Phase Formation of M-Type BaFe

12

O

19

/ZnO Magnetic Material

Syahrul Humaidi

1*

, Tua Raja Simbolon

1

, Diana A Barus

1

, Veryyon Hrp

1

, Perdamean S

2

, Chandra K

2

,

Eko Arif S

2

and Silviana S

3

1

Department of Physics, Universitas Sumatera Utara, Jln Bioteknologi 1 Padang Bulan, Medan 20155, Indonesia

2

Research Center for Physics, Indonesian Intitute of Sciences (LIPI), Puspiptek, Serpong, TangSel, Indonesia

3

Mechanical Engineering, Universitas Pamulang, Jl. Rajawali Blok G No.33 Tangerang Selatan, Banten 15417

simbolonsilvi@gmail.com, candra.fisika.lipi@gmail.com, eko.arif.setiadi@lipi.go.id

Keywords: BaFe

12

O

19

, HEM, magnet.

Abstract: High Energy Milling (HEM) followed by heat treatment was used to prepare M-type BaFe

12

O

19

/ZnO magnetic

material in toluene media. High purity of BaFe

12

O

19

and ZnO powder was milled for 12 h followed by drying

for 4 h before being calcined at a temperature of 900

o

C. The powder was then filtered by using T-200. An

appropriate amount of BaFe12O19 and ZnO were then mixed in wet-milling for 15 mins and dried at 200

o

C

for 1 h. The magnetic properties were analysed using VSM, whereas the phase formation was derived from

XRD-pattern (powder method) using X-ray CuKα 40kV-30mA with λ= 1.5418 Å. The phase occurrence was

determined using MATCH-software program. It was obtained that BaFe

12

O

19

lattice parameter: a = 5.8930

Å, c = 23.1940 Å. In order to get soft magnetic state, ZnO was added with a composition of: 0/100, 25/100,

50/100, 75/100, respectively. It was found that addition of 75% ZnO to BaFe

12

O

19

converted hard magnet to

soft magnet.

1 INTRODUCTION

It has been known that the magnetic material

development is very vast in practical technical use

and industry application. Magnetic materials are used

in electronics, sensors, biomaterial as well as

transportation. Since 1950s, there were intensive and

extensive researches have been done. This kind of

material became interesting in the hexagonal ferrites,

known as hexaferrites [Pullar, 2012], which is

increasing exponentially until nowadays.

Barium hexaferrite (BaFe

12

O

19

) is a permanent

magnet based on ferrite (Ahmed et al, 2013; Yu,

2013). BaFe

12

O

19

is a type of M-ferrite hexagonal

(Ba-M) has some advantages compare to other

materials. The advantages of this material are: high

coersivity and high Curie temperature (An, 2014;

Burak, 2015), chemical stability, corrosion resistant,

high coersivity (Burak Kaynar, 2015). These good

characteristics make this M-type of magnet becomes

an interesting material to be developed.

Many methods of synthesis have been developed

over the laboratory and research centre over the world

to obtain a low production cost of powder particles of

barium hexaferrite. The scientists have been

developing many methods like powder metallurgy

method and chemical routes such as sol-gel method

as well as co-precipitation method (Setiadi et al,

2015). Setiadi (2018) also reported the application of

the powder magnetic material as Pb ion adsorbent.

Syahrul Humaidi (2015) has reported the role of Cu

2+

in BaFe

12-x

Cu

x

O

19

preparation.

Sintering process is widely used to modify the

characteristics of the magnet. It is common that some

additives may be used to enhance the characteristic of

the magnet such as silica (SiO

2

), Al

2

O

3

, Na

2

O, Fe

2

O

3

.

Not only dampen the grain growth, but also those

additives have the ability to serve lower the sintering

temperatures (Li et al., 2012). Supradedi et al (2017)

have investigated the addition of Na

2

O to BaFe

12

O

19

.

All of them reported that the composition of additive

Na

2

O at the sintering temperature 1200

o

C did not

influence the crystal structure. In this work,

BaFe

12

O

19

magnet was prepared by High Energy

Milling (HEM) method and ZnO was used as additive

to the phase formation of M-type BaFe

12

O

19

. The

main goal of the work is a change from hard magnetic

to soft magnetic.

Humaidi, S., Simbolon, T., Barus, D., Hrp, V., S, P., K, C., S, E. and S, S.

Phase Formation of M-Type BaFe12O19/ZnO Magnetic Material.

DOI: 10.5220/0008856701130115

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 113-115

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reser ved

113

2 MATERIALS AND METHODS

The preparation of the magnetic material using solid

state reaction method was started from preparation of

precursor: BaFe

12

O

19

powder and ZnO powder. At

first, barium ferrit as a matrix was mixed together

with ZnO powder in wet medium (toluene) and

experienced High Energy Milling (HEM) for 12 h.

The powder was then dried at 200

o

C for 4 h in oven

before sintering at 900

o

C for 3 h. Rigaku Smartlab

X-Ray Diffraction (XRD) Cu Kα (30kV, 40mA, λ =

1.5406 Å) was used to collect the maximum peaks

XRD-pattern. Analyse of the pattern was used by

MATCH program. Permagraph was used at room

temperature and normal atmosphere to get magnetic

properties in hysteresis curve form.

3 RESULTS AND DISCUSSION

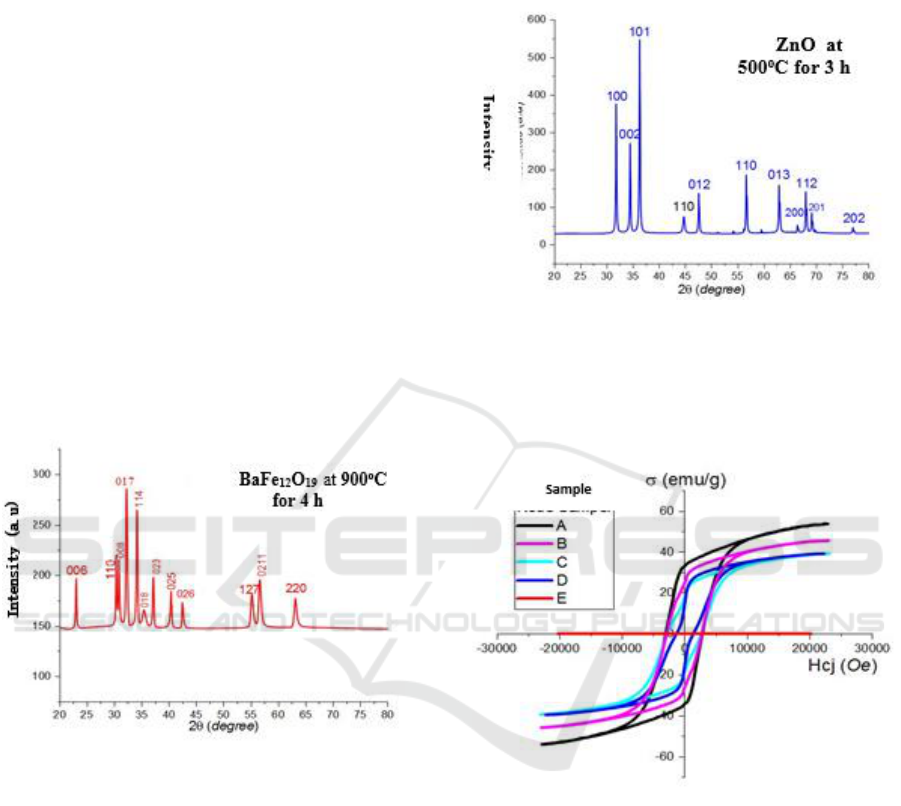

XRD-pattern of Ba-hexaferrit is shown in Figure 1,

whereas the ZnO phase is shown in Figure 2.

Figure 1: XRD -pattern of BaFe

12

O

19

at 900

o

C/4 h.

It can be seen clearly that four maximum peaks:

(110), (008), (017), and (114) occur in 30

o

< 2θ < 40

o

.

The occurrence of these peaks indicate that the phase

occurrence corresponds to BaFe

12

O

19

structure as a

major phase. This results are in a good agreement

with the previous finding (Syahrul Humaidi, 2015).

This sample has a hexagonal crystalline structure

whose space group (P63/mmc) with lattice parameter:

a = 5.8930Å and c=23.1940 Å. Preparation of ZnO

precursor with sintering temperature at 500

o

C as

shown in Figure 2 also a confirmation of ZnO as a

major phase. It can be seen that three maximum

peaks: (100) related to 2θ= 31.80

o

; (002) at 2θ= 31.8

o

and (101) at 2θ= 34.42

o

. According to the results of

MATCH program, the crystalline structure of ZnO is

hexagonal with the value of a parameter = 3.22Å and

b= 5.22Å space group of P63mc (wurtzite). As such,

ZnO can be used as a filler to barium-hexaferrit

magnet.

Figure 2: XRD -pattern of ZnO at 500

o

C/3 h.

Figure 3 tells magnetic characteristics of produced

composite magnet. Based on this graph, the value of

magnetic remanence (Mr) as well as coersivity (Hcj)

can be gained as tabulated in Table 1.

The curve style as presented in Figure 3 starts to

deviate in the composition of (50/50) % weight of the

precursor. A narrower curve can be observed in the

composition of (25/75) % weight of ZnO. Based on

the graphs, it can be concluded that the addition of

75%-weight of ZnO has turned the hard magnetic into

soft magnetic. The value of soft magnetic properties

can be referred on Table 1. As it can be seen, the

smallest value of Mr as well as the Hcj have been

noted in the sample C. However, further investigation

is still needed to confirm this phenomena. Based on

this result, this composition (25% BaFe

12

O

19

+ 75%

ZnO) is reasonable to be developed as a starting

material composition especially in the application of

microwave absorber.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

114

Table 1: Magnetic properties of composite magnet

Sample

code

Mr

(emu/g)

Hcj

(Oe)

A (100/0)

33.06

2943

B (75/25)

24.60

2821

C (50/50)

17.20

2728

D (25/75)

1.27

152.4

E (0/100)

14.69

1365

4 CONCLUSIONS

We have successful prepare a composite magnetic

material BaFe

12

O

19

/ZnO via solid state reaction. The

composition of 25/75 can be referred as a starting

composition in the next soft magnetic investigation.

ACKNOWLEDGEMENTS

We would like to thanks members of Physics

Research Centre (P2F) Serpong for sample

preparation and characterizations.

REFERENCES

Pullar, R., C., 2012, Hexagonal Ferrites: A review of the

Synthesis, Proerties, and Applications of Hexaferrite

Ceramics, Progress in Materials Science, vol 57, Issue

7, pp 1191-1334

An, G. H., Hwang, T. Y., Kim, J., Kim, J. B., Kang, N.,

Kim, S., Choi, Y. M., Choa, Y. H., 2014, Barium

hexaferrite nano particles with high magnetic properties

salt-assisted ultrasonic spray pyrolysis. Journal of

Alloys and Compounds 583 145-150.

Setiadi E. A., Yunus M, Nababan N , Simbolon S ,

Kurniawan C , Humaidi S, Sebayang P and Ginting M,

2018, The effect of temperature on synthesis of

MgFe2O4 based on natural iron sand by co-

precipitation method as adsorbent Pb ion, Journal of

Physics: Conf. Series 985 012046

Burak Kaynar, M., Şadan, Özcan S. Ismat Shah, 2015,

Synthesis and magnetic properties of nanocrystalline

BaFe12O19, Ceramics International, Vol.41, Issue 9,

Part A, Pages 11257-11263

Ahmed, M., A., Helmy, N., El-Dek, S. I., 2013, Innovative

Methodology for the Synthesis of Ba-M hexaferrite

BaFe12O19 nanoparticles Materials Research Bulletin

48, 3394-3398

Yu, H., F., 2013, BaFe12O19 powder with high

magnetization prepared by acetone-aided

coprecipitation. Journal of Magnetism and Magnetic

Materials 341, 79-85

Syahrul Humaidi, Ratna AS, Tua Raja S, Sri Dermayu S,

Perdamean S, 2015, Magnetic Properties of Cu2+

Substituted BaFe12-xCuxO19, Indonesian Journal of

Applied Physics vol.5 no.1 pp 71-78

Supradedi, P., Sardjono, Muljadi, N., Rusnaeni and

Humaidi, S., 2017, Effect of additive Na2O on sintering

temperature, crystal structure and magnetic properties

of BaFe12O19 magnet, Journal of Physics: Conf. Ser.

817 012056

Phase Formation of M-Type BaFe12O19/ZnO Magnetic Material

115