Kinetics of Petroleum Oil Recovery in Bio Surfactant of

Brevundimonas diminuta and Pseudomonas citronellolis Bacteria

Solutions

Bambang Yudono

1*

, Sri Pertiwi Estuningsih

2

, Muhammad Tri Handoko

1

and Muhammad Said

3

1

Department of Chemistry, University of Sriwijaya, Jl. Raya Palembang-Prabumulih Ogan Ilir South Sumatera,

Indonesia 30662

2

Department of Biology, University of Sriwijaya, Jl. Raya Palembang-Prabumulih Ogan Ilir South Sumatera,

Indonesia 30662

3

Department of Chemical Engineering, University of Sriwijaya, Jl. Raya Palembang-Prabumulih Ogan Ilir South Sumatera,

Indonesia 30662

Keywords: Bio Surfactant, Brevundimonas diminuta, Kinetics, Pseudomonas citronellolis.

Abstract: Kinetics of crude oil solubility in bio surfactant of Brevundimonas diminuta and Pseudomonas citronellolis

bacterias was studied by using a combination of differential and integral methods. The order of reaction and

reaction rate constants of crude oil solubility was determined by using differential and integral methods

respectively. The observation was carried out for 10 days, and integral method observation was carried out

every 2 days, for 10 days. The initial TPH concentration (Total Petroleum Hydrocarbon) of sludge sequently

were 1.64; 3.28; 4.91; 6.11 and 7.57 % (w/w). After 10 days’ treatment by using B. diminuta bacteria, the

TPH concentrations were decreased to 1.24; 2.43; 3.61; 4.32; 5.07% (w/w) and the TPH concentration using

P. citronellolis decreased to 1.07; 2.10; 3.13; 3.79; 4.40% (w/w). The order reaction which determined by

using differential method were 1.81 for B. diminuta and 1.1 for P. citronellolis. Furthermore, the order

reaction was put in the integral equation thus forming reaction rate constants equation of crude oil solubility

which are 0.018 day

-1

for B. diminuta and 0.033 day

-1

for P. citronellolis. Qualitative analysis which were

carried out by using GC showed that bio surfactant from B. diminuta was able to dissolve hydrocarbon

compounds of crude at fraction with lower C atomic chain <C10–C14 and C atomic longer >C22. Bio

surfactant from P. citronellolis was able to dissolve hydrocarbon compound with atomic chain C10 – C14.

1 INTRODUCTION

Petroleum is a very strategic natural resource to

increase the source of foreign exchange for the

country. This type of natural resource is classified as

non-renewable and its management must be carried

out very effectively and efficiently. Since the last

decade, the exploitation of oil fields in Indonesia has

not found a significant number of new reservoirs to

maintain and increase oil production. Meanwhile,

the role of petroleum has yet to be replaced even

though the search for petroleum deposits has become

increasingly difficult, which affected its exploitation

in an increasingly expensive manner (Juli and

Virmuda, 2001).

The process of exploitation or recovery of

petroleum in primary recovery method can recover

30-40% of petroleum, and secondary recovery that

can recover about 15-25% of petroleum. From this

method, it turns out that it still leaves around 60-

70% of the oil content trapped in the earth's crust

(Geetha, Banat and Joshi, 2018; Al-Bemani, 2011).

Given that the releasable oil trapped in rocks is

still quite high, which is around 60-70%. One of the

technologies to increase the acquisition of petroleum

is by using microorganisms known as the Microbial

Enhanced Oil Recovery (MEOR) method (Omoniyi,

2015; Nai, Magrini and Offe, 2016).

Isolating microbial indigen from Babat Toman

village which has the potential to produce bio

surfactants including P. acidovorans,

Brevundimonas diminuta, P. flourescens,

Bukholderia glumae, P. aeruginosa, Bacillus firmus,

P. peli, and P. citronellolis. In this study, Br.

diminuta and P. citronellolis bacteria are used. The

effect of salt on oil recovery oil, where the study

Yudono, B., Estuningsih, S., Tri Handoko, M. and Said, M.

Kinetics of Petroleum Oil Recovery in Bio Surfactant of Brevundimonas diminuta and Pseudomonas citronellolis Bacteria Solutions.

DOI: 10.5220/0008856401050112

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 105-112

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

105

showed optimal salt for B. diminuta bacteria was

reduced by 3% and P. citronellolis 6%. B. diminuta

and P. citronellolis bacteria were used because these

bacteria are able to produce bio surfactants and

recover petroleum. This is the basis of this research,

which needs further research to determine the

reduction in the concentration of Total Petroleum

Hydrocarbons (TPH) per unit time from the bacteria

B. diminuta and P. citronellolis. Kinetics

information is very important because kinetics

provides information on chemical concentrations

that are still lagging at any time and can be used to

predict the length of time the oil degradation process

will lead to the expected residual target (Marshall,

2008; Yudono et al., 2017).

In this study a sample concentration variation

was carried out with a treatment time of 10 days. All

data were evaluated using chemical kinetic theory

with differential and integral method approaches.

Qualitative studies were carried out using Gas

Chromatography (GC) which gave a more detailed

picture of the hydrocarbon compound fractions

before treatment and after treatment (Jovančićević et

al., 2004; Salminen et al., 2004).

2 MATERIALS AND METHODS

The material used in this study, namely microbial

isolates B. diminuta and P. Citronellolis (obtained

from the Microbiology Laboratory of the Biology

Department of FMIPA Sriwijaya University), NA

medium, aquadest, K

2

HPO

4

, peptone, FeSO

4

, yeast

extract, 70% alcohol, methanol, n-hexane, molasses

(taken from sugar waste from PT Cinta Manis,

Tanjung Raja, Ogan Ilir, South Sumatra) and oil

sludge obtained from Babat Toman Village, Musi

Banyuasin Regency.

2.1 Sterilization Tools

All heat-resistant equipment that will be used is

sterilized using an autoclave with a temperature of

121

o

C for 15 minutes, while non-heat-resistant

equipment is sterilized using 70% alcohol.

2.2 Regeneration of Bacteria

Each bacterium of B. diminuta and P. citronellolis

inoculated into NA solid media with zigzag

movements. Previously NA solid media was

sterilized in an autoclave at 121

o

C. Bacteria that

have been put into the NA medium are incubated in

an incubator for 24 hours. After incubation the

bacteria are ready to be used (Yudono et al., 2010).

2.3 Zobell Medium

The Zobell medium was made by dissolving 5 g of

peptone, 1 g of yeast extract, 0.012 g of K

2

HPO

4

,

and 0.01 g of FeSO

4

in distilled water with a

solution volume of 1000 mL. The mixture is boiled

on the hotplate and homogenized by stirring by a

magnetic stirrer. After boiling the mixture is

sterilized by autoclaving at 121

o

C for 15 minutes

(Yudono and Estuningsih, 2013).

2.4 Indigenous Bacterial Starters

The bacterial cultures of B. diminuta and P.

citronellolis as many as 5 ose were subcultured by

being put into each Erlenmeyer containing 100 mL

of Zobell medium, then aerated for 24 hours. The

100 mL Zobell medium is added to the mixture until

the total volume is 200 mL and the mixture is re-

aerated until the shortest generation time. The

shortest generation time of B. diminuta 12 hours and

P. citronellolis 9 hours (Young et al., 2005; Yudono

et al., 2011).

2.5 Crude Bio Surfactant Production

The total volume for bio surfactant production is 100

mL by mixing a bacterial starter, Zobell medium and

molasses concentration (taken from the sugar waste

of PT Cinta Manis, Tanjung Raja, Ogan Ilir, South

Sumatra) with a concentration of 15% molasses for

B. diminuta and 10% for the bacterium P.

citronilolis) with various volume variations. Then

the mixture is incubated based on the shortest

generation time. The shortest generation time of B.

diminuta is 12 hours and P. citronellolis 9 hours

(Yudono et al., 2010).

2.6 Initial TPH measurement

A total of 10 g of sludge is inserted using filter paper

that fits the size. The filter paper containing the

sludge sample is then inserted into the soxhlet tube.

Then the upper part of the soxhlet tube is connected

to the condenser and the lower part is connected to

the boiling flask containing n-hexane solvent with

the volume soaking the entire filter paper. Soxhlet is

done until the solvent drops back to boiling flask.

Soxhletion is stopped when the solvent is clear on

the soxhlet tube. Boiling flask which contains

extracts is then heated in an oven at 100

o

C, then

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

106

stored in a desiccator. Flask and oil are then

weighed. Then the residue from soxhletion is

weighed and the percentage of petroleum TPH is

calculated using the equation:

% TPH = (W

1

-W

2

) / W

2

x 100% (1)

Where: W

1

= Sludge sample weight (g), W

2

=

Residual weight (g)

2.7 GC Analysis

Petroleum filtrate obtained from the soxhletion

process is diluted with n-hexane 50 mL. The results

of the dilution are taken several mL, to be injected

on a Thermo Scientific GC device with a

programmed temperature of 40°C maintained for 4

minutes, the temperature is raised 5°C per minute

until the temperature reaches 300°C. The type of

column used is TG-5MS with a column length of 30

m and a diameter of 0.25 mm.

2.8 Reaction Order of Petroleum

Solubility

A total of 10 g sludge with a variation of TPH 1.5,

3.0, 4.5, 6.0, and 7.5% mixed with a bio surfactant

mixture: distilled water 10% (v/v) to a volume of

100 mL. The mixture is then aerated for 10 days.

The residue from the screening results was

calculated as the percentage of TPH. The percentage

of petroleum TPH is calculated using equation 2,

while the filtrate is extracted with n-hexane 25 mL

using a separating funnel. The top layer is taken by

repetition 4 times, then analysed using GC.

2.9 Oil Recovery Rate Constant

A total of 10 g sludge with a 4.5% TPH

concentration was added to each bio surfactant

mixture: distilled water to a total volume of 100 mL.

The mixture is then aerated according to the

variation time, for 2, 4, 6, 8 and 10 days. The residue

from the screening results was calculated as the

percentage of TPH. The percentage of petroleum

TPH is calculated using equation 1.

2.10 Determination of Reaction Order

Determining the value of the degradation reaction

order (n) through the differential method, obtained

directly from the graph of the ln [C] relationship

with ln r as shown in equation 3, where ln [C] is

TPH day 0 and ln r is TPH day 10 with the

percentage of TPH varying 1, 5%, 3%, 4.5%, 6%

and 7.5%, by determining the differential equation

tangent.

ݎൌ

ିௗሾሿ

ௗ௧

ൌ݇ሾܥሿ

(2)

ݎൌ

ௗሾሿ

ௗ௧

ൌെ݇ሾܥሿ

(3)

ln r = ln k + n ln [C] (4)

Thus, the order of degradation reaction (n) is the

same as the slope and can be directly determined

after the incubation period of day 0 to day 10, the

data is analysed using the integral and special

method at a concentration of 4.5% by measuring

TPH every 2 days. The integral method is done to

determine the degradation reaction constant (k),

based on the order of the degradation reaction (n),

which has been determined from the differential

method. Through the integration equation

continuously calculated according to order (n), a

graph of relationship time (days) was obtained with

[TPH] (Yudono, 1994).

3 RESULTS AND DISCUSSION

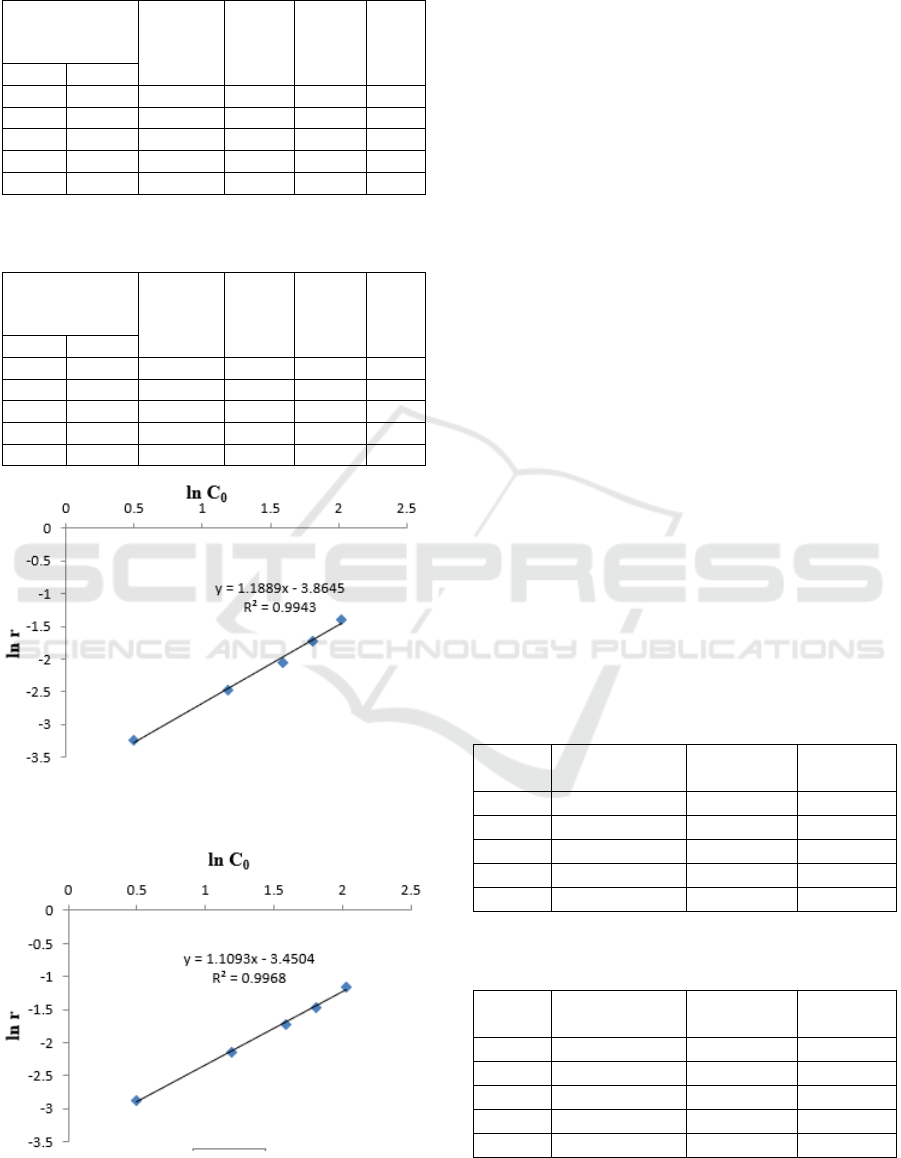

Determination of the reaction order of TPH due to

petroleum solubility is using differential methods.

The reaction order is determined by graphing the

relationship between ln [C] and ln r so that the

differential equation can be determined (Marshall,

2008). Based on the equation (4), ln r = ln k + ln [C],

if a graph is made of the relationship between ln [C]

and ln r, then a straight line graph will be obtained

with n being the slope and ln k being intercept. The

reaction constant will be more accurate when

measured using the integration method (Yudono et

al., 2011). The Table 1 shows the decreasing TPH

concentrations from day 0 to day 10 using bio

surfactant of B. diminuta bacteria.

3.1 Phytochemical Screening

Important phytochemicals, such as alkaloids,

triterpenoids, steroids, phenolics, flavonoids and

saponins for their presence and are presented in

Table 1.

The Table 2 shows the decreasing TPH

concentrations from day 0 to day 10 using bio

surfactant of P. citronellolis bacteria.

Kinetics of Petroleum Oil Recovery in Bio Surfactant of Brevundimonas diminuta and Pseudomonas citronellolis Bacteria Solutions

107

Table 1: Kinetics of solubility of petroleum sludge in bio

surfactant of B. diminuta bacteria.

TPH sludge

concentration

(%)

∆[TPH] r ln r ln C

o

C

o

C

10

1.64 1.08 0.56 0.056 -2.76 0.49

3.28 2.10 1.18 0.118 -2.09 1.18

4.91 3.13 1.77 0.177 -1.66 1.59

6.11 3.79 2.31 0.231 -1.32 1.81

7.57 4.41 3.16 0.316 -1.08 2.02

Table 2: Kinetics of solubility of petroleum sludge in bio

surfactant of P. citronellolis bacteria.

TPH sludge

concentration

(%)

∆[TPH] r ln r ln C

o

C

o

C

10

1.64 1.08 0.56 0.056 -2.76 0.49

3.28 2.10 1.18 0.118 -2.09 1.18

4.91 3.13 1.77 0.177 -1.66 1.59

6.11 3.79 2.31 0.231 -1.32 1.81

7.57 4.41 3.16 0.316 -1.08 2.02

Figure 1: Graph of the relationship ln [C0] with ln r for the

P. citronellolis bacteria.

Figure 2: Graph of the relationship ln [C0] with ln r for the

P. citronellolis bacteria.

From the Figure 1, a graph of the relationship ln

[C

0

] with ln r for B. diminuta bacteria obtained

regression value obtained at 0.9943. This shows the

graph is a straight line. From the results of the

calculation of the straight-line equation, the slope

(slope) is obtained by 1.18 with the intercept value

of -3.86. According to the differential method, the

slope value shows the order of the degradation

reaction (n), so based on this value, the order of

reaction for petroleum solubility using the bacterium

B. diminuta is a reaction order 1.18. Usually the oil

degradation reaction refers to first order reaction

(Yudono, 1994); while in this study the reaction

order is 1.18. For Figure 2, a graph of the ln [C

0

]

relationship with ln r P. citronellolis bacteria

obtained a slope of 1.1 with an intercept value of -

3.45. And the regression value is 0.9968. Based on

these values, it can be concluded that, the order of

reaction of petroleum solubility using P. citronellolis

is a reaction order 1.1.

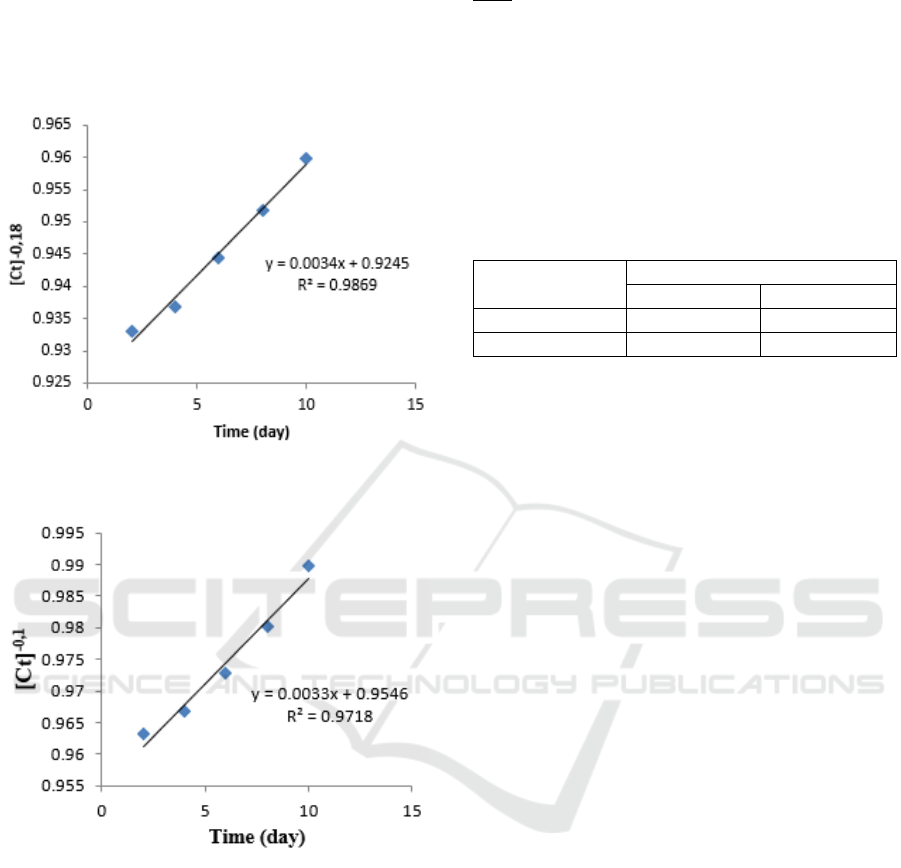

3.2 Determination of Petroleum

Solubility Constants with Integral

Methods

The reaction rate constant of petroleum solubility

can be determined using the integral method. The

integral method shows that the value of the slope is

the value of the reaction rate constant of petroleum

solubility. The kinetics data can be seen in Table 3

and 4.

Table 3: The kinetics data of petroleum sludge solubility

in bio surfactant of B. diminuta bacteria.

Time

(t)=x

Concentration

(C

t

)=y

ln [TPH] [Ct]

-0.18

2 4.35 1.47 0.933

4 4.21 1.43 0.936

6 3.95 1.37 0.944

8 3.73 1.31 0.951

10 3.51 1.25 0.959

Table 4: The kinetics data of petroleum sludge solubility

in bio surfactant of P. citronellolis.

Time

(t)=x

Concentration

(C

t

)=y

ln [TPH] [Ct]

-0.18

2 4.28 1.45 0.963

4 4.07 1.40 0.966

6 3.73 1.31 0.972

8 3.39 1.22 0.980

10 3.03 1.10 0.989

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

108

From the data table above each can be graphed

[Ct]

-0.18

relationship with time (days), so that the

slope and intercept values are known. Following is

the graph of the relationship [Ct]

-0.18

with time

(days):

Figure 3: Graph of correlations of time (days) with

concentrations [C]

-0.18

.

Figure 4: Graph of correlations of time (days) with

concentrations [C]

-0.1

.

Figure 4. Graph of the relationship of time (days)

with [C]

-0.18

shows the line equation Y = 0.0034x +

0.9245. The slope value obtained is 0.0069 and

intercept 0.9546. The regression value is 0.9869.

This shows the graph is a straight line. Then Figure

4. Graph of relations of time (days) with [C]

-0.1

shows the equation of line Y = 0.0033x + 0.9546.

The slope value obtained is 0.0033 with a regression

value of 0.9718.

To determine the reaction rate constant, the slope

values obtained from Figure 3 and 4 are inserted in

equation 7.

ିௗሾሿ

ௗ௧

ൌ݇ܥ

(5)

ሾܥሿ

݀

ሾ

ܥ

ሿ

ൌെ݇

݀ݐ

(6)

C

t

-n+1

= C

t

-n+1

– (n+1)kt (7)

So that the constant value for B. diminuta

bacteria is 0.0189 days

-1

and P. citronellolis is 0.033

days

-1

. From Figures 1, 2, 3 and 4 we can see the

comparison of each bacterium shown in Table 5.

Table 5: Order and constant of each bacterium.

Bacteria

Parameter

n K (day

-1

)

B. diminuta 1.18 0.018

P. citronellolis 1.1 0.033

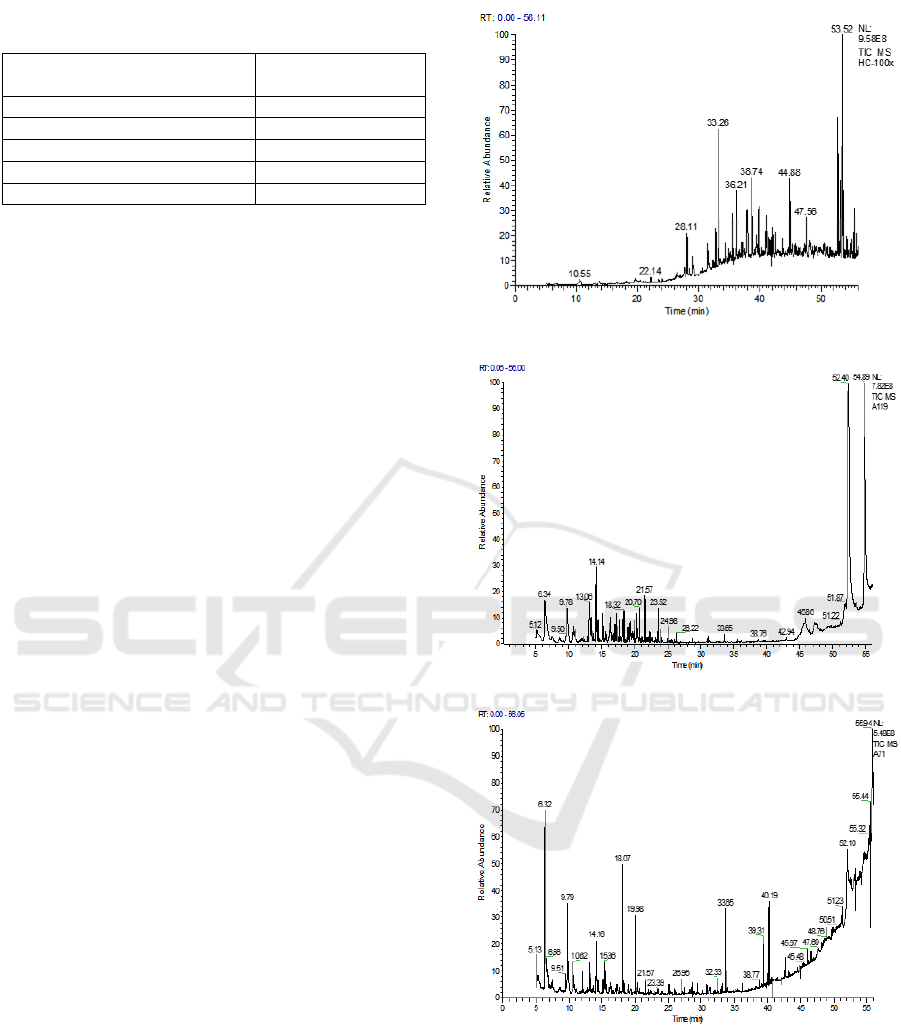

3.3 GC Chromatogram Analysis

The results of extracting petroleum sludge from

petroleum sludge in the initial conditions and after

extracting it with bio-surfactant were analyzed using

GC. These results were then analyzed qualitatively

using Thermo Scientific GC-MS to determine the

difference in the number of sludge components

before treatment with the number of sludge

components after the addition of bio surfactant

treatment from each bacterium (Jovančićević et al.,

2004). Based on the GC-MS data that has been

obtained, it can also be qualitatively analyzed the

dissolved and non-dissolved hydrocarbons left on

the residue shown in the histogram in the form of

percent abundance of each bacteria.

Components that are dissolved in bio surfactants

and components that become residues can be

explained through histograms of changes in

abundance. Based on the histogram, the x axis is the

C chain fraction identified which is determined by

determining the temperature range calculated from

the retention time and the y axis is the change in

abundance. The histogram was generated from the

acquisition of the initial component chromatogram

data and after the addition of bio surfactants from

each bacterium. The abundance change is indicated

by ∆A = %A

t

- %A

o

, if the resulting data is a

positive number, it shows the component of the

dissolved hydrocarbon chain. Otherwise, if it is a

negative number, it indicates that the hydrocarbon

chain component is residual.

The fractions of C which are residues and

dissolved ones can be seen in Table 6 which shows

the C chain fraction based on its temperature

(Fanani, Yudono and Situmorang, 2014).

Kinetics of Petroleum Oil Recovery in Bio Surfactant of Brevundimonas diminuta and Pseudomonas citronellolis Bacteria Solutions

109

Table 6: Hydrocarbon chain fractions based on

temperature.

Temperature range (

o

C)

Carbon chain

fraction

<100 <C

10

100-150 C

11

-C

14

150-200 C

15

-C

17

200-250 C

18

-C

21

250-300 >C

22

Based on Figure 8a, it can be seen that there is a

significant number of chromatogram peaks of

petroleum constituent compounds in initial

condition.

Based on the total retention time for 56 minutes,

there were some of the highest peak chromatograms,

which occurred at retention times 28.11; 33.26;

36.21; 38.74; 44.88; and 53.52, whereas for other

retention times it has a chromatogram with a low

peak. In Figure 4b chromatogram, it can be seen in

the chromatogram that small peaks appear which

indicate the presence of new compounds at the

retention time of 6.34 which was previously not

detected in Image Chromatogram 4a. After the

addition of bio surfactants from the bacterium B.

diminuta, Figure 4b shows a decrease and addition

of the chromatogram peak with a total retention time

of 56 minutes. In addition, Figure 4c also shows that

small peaks have appeared at retention times of 5.13

which indicate the presence of new compounds.

These compounds have low molecular weight

because they appear at earlier retention times and are

branching alkane isomers. There are several highest

peak chromatograms, namely at retention time of

6.32; 9,79; 18.07; 33.65; 40.19, while for other

retention times have a chromatogram with a low

peak. From the picture above it can be concluded

that there is a change in the rise and fall of the peak

area in the chromatogram, whether it increases or

decreases. Changes in the rise and fall of the peak

area indicates that bio surfactants work to dissolve

the hydrocarbon components to form new, simpler

hydrocarbon components (Fanani, Yudono and

Situmorang, 2014).

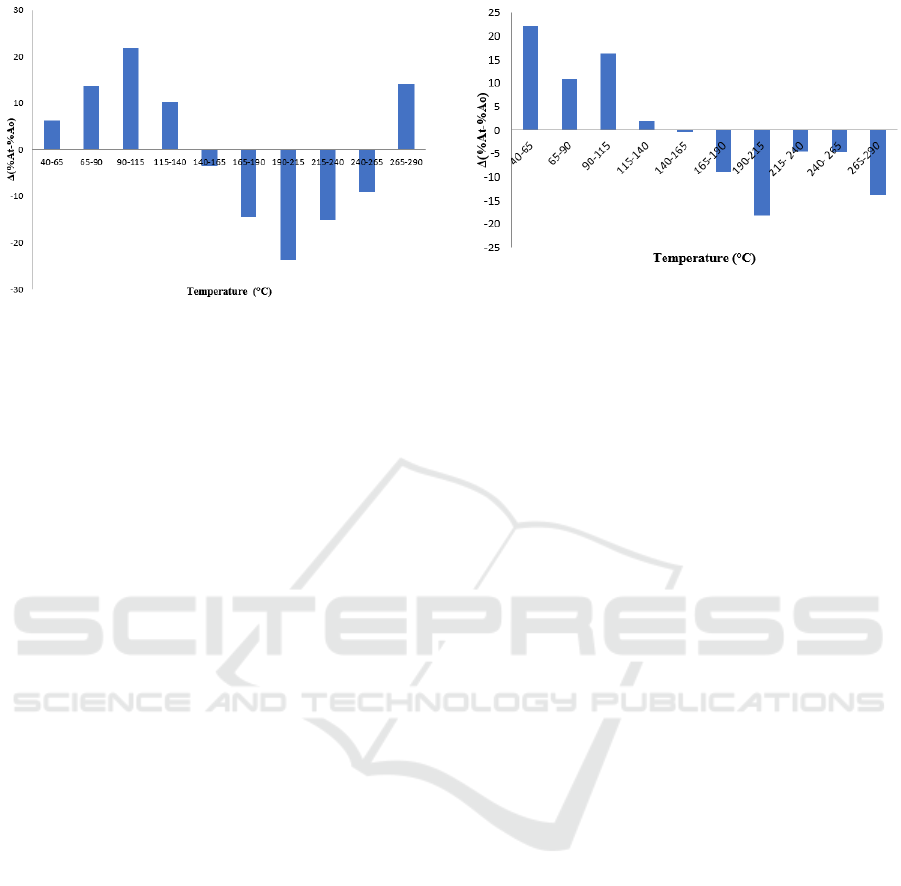

The component changes that occurred can be

explained qualitatively on the changes in abundance

shown in Figure 5 in the form of a histogram.

(a)

(b)

(c)

Figure 4: (a) Chromatogram TPH initial sludge before

crude bio surfactant treatment, (b) Chromatogram TPH

end sludge after treatment using bio surfactant from

bacteria Brevundimonas diminuta, (c) Chromatogram TPH

end sludge after treatment using bio surfactant from

Pseudomonas citronellolis bacteria.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

110

Figure 5: Histogram of changes in soluble oil abundance

in bio surfactants of bacteria Brevundimonas diminuta.

Based on the histogram above, the percentage

difference in abundance is calculated by subtracting

the percentage of abundance after the addition of

crude bio surfactant (A

t

) from the bacterium B.

diminuta minus the peak abundance percentage

before the addition of crude bio surfactant (A

0

). The

positive reduction results show that dissolved

hydrocarbons in bio surfactant. Increased histogram

shows that short chain hydrocarbons dissolve in bio

surfactants, so that at the peak of the chromatogram

there are carbon chains that are lost and decompose

into short chains. This histogram explained that bio

surfactants from B. diminuta bacteria at a 5-20

minute retention time showed a percentage increase

in abundance compared to the initial one, indicating

that bio surfactants were able to dissolve short-chain

C hydrocarbons namely atomic chains <C

10

– C

14

at

temperatures 40-140

o

C and at retention times 50-55

minutes are able to dissolve long C hydrocarbons,

namely the atomic chain >C

22

at a temperature of

265-290

o

C which is at a positive value. But bio

surfactants from B. diminuta bacteria at a retention

time of 25-50 minutes were unable to dissolve long

C hydrocarbons, namely C

15

-C

17

and C

18

-C

21

at

temperatures of 140-265

o

C. While the component

changes that occur in the use of P. citronellolis

bacteria can be seen in Figure 6.

Based on the Figure 6, the increasing histogram

shows that short-chain hydrocarbons dissolve in bio

surfactants, so that at the peak of the chromatogram

there are long carbon chains that are lost and break

down into short carbon chains. the per cent

difference in abundance is calculated by subtracting

the per cent peak abundance after the addition of

crude bio surfactant (A

t

) from the bacterium P.

citronellolis minus the percent peak abundance

before the addition of crude bio surfactant (A

0

).

Figure 6: Histogram of changes in soluble oil abundance

in bio surfactants of Pseudomonas citronellolis bacteria.

If the result of the reduction is positive, it means that

the hydrocarbon compound dissolves in bio

surfactant, where if bio surfactant and bacterial

culture have a larger hydrophobic head then it will

also produce a large oil recovery. On the histogram,

it can be seen that most of the atomic chain

hydrocarbons <C

10

- C

14

are in a positive value,

which means that the atomic chain hydrocarbons

<C

10

- C

14

are mostly soluble in bio surfactants.

4 CONCLUSIONS

B. diminuta and P. citronellolis bacteria can reduce

the Total Petroleum Hydrocarbons (TPH) in all

treatment media concentrations. The optimal

reduction in TPH using bio surfactant from B.

diminuta bacteria occurred at variations in media

concentration of 7.51% (b / b) for 10 days with TPH

values falling to 5.07% (b / b), while for P.

citronellolis bacteria able to reduce TPH 7.51% to

4.40% within 10 days.

The reaction order and reaction rate constants

obtained from petroleum solubility using the bio

surfactant of the B. diminuta bacteria are 1.18 and

0.0189 days

-1

. Based on the kinetics model, the time

needed to dissolve petroleum sludge completely is in

73 days, while the reaction order and reaction rate

constants of P. citronellolis are 1.1 and 0.033. the

time needed to dissolve petroleum sludge

completely is in 44 days.

The results of GC and Histogram analysis of

changes in oil abundance from each bacterium can

be seen that bio surfactants from B. diminuta

bacteria based on 5-20 minutes retention time appear

short-chain C hydrocarbons which are < C10 – C14

atomic chains obtained from long chain hydrocarbon

degradation and at retention time of 50-55 minutes,

it is able to dissolve long chain C hydrocarbons

Kinetics of Petroleum Oil Recovery in Bio Surfactant of Brevundimonas diminuta and Pseudomonas citronellolis Bacteria Solutions

111

namely atomic chain> C22, while bio surfactant

from P. citronellolis bacteria based on 5-20 minute

retention time can be seen dissolving hydrocarbon C

atomic chain <C10-C14 which is the result of

hydrocarbon decomposition long chains that can be

seen from the decrease in the area of peak

abundance.

REFERENCES

Al-bemani, A., 2011. Microbial biotechnology for

enhancing oil recovery : Current developments and

future prospects.

Fanani, Z., Yudono, B. and Situmorang, V. R., 2014.

‘Degradasi Tanah Lahan Suboptimal oleh Bacillus

Mycoides Indigenous dan Kinetika Reaksinya

Degradation Soil of Suboptimal Land by Bacillus

Mycoides Indigenous and its Kinetics Reaction’,

Prosiding Seminar Nasional Lahan Suboptimal, 3(1),

pp. 979–587.

Geetha, S. J., Banat, I. M. and Joshi, S. J., 2018.

‘Biosurfactants: Production and potential applications

in microbial enhanced oil recovery (MEOR)’,

Biocatalysis and Agricultural Biotechnology. doi:

10.1016/j.bcab.2018.01.010.

Jovančićević, B. et al., 2004. Investigation of Interactions

between Surface Water and Petroleum Type Pollutants

(9 pp). Environmental Science and Pollution Research

- International, 12(4), pp. 205–212. doi:

10.1065/espr2004.12.229.

Juli, N. and Virmuda, B., 2001. Penelitian Awal Terhadap

Delapan Isolat Bakteri Reservoar Dalam

Mengembangkan Volume Minyak Bumi Secara

Monokultur. MI, pp. 3–5.

Marshall, S., 2008. Fundamental Aspects of Microbial

Enhanced Oil Recovery: A Literature Survey. National

Research Flasgships, 1(1), pp. 1–41. doi:

https://doi.org/10.4225/08/585ac3b461b3e.

Nai, C., Magrini, B. and Offe, J., 2016. Let

microorganisms do the talking, let us talk more about

microorganisms. Fungal Biology and Biotechnology.

BioMed Central, 3(1), p. 5. doi: 10.1186/s40694-016-

0023-9.

Omoniyi, O. A., 2015. A Review of Microbial Enhanced

Oil Recovery : Current Development and Future

Prospects. 6(1), pp. 1378–1389.

Salminen, J. M. et al., 2004. Potential for aerobic and

anaerobic biodegradation of petroleum hydrocarbons

in boreal subsurface. Biodegradation, 15(1), pp. 29–

39. doi: 10.1023/B:BIOD.0000009954.21526.e8.

Young, C. C. et al., 2005. Identification and kinetic

characteristics of an indigenous diesel-degrading

Gordonia alkanivorans strain. World Journal of

Microbiology and Biotechnology, 21(8–9), pp. 1409–

1414. doi: 10.1007/s11274-005-5742-7.

Yudono, B., 1994. Kinetics of Indigenous Isolated

Bacteria Bacillus mycoides Used for Ex-Situ

Bioremediation of Petroleum Contaminated Soil in PT

Pertamina Sungai Lilin South Sumatera. 2(3), pp. 64–

71.

Yudono, B. et al., 2010. Kinetics of Petroleum-

Contaminated Soil Biodegraded by An Indigenous

Bacteria Bacillus megaterium. HAYATI Journal of

Biosciences. Institut Pertanian Bogor, 17(4), pp. 155–

160. doi: 10.4308/hjb.17.4.155.

Yudono, B. et al., 2011. Kinetics Approach of

Biodegradation of Petroleum Contaminated Soil by

using Indigenous Isolated Bacteria. Jurnal TANAH

TROPIKA (Journal of Tropical Soils), 16(1), pp. 33–

38. doi: 10.5400/jts.2011.16.1.33.

Yudono, B. et al., 2017. Oil recovery test using bio

surfactants of indigenous bacteria in variation

concentration of carbon source. IOP Conference

Series: Earth and Environmental Science, 65(1). doi:

10.1088/1755-1315/65/1/012029.

Yudono, B. and Estuningsih, S. P., 2013. Kinetika

Degradasi Limbah Minyak Bumi Menggunakan

Sinergi Bakteri Konsorsium (Microccoccus sp,

Pseudomonas pseudomallei, Pseudomonas

pseudoalcaligenes dan Bacillus sp) dan Rumput

Eleusine Indica (L.) Gaertn. Prosiding Semirata

FMIPA Universitas Lampung.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

112