Effect of Particle Size from Oil Palm Wood Powder as Pore Forming

Agent on Porosity and Hardness of Porous Ceramics based on Clay

and Polyvinyl Alcohol

Marpongahtun

*

, Darwin Yunus Nasution and T. Hidayat

Chemistry Departement University of Sumatera Utara, Medan, North Sumatera , Indonesia

Keywords: Porous Ceramic, Polyvinyl Alcohol, Clay, Pore Forming Agent.

Abstract: Preparation of porous ceramics based on polyvinyl alcohol and clay has been carried out by using oil palm

wood powder as a pore forming agent. Porous ceramics are made with a composition: 80% clay, 15% PVA

and 5% oil palm wood powder. The size of the particles of palm oil wood powder is varied, namely 100,

150 and 200 mesh. The sintering process is carried out at a temperature of 1000 °C with a holding time of 2

hours. The chemical composition of clay is determined by EDX analysis. The porous ceramics produced

were tested for porosity and hardness. The result shows that the particle size of oil palm wood powder is

very influential on the hardness and porosity of the ceramic. The larger the mesh size of the particles of oil

palm (the smaller the particle size) the higher the hardness of the ceramic, but the porosity is getting

smaller.

1 INTRODUCTION

Polymer Porous ceramics are ceramics that have

many pores so that the fluid can be absorbed into it.

Porous ceramics, besides being able to absorb

liquids and gases, are also relatively more resistant

to high temperatures, corrosion and contamination of

foreign matter, so that they can be used in various

fields of application such as motorized vehicle

exhaust gas filters. The quality of a porous ceramic

product is largely determined by the pore size and

the sintering temperature. Pore formation can be

done by mixing ceramic raw materials with pore-

forming agents based on organic materials such as

cellulose. At the time of sintering at high

temperatures the organic material will be oxidized to

carbon dioxide gas which escapes out of the ceramic

so that a small cavity is formed on the ceramic.

Agricultural wastes or industrial waste used as pore

forming agents are graphite (ALI et al., 2017), rice

husk ash (P.Sebayang, 2009), industrial fly ash

waste (Dong et al., 2010), paper waste (Dasgupta

and Das, 2002), potato starch (Sengphet et al., 2013)

and Kenaf Powder (de Oliveira et al., 2015).

The oil palm stem waste originating from the

rejuvenation of oil palm plantations is mostly found

in North Sumatra. The main components contained

in oil palm stems are cellulose (39.77%), pentose

(21.53%), lignin (18.10%), water (12.05%) ash

(2.20%), SiO2 (0.71%). Based on the composition of

the palm oil stem, which is mostly an organic

compound, where high temperatures will be

converted into gases, the oil palm stem can be a

potential source of pore-forming agents.

In this study, palm oil stem waste powder was

used as a pore-forming agent in the manufacture of

porous ceramics which as far as is known has never

been done. It is estimated that oil palm stem powder

will be a good pore forming agent because it

contains a lot of organic compounds such as

cellulose, starch and lignin which at the sintering

temperature will be oxidized to gases, especially

carbon dioxide gas. This carbon dioxide gas will

come out of the ceramic material and will leave

pores on the ceramic produced. The number and size

of ceramic pores can be adjusted by varying the

particle size of the oil palm stem powder (100, 150

and 200 mesh). Next will be the characterization and

testing of resistance and porosity. It is hoped that

high quality porous ceramics will be obtained.

Marpongahtun, ., Yunus Nasution, D. and Hidayat, T.

Effect of Particle Size from Oil Palm Wood Powder as Pore Forming Agent on Porosity and Hardness of Porous Ceramics based on Clay and Polyvinyl Alcohol.

DOI: 10.5220/0008925902930296

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 293-296

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

293

2 MATERIALS AND METHODS

2.1 Materials

Clay is obtained from Wonosari Village,

TanjungMorawa Sub-District, DeliSerdang District.

Oil palm stem powder originated from Southeast

Aceh District, Poliviniyl Alcohol produced by

Sigma Aldrich.

2.2 Methods

2.2.1 Preparation of Palm Oil Stem Powder

The oil palm stems used are oil palm stems resulting

from the rejuvenation of oil palm plantations.

Furthermore, the outer bark of the oil palm stem skin

is peeled and it is cut into smaller sizes. The inside

of the palm oil stem is dried and then made into

powder with sizes 100, 150 and 200 mesh and then

soaked in water for 24 hours. Then dried until the

water content is below 5%.

2.2.2 Clay Treatment

Clay is dried using an oven for 30 minutes at 105

o

C.

The dried clay is smoothed using a ball mill and

sieved with a 200 mesh size sieve. Then weigh 10

grams, put it into a glass beaker and add 40 mL of

37% HCl solution. The mixture is stirred using a

magnetic stirrer at 70

o

C for 40 minutes. After the

stirring process is complete, filtering is done using

filter paper. Then the residue is put in a glass beaker

andadd 40 mL of 15% NH

4

OH solution, stirred,

filtered and dry for 4 hours at 70

o

C. Furthermore, the

chemical composition ofthe clay that has been

treated (activated) is determined by EDX analysis.

2.2.3 Manufacturing of Porous Ceramic

Manufacturing of porous ceramics is done by mixing

and stirring until homogeneous clay, oil palm stem

powder and PVA with a percent ratio of clay: oil

palm stem powder: PVA is 80: 15: 5. Variations in

particle size of oil palm wood are 100, 150 and 200

mesh. Then the dough is pressed with a pressure of

300 M.Pa with a hold time of 10 minutes. Then the

specimen was removed from the mold and sintered

at 1000 ° C for 2 hours. The porous ceramic material

produced is determined by its porosity and

morphology (Gregorová et al., 2009) (Putri et al.,

2018).

2.3 Characterization

2.3.1 Hardness of Porous Ceramics

Ceramic hardness is determined using Digital

Vickers Hardness Tester TH723/724 Closed-loop

control system The hardness’s calculated using the

following formula: Hardness = 1.854(F/D

2

), with D

2

the area of the indentation (measured in square

millimetres) and F = the applied load (measured in

kilograms-force)

2.3.1 Porosity of Porous Ceramics

Measurement of ceramic porosity is carried out

by weighing the dry weight of the ceramic, then

soaking the ceramic in water for 24 hours, after the

ceramic has been dried with a cloth and then

weighed again. Ceramic porosity is calculated using

the formula:

%100]

20

)1

[ x

WW

WW

P

−

−

=

(1)

P = porosity of ceramics

W

1

= wet sample weight

W

2

= dry sample weight

W

0

= sample weight in water

3 RESULT AND DISCUSSION

3.1 The Oil Palm Wood Powder

The particle sizes of oil palm stem powder particles

are 100, 150 and 200 mesh. The results are shown in

Figure 1.

3.2 Clay

Prior to ceramic printing, the clay raw material is

first activated with 37% Chloride Acid. Activation

aims to increase the size of the pores of the clay so

that the absorption of clay fluid increases. Figure 2

shows clay before and after activation.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

294

Figure 1: Oil palm stem powder (a) 100, (b) 150, (c) 200

mesh.

Figure 2: a) Clay before activation b) Clay after activation.

Table 1: Ceramic composition.

No

Composition

Particle size

(Mesh)

Clay

OPTP

PVA

1

80

15

5

100

2

80

15

5

150

3

80

15

5

200

Table 2: Ceramic properties.

No

Porosity (%)

Hardness (MPa)

1

27

221.62

2

22

302.88

3

20

363.46

Table 3: Chemical element composition of clay after

activation.

Element

Percentage

Si

23.72

Al

15.80

O

47.94

Fe

5.53

C

5.09

K

0.87

Ti

0.66

Mg

0.59

Elemental Analysis of activated clay were obtained by

EDX analysis. Elemental composition were listed in Table

3.

3.3 Porous Ceramic

Porous ceramics are made with a weight percent

ratio of clay: PVA: oil palm stem powder 80: 15: 5.

Variation is the particle size of oil palm stem powder

is 100, 150 and 200 mesh. Then sintered at 1000

o

C

for 2 hours. The results can be seen in Figure 3.

Figure 3: Porous ceramics with particle sizeoil palm stem

powder a) 100 b) 150 c) 200 mesh.

3.4 Porosity of Porous Ceramics

There is a correlation between particle size of palm

oil stem powder and porosity and hardness of

ceramics. The smaller the particle size of oil palm

stem powder, the size of porosity increases while the

hardness decreases (Putri et al., 2018) (Zhi-, 2012).

This means that if the porosity rises, the cavity in the

ceramic material will increase so that the resistance

to pressure decreases. On the one hand, with

increasing porosity, it is estimated that the

absorption capacity will increase.

Effect of Particle Size from Oil Palm Wood Powder as Pore Forming Agent on Porosity and Hardness of Porous Ceramics based on Clay

and Polyvinyl Alcohol

295

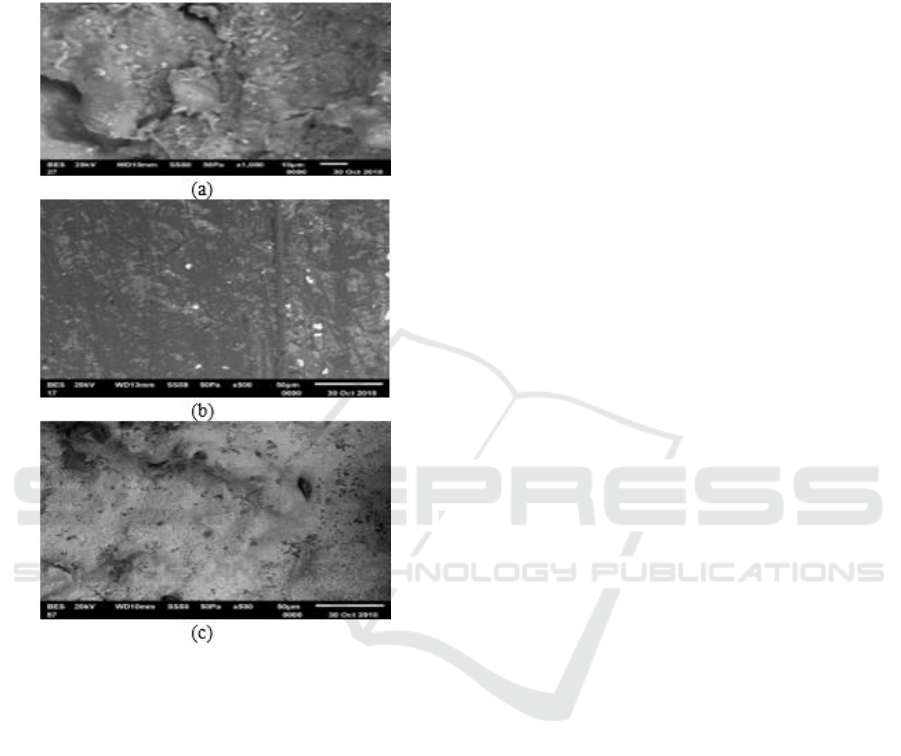

3.5 Ceramics Morphology

The porous ceramics produced were tested for SEM

to evaluate of the morphology of ceramics. The

SEM photographs are shown in Figure 4.

Figure 4: Photograph SEM of Porous Ceramics a) 100 b)

150 and c) 200 mesh.

From the SEM photograph, it can be seen that the

larger the particle size the larger the ceramic pore is

formed (Korjakins, Upeniece and Bajare, 2006)

(Sandra, Budi and Sulsilo, 2014) Photo SEM in

figure a shows a larger pore size compared to images

b and c. This is in accordance with the smaller

particle size of the coconut stem powder.

4 CONCLUSIONS

Porous ceramics can be made from clay and PVA by

using palm oil stem powder as a regulating agent

and pore forming. The particle size of palm oil

powder has a significant effect on the hardness and

porosity of the ceramic. The smaller the powder size

the stronger the ceramic but the porosity decreases.

ACKNOWLEDGEMENTS

Author would like to thank to Rector of University

of Sumatera Urara for the funding from the project

of PD-TALENTA 2018.

REFERENCES

Ali, M. S. et al. (2017) ‘Preparation and characterization

of porous alumina ceramics using different pore

agents’, Journal of the Ceramic Society of Japan,

125(5), pp. 402–412. doi: 10.2109/jcersj2.16233.

Dasgupta, S. and Das, S. K. (2002) ‘Paper pulp waste - A

new source of raw material for the synthesis of a

porous ceramic composite’, Bulletin of Materials

Science, 25(5), pp. 381–385. doi:

10.1007/BF02708014.

Dong, Y. et al. (2010) ‘Recycling of fly ash for preparing

porous mullite membrane supports with titania

addition’, Journal of Hazardous Materials. Elsevier

B.V., 180(1–3), pp. 173–180. doi:

10.1016/j.jhazmat.2010.04.010.

Gregorová, E. et al. (2009) ‘Porous Ceramics Made Using

Potato Starch as a Pore-forming Agent’, Ceramics

International. doi: 10.1016/j.ceramint.2015.10.019.

Korjakins, A., Upeniece, L. and Bajare, D. (2006)

‘Building and Renovation High Efficiency Porous

Ceramics with Controllable’, International Conference

Civil Engineering, pp. 5–10.

de Oliveira, I. R. et al. (2015) ‘Production of porous

ceramic material using different sources of alumina

and calcia’, Revista Materia. doi: 10.1590/S1517-

707620150003.0078.

P.Sebayang (2009) ‘99 Pembuatan Bahan Filter Keramik

Berpori Berbasis Zeolit Alam Dan Arang Sekam

Padi’, Teknologi indonesia 32 (2) 2009: 99–105

Teknologi indonesia, 32 (2)(November), pp. 99–105.

Available at: e-mail:

perdameansebayang@yahoo.com.

Putri, S. E. et al. (2018) ‘Performance Test of Gelcasted

Porous Ceramic as Adsorbent of Azo Dyes’, Journal

of Physics: Conference Series, 1028(1), pp. 0–8. doi:

10.1088/1742-6596/1028/1/012039.

Sandra, K. O., Budi, A. S. and Sulsilo, A. B. (2014)

‘Pengaruh Suhu Sintering Terhadap Densitas dan

Porositas pada Membran Keramik Berpori Berbasis

Zeolit, Tanah Lempung, Arang Batok Kelapa, dan

Polyvinylalcohol (PVA)’, Prosiding Pertemuan Ilmiah

XXVIII, (April), pp. 392–395.

Sengphet, K. K. D. et al. (2013) ‘Fabrication of Porous Clay

Ceramics Using Kenaf Powder Waste’, 3(8), pp. 1–5.

Zhi-, W. F. X. I. E. (2012) ‘Preparation and Development

of Porous Ceramic Membrane Supports’, 55, pp. 277–

282. doi: 10.3303/CET1655047.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

296