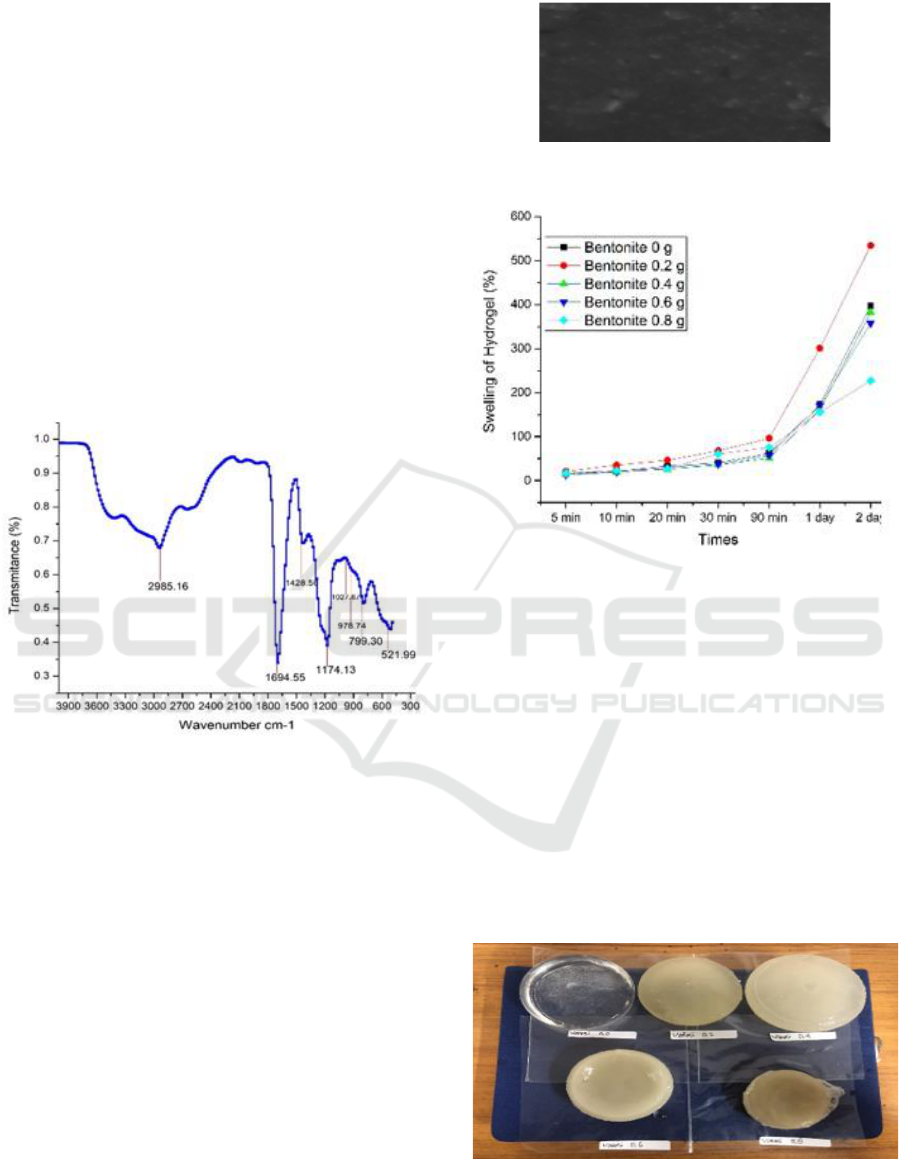

FTIR functional group test results on bentonite hy-

drogel, 2 ml PVA: 7 ml AA, and APS 0.05: NBA

0.2 grams with the addition of MBA as much as 0.04

grams can be seen in Figure 1. Hydrogel that has

been made in cluster analysis its function using

FTIR. The main functional group of bentonite con-

stituents can be seen through absorption of the OH

group at 2985.16 cm

-1

, Si-OH-Si group at 1027.67

cm

-1

, AL-O-Si group at 799.30 cm

-1

, Si-O group at

521.99 cm

-1

, the 0-H group bending at 978.74 cm

-1

and at 3392.96 cm

-1

and 1647.54 cm

-1

are adopted

water molecules. The above functional group is the

main functional group of bentonite in the hydrogel.

This result is in accordance with the research

(Darvishi, 2010).

Figure 1: FTIR of hydrogel bentonite 0,2 g.

Figure 2 shows the results of SEM 500x

magnification in PVA / AA / APS / NBA / MBA

hydrogel composite samples. Because PVA

dissolves in water (Gao, 2015). whereas bentonite is

a hydrophilic polymer and swelling in water, the

three can be mixed like shown in Figure 2. In

general, it can be seen that the morphology of the

full PVA / AA / APS / bentonite / MBA hydrogel

SEM has a rough surface and large density. This

shows that the polymer network formed will

converge and interact with each other. Irregular

shapes provide porous space so that absorption can

occur. Heterogeneous surfaces indicate that there are

areas that experience interactions between bentonite

chains and there are also areas that do not form

interactions of the bentonite chain.

Figure 2: SEM image of NBA 0,4 g.

Figure 3: Graph of Absorption Test Results.

Based on the table and graph above, shows that

the hydrogel semi-interpenetration polymer network

on the weight of the addition of bentonite is 0.4 g;

0.6 g and 0.8 g still have low absorption compared

to the blank. It can be said that the more the amount

of bentonite used, the smaller the value of the

absorbed water. The solvent re-sistance test is

carried out to see how far the hydrogel is resistant to

solvents such as water. The polymer Material for the

build up of the hydrogel should inflate (swell) and

retain the water fraction of its structure, but not

soluble in water. Both natural and synthetic

materials have been widely used to synthesize

hydrogels (Dragan et al., 2012)., (Matricardi,2013).

Figure 4: Graph of Absorption Test Results.

Preparation and Characteristics of Polyvinyl Alcohol-based Hydroel Containing Natural Microbentonite

303

Hydrogels with crosslinked structures can absorb

water, but are not soluble in water. The process of

entering water into the hydrogel matrix results in the

development of the hydrogel it self (Yang,2012).

Revealed that at the beginning of the absorption

process, water diffuses in the network continuously

until it reaches equilibrium conditions, with

maximum development. After the equilibrium phase,

the amount of water absorbed decreases due to the

gel liquefaction cycle. In Figure 4, the percent of

devel-opment increases as a function of time and

reaches the maximum condition after ± 24 hours of

immer-sion, for all bentonite / PVA hydrogel

concentrations which are 0 g; 0.2 g; 0.4 g; 0.6 g and

0.8 g.

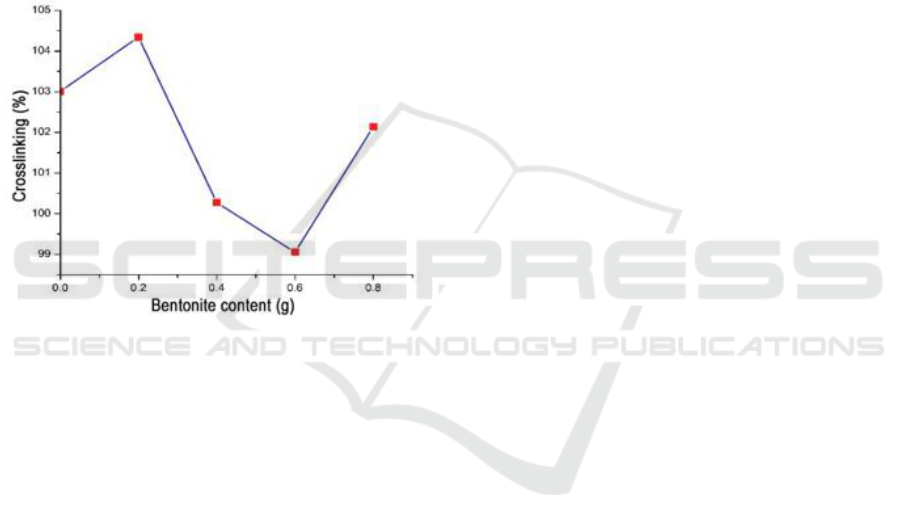

Figure 5: Graph of test results% Crossed.

4 CONCLUSIONS

Optimum condition obtained through hydrogel

absorbent power test and superabsorbent cross tie

test using full IPN method with a variation of time 5

minutes, 10 minutes, 20 minutes, 30 minutes, 90

minutes 1 day and 2 days with variations of ben-

tonite 0.2 grams. Cross-binding agent concentration

of MBA 0.4%, and the concentration of APS

initiator 0.5%. The value of this site hydrogel ratio is

533.83% and the cross belt is 104.34%. The power

of the bentonite structure can be improved by

conducting polymerization using the full IPN

method.

ACKNOWLEDGEMENTS

This research was funded by the DRPM Republic of

Indonesia Ministry of Research and Technology

Republic of Indonesia Fiscal Year 2019.

REFERENCES

Nesa. F., 2017. Sintesis dan pencirian hidrogel poli (asam

akrilat)-ko-polivinil alkohol dengan teknik iradiasi

gamma. Skripsi Departemen kimia. FMIPA IPB.

Erizal,, and Rahayu, C,.1998. Characterization of poly

(vinyl alcohol) (PVA) hydrogel prepared by radia-tion

polymerization; Karakterisasi hidrogel PVA hasil

polimerisasi radiasi. Indonesia

Zohuriaan-Mehr, M. J., & Kabiri, K., 2008. Superabsor-

bent polymer materials: a review. Iranian polymer

journal, 17(6), 451.

Kobayashi M., and S. H. Hyon., 2010, Development and

Evaluation of Polyvinyl Alcohol-Hydrogels as an Arti-

ficial Atrticular Cartilage for Orthopedic Implants,

Materials, 3, 2753-2771.

Darvishi, Z., 2010. Morzali, A. Ultrason. Sonochem. 18,

238–242

Gao,Q., He,Y., Fu,J., Liu,A., and MaA.,2015. “Coaxial

nozzle-assisted 3D bioprinting with built-in micro-

channels for nutrients delivery,” Biomaterials, vol. 61,

pp. 203–215.

Dragan, E. S.;Perju, M. M.;& Dinu, M. V., 2012. Prepa-

ration and characterization of IPN composite hydrogel

based on polyacylamide and chitosan and their inter-

action with ionic dyes. Carbohydrate Polymers, 270-

281

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

304