Phosphate Adsorption using KOH Activated Coal Bottom Ash

Fatimah Agussalim, Alfikri Ramadhan, Budi Pratama Tarigan

Chemical Engineering Department, Engineering Faculty, Universitas Sumatera Utara, Medan, Indonesia, 20155

Keywords: Adsorption, Adsorption capacity, Bottom ash, Freundlich isotherm model.

Abstract: Research on phosphate adsorption using activated KOH coal bottom ash has been carried out. This study aims

to assess the utilization of bottom ash as an adsorbent to adsorb phosphate ions from water bodies. Research

starts from the activation process for 5 hours with 3 M NaOH solution. Then the pre-activated and post-

activated bottom ash are characterized using Scanning Electron Microscopy-Energy Dispersive X-ray

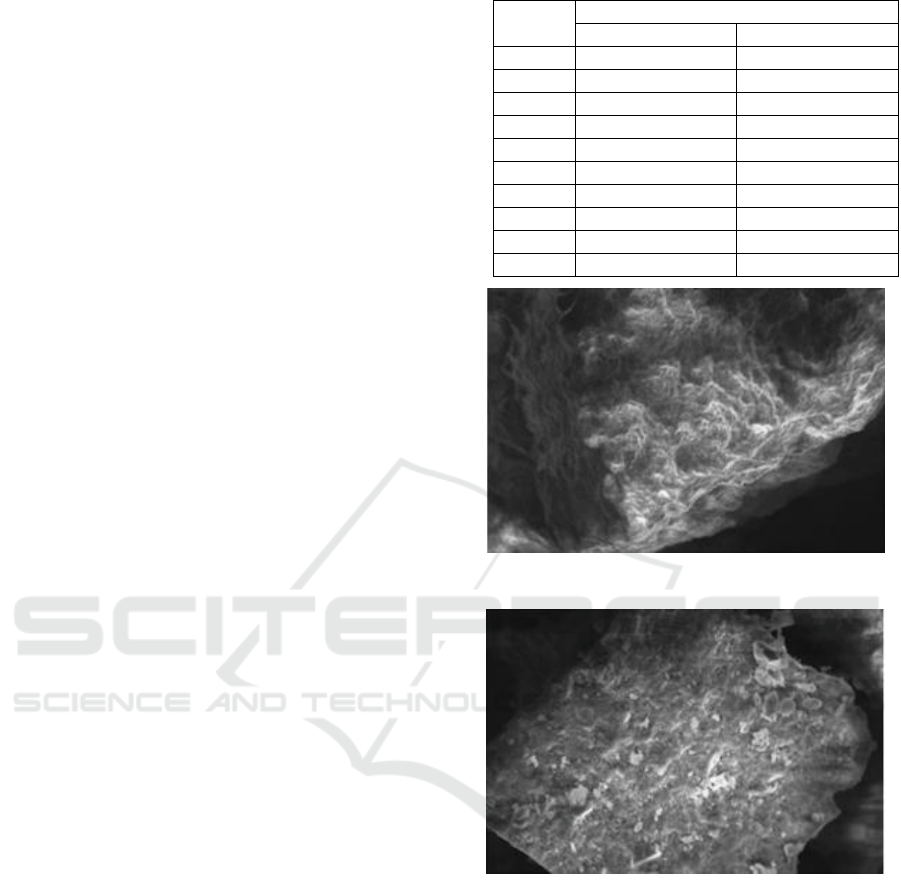

Spectroscopy (SEM-EDS). Based on the results of the characterization with SEM-EDS, the surface of pre-

activated bottom ash surfaces seems smooth because they are still covered by impurity metals such as Fe, Ti

and Mg. After activation, bottom ash surfaces become rough because impurities such as Fe, Ti, and Mg are

lost and thus the pores are opened. The bottom ash then was applied to absorb phosphate ions with variations

of particle size (50-70 mesh, 70-110 mesh, and 110-140 mesh) and dosage of adsorbent (1, 2, and 3 g) and

were contacted for 60 minutes to 1000 ml phosphate solute of concentration 10 mg/l. Remaining phosphate

ions concentration in solute after adsorption are analyzed using UV-vis spectrophotometer. Best adsorption

of phosphate ions with 74.8% efficiency was obtained at particle size of 110-140 mesh and dosage adsorbent

of 3 g. The highest adsorption capacity (7.02 mg / g) was obtained with dosage of 1 g adsorbent. Freundlich

and Langmuir's models were used to describe the phosphate ion adsorption by KOH activated bottom ash

isotherm. Based on the data obtained, the suitable model for this study is Freundlich model with a value of R

2

= 0.9721.

1 INTRODUCTION

Phosphate is a nutrient that is very important for life.

Phosphate is a key component added in making

fertilizers to produce food (Ashley et al, 2011;

Cordell et al, 2009). However, the presence of

phosphate with a range of more than 0.01-0.1 mg/L

in a body of water can trigger a eutrophication process

which will reduce the penetration of sunlight into the

body of water during the day so that photosynthesis

that will produce oxygen is also reduced (Kumar et

al, 2019).

The phenomenon of eutrophication can trigger

the growth of algae and microorganisms so that the

waters become green, turbid, odourless and reduce

oxygen levels (Ajmal et al, 2018). There are several

ways that have been successful in reducing phosphate

levels in the body of water, namely biological

treatment (Peng el al, 2016), chemical precipitation

(Van der Houwen et al, 2001), struvite formation

(Muhmood et al, 2018), membrane processing

(Peleka, 2006), and adsorption (Ghaneian et al, 2014;

Usman et al, 2018). The adsorption method has

several advantages compared to other methods, which

are simple, inexpensive, and high efficiency (Seftel et

al, 2018).

Bottom ash from burning coal PT. SOCIMAS was

used as an adsorbent in this study. Bottom ash has a

high particle size, surface area and porosity making it

a good choice for use as an adsorbent (Gorme et al,

2010). Bottom ash has a large Si and Al content that

makes bottom ash can be used as zeolite or adsorbent

(Bertolini et al, 2013). Some previous studies have

used bottom ash as an adsorbent and its absorption

efficiency is quite high (Gorme et al, 2010; Bertolini

et al, 2013; Gandhimathi et al, 2013; Mittal et al,

2013., Dincer et al, 2007; Saleh et al, 2012)

This study aims to examine the potential of

bottom ash which has been activated with KOH as an

adsorbent by looking at the effect of particle size and

dosage of adsorbent usage. The Langmuir and

Freundlich isotherm models were used to model the

isotherm data for their applicability.

100

Agussalim, F., Ramadhan, A. and Tarigan, B.

Phosphate Adsorption using KOH Activated Coal Bottom Ash.

DOI: 10.5220/0008855501000104

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 100-104

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 RESEARCH METHOD

The activation of bottom ash using KOH solute has

been held with the following procedures: dissolve 30

gr of bottom ash in 250 ml KOH solute of 3 M, stir

with stirring rate of 200 rpm for 5 hours at

temperature of 85-95

o

C. The mixture then washed,

filtered, and dried in oven at temperature of 105

o

C.

The structure and composition of pre-activated and

activated bottom ash was analyzed using SEM-EDS.

A batch experiment was performed by taking a

specified amount of adsorbent and combining it with

1000 ml phosphate solution at concentration of 10

mg/l. After adsorption, the concentration of

phosphate was determined using a spectrophotometer

UV-Vis with SNI 06-6989.31-2005 method.

In order to investigate the effect of particle size on

phosphate adsorption, three different sizes of

adsorbent (between 50 and 70 mesh, between 70 and

110 mesh, and between 110 and 140 mesh) and

constant adsorbent dosage (1 g) was used. To observe

the effect of adsorbent dosage on phosphate removal

and adsorption capacity, three different adsorbent

dosage (1, 2, and 3 g) were used. In order to determine

the fitting isotherm model, the initial concentrations

of adsorbate was varied accordingly (2, 4, 6, 8, and

10 mg/l).

3 RESULTS AND DISCUSSION

3.1 Effect of Activation

The effect of activation is shown in Fig. 1 and 2. As

shows in Fig. 1, bottom ash before activation doesn’t

have pores because covers by impurities and Fig. 2,

bottom ash after activation have more much pores

because bottom ash after activation have fewer

impurities than bottom ash before activation. This can

make bottom ash has bigger adsorption capacity

(Bronislaw, 2016).

Similar result was observed in a study of overview

on the effect of activation on the performance of

graphene based adsorbent by Jie, et al. (Ma, 2017).

According to cited authors, adsorbent with more

much pores increase the amount of adsorbate which

could adsorbed.

The activation process also change the chemical

composition of bottom ash. Activation process can

eliminate impurities in the bottom ash. In Table 1, it

can be seen elements such as Fe, Mg, and Ti are lost

after the activation process. The lost elements can

provide additional pores for adsorption process.

Table 1: Chemical composition of bottom ash before and

after activation

Element

Percentage

Before activation

After activation

O

47.67

48.79

Si

19.59

13.92

Al

8.58

12.69

Br

15.13

16.44

K

0.61

6.25

Ca

1.49

1.18

Na

2.07

0.73

Fe

3.08

-

Mg

1.08

-

Ti

0.70

-

Figure 1: SEM bottom ash result before activation

Figure 2: SEM bottom ash result after activation

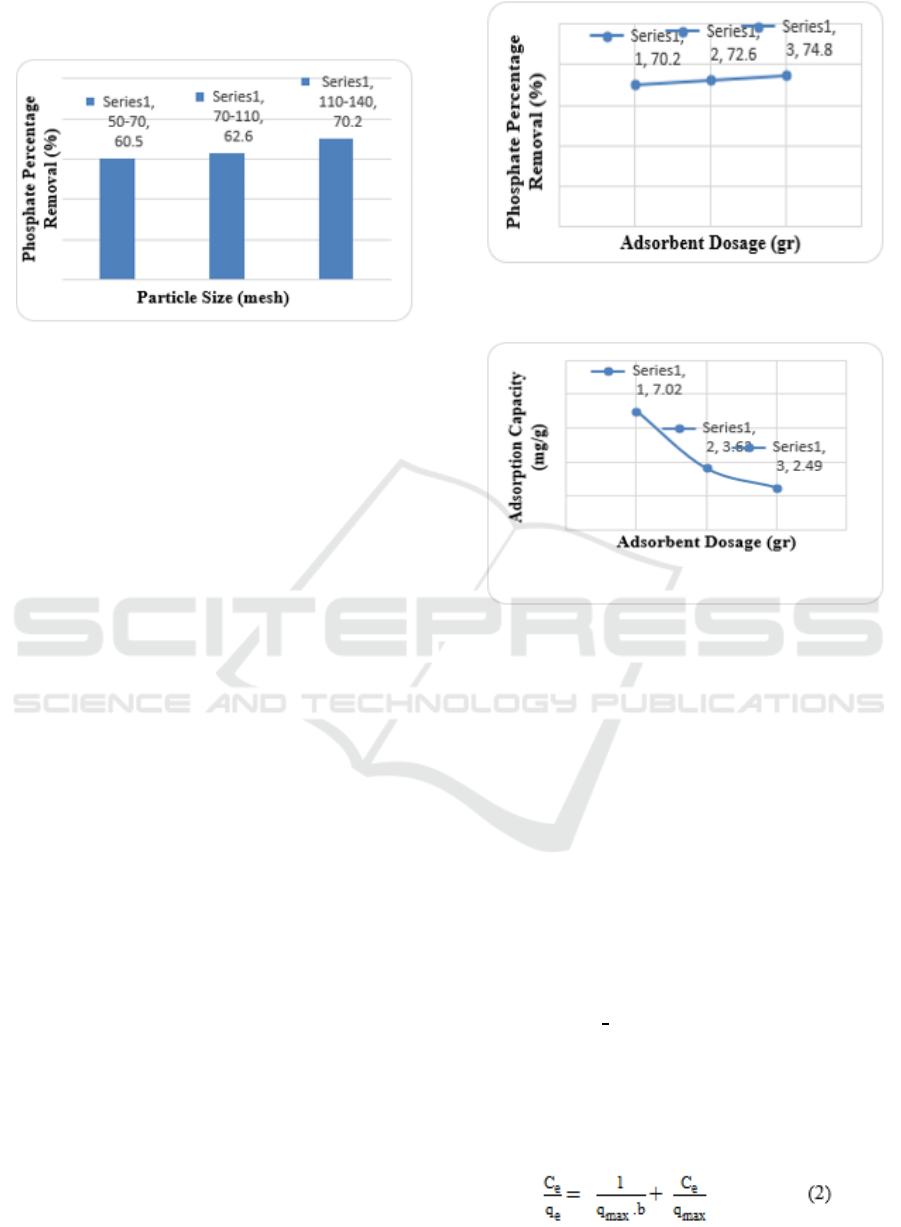

3.2 Effect of Particle Size

The effect of particle size is shown in Fig. 1. As

shown in Fig. 1, the phosphate removal percentage

increase as the particle size was decreased. The

highest phosphate percentage removal (70.2 %) was

achieved by the adsorbent of particle size between

110 and 140 mesh.

Similar result was observed in a study of overview

on the effect of particle size on the performace of

wood-based adsorbent by Ikenyiri and Ukpaka

(Ikenyiri, 2016). According to cited authors,

adsorbent with smaller particle size has higher surface

Phosphate Adsorption using KOH Activated Coal Bottom Ash

101

area, thus increase the amount of adsorbate which

could adsorbed.

Figure 3: Phosphate percentage removal at three different

particle size

3.3 Effect of Adsorbent Dosage

The effect of adsorbent dosage on phosphate

adsorption is shown in Fig. 2 and 3. It was observed

that phosphate percentage removal increase with an

increase of adsorbant dosage. In contrast, adsorption

capacity decrease with an increase of adsorbent

dosage. The highest adsorption capacity (7,02 mg/g)

was achieved with adsorbent dosage of 1 gr. The

similar trend was reported by Hasfalina, et al

(Hasfalina et al, 2012). Futher increment of adsorbent

dosage above 1 g/L resulted in a decline in adsorption

capacity.

Charles and Odoemelam had stated in their study

that an increase in adsorbent dosage will provide

greater availability of the exchangeable sites or

surface area (Charles et al, 2010). Hence, the

percentage of phosphate removal in this study

increases as the adsorbent dosage increases (Fig. 2).

However, the increase is not significant and higher

adsorbent dosage does not provide higher adsorption

capacity (Fig. 3). The trend where phosphate

adsorption capacity descreases as adsorbent dosage

increases in this study might be due to the adsorptive

capacity of bottom ash that was available was not

fully utilized at higher adsorbent dosage in

comparison to lower adsorbent dosage.

Figure 4: Phosphate percentage removal at different

adsorbent dosage

Figure 5: Phosphate adsorption capacity at different

adsorbent dosage

According to Waseem et al, high adsorbent dosage

does not always gives optimum result and higher

adsorption capacity compared to lower dosage

(Waseem et al, 2012). This is possibly because of at

higher adsorbent dosage, lumps was formed and thus

decrease overall surface area of adsorbent.

3.4 Adsorption Isotherm Model

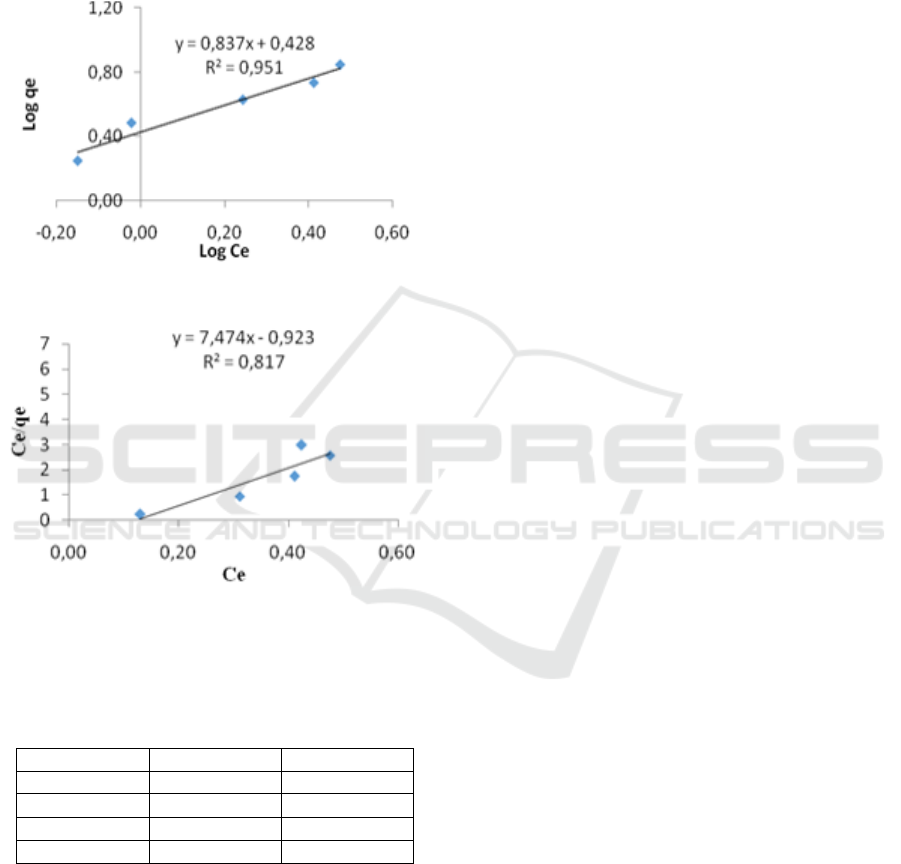

The Freudlich and Langmuir adsorption models were

used to determine the fitting model for phosphate

adsorption using KOH activated bottom ash. The

Freudlich and Langmuir isotherm are given in Eq. 1

and 2, respectively (Ahmed et al, 2010).

log q

e

= log K

f

+

1

n

log C

e

(1)

Where qe is the amount of phosphate adsorbed per

mass adsorbent used (mg/g), Ce is equilibrium

concentrate of solution (mg/l), Kf is Freudlich

constants and 1/n is adsorption intensity.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

102

Where q

max

is adsorption capacity at monolayer, b

is Langmuir constants, qe is the amount of phosphate

adsorbed per mass adsorbent used (mg/g), and Ce is

equilibrium concentrate of solution (mg/l).

The experimental data was applied to the isotherm

models, and corresponding plots are given in Fig. 4

and 5.

Figure 6: Freudich plot for phosphate removal

Figure 7: Langmuir plot for phosphate removal

Based on Fig. 6 and 7, a summary table was made

and shown in Table 2.

Table 2: Freudlich and Langmuir Constants

Parameter

Freudlich

Langmuir

R

2

0.9512

0.8171

Q

max

-

9.149

K

2.671

0.662

n

1.194

-

In Table 2, the values of R2 were compared. The

R

2

value of Freudlich model (0.9512) is well fitted

compared to the R

2

value of Langmuir model

(0.8171). This is indicating that the mechanism of

phosphate adsorption using KOH activated bottom

ash obeyed the Freudlich isotherms. The good fit of

the Freudlich isotherm to an adsorption system

assumes tha there is a multilayer adsorption and

reversible adsorption which considers the interaction

between adsorbate molucules (Freundlich, 1906).

4 CONCLUSIONS

In general, it can be concluded that the parameters

such as particle size and adsorbent dosage did affect

the adsorption of phosphate removal using KOH

activated bottom ash. The highest percentage removal

value of 70.2 % was achieved by using adsorbent with

particle size between 110 and 140 mesh. Higher

adsorbent dosage gives a decrease in adsorption

capacity, with the highest value of adsorption

capacity was achieved by using adsorbent dosage of

1 gr. Equilibrium data by the Freudlich isotherms (R

2

= 0.9512) was found to be well fitted in describing

adsorption isotherm of KOH activated bottom ash for

phosphate removal.

ACKNOWLEDGEMENTS

The authors would like to express thanks for the

support of Chemical Engineering Department of

Universitas Sumatera Utara for providing research

facilities.

REFERENCES

Ahmed, Y.M., Abdullah Al-Mamun, Suleyman Aremu

Muyibi, Ma’an Fahmi R., Al-Khatib, Ahmed Tariq

Jameel, and Mohammed A., Al Saadi., 2010. Effect of

Adsorbate Initial Concentration on the Removal of Pb

from Aqueous Solutions by Carbon Nanofibers.

Nanoscience and Nanotechnology Research Group

(NANORG), Malaysia.

Ajmal, Z., Muhmood, A., Usman, M., Kizito, S., Lu, J.,

Dong, R., Wu, S., 2018. Phosphate Removal from

Aqueous Solution Using Iron Oxides: Adsorption,

Desorption and Regeneration Characteristics. Journal

of Colloid and Interface Science.

Ashley, K., Cordell, D., Mavinic, D., 2011, A Brief History

of Phosphorus: From The Philosopher's Stone to

Nutrient Recovery and Reuse. Chemosphere 84 737–

746.

Babayemi, Kamoru, A., Onukwuli, Dominic. O., 2017.

Equilibrium Studies and Optimization of Phosphate

Adsorption from Synthettic Effluent Using Acid

Modified Bio-Sorbent. American Journal of

Engineering and Applied Sciences 2017, 10 (4) :

980.991.

Bertolini, T.C.R., Izidoro, J.C., Magdalena, C.P., Fungaro,

D.A., 2013.. Adsorption of Crystal Violet Dye from

Phosphate Adsorption using KOH Activated Coal Bottom Ash

103

Aqueous Solution onto Zeolites from Coal Fly and

Bottom Ashes. Orbital: Electron. J. Chem. 5 (3):179-

191.

Bronislaw Buczek., 2016. Preparation of Active Carbon by

Additional Activation with Potassium Hydroxide and

Characterization of Their Properties. Advances in

Materials Science and Engineering, Volume 2016,

Article ID 5819208, 4 pages.

Charles, Osu., and Odoemelam, S.A., 2010. Study on

Adsorbent Dosage, Particle Sizes and Ph Constraints on

Biosorption of Pb (II) and Cd (II) Ions from Aqueous

Solution Using Modified and Unmodified Crasstrotrea

Gasar (Bivalve) Biomass. International Archive of

Applied Sciences and Technology, Vol. 1 (1) June

2010: 62-68 (2010).

Cordell, D., Drangert, J. O., White, S., 2009. The Story of

Phosphorus: Global Food Security and Food for

Thought. Global Environmental Change 19 (2009)

292–305.

Dincer, A.R., Gunes¸ Y., Karakaya, N., 2007. Coal-based

Bottom Ash (CBBA) Waste Material as Adsorbent for

Removal of Textile Dyestuffs from Aqueous Solution.

Journal of Hazardous Materials 141 529–535.

Freundlich, H. M. F., 1906. Uber die Adsorption in

Losungen. Zeithschrift fur Physikalische Chemie

(Leipzig). 57A, 385-470.

Gandhimathi, R., Ramesh, S.T., Sindhu, V., Nidheesh,

P.V., 2013.. Bottom ash Adsorption of Basic Dyes from

Their Binary Aqueous Solutions. Songklanakarin J. Sci.

Technol. 35 (3), 339-347.

Ghaneian, M.T., Ghanizadeh, G., Alizadeh, M.T.H.,

Ehrampoush, M.H., Said, F.M., 2014. Equilibrium and

Kinetics of Phosphorous Adsorption onto Bone

Charcoal from Aqueous Solution. Environ Technol. 35

882-890.

Gorme, J.B., Maniquiz, M.C., Kim, S.S., Son, Y.G., Kim,

Y.T., Kim, L.H., 2010. Characterization of Bottom Ash

as an Adsorbent of Lead from Aqueous Solutions.

Environ. Eng. Res.15(4) : 207-213.

Hasfalina, Man, C., Chin, W.H., Zadeh, M.R., Rashid, M.,

Yusof., M., 2012. Adsorption Potential of Unmodified

Rice Husk for Boron Removal. Bioresources 7 (3),

3810-3822.

Ikenyiri PN., Ukpaka CP., 2016. Overview on the Effect of

Particle Size on the Performance of Wood Based

Adsorbent. J Chem Eng Process Technol 7: 315. doi:

10.4172/2157-7048.1000315.

Kumar, P.S., Korving, L., Keesman, K.J., M.C.M. van

Loosdrecht, M.CM., 2019. Eff ect of Pore Size

Distribution and Particle Size of Porous Metal Oxides

on Phosphate Adsorption Capacity and Kinetics.

Chemical Engineering Journal 358 (2019) 160–169.

Ma J., Sun Y., Yu F., 2017. Efficient Removal of

Tetracycline with KOH-Activated Graphene from

Aqueous Solution. R. Soc. open sci. 4: 170731.

Mittal, J., Jhare, D., Vardhan, H., Mittal, A., 2013.

Desalination and Water Treatment : Utilization of

Bottom Ash as a Low-Cost Sorbent for the Removal

and Recovery of a Toxic Halogen Containing Dye

Eosin Yellow. Desalination and Water Treatment, DOI:

10.1080/19443994.2013.803265.

Muhmood, A., Wu, S., Lu, J., Ajmal, Z., Luo, H., Dong,

R., 2018. Nutrient Recovery from Anaerobically

Digested Chicken Slurry via Struvite: Performance

Optimization and Interactions with Heavy Metals and

Pathogens. Sci. Total Environ. 635 1-9.

Onar, A. Nur, Balkava, N., Akyuz. T., 1996. Phosphate

Removal by Adsorption. Enviromental Technology,

Vol. 17 pp 207-2013, Publications Division Selper Ltd.

Peleka, E.N., Mavros, P.P., Zamboulis, D., Matis, K.A.,

2006. Removal of Phosphates from Water by a Hybrid

Flotation–Membrane Filtration Cell. Desalination 198

198-207.

Peng, Y.Z., Wang, X.L., Li, B.K., 2006. Anoxic Biological

Phosphorus Uptake and the Effect of Excessive

Aeration On Biological Phosphorus Removal In The

A(2)O Process. Desalination 189(1-3) 155-164.

Saleh, S.M., Maarof, H.I., Rahim, S.N.S.A., Nasuha, N.,

2012.. Adsorption Congo Red into Bottom Ash. Journal

Of Applied Sciences 12 (11): 1181-1185.

Seftel, E.M., Ciocarlan, R.G., Michielsen, Meynen, V.,

Mullens, S., Cool, P., 2018. Insights into Phosphate

Adsorption Behavior on Structurally Modified ZnAl

Layered Double Hydroxides. Applied Clay Science 165

234–246.

Siwek, Hanna, Artur Bartkowiak, and Malgorzata

Wlodarczyk., 2019. Adsorption of Phosphates from

Aqueous Solutions on Alginate/Goethite Hydrogel

Composite. Water 2019, 11, 633;

doi:10.3390/w11040633.

Usman, M., Byrne, J.M., Chaudhary, A., Orsetti, S., Hanna,

K., Ruby, C., Kappler, A., Haderlein, S.B., 2018.

Magnetite and Green Rust: Synthesis, Properties, and

Environmental Applications of Mixed-Valent Iron

Minerals. Chem. Rev. 118(7) 3251-3304.

Van der Houwen, J., Valsami-Jones, E., 2001. The

Application of Calcium Phosphate Precipitation

Chemistry to Phosphorus Recovery: The Influence of

Organic Ligands Environ. Technol. 22 1325-1335.

Waseem, S., Din, M.I., Naseer, S.,. Rasool, A., 2012.

Evaluation of Acacia Nilotica as a Non Conventional

Low Cost Biosorbent for the Elimination of Pb (II) and

Cd (II) Ions from Aqueous Solutions. Arabian Journal

of Chemistry, VII.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

104