Sustainable Supply Chain Management in Manufacture

Nurhayati Sembiring*, Mangara M. Tambunan, Elizabeth Ginting, Intan Sari Dewi

Department of Industrial Engineering, Faculty of Engineering, Universitas Sumatera Utara,

Jalan Almamater Kampus USU, Medan, Indonesia 20155

Keywords: Manufacturing industry, Sustainable Supply Chain Management, SSCM.

Abstract: This paper introduces sustainable supply chains in the manufacturing industry, which include environmental,

social and financial aspects and several variables that influence them. This paper contains a review of several

studies on sustainable supply chains that have been carried out previously from 2005 to 2018. This paper

begins with an introduction to sustainable supply chains and exposure to problems underlying the ongoing

supply chain. Then the methodology and steps are explained. This paper objective is to afford a simple review

of sustainable supply chain management (SSCM). The manufacturing industry is always related to chemical

processes at the stages of the production process. This also always influences the environment. That is why

the sustainable topic becomes an important thing to study and to find the solutions. In addition, conclusions

and suggestions can be given to the supply chain of the manufacturing industry in the future.

1 INTRODUCTION

Sustainable development is an important problem

and is very rapidly developing in the industrial world.

This is indicated by the existence of several issues

regarding sustainable performance. The existence of

sustainable concepts in the company shows the

direction of developing economic aspects, and many

companies also involve social and economic aspects.

However, the implementation of the concept of

sustainable development requires a new strategy to

enable the integration of various aspects that are

considered separate (Kot, 2018).

The researchers that interested in sustainable

supply chain (SSCM) field, and also business

practitioners in manufacturing industries and supply

chain are growing fast. Due to solve problems in labor

conditions, geopolitics, climate change and also

pressure from company managers and supply chain

partners to encouragement the performance of

environmental, economic and social (Castillo,

Mollenkopf, Bell, & Bozdogan, 2018). The concept

of sustainability has been emphasized in many

manufacturing industries with government pressure

and increasing customer demand. sustainability

organization management involves good cooperation

between the government and the company (Orji,

2019).

This paper objective is to afford a simple review

of sustainable supply chain management (SSCM).

The manufacturing industry is always related to

chemical processes at the stages of the production

process. This also always influences the environment.

That is why the sustainable topic becomes an

important thing to study and to find the solutions. In

addition, this paper introduces sustainable supply

chains in the manufacturing industry, which include

environmental, social and financial aspects and

several variables that affect them.

2 LITERATURE REVIEW

The issue of sustainability is a very big problem in the

business world today, which is wider than the

community. For example, to bring up alternative

energy sources at a magazine kiosk needs some

assistance. This can be overcome by several factors

from aspects of sustainability such as energy

consumption related to climate change and involving

environmental problems. To do this. There are several

factors that influence the improvement of

sustainability, including supply and demand, and

improvements related to the environment (Carter,

Easton, & Carter, 2011).

SSCM as a new thing aims to advance the

performance of social and environmental related with

74

Sembiring, N., Tambunan, M., Ginting, E. and Sari Dewi, I.

Sustainable Supply Chain Management in Manufacture.

DOI: 10.5220/0008854300740078

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 74-78

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the supply chain area and also increase demand for

company needs and increase profits and minimize

competitiveness (Rentizelas, de Sousa Jabbour, Al

Balushi, & Tuni, 2018). Environmental performance

discussion focuses on the manufacturing industry in

the fields of chemistry, mining and industry that

produce toxic gases. In recent years, many companies

have not prioritized the impact on the environment,

but are only concerned with the company's profits

(Handfield, 2005). The impact of globalization shows

that outsourcing shows the importance of supply

chain networks from upstream to downstream, which

causes selection strategies for suppliers to be

considered to minimize competitiveness (Rentizelas

et al., 2018). Some studies show that the lack of

management level of the company can harm the

company itself in the financial aspect (Rentizelas et

al., 2018).

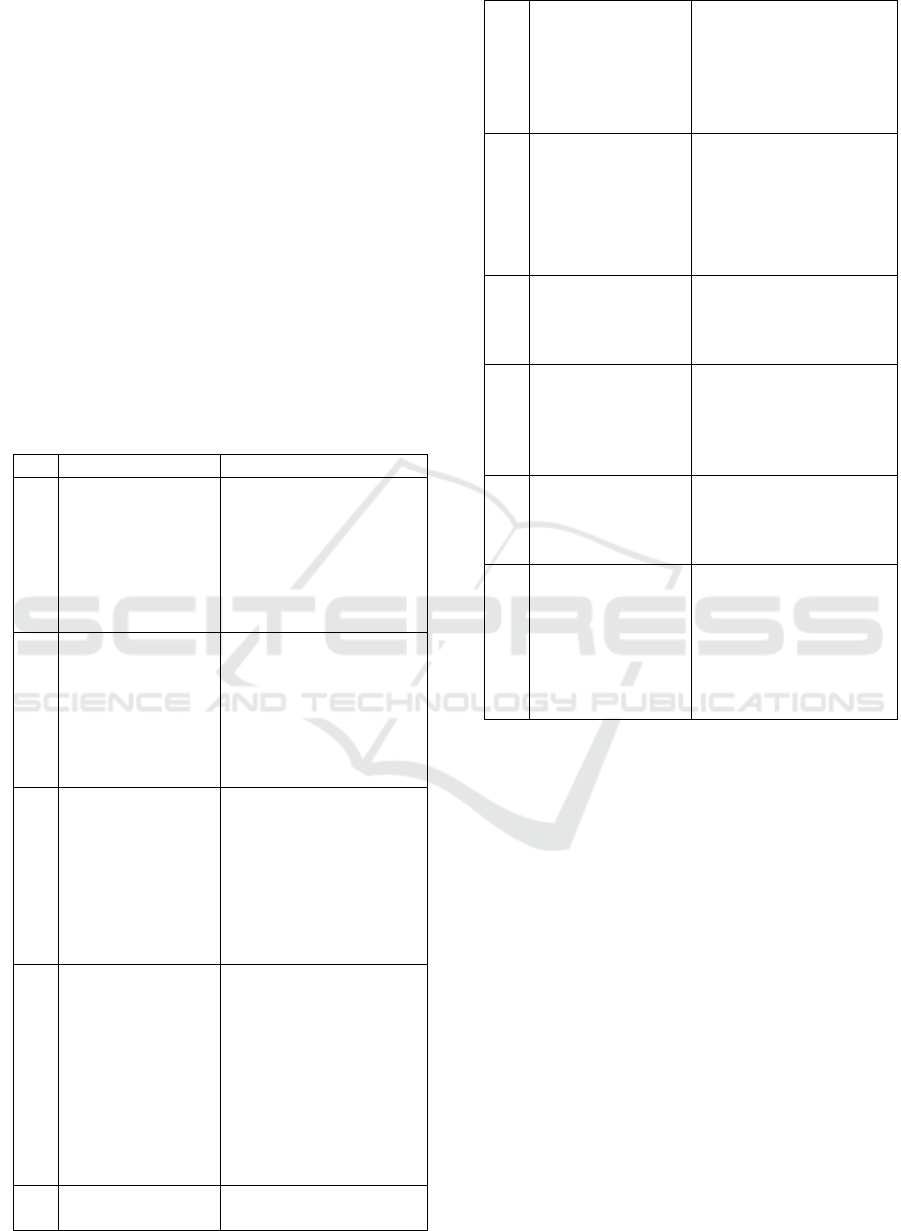

Table 1: Previous literature about SSCM

No

Author

Findings

1

Cantor et al, 2012

• Company provision

and environmental

activities influenced

by environmental

training.

• There is a variability in

employee involvement

2

Carter et al, 2011

• The environmental and

social area are studied

in the field of SSCM.

• Corporate social

responsibility is an

interesting object to be

studied.

3

Castilo et al, 2018

• As a future research,

SCI could explore the

interdependence of the

SSCM.

• SCI help firms to

construct and develop

sustainable supply

chain.

4

Esfahbodi et al,

2016

• The cost and

environmental

performance involved

by SSCM adoption on

within two emerging

markets.

• Performance levels of

the environmental

become higher after

implementing SSCM.

5

Taylor et al

• Only green and social

behavior are affected

by Sustainable

supplier co-ordination.

• There is no positive

impact on cost

reduction related with

Social practices.

6

Hsu & Tan, 2012

Company’s initiatives in

reverse logistics, design-

for-environment and

green purchasing are

drivers in green supply

chain implementation.

7

Lin et al, 2018

Approximate fuzzy

arithmetic applied for

analysed cause and effect

relationships.

8

Linton et al, 2007

Business models,

government policy, and

production operations

could be affect by

Sustainable development.

9

Zhu et al, 2013

The economic

performance could be

improved by GSCM

practices.

10

Barbosa, 2017

By assessing

environmental, and

economic aspects, the

sustainability has been

mainly attempted,

desertion the social

aspects.

3 METHOD

The steps to design a sustainable supply chain

continue by doing a research question as follows:

• What factors need to be considered before SSCM

is adopted?

• What is the impact of SSCM related with

environmental performance?

• What is the impact of SSCM related with

economic performance?

• What is the impact of SSCM related with social

performance?

By conducting research in the supply chain

through the questions above, there will be found a

causal relationship that continues to involve the

economic, environmental and social performance of

the company. The results of research through

questions can make it easier for companies to know

the factors that affect the company's continued

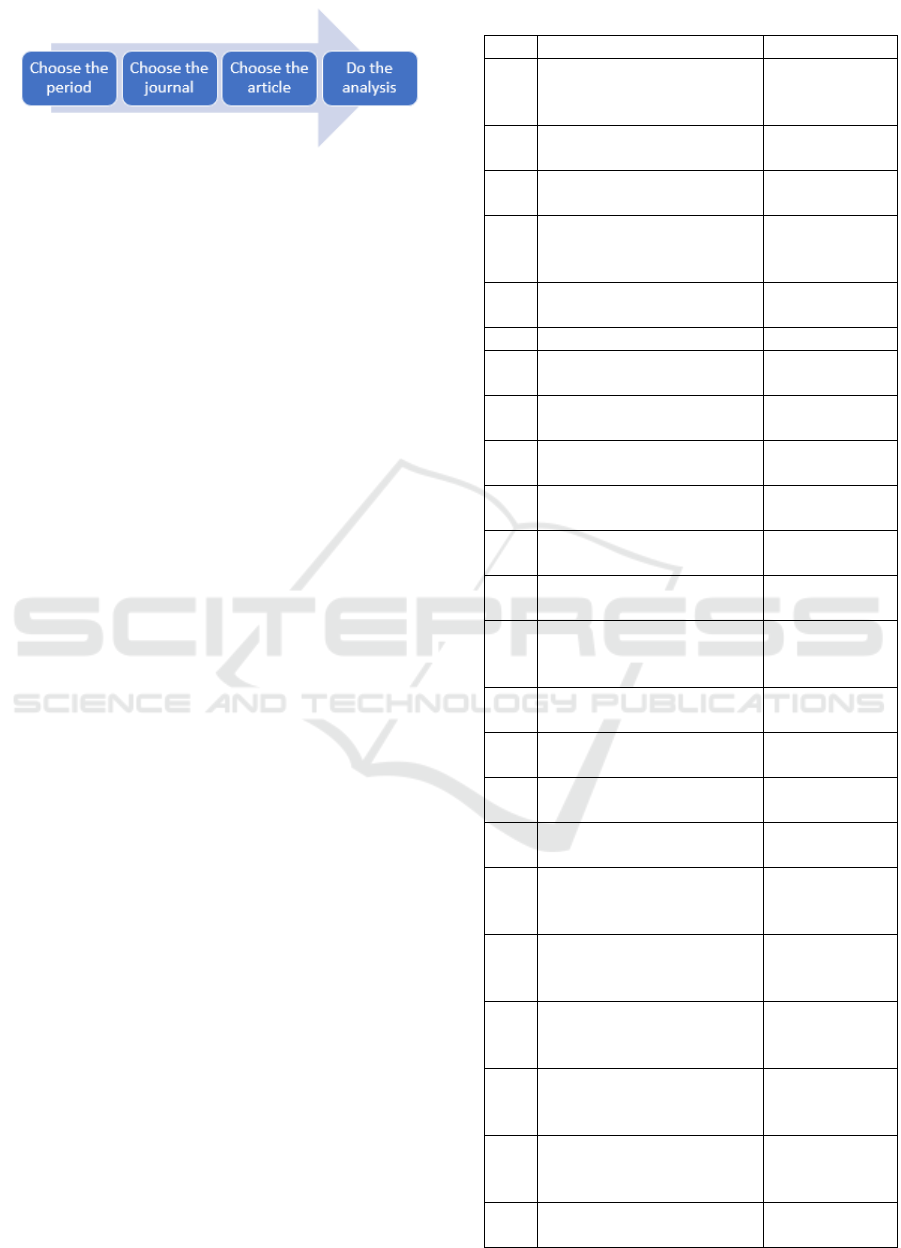

achievement (Esfahbodi et al., 2016). Figure 1 shows

an overview of the literature review methodology.

Sustainable Supply Chain Management in Manufacture

75

Figure 1: Steps to overview a literature

• Step 1, select the period: choosing a period of

time is considered to have enough to represent

the thought that is developing science.

• Step 2, select the journal: the selection of

journals aims to determine journals relating to

sustainable supply chains

• Step 3, select the article: choosing an article is

the purpose to be included in the analysis is a

clear relationship of the contents of the article to

the text framework that was previously set.

• Step 4 - carry out the analysis: the analysis was

carried out to find out the differences between

several studies so that development can be found

for further research.

4 RESULTS AND DISCUSSION

In this paper, a review of the supply chain

management's sustainability literature is to determine

several factors that influence aspects of sustainability.

From discussion and analysis could be seen that there

are several opportunities that allow the SSCM topic

to be applied in the company. Analysis shows that

pressure from government, consumers and company

managers is very influential in SSCM. For this

reason, companies need to improve supplier

performance in order to carry out the right sustainable

supply chain strategy. Please note that the concept of

sustainability is not something that guarantees the

running of a company's business in the twenty-first

century (Carter & Rogers, 2004).

This study uses a type of deductive research,

which develops concepts from previous research.

Following this approach, the model of causal

relations is conceptualized by a comprehensive study

of contemporary literature around the phenomenon of

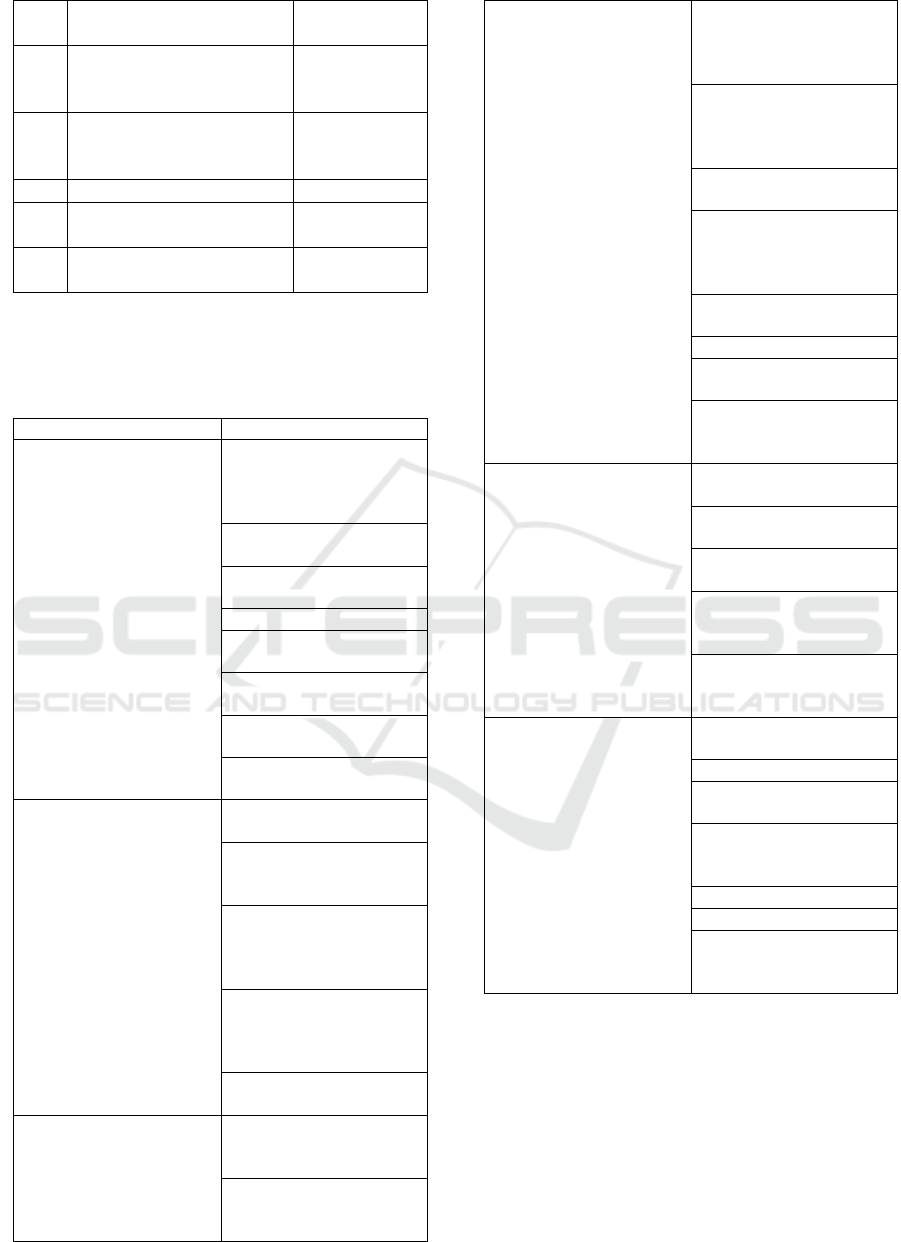

research. In Table 2, we can see the important factors

of SSCM obtained from previous studies.

Table 2: The important factor of SSCM

No.

Important factor

References

1

Establishment of

environmental requirements

on purchases of goods

Seuring and

Gold, 2013

2

ISO14001 Certification of

Suppliers

Zhu et al, 2007

3

Risk Management system

for SSCM

Seuring and

Muller, 2008

4

A good relationship

platform within the

company and with suppliers

Hollos et al,

2012

5

Environmental Audits for

Suppliers

Rao and Holt,

2005

6

The whole integration

Sarkish, 2012

7

Environmental Policy for

SSCM

Zailani et al,

2012

8

Environmental Education

and Training

Sarkish, 2001

9

The involvement of the

workforce

Cantor et al,

2012

10

Information Systems

Hollos et al,

2012

11

Quality Environment

Management

Seuring and

Muller, 2008

12

TOP Management

Commitment & Support

Seuring and

Gold, 2013

13

Set Up Database

Lingallows product

De Giovannia,

and Vinzi,

2012

14

Environmental Compliance

Agreement

Sarkis et al,

2010

15

Buy Eco-Friendly

Seuring and

Muller, 2008a

16

Selection and evaluation of

suppliers

Koplin et al,

2007

17

ISO 14001 Certification

Seuring and

Muller, 2008a

18

Commitment use less

energy during the

distribution of products

Green et al,

2008

19

Renewable energy as

prioritized in packaging

products

Hollos et al,

2012

20

Renewable energy as

prioritized in distribute

products

Green et al,

2008

21

Collaboration with clients

for green packaging

De Giovannia

and Vinzi,

2012

22

Product designed for

reducing the consumption

of energy or materials

Hsu et al, 2013

23

Dangerous materials is not

used for product design

Green et al,

2012a

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

76

24

Product designed for

reusing and recycling.

Hsu et al, 2013

25

Application of LCA to

perform environmental

reporting

Chunga and

Wee, 2011

26

Collaboration with clients

design and clean production

environment

Green et al,

2012a

27

Product Test Reports

Zhu et al, 2007

28

Surplus materials or

supplies will be sale

Green et al,

2012a

29

Waste and materials or

products will be sale

Zhu and

Sarkis, 2007

Based on such important factors compiled

research variables yangdiring cabinets in the Table 3.

Table 3: Important factor related dimension and SSCM

Variable

Important Factors

Sustainable Procurement

(Zhu et al., 2008A)

Establishment of

environmental

requirements for the

purchase of goods

Set the database

environmental product

Environmental

Compliance Statement

Buy Eco-Friendly

The character Bill of

Materials (BOM)

Selection and evaluation

of suppliers

ISO14001 Certification

of Suppliers

Environmental Audits for

Suppliers

Sustainable spread

(Green et al., 2012b)

Using renewable energy

in transport products

Collaboration with

clients for Green

Packaging

Cooperation with clients

to use less energy during

the transport of the

product

Using renewable energy

in the process of

packaging Product

Sivoice information

Using renewable energy

in transport products

Sustainable Design

(Zhu et al. 2008A)

Product designed to

reduce the consumption

of materials and energy

Product design to avoid

or reduce the use of

dangerous materials

Product designed for

reusing, recycling,

recovery of materials or

parts

Apply the report

environment to carry out

the LCA (Life cycle

management)

Follow the development

of reference

Establish the

environmental risk

management system for

SSCM

Generate Manual

Meeting

Product Test Reports

The involvement of the

workforce

Cooperation with clients

to design Green &

production

Investment Recovery

(Zhu et al., 2008A)

Sale of surplus materials

or supplies

Sales of used materials

and waste or byproducts

Excess Capital

Equipment Sales

Cooperation products

with Recycling the same

industry sector

Cooperation products

with Recycling the same

industry sector

Environmental

Management

Organization

(Hsu et al., 2013)

Support and commitment

of top management

ISO 14001 Certification

Environmental Education

and Training

Total Quality

Environmental

Management

Integration of some field

Environmental Criteria

Intensive communication

between suppliers and the

company

Environmental sustainability and minimization of

pollution levels are things that greatly affect the

manufacturing industry. This has triggered the

company to implement a new strategy in the

manufacturing industry in carrying out environmental

sustainability. Sustainable supply chains are an

important topic in the manufacturing industry now,

because there are several factors that influence supply

chain systems from various aspects such as the

existence of social pressure from the government or

Sustainable Supply Chain Management in Manufacture

77

consumers, increasing customer demand, corporate

image, tighter government regulations, scarcity of

resources natural power and so on.

5 CONCLUSIONS

The results of the study by conducting research

through several questions indicate that the practice of

SSCM shows that the implementation of SSCM

results in a different level of environmental

performance but perhaps have no affect to the

economic performance or costs of companies in

developing countries. From the results of question

research, it can be seen what factors influence

environmental, economic and social performance that

influence sustainable supply chain adoption. The cost

aspect must cover the total costs used for resources

and handling waste.

ACKNOWLEDGEMENTS

This research was already accepted with the number

of research contract 375/UN5.2.3.1/PPM/KP-

TALENTAUSU/2019, on 2 April 2019 and funded

by Directorate of Research and Community Service,

Directorate General for Research and Development at

the Ministry of Research, Technology and Higher

Education of Indonesia.

REFERENCES

Barbosa-p, A. P., 2017. PT.

https://doi.org/10.1016/j.ejor.2017.10.036

Cantor, D. E., Morrow, P. C., & Montabon, F., 2012.

Engagement In Environmental Behaviors Among

Supply Chain Management Employees : An

Organizational Support Theoretical Perspective. 33–51.

Carter, C. R., Easton, P. L., & Carter, C. R., 2011.

Sustainable supply chain management : evolution and

future directions.

Carter, C. R., & Rogers, D. S., 2004. A framework of

sustainable supply chain management : moving toward

new theory.

Castillo, V. E., Mollenkopf, D. A., Bell, J. E., & Bozdogan,

H., 2018. Supply Chain Integrity : A Key to Sustainable

Supply Chain Management. 39(1), 38–56.

Esfahbodi, A., Zhang, Y., & Watson, G., 2016. Author ’ s

Accepted Manuscript. Intern. Journal of Production

Economics. https://doi.org/10.1016/j.ijpe.2016.02.013

Handfield, R., 2005. Integrating Environmental

Management and Supply Chain Strategies. 19, 1–19.

Hsu, C., & Tan, K. C., 2012. Supply chain drivers that foster

the development of green initiatives in an emerging

economy. 656–688. https://doi.org/10.1108/IJOPM-10-

2011-0401

Kot, S., 2018. Sustainable supply chain management in

small and medium enterprises. Sustainability

(Switzerland), 10(4), 1–19.

https://doi.org/10.3390/su10041143

Lin, K., Tseng, M., & Pai, P., 2018. Resources ,

Conservation and Recycling Sustainable supply chain

management using approximate fuzzy DEMATEL

method. “Resources, Conservation & Recycling,” 128,

134–142.

Linton, J. D., Klassen, R., & Jayaraman, V., 2007.

Sustainable supply chains : An introduction. 25, 1075–

1082. https://doi.org/10.1016/j.jom.2007.01.012

Orji, I. J., 2019. Examining barriers to organizational

change for sustainability and drivers of sustainable

performance in the metal manufacturing industry.

Resources, Conservation and Recycling, 102–114.

https://doi.org/10.1016/j.resconrec.2018.08.005

Rentizelas, A., de Sousa Jabbour, A. B. L., Al Balushi, A.

D., & Tuni, A., 2018. Social sustainability in the oil and

gas industry: institutional pressure and the management

of sustainable supply chains. Annals of Operations

Research, 1–22. https://doi.org/10.1007/s10479-018-

2821-3

Taylor, P., Hollos, D., Blome, C., & Foerstl, K., 2015. Does

sustainable supplier co-operation affect performance ?

Examining implications for the triple bottom line. 37–

41. https://doi.org/10.1080/00207543.2011.582184

Zhu, Q., Sarkis, J., & Lai, K., 2013. Journal of Purchasing

& Supply Management Institutional-based antecedents

and performance outcomes of internal and external

green supply chain management practices. Journal of

Purchasing and Supply Management, 19(2), 106–117.

https://doi.org/10.1016/j.pursup.2012.12.001

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

78