Analysis of Denoising Method and Study of Denoising Fusion

Optimization Algorithms for Industrial Gear Image

Dan Liu

1, 2, a

, Xiaogang Wang

1, 2

and Shuchuan Gan

1, 2

1

School of automation and information engineering, Sichuan university of science and engineering, Yibin, 643030, China

2

Artificial intelligence key laboratory of Sichuan,Yibin, 643030, China

Keywords: Industrial gear, Image processing, Filter method, Optimization algorithms.

Abstract: Aiming at the problem of noise filtering in the detection of industrial gear defects by machine vision

technology, this paper makes some analysis and study for industrial gear image. For the analysis of

denoising method, it uses the method of MATLAB numerical simulation to apply single noise (like Gauss

noise, salt and pepper noise, multiplicative noise) to gear image, and uses median filter, mean filter,

Gaussian smoothing filter and Wiener filter separately to filtering and compare the different filtering effects.

For the study of denoising fusion optimization, a neighborhood mean method based on extremum median

filter and a fusion filter method are proposed for the mixed noise. The simulation results show that the

median filtering is the best for salt and pepper noise, the smooth filtering and Wiener filtering are better for

Gauss noise and multiplicative noise, and the fusion filtering method with improved mean filtering is the

best for gear images with mixed noise.

1 INTRODUCTION

As the basic element of industry, gear is the most

basic and key component in manufacturing

equipment industry. Its precision directly affects the

working performance and service life of the machine,

so the quality inspection technology of gear has

become a focus of attention and research (

Yang, Y.H.

Yang, Y. and Yu C. B, 2018)

. In recent years, machine

vision technology has been widely used in defect

detecting of product and image recognition (

César, D.

Jónathan, H. and Pascual, V, 2017

; Ma, Y. Jiang, Q. 2018),

the technical scheme is mature, which improvs the

quality and the flexibility of industrial production.

Therefore, it can also be applied to the real-time

monitoring of industrial gear (

Wu, Q. Gu, J.N. and

Zhang, P.L, 2017

; Yin, H.M, 2017).

The defect detecting of gear based on image

recognition mainly includes image preprocessing

(filtering and enhancement) (

Dong, C.Z. Ye, X.W. and

Jin, T, 2017), edge inspection (Peng, H. Zhao, P.B,

2017), target extraction (Shan, Z.W, 2017), region

segmentation and defect feature extraction (

Cui, J.H.

Zhao, W.X. and Wang, X.Z, 2009). Among them filter

regards primary job, its importance is self-evident.

For the detection of engine defects, Xiao Jing

proposed wavelet transform can be applied to image

denoising (

Xiao, J. You, S.H, 2018), and the effect was

greatly improved compared with the median filtering.

For the needs of image processing, Bi Siwen

proposed an image denoising algorithm based on

double tree complex wavelet transform. Compared

with other methods (

Bi, S. Chen, W.H. and Shuai, T. et

al, 2019), the PSNR of the denoised image was

improved 0.2dB. In the sonar detection image of

submarine pipeline, it is easy to be influenced by the

external environment. On the basis of wavelet, Liu

Xiaojuan et al. proposed an ultra-wavelet ridged

wave transform with the function of maintaining

linear features such as obvious edges (

Zhang, X.J. Liu,

Z. and Yang, X. et al, 2017)

. For the industrial gear, its

image mainly includes the noise of itself, the

electronic noise generated by the high-speed camera,

and the quantization noise of the digital image.

Among them, the noise of itself is mainly affected

by the environment, such as light and air quality.

The noise can be controlled and can be ignored due

to the small error. Digital image noise is generated

in the process of digital sampling of the original

image and it is inevitable. For the electronic noise

produced by high-speed camera, it cannot be ignored

and is the most important factor affecting the gear

image. Gear image noise can be divided into

244

Liu, D., Wang, X. and Gan, S.

Analysis of Denoising Method and Study of Denoising Fusion Optimization Algorithms for Industrial Gear Image.

DOI: 10.5220/0008873502440250

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 244-250

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

gaussian noise, salt-pepper noise and multiplicative

noise. Because of that each noise has its own

characteristics, so different filtering methods are

required (Li, J. Deng, F. and Chen, J, 2018; Erkan, U.

Gökrem, L. and Enginoğlu, S, 2018).

In order to get better image preprocessing effect,

the MATLAB is used to simulate calculation (

Li,

X.M. Zhang, Q.W. and Ying, G.Z, 2012), the noises in

gear images are filtered by various methods, and the

best filtering method of each noise is obtained.

Finally, the best filtering method to a mixture of

gaussian noise and multiplicative noise of the gear

image is obtained.

2 FILTERING ANALYSIS

Assuming that industrial gear images mainly

includes gaussian noise, salt-pepper noise and

multiplicative noise. Median filter, mean filter,

gaussian smooth filter and two-dimensional adaptive

wiener filter are proposed to filter the above noises

respectively, and the optimal filtering method of

each noise can be obtained.

2.1 Gaussian Noise

Gaussian noise in industrial gear images mainly

comes from the electronic noise generated by high-

speed cameras. Due to the extremely short exposure

time and sufficient light in the real-time monitoring

process of gears, the noise of high-speed cameras

conforms to the characteristics of gaussian noise.

Gaussian noise can be expressed by probability

density function.

22

1

() exp[( )/2 ]

2

px x u

(1)

x

is pixel value,

u

is the average of image gray

value,

2

is the standard deviation of pixel value, is

the variance of pixel value. In the Matlab program,

the density of gaussian noise depends on the formula

2

(, )Gu

. For each input pixel value, a normal

gaussian sampling distribution formula can be used

to obtain the output pixel value.

2

+()P x uMeans G d

(2)

d

is a linear random number and

()Gd

is the

gaussian random value of the random number. The

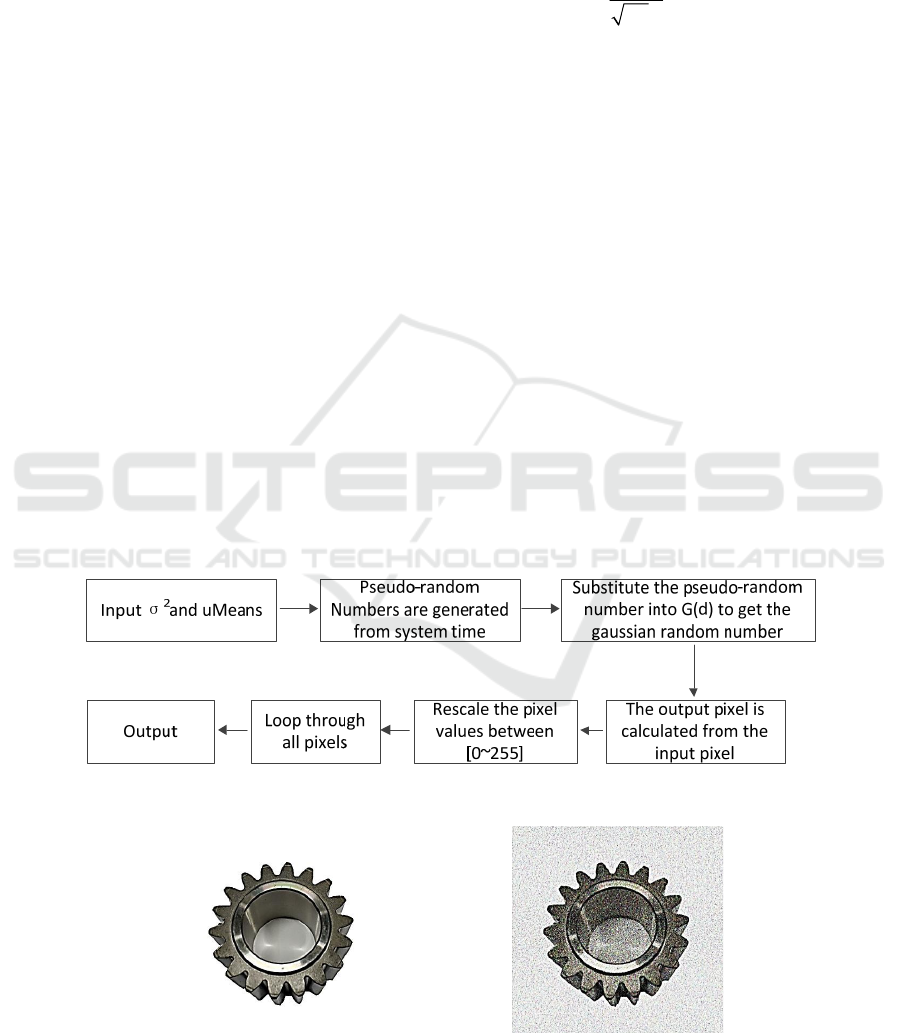

sequence of adding gaussian noise to the gear image

is shown in Fig.1.

According to the process in Fig.1, gaussian noise

is adding to the original gear image in Matlab, where

the

u

is 0 and the

2

is 0.05. The results are shown

in Fig.2, where Fig.2 (a) is the actual image of the

industrial gear and Fig.2 (b) is the image after

gaussian noise is applied.

Figure 1. Sequence of adding gaussian noise.

Figure 2(a). Original gear image. Figure 2(b). Adding gaussian noise.

Analysis of Denoising Method and Study of Denoising Fusion Optimization Algorithms for Industrial Gear Image

245

Figure 3(a). Median filtering. Figure 3(b). Mean filtering.

Figure 3(c). Gaussian smooth filtering. Figure 3(d). Wiener filtering

As shown in Figure 2(b), gaussian noise is a

color noise. Median filter, mean filter, gaussian

smooth filter and two-dimensional adaptive wiener

filter are respectively performed on the gear images.

The filtering result of each method is shown in

Figure.3.

As shown in Fig.3, there is little difference in

subjective evaluation of gaussian noise. From the

perspective of objective evaluation, peak-signal-to-

noise-ratio (PSNR) is proposed to carry out full

reference evaluation in order to clarify the

advantages and disadvantages of each filtering

method. The PSNR values of each method are

shown in Table 1.

Table 1. Evaluation index of image filtering with

gaussian noise.

Methods Noise

image

Median

filtering

Mean

filtering

Gaussian

smooth

filtering

Wiener

filtering

PSNR

21.71 31.39 32.114 32.987 34.46

It can be seen from Table 1 that PSNR value of

gear image with noise is 21.715dB.The PSNR values

after median, mean and gaussian smoothing filter are

all around 32dB.The image quality after wiener

filtering is obviously better than the other three

methods. The PSNR values of images filtered by

each method are: wiener filter>aussian smooth

filter>mean filter>median filter, so the best method

to filter gaussian noise is wiener filter.

2.2 Salt-pepper noise

The salt-pepper noise may be produced in the

process of high-speed photography and digital image

quantization. Salt-pepper noise is a random

occurrence of white or black dots. The sequence of

adding salt-pepper noise in the digital image is

shown in Fig.4.

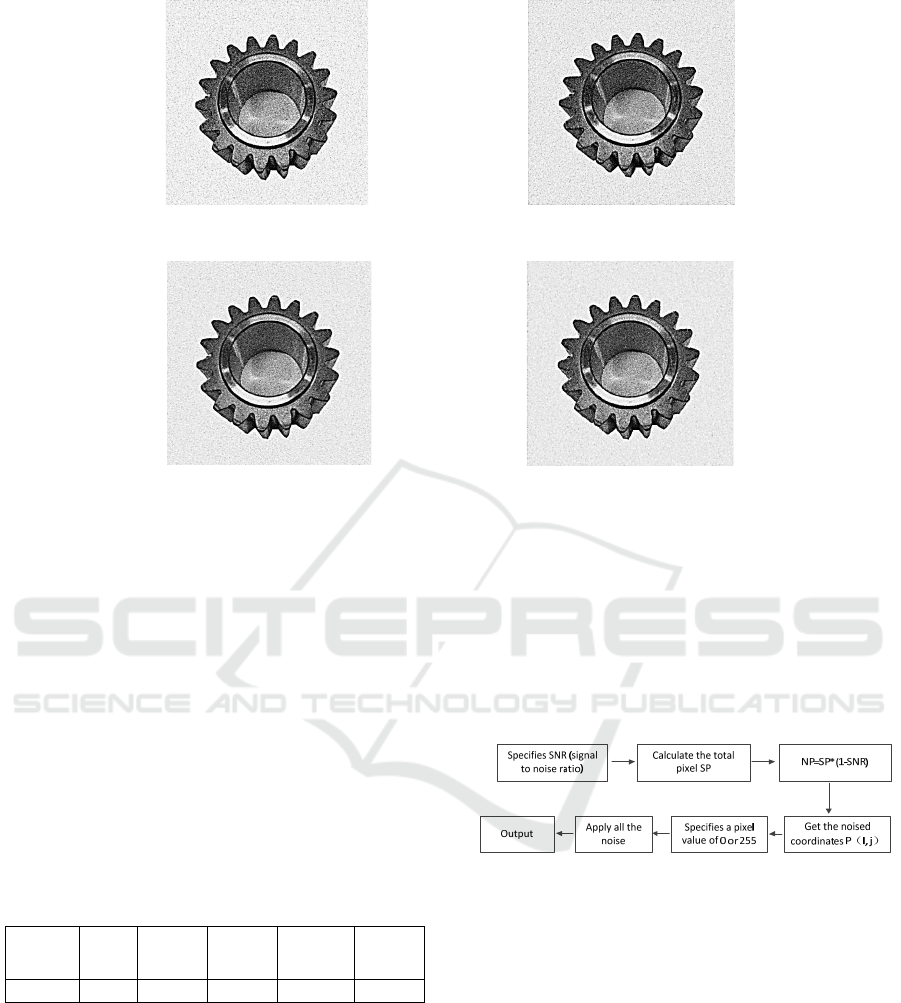

Figure 4. Sequence of adding salt-pepper noise in gears

image.

In MATLAB, salt-pepper noise is adding to gear

image, where SNR is 0.05. Fig.5 is the gear image

with salt-pepper noise.

As shown in Fig.5, black or white dots appear in

the image after noise is added, which conforms to

the characteristics of salt-pepper noise. Median filter,

mean filter, gaussian smooth filter and two-

dimensional adaptive wiener filter were applied to

the gear images. The filtering effect of each method

is shown in Fig.6.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

246

Figure 5. Adding salt-pepper noise.

Figure 6(a). Median

filtering.

Figure 6(b). Mean filtering.

Figure 6(c). Gaussian

smooth filtering.

Figure 6(d). Wiener filterin.

As shown in Fig.6, for the salt-pepper noise in

gear image, the median filter has the best effect and

basically eliminates the black and white noise.

Among other filtering methods, the gaussian smooth

filter is better than wiener filter and mean filter, but

the filtering effect cannot be compared with the

median filter. It is difficult to meet the requirements

of image post processing. The reason is that in the

process of median filtering, the value of each

position in the filtering matrix is replaced by the

median value, while the pixel value of the black

point is 0 and the white point is 255, which belongs

to the extreme value at both ends of the pixel. When

the median value is taken, it can be basically

eliminated, so that the filtering effect is better.

Therefore, median filter should be used to

preprocess industrial gear images with salt-pepper

noise.

2.3 Multiplying Noise

Assuming that the pixel of the gear image is

(, )

f

ij

and the pixel of the noise is

(, )hi j

, then both

gaussian noise and salt-pepper noise belong to

additive noise, the total pixel of the noise-containing

image is

(, ) (, )

f

ij hij

. If the total pixel value of

the image is

(, ) (, )

f

ij hij

, the noise is

multiplicative noise. The multiplicative noise is

closely related to signal of gear image. It varies with

the intensity of the image signal. For the industrial

gear image, in the process of image acquisition and

image digitization, there will be some multiplicative

noise due to the camera particle noise and other

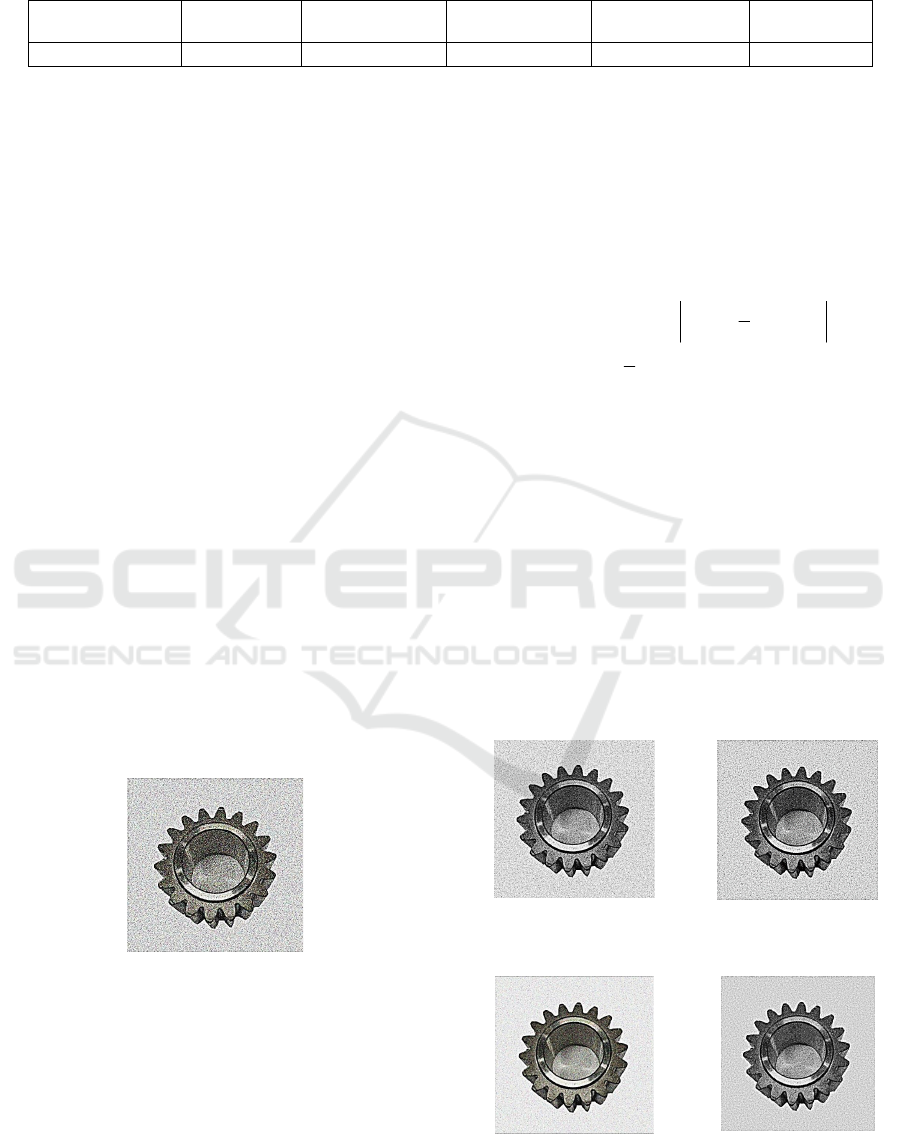

reasons. Fig.7 shows the superposition of

multiplicative noise in the original image.

Figure 7. Adding multiplicative noise.

As shown in Fig.7, compared with gaussian

noise and salt-pepper noise, multiplicative noise is

more densely distributed and has a greater impact on

the image. Median filtering, mean filtering, gaussian

smoothing filtering, and two-dimensional adaptive

wiener filtering were performed on the gear images.

The filtering effect of each method is shown in Fig.8.

Figure 8(a). Median

filtering.

Figure 8(b). Mean

filtering.

Figure 8(c). Gaussian

smooth filtering.

Figure 8(d). Wiener

filtering.

Analysis of Denoising Method and Study of Denoising Fusion Optimization Algorithms for Industrial Gear Image

247

Table 2. Evaluation index of image filtering with gaussian noise.

Methods Noise image Median filtering Mean filtering

Gaussian smooth

filtering

Wiener

filtering

PSNR 24.32 32.835 33.008 33.752 36.813

Similar to gaussian noise, the above four filtering

methods have little difference in subjective

evaluation. In terms of objective evaluation, PSNR

was used for full reference evaluation. The PSNR

values of each method are shown in Table 2.

It can be seen from Table 2 that the PSNR values

of images with multiplicative noise are all around

33dB after the median, mean and gaussian

smoothing filtering. However, the wiener filtering is

obviously better than the other three methods, and

the peak-signal-to-noise-ratio after denoising is

36.813dB.

From what has been discussed above, wiener

filter has the best effect among all kinds of noise

filtering methods for gear image. It is suitable for

gaussian noise and multiplicative noise. For salt-

pepper noise, the median filter should be selected.

3 OPTIMIZED FILTERING

After median filtering, the quality of gear image

with salt-pepper noise basically meets the

requirements of image post-processing. Therefore,

salt-pepper noise is no longer considered in the

fusion noise, and gaussian noise and multiplicative

noise are mainly superimposed. As shown in Fig.9,

gaussian noise and multiplicative noise are

superimposed on the original image.

Figure 9. Gear image with gaussian noise and

multiplicative noise.

3.1 Improved Mean Filtering

When filtering the gear image with fusion noise, the

conventional filtering method is that all pixels are

processed in the same way, but the filtering effect is

poor. Based on the idea of extreme median filtering,

the mean filtering can be improved and get the

neighborhood mean method of domain value based

on extreme median filtering. The basic idea is: select

a pixel of the gear image, if the difference between

its gray value and the average gray value of its

neighborhood is greater than the given maximum

value M(or less than the given minimum value N),

then the average gray value of its neighborhood can

be used to replace. The expression is as follows:

,

,

1

(, ), (, ) ( , )

(, )

1

(,) else

mn C

mn C

f

xy N f xy f mn M

T

fxy

fmn

T

,

(3)

(, )

f

xy

is the gray value of the original image

containing

SS

pixels, and

(, )

f

xy

is the gray

value of the processed image, x, y=0,1,2...S-1, C is

the set of coordinates in the neighborhood of the

(x,y), but it doesn't include the point (x,y), T is the

total number of coordinate points in the set.

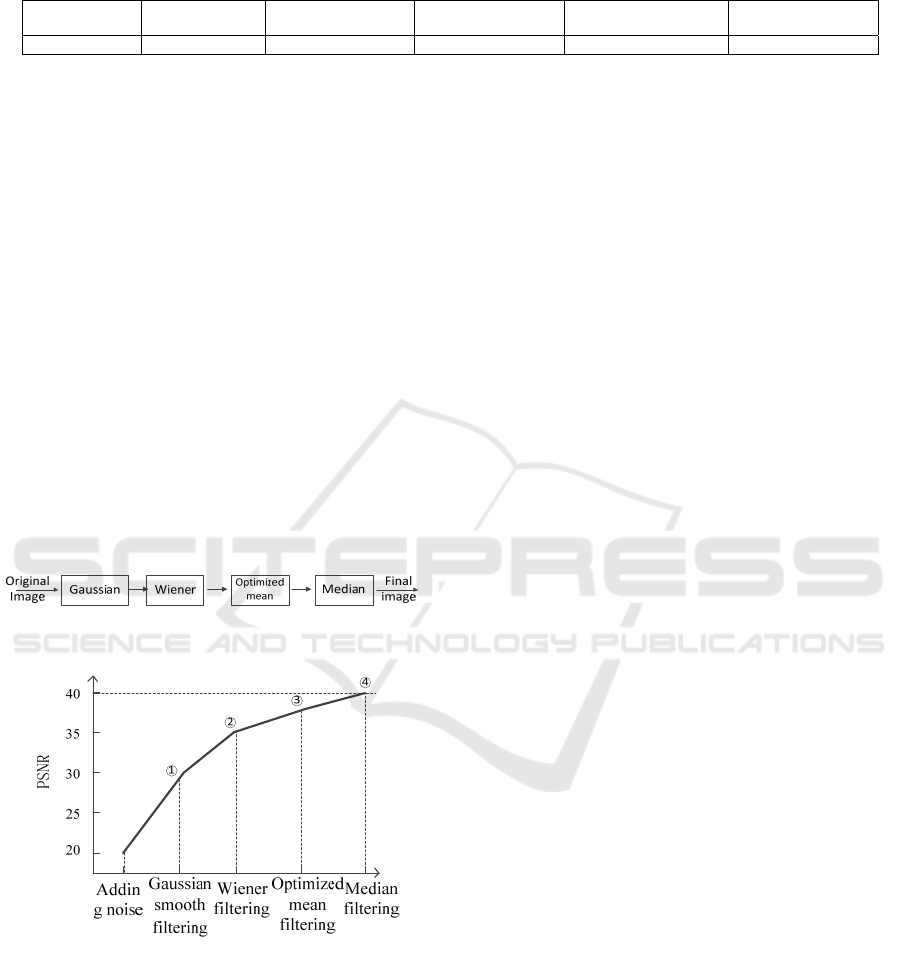

3.2 Composite Filtering

The gear images with fusion noise (gaussian noise

and multiplicative noise) are filtered by the above

four methods separately, and the filtering effect of

each method is shown in Fig.10.

Figure 10(a). Median

filtering.

Figure 10(b). Mean

filtering.

Figure 10(c). Gaussian

smooth filtering.

Figure 10(d). Wiener

filtering.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

248

Table 3. Filtering evaluation indicators for images with multiplicative noise.

Methods Noise image Median filtering Mean filtering

Gaussian smooth

filtering

Wiener filtering

PSNR 20.32 29.530 29.688 32.091 31.715

As shown in Fig.10, median filtering and mean

filtering are poor. PSNR is still used for full

reference evaluation in objective evaluation to

characterize the effect of each filtering method. The

PSNR values of each method are shown in Table 3.

It can be seen from Table 3 that after median

filtering or mean filtering, the PSNR value of the

noise image is about 29dB. However, the image

quality after wiener filtering or gaussian smooth

filtering is relatively good, and PSNR is 32dB, with

better filtering effect.

In order to get the best filtering effect, multi-

method superposition filtering is performed on the

gear image on the basis of single filtering. As shown

in figure 11, the original image is firstly processed

by gaussian smooth filtering, then the secondary

image is processed by wiener filtering, next the

above improved mean filtering is performed, and

finally the fourth image is processed by median

filtering. Fig 12 shows the change of PSNR value of

the original image after each filtering method.

Figure 11. Sequence of fusion filtering.

Figure 12. Multiple filtering of the fusion model.

As shown in Fig.12, after median filtering and

mean filtering, the noise in the gear image basically

disappears. And PSNR value of the image is

basically equal to the original image, with good

filtering effect. It can be seen from the slope of

broken line, the gaussian filter has the highest slope

and the best filtering effect. After gaussian filtering

and wiener filtering, most of the image noise

disappears, which is consistent with the conclusion

in Table 3.

4 CONCLUSIONS

In order to describe all kinds of noise that may be

encountered in the process of industrial gear image

processing, single noise model and the fusion noise

are analyzed respectively. The following

conclusions are as follows: firstly, the median filter

method should be used to remove the salt-pepper

noise in the gear image, the result is obviously,

which can basically remove all the noise. Secondly,

for gaussian noise and multiplicative noise, the

effect of each filtering method is little different,

which can filter noise to some extent, the two-

dimensional adaptive wiener filtering method is little

better. For the fusion noise, when there are three

kinds of noise in the image, the salt- pepper noise

can be filtered out by the median filtering, gaussian

smoothing and Wiener filtering are used to filter out

the remaining Gaussian noise and multiplicative

noise. Finally, on the basis of the existing filtering

methods, a new filtering method is proposed for gear

image noise, and the filtering effect is obvious.

ACKNOWLEDGEMENTS

This work is supported by the Foundation of

Sichuan Educational Committee of China (Grant

No.18ZA0357), Sichuan Science and Technology

Program of China(Grant No.2018JY0197,

2016SZ0074), Foundation of Artificial Intelligence

Key Laboratory of Sichuan Province (2017RZJ02),

Nature Science Foundation of Sichuan University of

Science &Engineering (No. 2017RCL12), and

Foundation of Deyang Open School-City

Cooperative Technology Research and Development

(Grant No. 2018CKJSD017).

REFERENCES

Bi, S. Chen, W.H. and Shuai, T. et al(2019),”An Image

Denoising Algorithm Based on Doubletree Complex

Analysis of Denoising Method and Study of Denoising Fusion Optimization Algorithms for Industrial Gear Image

249

Wavelet Transform”, radio engineering, vol.49 No.1 ,

pp.27-31.

Cui, J.H. Zhao, W.X. and Wang, X.Z. (2009),”Research of

Image Feature Extraction”, Journal of Hebei

University (Natural Science Edition), vol. 29 No.1,

pp.106-112.

César, D. Jónathan, H. and Pascual, V. (2017), “IJ-

OpenCV: Combining ImageJ and OpenCV for

processing images in biomedicine”, Computers in

Biology and Medicine, vol.84, pp.189-194.

Dong, C.Z. Ye, X.W. and Jin, T. (2017), “Identification of

Structural Dynamic Characteristics Based on Machine

Vision Technology”, Measurment, vol S0263-2241 No.

17, pp. 30615-2.

Erkan, U. Gökrem, L. and Enginoğlu, S. (2018),”

Different applied median filter in salt and pepper

noise”, Computers & Electrical Engineering, vol.70,

pp.789-798.

Li, J. Deng, F. and Chen, J. (2018),” A Fast Distributed

Variational Bayesian Filtering for Multisensor LTV

System With Non-Gaussian Noise”, IEEE

Transactions on Cybernetics, pp (99).1-13.

Li, X.M. Zhang, Q.W. and Ying, G.Z.(2012),”A Matlab -

based Visual System Design for Image

Denoising”,Journal of Hangzhou Normal University

(Natural Science Edition), vol.11 No. 6, pp.551-555.

Ma, Y. Jiang, Q. (2018), “A robust and high-precision

automatic reading algorithm of pointer meters based

on machine vision”, Measurement Science and

Technology, vol.015401, pp.

Peng, H. Zhao, P.B. (2017),”Improved Mean Filtering

Algorithm in Edge Detection”, Computer Engineering,

vol.43 No. 10, pp.172-178.

Shan, Z.W. (2017), “Research of Gear Image Boundary

Extraction Algorithm Based on Machine Vision

Measurement”, Shengyang University of Engineering.

Wu, Q. Gu, J.N. and Zhang, P.L. (2017), “Research on

Spur Gear Recognition Technology Based on Image

Processing”, Tool technology, 6.

Xiao, J. You, S.H. (2018), “Denoising Method of Engine

Surface Defect Image Based on Wavelet Transform”,

Surface Technology, vol.47 No. 12, pp.328-333.

Yang, Y.H. Yang, Y. and Yu C. B. (2018),”Research and

Application of SURF and Gray Difference in

Detection of Small Modulus Plastic Gear Defect”,

Mechanical transmission, vol.257 No.5, pp.162-166.

Yin, H.M. (2017),” Research on Gear Detection and

Measurement System Based on Machine Vision”,

Liaocheng University.

Zhang, X.J. Liu, Z. and Yang, X. et al (2017),” Research

on the Method of Sonar Seabed Pipeline Image

Denoising”, Journal of Ocean Technology.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

250