Development of Maceration Methods in the Investigation and

Analysis of Lard in Industrial Food Products to Improve Halal

Product in Indonesia

Muhammad Taufik

1*

, Zul Alfian

1

, Desi Ardilla

2

, Mariany Razali

3

, Irfan Kurniawan

2

, Nur Waridah

Angriani Nasution

2

, Rika Astuti Pulungan

2

and Sri Dewi Sitohang

4

1

Department of Chemistry, Faculty of Mathematics and Natural Science, Universitas Sumatera Utara,

Medan, Indonesia, 20155

2

Agricultural Technology Department, Universitas Muhammadiyah Sumatera Utara, Medan, Indonesia

3

Pharmacy Department, Universitas Tjut Nyak Dhien, Medan, Indonesia

4

Pharmacy Department, Universitas Muslim Nusantara Al Washliyah, Medan, Indonesia

irfankurniawan0987@gmail.com, nurwaridahnst@gmail.com, rikaastuti732@gmail.com, sdsihotang@gmail.com

Keywords: Halal Products, Maceration, Lard, Physical Properties.

Abstract: The high demand for halal products in Indonesia requires chemists to produce a fast and accurate method of

using them. The rapid development of Forensic Chemistry led to the emergence of a simple new method to

analyze of lard in these industrial food products. In this study, the maceration method coupling electro

synthesis using aluminium electrodes so that the extraction time was shorter. The investigation begins by

collecting and preparing industrial food products (pork corned). The extraction time process used at 30, 60, 90,

120, 150 minutes (optimal time = 120 minutes). Analysis of the physical properties was carried out: iodine

numbers, index bias, melting point, and acid number and the data obtained were 0.893, 72, 1.463, 370C, and

2,542 respectively. Lard quantity in food produced at the optimal conditions is 37%. However this method is

very helpful in the field of forensic chemistry especially in the analysis of the presence or absence of lard in

industrial food products. This research will support the improvement of halal products in Indonesia.

1 INTRODUCTION

Halal food is a food that does not contain elements

that are unclean or prohibited for consumption by

Muslims, both concerning food raw materials, food

additives, auxiliary materials and other auxiliary

materials including foodstuffs which are obtained

through the process of genetic engineering and food,

and whose management is carried out in accordance

with the provisions of Islamic religious law. Halal

food is food that is permitted to be consumed or not

bound by the provisions that forbid it, good is

delicious, good, healthy and reassuring (Hidayat,

2015).

The halal food industry is experiencing rapid

growth in the world, especially in Indonesia. Halal

lifestyle spread to various countries (Rohman,

2012). Halal is the main indicator for product quality

assurance (Burlian, 2013). Consumers of halal

products not only come from Muslims, but also

countries with a majority of non-Muslims also

consume halal food including Russia (Hidayat et al.,

2015). The quality of halal products is the reason for

using halal products (Salehudin, 2014) because there

are guarantees of cleanliness, safety, and product

quality for the entire production chain (Faridah Jalil,

2014). Providing halal and safe food is a must for a

company so that its products are in demand by the

wider community. Investigation and analysis on a

laboratory scale by government and private agencies

needs to be improved considering the recent halal

products have received serious attention from all

parties.

Lard is a basic ingredient of food commonly used

as cooking oil or as a complement to dishes such as

beef or goat fat, or as butter. The quality of taste and

use of lard itself depends on what part of the fat is

taken and how the fat is processed. Pig fat has

saturated fat and cholesterol which is lower than

butter. Fats in pigs need to go through a process to

Taufik, M., Alfian, Z., Ardilla, D., Razali, M., Kurniawan, I., Waridah Angriani Nasution, N., Astuti Pulungan, R. and Dewi Sitohang, S.

Development of Maceration Methods in the Investigation and Analysis of Lard in Industrial Food Products to Improve Halal Product in Indonesia.

DOI: 10.5220/0008919902390244

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 239-244

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

239

become lard which can be used as food. Pig fat

contains 3770 kJ of energy per 100 grams (Hilda,

2014).

There are various food products that are very

diverse, with special quality and prices. It's just that,

sometimes to get it, materials are needed from one

or more parts of the pig's body and then mix the

parts with other processed food products.

Economically, the use of pig ingredients can provide

many benefits, because it is cheap and easy to

obtain. These materials when processed into food

products are very difficult to recognize (Nina, 2017).

The cases of food containing ingredients from pigs

have been prevalent in Indonesia since the 1980s

until now (Fibriana, 2009). Therefore, knowledge of

the various possibilities of using pig elements needs

to be improved. One case example of containing

pork is the Solaria restaurant pig oil case that

appeared on August 15, 2013 so PT. Solaria rays

experience a critical phase. PT. Sinar Solaria, under

the Solarian restaurant, is currently in crisis because

the restaurant does not yet have Hahal certification

from MUI and Solaria restaurant and is also hit by

the issue of pork oil used in its spices, besides PT.

Indonesian walls, especially in Magnum ice cream

products, are rumored to have pig oil in the

packaging of their ice cream, and recently a

horrendous case in Indonesia is the circulation of

four Korean instant noodle products containing pig

specific DNA fragments. The four products

containing the pig, namely Samyang with the

product name U-Dong, Nongshim, with the product

name Shin Ramyun Black, Samnyang with Instant

Kimchi flavored noodle products, and Ottogi with

the name Yeul Ramen product.

Investigation is an active effort to find something

(Rendle, 2005). In an investigation, chemists can

provide a direction of examination that confirms the

assumption that substances contained in a compound

include the process of investigation and analysis

(Sisco, 2018). Lard has been analyzed on pig

nuggets using UV spectroscopy (max λ = 270 nm)

with a 12 hour extraction time (Taufik, 2019).

Analysis of the physical properties of lard fat that

was adapted with beef, chicken and tuna was also

analyzed using the Completely Randomized Design

(CRD) method (Ardilla, 2018). The composition

contained in lard was analyzed using the

Chromatography and FTIR methods. Pig fat spectra

differ from other animal fats. The extraction process

used still uses maceration with n-hexane solvent so

that the solvent is volatile and the lard is oxidized

(Erwanto, Y., Rohman, A., Arsyanti, L. and Pranoto,

2018). Animal fats including lard will be damaged

quickly if they are exposed to air for too long (12

hours) (Razali, 2018). However, maseration

coupling electrosynthetic will be developed to

reduce maceration time.

The simple maceration method is carried out by

means of extracting by immersing the mashed

sample. The principle of maceration is the extraction

of active substances by soaking the powder in the

appropriate solvent for several days at room

temperature protected from light, the solvent will be

inserted into the cell wall. Cell contents will dissolve

because there is a difference between inner cell

contents and outer cells. A high concentration

solution will be pushed out and replaced by a low

concentration solvent (diffusion process). This event

will repeat until it occurs between cells inside and

cells outside. The maceration method was developed

and matched with an electrochemical method based

on the electrolysis process, which is a chemical

reaction in an electrochemical system that produces

electricity from outside sources. This process is the

opposite of the Galvani process, where chemical

reactions that occur in electrochemical systems are

used to produce electric currents, for example in fuel

cells (fuel cells).

The other applications of electrochemical methods

besides metal purification and electroplating are

electroanalytic, electrocoagulation, electrocatalyst,

electrodialysis and electrorefining (Walsh, 1994).

Electrosynthetic techniques / methods are a way to

synthesize / make and or produce a material based on

electrochemical techniques. In this method there is a

change in chemical elements / compounds into

compounds that are desired. The use of this method

by researchers in synthesizing materials is based on

various advantages offered such as the equipment

needed is very simple, which consists of two or three

electrode rods that are connected to an electric current

source, electrode potential and current density can be

adjusted so that selectivity and reaction speed can be

placed at the desired limits through setting the

magnitude of the electric potential and the pollution

level is very low and easily controlled. From the

advantages offered, the electrosynthetic technique is

more advantageous than conventional synthetic

methods, which are strongly influenced by pressure,

temperature, catalyst and concentration (Cheng,

2009).

The principle of the electrosynthetic method is

based on the application of electrochemical theories

as explained previously. Both electrosynthetic

techniques and conventional synthetic methods have

the same variables such as temperature, solvent, pH,

reactant concentration, mixing method and time. But

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

240

the difference, if electrosynthetic has additional

variables namely electrical and physical variables

such as electrodes, electrolyte types, multiple

electrical layers, material / type of electrode,

electrolytic cell type used, electrolysis media and

stirring degree. In electrolysis cells there will be

chemical changes in the area around the electrode,

because of the flow of electricity. If no chemical

reaction occurs, the electrode will only be polarized,

due to the electrical potential given. Chemical

reactions will only occur if there is an electron

transfer from the solution to the electrode (oxidation

process), whereas at the cathode there will be an

electron flow from the cathode to the solution

(reduction process). The process of electron

displacement is distinguished by the displacement of

primary electrons, meaning that the subject matter

reacts directly to the surface of the electrode, while

in the secondary electron transfer, electrons will

react with supporting electrolytes, so that an

intermediate reactant will be generated which will

react further with subject matter in solution. These

reactants can be produced internally or externally

(Lawrence, 2016; Cheng, 2009).

The electrosynthetic method has been widely used

by researchers in synthesizing organic compounds

(organic electrosynthetic) and electrosynthetic organic

conductors as well as those that are not less

prestigious and currently being developed are the use

of pollutants into useful compounds through

electrosynthetic methods. synthetic organic matter,

based on the reaction of merging, substitution,

cyclization, and elimination reactions followed by

electrochemical rearrangement. This is different from

the conventional method which uses the basis of

aldehyde reduction, alcohol oxidation, nitro

compound reduction and oxidation of sulfur

compounds. The difficulty that arises during organic

electrosynthesis is that if the desired intermediate has

low stability, the way to overcome it is by providing

trapping agents in the solution provided that these trap

substances do not react with electro-active substances

and do not undergo electrolysis (Taufik, 2017).

Some examples of organic electrosynthesis are

the manufacture of chiral drug for the

pharmaceutical industry, synthetic p-aminophenol

through the reduction of electrolysis nitrobenzene,

the manufacture of soda (NaOH) and sulfuric acid

(H

2

SO

4

) from Na

2

SO

4

through the electrochemistry

splitting process, reduction of Triphenyl

biomoethylene compounds into Triphenilethylene

and Triphenylethane and hundreds of other organic

compounds that have been successfully made for the

purposes of medicinal raw materials (Walsh, 1994).

In this research. Lard was extracted used maceration

coupling electrosynthetic method. The concentration

was detected used UV spectofotometry.

2 METHODS

2.1 Investigation Process (Collection,

Preparation and Extraction)

Collecting of sample used purposive sampling

method. In this work, we used pork corneds @ 25 g.

Maceration coupling electrosynthesis was developed

used n-hexane as solvent. Temperature was setting

at 50

o

C, and centrifugation process at 3000 rpm for

20 minutes, and then filtering process used

anhydrous Na

2

SO

4

, dried and then repeated for each

treatment. The electrodes used are Aluminum at the

cathode and anode. Voltage was used 22 EV. The

maceration time was varied at 30, 60, 90, 120, and

180 minutes.

2.2 Physical Properties Analysis

Physical properties was analysed used stain test and

solubility in water test. Stain Test procedured: A

total of 10 drops of fat + 2 mL of ether alcohol

mixture into the test tube, shaken until dissolved.

The mixture is dropped on filter paper, and the

solvent is evaporated and the stain is formed.

Solubility in water Test procedure: A total of 10

drops of fat are mixed with 1 mL of distilled water,

shaken and then left for a while and observed the

solubility properties. Physical properties analysis in

this work used determination of Iodine number,

refractive index, melting point, acid numbers.

3 RESULTS AND DISCUSSION

3.1 Extraction Process

In this work, maceration coupling electrosynthetic

was developed in order to obtain lard in the pork

corned. Non-polar solvent (n-hexane) is used to

accelerate extraction at a temperature of 50

o

C. The

filtering process is carried out with flannel. The

centrifugation process at 3000 rpm for 20 minutes is

intended to precipitate impurities and final

purification is done by filtering used whatman paper

containing anhydrous Na

2

SO

4

to bind water

molecules (Taufik, 2017). Electrode aluminium was

used at the cathode and anode. Voltage = 22 EV.

Development of Maceration Methods in the Investigation and Analysis of Lard in Industrial Food Products to Improve Halal Product in

Indonesia

241

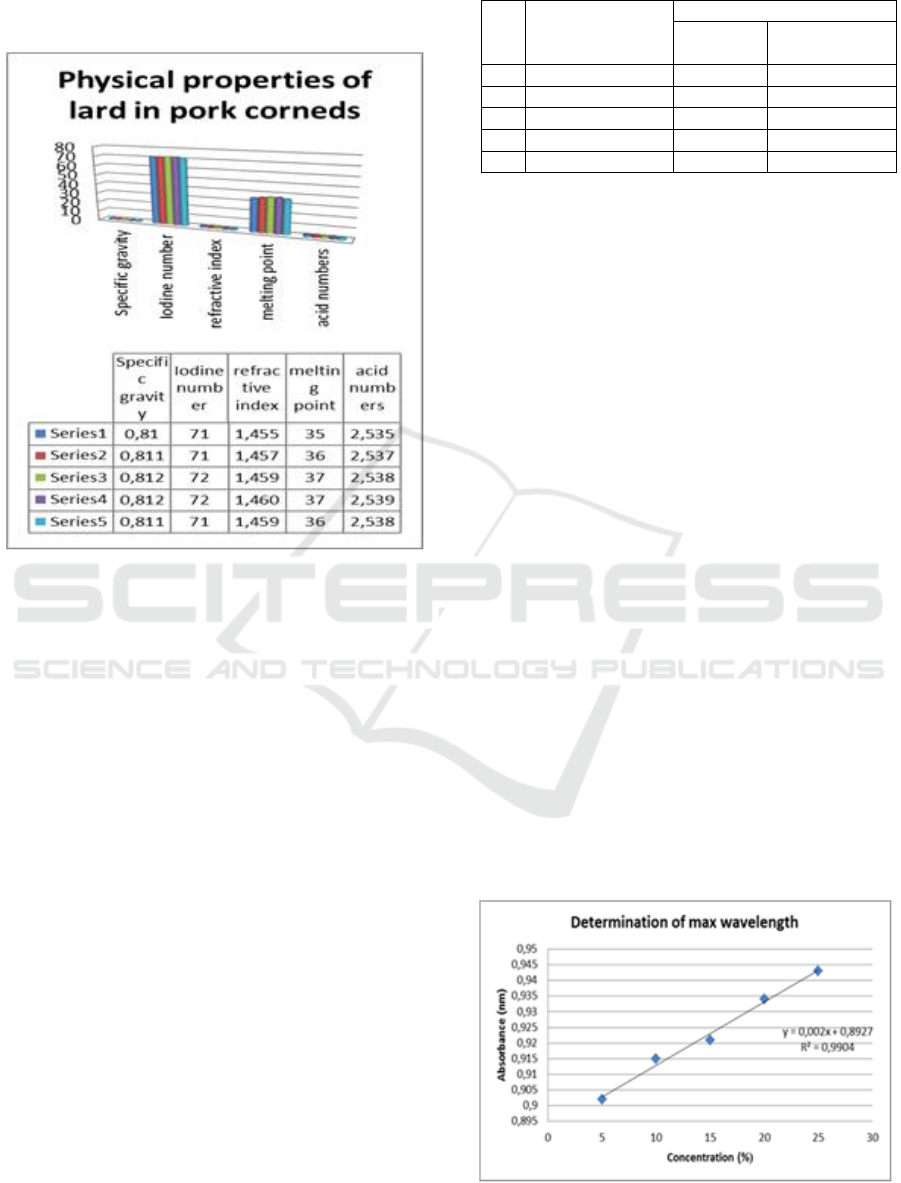

Maceration time was varied at 30, 60, 90, 120, and

180 minutes. Figure 1 showed the results of the

physical properties of lard :

Figure 1: The physical properties of lard.

Figure 1 shows the specific gravity values, iodine

number, refractive index, melting point, and acid

number of lard in pork corned.

The physical properties was obtained is not much

different from the value obtained from reference

(Hilda, 2014) about the physical nature of lard. The

difference in melting point is caused by the fatty

acid composition of each sample extracted in this

work. The amount of saturated fatty acids and long

chain fatty acids contributes significantly to the

increase in overall fat melting point. It also gives a

significant value to the value of iodine, the

composition of unsaturated fatty acids in each

sample extracted with a variation of time 30, 60, 90,

120, 160 minutes will contribute to the increase in

the price of this iodine number.

3.2 Physical Properties Analysis

The Stain test shown the presence of lard contained

in pork corned. The sample is stirred in alcohol ether

into the test tube and then dripped in filter paper, the

oil stains formed indicate the presence of fat. The

water solubility test was also developed and showed

the presence of fat in the extracted sample as shown

in Table 1 about qualitative analysis below:

Table 1: Qualitative analysis data.

No

Maceration time

(min)

Qualitative analysis

Stain test

Solubility in

water

1

30

++

Not dissolved

2

60

++

Not dissolved

3

90

++

Not dissolved

4

120

++

Not dissolved

5

180

++

Not dissolved

Table 1 showed a qualitative analysis of the

presence of lard in the sample. The stain test was

developed simply to see lard in the extraction

preparation. The positive (++) values indicate the

abundance currently in this analysis. Lard obtained

from extraction results is also analyzed for solubility

in water using the solubility test method. The results

obtained showed that all samples were insoluble in

water.

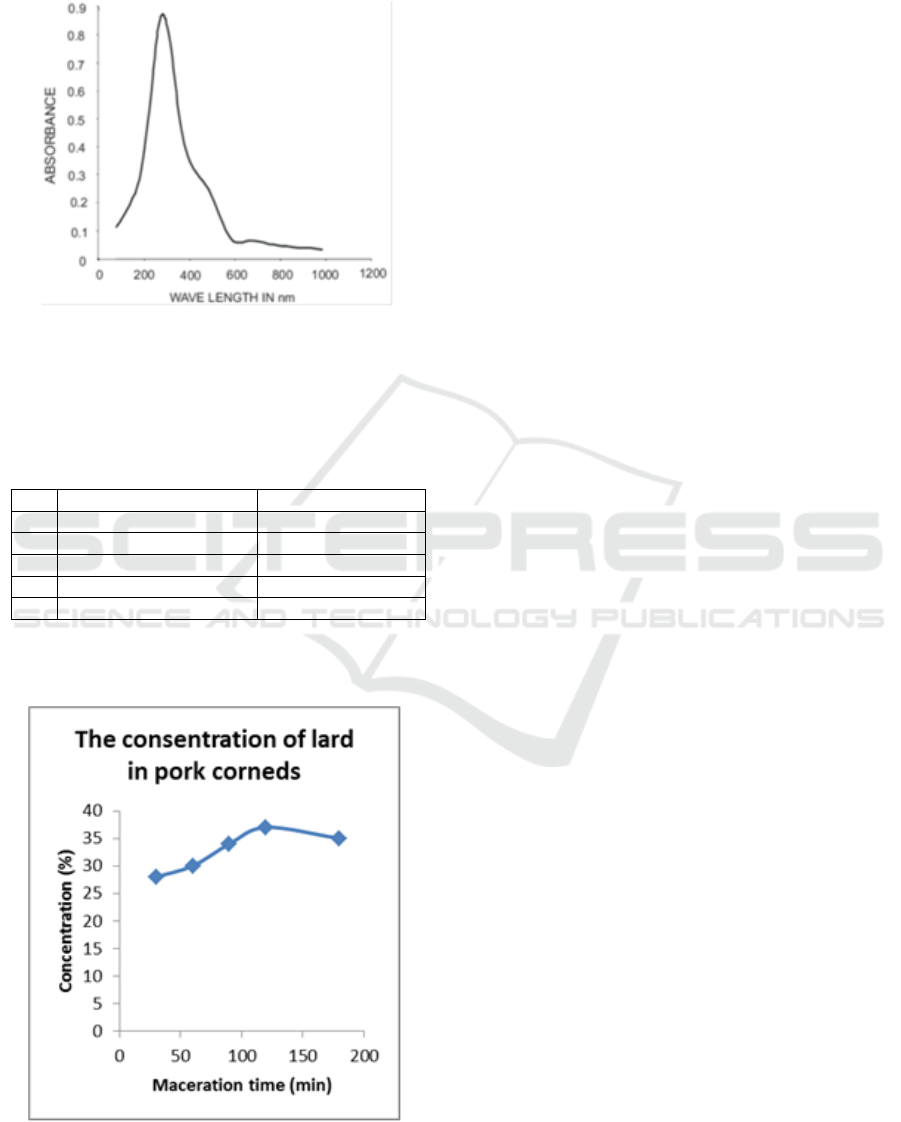

3.3 Spectrophotometry UV

UV spectroscopy using DU640 UV / Vis type using

a wavelength of 200-400 nm. The standard lard

solution is made in concentrations of 5, 10, 15, 20,

25%. This method measured relative light energy if

the energy obtained from the sample is transmitted,

reflected or emitted as a function of the wavelength.

In this work, UV-Vis (Ultra Violet-Visible)

spectrophotometer was chosen from many

instruments commonly used in analyzing lard in

animals. Spectrophotometers are commonly used

because of their ability to analyze so many chemical

compounds and their practicality in terms of sample

preparation when compared with several methods of

analysis. The concentration of the solution analyzed

will be proportional to the amount of light absorbed

by the substance contained in the solution. The

optimum wavelength is obtained at 270 nm with the

absorbance value obtained in Figure 2:

Figure 2: Determination of maximum wavelength (270 nm).

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

242

Figure 2 shows that the straight line equation

produced is 0.002x + 0.8927. The absorbance curve

is generated as shown in the following Figure 3:

Figure 3: The absorbance curve.

The concentration of the sample with five

variations of maceration time is produced in the

following Table 2:

Table 2: Maceration time vs concentration.

No

Maceration time (min)

Concentration (%)

1

30

28

2

60

30

3

90

34

4

120

37

5

180

35

The concentration of lard in pork corneds can be

seen in Figure 4 below:

Figure 4: The concentration of lard in pork corneds.

The optimal maceration time is obtained in 120

minutes. This simple method is able to process data

optimally about the use of UV spectroscopy in the

analysis of lard in the laboratory. However, the

application of the electrochemical method is very

helpful in optimizing the extraction process,

especially in determining fat and oil. This condition

is very advantageous in determining halal products

in Indonesia. This is due to the high demand for

halal products from the people in Indonesia, which

directly require simple and easy to implement

technology must also be met by researchers in

Indonesia. The informal investigation process also

requires a scientific, up-to-date and simple method.

However, this method can be developed with

various considerations of processes that are fast and

easy to follow so that they can become models in

future research.

4 CONCLUSIONS

Investigation of lard in pork corneds (five samples)

have been done. The maceration coupling

electrosynthesis have been developed to extracted of

the lard used variating of extraction time at 30, 60,

90, 120, 150 minutes and we had the optimal time at

120 minutes. The physical properties was carried out

by analyzing iodine numbers, index bias, melting

point, and acid number and the data obtained were

0.893, 72, 1.463, 370C, and 2,542 respectively. Lard

quantity in food produced at the optimal conditions

is 37%. This research will support the improvement

of halal products in Indonesia. This method can be

developed to investigate the other of samples.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge Rector of

University of Sumatera Utara for the financial

support via Penelitian Dasar Talenta Project 2019

contract number: 328/UN5.2.3.1/PPM/KP-

TALENTA USU/ 2019.

REFERENCES

a. N. Nina Naquiah, J. M. N. Marikkar, M. E. S. Mirghani,

A. F. N. & N. A. M. Y., 2017. Differentiation of

Fractionated Components of Lard from Other Animal

Fats Using Different Analytical Techniques. Sains

Malaysiana 46, 209–216.

Development of Maceration Methods in the Investigation and Analysis of Lard in Industrial Food Products to Improve Halal Product in

Indonesia

243

Ardilla, D., Taufik, M., Tarigan, D. M., Thamrin, M.,

Razali, M., Siregar, H. S., 2018. Analisis Lemak Babi

Pada Produk Pangan Olahan Menggunakan

Spektroskopi UV – Vis Analysis Of Lard In The Meat

Processed Using UV - Vis Spectroscopy. Agrintech -

J. Teknol. Pangan Has. Pertan. 1, 111–116.

Burlian, P., 2013. Reformulasi Yuridis Pengaturan Produk

Pangan Halal. Ahkam XIV, 43–52.

Cheng, S. S., Huang, C. G., Chen, Y. J., Yu, J. J., Chen,

W. J., Chang, S. T., 2009. Chemical compositions and

larvicidal activities of leaf essential oils from two

eucalyptus species. Bioresour. Technol. 100, 452–456.

https://doi.org/10.1016/j.biortech.2008.02.038

Erwanto, Y., Rohman, A., Arsyanti, L. and Pranoto, Y.,

2018. Identification of pig DNA in food products

using polymerase chain reaction (PCR) for halal

authentication-a review. Int. Food Res. J. 25, 1322–

1331.

Faridah Jalil, N. M., 2014. Administration and

Enforcement of Halal Certification in Malaysia – a

Possibility towards Cooperative Federalism.

MIHREC.

Fibriana, F., Widianti, T., 2009. Deteksi Kandungan

Daging Babi pada Bakso yang Dijajakan di Pusat Kota

Salatiga Menggunakan Teknik Polymerase Chain

Reaction. Biosaintifi ka 2, 10–17.

Hidayat, A. S., Siradj, M., Selatan, J., 2015. Sertifikasi

Halal dan Sertifikasi Non Halal pada Produk Pangan

Industri. Ahkam XV, 1–12.

Hilda, L., Si, M., 2014. Analisis Kandungan Lemak Babi

dalam produk pangan di Padangsidimpuan secara

kualitatif dengan menggunakan Gas Kromatografi

(GC). Tazkir 9, 1–15.

Lawrence, E. J., Blagg, R. J., Hughes, D. L., Ashley, A.

E., Wildgoose, G. G., 2016. A Combined

“Electrochemical – Frustrated Lewis Pair” Approach

to Hydrogen Activation : Surface Catalytic Effects at

Platinum Electrodes A Combined “Electrochemical –

Frustrated Lewis Pair” Approach to Hydrogen

Activation : Surface Catalytic Effects at Platinum

Electrodes. https://doi.org/10.1002/chem.404242

Razali, M., Siregar, R. T., Sari, N., Sinaga, M. H., 2018.

Analisis Mikrobiologi Forensik Total Mikroba Sosis

Sapi yang Bercampur Lemak Babi dalam Rangka

Kehalalan Produk. AGRINTECH - J. Teknol. Pangan

Has. Pertan. 2, 33–39.

Rendle, D. F., 2005. Advances in chemistry applied to

forensic science. Chem. Soc. Rev. 34, 1021–1030.

https://doi.org/10.1039/b415890n

Rohman, A., Triyana, K., Sismindari, S., Erwanto, Y.,

2012. Differentiation of lard and other animal fats

based on triacylglycerols composition and principal

component analysis Fourier Transform Infrared

Spectroscopy applied for rapid analysis of lard in palm

oil. Int. Food Res. J. 19, 1161–1165.

Salehudin, I., 2014. Halal Literacy : A Concept Exploration

and Measurement Validation. SSRN Electron. J. 1, 1–

21. https://doi.org/10.2139/ssrn.2004762

Sisco, E., Najarro, M., Burns, A., 2018. A snapshot of

drug background levels on surfaces in a forensic

laboratory. Forensic Chem. 11, 47–57.

https://doi.org/10.1016/j.forc.2018.09.001

Taufik, M., Ardila, D., Razali, M., Alfian, Z., 2019.

Investigation of Lard on Pork Nuggets using UV

Spectrophotometry. Indian J. Sci. Technol. 12, 10–13.

https://doi.org/10.17485/ijst/2019/v12i2/138333

Taufik, M., Taufik, M., Wanto, R., Cibro, S. R., Ardilla,

D., Razali, M., Tarigan, D. M., 2017. Studi

Pendahuluan Maserasi Coupling Elektrosintesis

Dalam Mengekstraksi Nikotin Yang Terkandung

Dalam Puntung Rokok, in: Seminar Nasional Kimia

Unmul 2017.

Walsh, F., Reade, G., 1994. Design and performance of

electrochemical reactors for efficient synthesis and

environmental treatment. Part 1. Electrode geometry

and figures of merit. Analyst 119, 1–7.

https://doi.org/10.1039/an9941900791

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

244