Synthesis of Carboxymethyl Polysaccharide from Arenga Pinnata

Polysaccharide and Monochloroasetic

Juliati Br. Tarigan

1*

, Diana A. Barus

2

and Nico Hot Asi Naibahao

1

1

Department of Chemistry,Universitas Sumatera Utara, Jl. Bioteknologi No. 1 Kampus USU, Medan, Indonesia

2

Department of Physics, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Arenga pinnata Merr., polysaccharide, carboxymethyl, monochloroacetate.

Abstract: Synthesis of carboxymethyl polysaccharide Arenga pinnata has been prepared through etherification of

Arenga pinnata polysaccharide and monochloroacetate (MCA). Firstly the polysaccharide was extracted

from Arenga pinnata endosperm with different toughness (soft and hard) followed by etherification with

monochloroacetate using sodium hydroxide as a catalyst with variation of molar ratio MCA : NaOH of 0.50;

0.55; and 0.60 and ethanol 96% as solvent at temperature of 60C for 10 hours in oven. The substitution

degree was determined using titration method in which the Na-carboxymethyl was hydrolysis with HCl 2M

in methanol 70% to form carboxymethyl polysaccharide. The yields of carboxymethyl polysaccharide were

90% and 83% for hard and soft, respectively. The substitution degree of carboxymethyl polysaccharide

from soft Arenga pinnata endosperm was 1.600; 1.068 and 0.403 and from hard endosperm was 0.688;

0.467 and 0.202. The substitution degree of carboxymethyl polysaccharide was increased in the increasing

of NaOH used which polysaccharide from Arenga pinnata endosperm soft has higher substitution degree

than from the hard. The appearance stretching vibration of the carbonyl group (C=O) at a wavelength of

1730 cm-1 confirmed the formation of carboxymethyl polysaccharide. The morphology surface of

carboxymethyl polysaccharide showed rough surface than Arenga pinnata polysaccharide revealed that the

granule of polysaccharide have been changed.

1 INTRODUCTION

Chemical modification of polysaccharides is

considered as one very important pathway to

improve the properties of this biopolymer. Recently

research has been directed towards the

functionalization of a material. Carboxymethylation

of polysaccharides is one of the conversions widely

studied for the development of new biomaterials

with very promising applications (Parvathy et al.,

2005). Carboxymethylation could improve solubility

in water (increases hydrophilicity), insoluble

polysaccharides or low solubility in water (Yang and

Zhang, 2009). Gum polysaccharides are often not

completely dispersed and commercially available

gum solutions are usually cloudy and contain

suspended solid particles. Such solutions are usually

quite thick and cannot be filtered to separate

suspended solids, for this purpose they need to be

modified into carboxymethyl gum which can form

bright dispersion solutions compared to untreated

gum (Moe, 1949). One source of polysaccharide that

is abundant in Indonesia is the endosperm of palm

seeds (Arenga pinnata Merr.) which is often known

as “kolang-kaling” (Mogea et al., 1991). The

utilization of this endosperm is remaining limited for

food (Orwa et al., 2009, Tarigan et al., 2018b).

The polysaccharide containing in Arenga pinnata

endosperm (APE) is galactomannan consisting of

mannose and galactose with a ratio of galactose :

mannose of 1 : 1,33. Those monosaccharide linked

in a linear chain of 1,4- β-D-mannopyranosil and is

water soluble if the galactose residue is >5% and is

insoluble in water if <5% (Aspinall, 1959, Bento et

al., 2013, Tarigan et al., 2012, Tarigan et al., 2018a).

Carboxymethylation reactions have been studied

in some natural polymers such as cellulose,

funegeric gum, sesbania gum flour, guar gum (Gong

et al., 2012, Liyanage et al., 2015, Noleto et al.,

2009, Parvathy et al., 2005). In general, the

carboxymethylation method is carried out using the

catalyst NaOH and NaHCO

3

and monochloroacetate

(MCA) reagents. Reactions can take place either in

with or without water in increasing temperatures

Tarigan, J., Barus, D. and Hot Asi Naibaho, N.

Synthesis of Carboxymethyl Polysaccharide from Arenga Pinnata Polysaccharide and Monochloroasetic.

DOI: 10.5220/0008854100630068

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 63-68

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

63

(Parvathy et al., 2005). Gong et al. (2012) have

examined the synthesis and characterization of

carboxymethyl guar gum with the dry method and

alkalization process using NaOH catalyst and

carboxymethylation using (MCA) and the degree of

substitution was determined by titrimetric. The dry

method is used to avoid the formation of gels that

can resist the effective penetration of the catalyst

and reagent rendering incomplete reaction resulting

in very low substitution degrees.

Based on the description above, this study aimed

to modify the polysaccharide of APE into

carboxymethyl using MCA and NaOH as a catalyst

through the dry method. The type of APE powder

used is hard and soft which is determined by the

penetrometer. The carboxymethyl obtained was

determined by FT-IR spectrophotometer, surface

properties with SEM, and degree of substitution by

titration.

2 MATERIALS AND METHODS

2.1 Materials

The Arenga pinnata was collected from a traditional

market in Medan – Indonesia. All chemicals used in

this study were brought from the local chemical

supplier without any purification.

2.2 Methods

2.2.1 The APE Texture Determination

The stratified random sampling method was used to

collect palm seeds. Texture measurements are

carried out using a penetrometer. The prepared

sample was stabbed at four points using a precision

penetrometer which was pressured 250 g with a

scale of 1/10 mm for 10 seconds. Texture values can

be read on the scale indicated by the needle

instructions and the four values are averaged. The

texture value was calculated with the formula as

below.

/

/

/

(1)

2.2.2 Preparation APE Extract

The preparation of APE extract was conducted

following the previous procedure (Tarigan and

Purba, 2015). The APE group I (hard) was chopped

as thick as 2 mm and crushed roughly with a blender

at a scale speed of 1 for 2 minutes with 250 mL of

water. The hydrogel obtained was immersed in 96%

ethanol for 48 hours at a ratio of 1: 2, then filtered,

the residue obtained was soaked again with ethanol

which was half volume from the initial ethanol

volume for 48 hours and finally with pure grade

ethanol for 12 hours until the residue is submerged.

The residue obtained is dried in a desiccator in a

vacuum until the weight is constant. The same

procedure is conducted for soft palm seeds (group

II). The obtained APE powder was characterized by

FT-IR analysis and SEM surface morphology.

2.2.3 Preparation of Carboxymethyl APE

The preparation of carboxymethyl APE was done

using a method developed by Gong et al. (2012)

with slight modification. 1.65 grams of

galactomannan from APE group I were put into

glass beakers and then added with NaOH in varying

concentration. The mole ratio of MCA : NaOH used

was 1:0.5; 1:0.55 and 1:0.6. Next, the solution was

added with 1 mL ethanol 96%, heated at 30

o

C while

stirring using a magnetic stirrer for 20 minutes and

then was added 1.05 grams of MCA and stirring

using a magnetic stirrer for another 20 minutes, then

transferred into a watch glass and heated in the oven

for 10 hours with a temperature of 60

o

C.

Carboxymethyl polysaccharide produced was dried

at room temperature, crushed and stored in a

desiccator. The same treatment was carried out for

APE group II.

2.2.4 Determination of Substitution Degree

The determination of substitution degree according

to the procedure established by the previous

researcher (Gong et al., 2012). Determination of

substitution degree (SD) was carried out firstly with

converting Na-carboxymethyl polysaccharide into

carboxymethyl polysaccharide of palm seeds. 1.5

grams of Na-carboxymethyl polysaccharide from the

group I with a mole ratio of MCA : NaOH of 1:0.50

was poured into a glass beaker which already

contains 2 M HCl (in methanol 70%), stirred with a

magnetic stirrer for 2 hours, then filtered. The solids

of carboxymethyl polysaccharide obtained were then

washed using ethanol 96% until chlorine free (tested

using silver nitrate / AgNO3 0.1 M solution). The

resulting solid is dried in an oven at 60

o

C for 2

hours. 0.2 grams of carboxymethyl polysaccharide

that has been dried then dissolved in 20 mL of 0.1 M

NaOH, stirred for 2 hours with a magnetic strider.

The carboxymethyl polysaccharide which has excess

NaOH is then titrated using a standard 0.1 M HCl

solution with the addition of phenolphthalein as an

indicator. The same treatment was carried out for the

comparison of MCA : NaOH 0.55; 0.60 and

carboxymethyl galactomannan from APE group II.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

64

The carboxymethyl polysaccharides obtained were

analyzed using FT-IR spectrophotometer and SEM.

3 RESULTS AND DISCUSSIONS

3.1 Texture

The sample is prepared by grouping samples using

the stratified random sampling method. The

population of 100 APE is grouped into 2 groups with

almost the same level of similarity. Group 1 (50

pieces) and group 2 (50 pieces). Samples were taken

randomly at 2% for each group which was for

groups 1 (10 pieces) and group 2 (10 pieces) and

determined in 4 positions namely: up, down, right

and left, then taken evenly the points, but the data is

not included in this paper. The texture and yield of

APE powder and yield carboxymethyl product

showed in Table 1.

Tabel 1: The texture value and yield of APE powder and

carboxymethyl

Parameter

Seed of A. pinata

Hard Soft

Texture

(g/mm)

0.1054–0.1342 0.0846-0.0999

Yield of APE

powder (%)

4.72 4.52

Yield of

carboxymethyl

(%)

90 83

The difference in texture value (Table 1) is

caused by the level of maturity which in soft APE is

lower than that of hard APE. The more mature the

sugar palm seeds, the harder and the higher the

content in the endosperm, the more resistant to

mechanical damage even to water (Cerqueira et al.,

2009). The hard and soft texture is also affected by

the treatment given to the process of making APE,

for example, soaking time, cooking, stripping, etc.

that allow for differences in the texture between one

APE and another. Thus the texture obtained is

different from the texture we have reported in our

previous study, where the hard and soft texture of

the value is lower than our previous research report,

this is because the APE is used uniformly and are

softer and rounder (not flattened) and the source is

also different. Likewise, the percentage of the APE

powder obtained is also different from our previous

research.

3.2 FT-IR Analysis

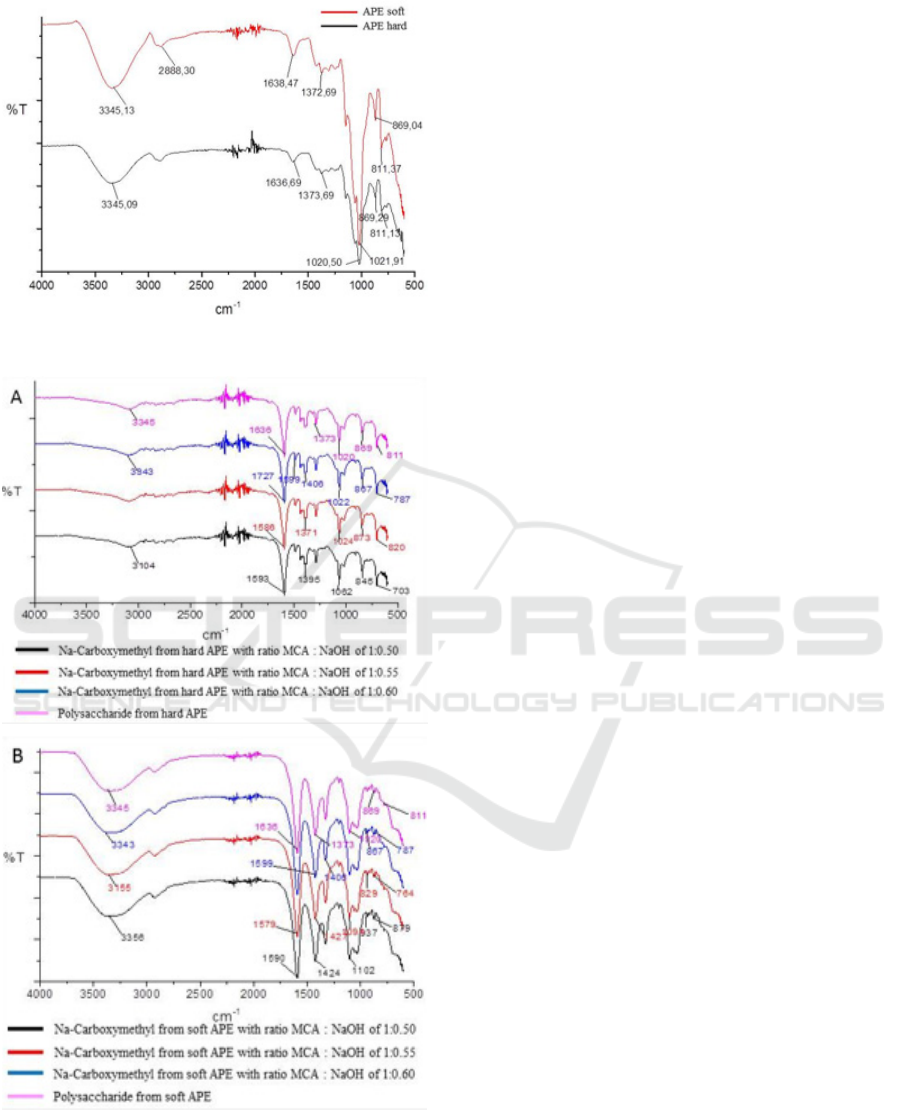

FT-IR spectrum (Figure 1) shows the peak

characteristics of galactomannan which is similar

with the literature of Boual et al. (2015) and

(Tarigan, 2014); there is no difference in absorption

bands for hard and soft APE, respectively. The

absorption peak at 3345 cm

-1

shows the stretching

vibration of the OH group from the polysaccharide

and the absorption band at 2888 cm

-1

shows the

stretching vibration -CH of -CH

2

- (Singh et al.,

2009) supported by bending vibrations -CH

2

- on the

wavelength of 1372 and 1373 cm

-1

. Absorption at

1638 and 1636 cm

-1

indicates the presence of an OH

group bound to water. The wide peaks at an area of

900 - 1200 cm

-1

due to stretching vibrations of -C-C-

O, C-OH, and C-O-C from the main polymer chain

(Buriti et al., 2014). The peak at 1021 cm

-1

, 1020

cm

-1

shows the C-O bending vibration of the

pyranose ring. The band at 869 cm

-1

characteristics

of the β-D-manopiranose bond present in the

polysaccharide (Buriti et al., 2014) and the band at

811 cm-1 showed the presence of α-D-

galactopiranose bonds (Buriti et al., 2014).

Carboxymethyl polysaccharide from hard and

soft APE was carried out in two stages, namely the

process of adding NaOH as a catalyst (alkalization)

and formed Na-carboxymethyl polysaccharide

which was analyzed by FT-IR (Figures 2) followed

by the addition of MCA (carboxymethylation). The

carboxymethyl polysaccharide of APE formed was

analyzed with an FT-IR spectrophotometer (Figures

3).

In the formation of Na-Carboxymethyl

polysaccharides the peak changes at wave number

1636 cm

-1

on hard APE and wave number 1638 cm

-1

on soft APE. The formation of carboxymethyl

polysaccharide from hard and soft APE is shown by

the formation of absorption bands at wave numbers

around 1730 cm

-1

which states the formation of

carbonyl groups (C = O). Figure 3A shows that the

peak formation of carboxymethyl carbonyl groups of

hard APE at a ratio MCA : NaOH of 1 : 0.50 while

for carboxymethyl soft palm seeds (figure 3B) the

appearance of carbonyl peaks at mole ratio MCA :

NaOH of 1 : 0.50 and 1 : 0.55. This is inseparable

from the less crystalline polymer structure in soft

APE. The structure is increasingly crystalline

because of the presence of hydrogen bonds

(Niroomand et al., 2016). The release of galactosyl

residues from galactomannan polymers will provide

an increase in the mannose ratio in galactomannan

or the formation of mannan (Bento et al., 2013)

rendering the APE get harder.

Synthesis of Carboxymethyl Polysaccharide from Arenga Pinnata Polysaccharide and Monochloroasetic

65

Figure 1: FT-IR spectrum of APE powder hard and soft

Figure 2: FT-IR spectrum of Na-carboxymethyl with ratio

MCA : NaOH of 1 : 0.50; 1 : 0.55; 1 : 0.60 from

(A) hard APE and (B) soft APE.

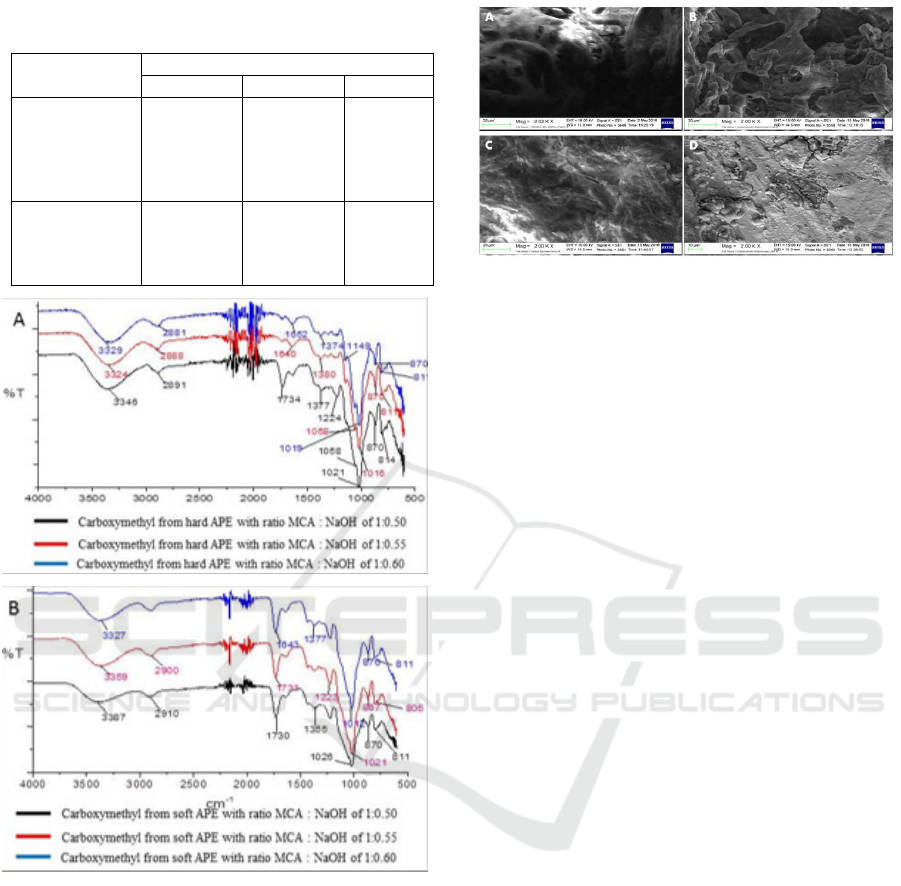

3.3 SEM Images

The surface morphology images polysaccharide of

hard and soft APE and carboxymethyl

polysaccharide of hard and soft APE is shown in

Figure 4. The surface morphology of hard APE is

indicated by a rough and irregular surface and fused

with each other while soft APE is soft and the

surface is smoother. The morphology of the surface

of carboxymethyl polysaccharides of hard APE

becomes rough and bumpy which indicates that the

interaction between the polymer chains is irregular.

3.4 The Substitution Degree

The substitution degree was determined using

titrimetric method and the result is presented in table

2. The substitution degree (DS) is the average value

of the hydroxyl group exchanging with the

carboxymethyl group present in each

anhydroglucose monomer unit. Substitution degree

test was conducted to determine the number of

carboxyl compounds present in each polysaccharide

monomer. The substitution degree describes the

quality of the carboxymethyl polysaccharide

produced. Theoretically, the maximum substitution

degree value is 3. The substitution degree value

produced from hard APE carboxymethyl

polysaccharide is 0.688 whereas in the

carboxymethyl polysaccharide of soft APE produced

a substitution degree value of 1,600. From the table

above it can be said that the higher or more the

amount of sodium hydroxide (NaOH) is used, the

greater the degree of substitution possessed by the

carboxymethyl polysaccharide. The increasing

amount of NaOH used makes the etherification

process better because the alkali polysaccharide

forms reactivity which is higher in proportion to the

high concentration of NaOH used. The substitution

degree in carboxymethyl polysaccharide of soft APE

is greater than that of carboxymethyl polysaccharide

of hard APE. This is because NaOH is easier to

penetrate increasing swelling properties, for which

monocloroacetic compounds are easier to substitute.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

66

Tabel 2: The substitution degree of carboxymethyl

polysaccharide

Parameter

Mole ratio of MCA : NaOH

0.60 0.55 0.50

SD of

carboxymethyl

polysaccharide

from hard

APE

0.202 0.467 0.688

SD of

carboxymethyl

polysaccharide

from soft APE

0.403 1.068 1.600

Figure 3: The FT-IR spectrum of carboxymethyl

polysaccharide with ratio MCA : NaOH of 1 :

0.50; 1 : 0.55; 1 : 0.60 from (A) hard APE and

(B) soft APE

Figure 4: The SEM images polysaccharide of (A) hard

APE, (B) soft APE and carboxymethyl

polysaccharide from (C) hard APE, (D) soft

APE

4 CONCLUSIONS

Carboxymethyl polysaccharide from hard and soft

APE can be synthesized by the dry method with 2

stages, namely alkalization and carboxymethylation.

Carboxymethyl formation is characterized by the

appearance of C = O peaks at wave number 1730

cm-1. Percent yield for hard and soft APE was 90%

and 83%, respectively. The surface morphology of

polysaccharide was change from smooth to wavy in

carboxymethyl. The degree of substitution of

carboxymethyl hard APE is smaller than that of soft

APE.

REFERENCES

Aspinall, G. O. 1959. Structural Chemistry of the

Hemicelluloses. In: WOLFROM, M. L. (ed.)

Advances in Carbohydrate Chemistry. Academic

Press.

Bento, J. F., Mazzaro, I., De Almeida Silva, L. M., De

Azevedo Moreira, R., Ferreira, M. L. C., Reicher, F. &

De Oliveira Petkowicz, C. L. 2013. Diverse patterns of

cell wall mannan/galactomannan occurrence in seeds

of the Leguminosae. Carbohydrate Polymers, 92, 192-

199.

Boual, Z., Pierre, G., Delattre, C., Benaoun, F., Petit, E.,

Gardarin, C., Michaud, P. & El Hadj, M. D. O. 2015.

Mediterranean semi-arid plant Astragalus armatus as a

source of bioactive galactomannan. Bioactive

Carbohydrates and Dietary Fibre, 5, 10-18.

Buriti, F. C. A., Dos Santos, K. M. O., Sombra, V. G.,

Maciel, J. S., Teixeira Sá, D. M. A., Salles, H. O.,

Oliveira, G., De Paula, R. C. M., Feitosa, J. P. A.,

Monteiro Moreira, A. C. O., Moreira, R. A. & Egito,

A. S. 2014. Characterisation of partially hydrolysed

Synthesis of Carboxymethyl Polysaccharide from Arenga Pinnata Polysaccharide and Monochloroasetic

67

galactomannan from Caesalpinia pulcherrima seeds as

a potential dietary fibre. Food Hydrocolloids, 35, 512-

521.

Cerqueira, M. A., Lima, Á. M., Teixeira, J. A., Moreira, R.

A. & Vicente, A. A. 2009. Suitability of novel

galactomannans as edible coatings for tropical fruits.

Journal of Food Engineering, 94, 372-378.

Gong, H., Liu, M., Chen, J., Han, F., Gao, C. & Zhang, B.

2012. Synthesis and characterization of carboxymethyl

guar gum and rheological properties of its solutions.

Carbohydrate Polymers, 88, 1015-1022.

Liyanage, S., Abidi, N., Auld, D. & Moussa, H. 2015.

Chemical and physical characterization of

galactomannan extracted from guar cultivars

(Cyamopsis tetragonolobus L.). Industrial Crops and

Products, 74, 388-396.

Moe, O. A. 1949. Carboxyalkyl ethers of carbohydrate

gums. Google Patents.

Mogea, J., Seibert, B. & Smits, W. 1991. Multipurpose

palms: the sugar palm (Arenga pinnata (Wurmb)

Merr.). Agroforestry Systems, 13, 111-129.

Niroomand, F., Khosravani, A. & Younesi, H. 2016.

Fabrication and properties of cellulose-nanochitosan

biocomposite film using ionic liquid. Cellulose, 23,

1311-1324.

Noleto, G. R., Petkowicz, C. L. O., Mercê, A. L. R.,

Noseda, M. D., Méndez-Sánchez, S. C., Reicher, F. &

Oliveira, M. B. M. 2009. Two galactomannan

preparations from seeds from Mimosa scabrella

(bracatinga): Complexation with oxovanadium(IV/V)

and cytotoxicity on HeLa cells. Journal of Inorganic

Biochemistry, 103, 749-757.

Orwa, C., Mutua, A., Kindt, R., Jamnadass, R. & Simons,

A. 2009. Agroforestree database: a tree species

reference and selection guide version 4.0. World

Agroforestry Centre ICRAF, Nairobi, KE.

Parvathy, K. S., Susheelamma, N. S., Tharanathan, R. N.

& Gaonkar, A. K. 2005. A simple non-aqueous

method for carboxymethylation of galactomannans.

Carbohydrate Polymers, 62, 137-141.

Singh, V., Sethi, R. & Tiwari, A. 2009. Structure

elucidation and properties of a non-ionic

galactomannan derived from the Cassia pleurocarpa

seeds. International Journal of Biological

Macromolecules, 44, 9-13.

Tarigan, J. B. 2014. Karakterisasi Edible Film Yang

Bersifat Antioksidan Dan Antimikroba Dari

Galaktomanan Biji Aren (Arenga pinnata) Yang

Diinkorporasi Dengan Minyak Atsiri Daun Kemangi

(Ocimum basilicum L.). Doktor Disertasi, Universitas

Sumatera Utara.

Tarigan, J. B., Barus, T., Kaban, J. & Marpongahtun.

Characteristic and Study of Antioxidant Activity

Galactomanan from "Kolang-Kaling" (Arenga

pinnata). Asian International Conference on

Materials, Mineral and Polymer, 23 - 24 March 2012

2012 Penang. Penang.

Tarigan, J. B., Kaban, J. & Zulmi, R. 2018a.

Microencapsulation of vitamin e from palm fatty acid

distillate with galactomannan and gum acacia using

spray drying method. IOP Conference Series:

Materials Science and Engineering, 309, 012095.

Tarigan, J. B. & Purba, D. 2015. Karakterisasi

Polisakarida Galaktomanan Kolang Kaling (Arenga

pinnata) Terikat Silang Fosfat. Majalah Polimer

Indonesia, 18, 1-8.

Tarigan, J. B., Purba, D. & Zuhra, C. F. 2018b.

Incorporation of vitamin E onto cross-linked

galactomannan phosphate matrix and in vitro study.

Asian Journal of Pharmaceutical and Clinical

Research, 11, 355-358.

Yang, L. & Zhang, L. M. 2009. Chemical structural and

chain conformational characterization of some

bioactive polysaccharides isolated from natural

sources. Carbohydrate Polymers, 76, 349-361.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

68