Design of Welding Positioning Device for Big-Caliber Steel Tube

based on TRIZ Theory

Liangbo Ji

1

, Xuejiao Sun

1

, Ning Zhang

1

and Min Wan

1

1

Yingkou Institute of Technology, Yingkou, Liaoning, China

Keywords: TRIZ theory, Welding, Positioning Device.

Abstract: TRIZ theory is one of the most practical and efficient methods of innovation in modern times, The article

aims to solve the problem of "low efficiency in welding production of Big-caliber steel tube ", based on

TRIZ theory, the design of large diameter steel tube auxiliary welding positioning device can be flexible

clamping of various sizes of steel tubes, ensure that the big-caliber steel tube fitting can be welded flexibly

after being fixed, The practical problem of repeated clamping during welding is solved.

1 APPLICATION OF TRIZ

THEORY

1.1 Initial Investigation of Positioning

Device Design

According to market research, the main function of

existing auxiliary welding positioning devices is to

completely fix the workpiece, ensure smooth

operation of welding, its usage characteristics lead to

the tube cannot be rotated or moved after the welder

has fixed it, after welding some welds, the rest parts

are difficult to be welded, it needs to be fixed and

welded again, the working process is time-

consuming and laborious, and easy to appear the

sealing-off welding situation, the equipment is not

easy for operators to use.

Based on the analysis of existing relevant

patents, TRIZ theory "SVOP" expression method is

used to express the function of the system to be

designed, setting design objectives (Countinho J S,

1964):

Technology System(S): Auxiliary welding

positioning device;

Apply Action(V): Fixed/rotated;

Action Object(O): Big-caliber steel tube;

Parameters of the action object(P): Displacement

changes

Therefore, the function of the design system is

expressed as "auxiliary welding positioning device

to fix/rotate the displacement change of big-caliber

steel tube". The key problem to be solved in its

design is how to save time and effort. Single

clamping can complete the whole circle welding

with less labor, and put the welding personnel in the

best position for easy welding.

1.2 Analysis Design System Problem

TRIZ theory has a very systematic analysis method

for the problem of innovative design. The main

purpose of system analysis is to find the key

problems of the whole design system, for the design

problems in this article, analysis the function, cause

and effect and resources of the design system that

can effectively determine the key problems to be

solved in the whole system.

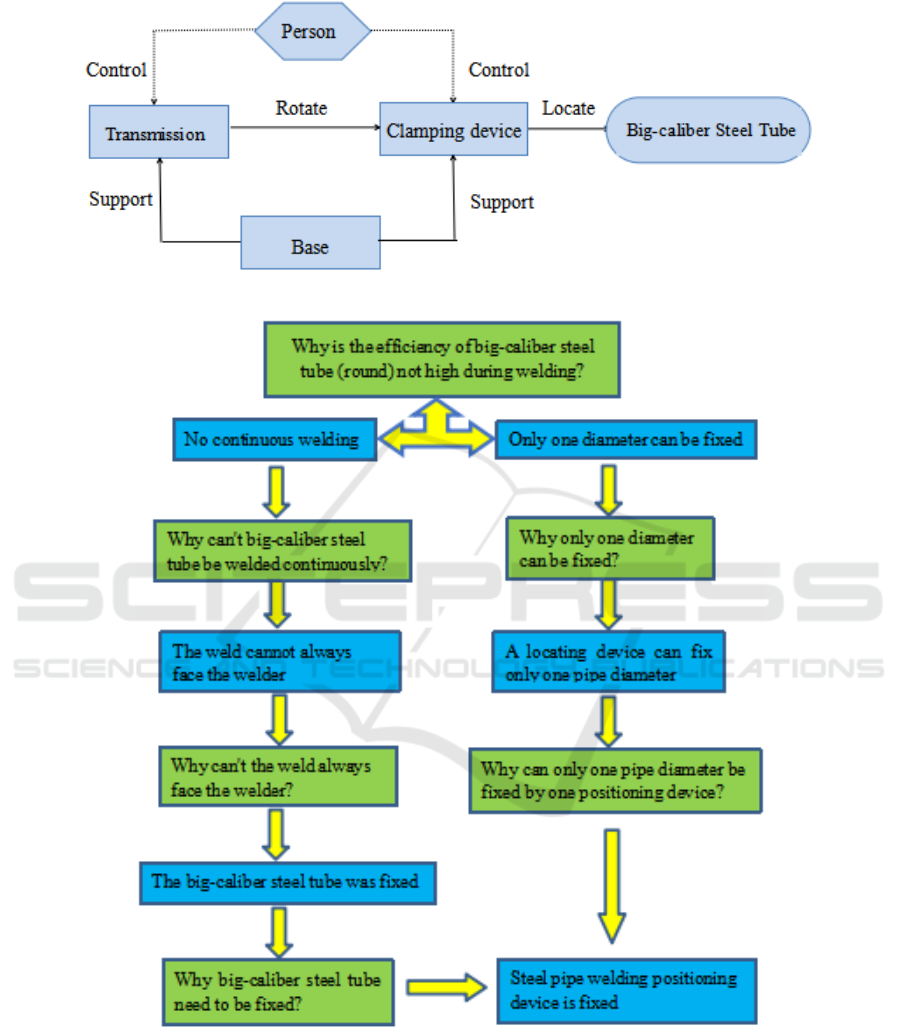

1.2.1 System Function Analysis

The function of this system is expressed as "the

displacement change of big-caliber steel tube

fixed/rotated by the auxiliary welding positioning

device", according to the system function model

figure 1, the negative function of the system is

insufficient control of the driving device and

clamping device in the human positioning device

(Gofuku A, Koide S, Shimada N, 2006).

1.2.2 Systematic Causal Analysis

5Whys analysis method is adopted to carry out

causal analysis on the design system, In the five-

question analysis method (figure 2), Let's start with

Ji, L., Sun, X., Zhang, N. and Wan, M.

Design of Welding Positioning Device for Big-Caliber Steel Tube based on TRIZ Theory.

DOI: 10.5220/0008848901650171

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 165-171

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

165

the question "why is the efficiency of big-caliber steel tube (round) not high in the welding process?”,

Figure 1. Function model diagram of auxiliary welding positioning device.

Fig 2. 5Whys method diagram of auxiliary welding positioning device.

explore the cause of the problem through two lines

of questions, derive the ultimate cause of the

problem finally "Steel tube welding positioning

device is fixed", it follows that, We believe that the

design of the welding positioning device of steel

tube into an overall adjustable type may become a

research focus of this product.

1.2.3 System Resource Analysis

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

166

The resource analysis list of auxiliary welding devices is shown in table 1.

Table 1. Resource analysis list of auxiliary welding devices.

Resource Type System level

Subsystem System Super system

Material resources

Transmission

mechanism,clamping mechanism,

engine base

Welding

positioner

device

Welding steel tube

Energy resources Mechanical energy

Mechanical

energy

Mechanical energy,

Electrical energy,

Magnetic energy

Space resources Manual operation space

Inside the

device, steel

tube turnover

space

Steel tube connection

space

Time resources Transmission time, clamping time

Steel tube

fixing and

turning time

Steel tube connection

time

Information

resources

Personal experience

Mechanical

principle

mechanical principle,

electromagnetic principle

Functional

resources

Control-system

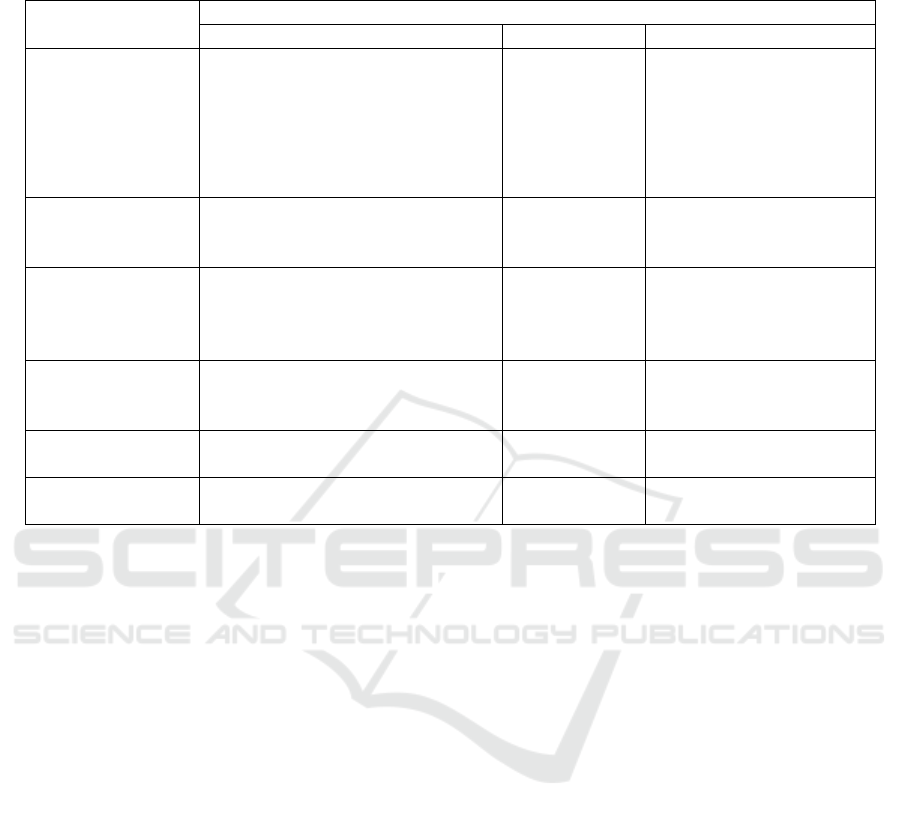

Draw the nine-screen diagram of the auxiliary

welding positioning device through the analysis list

(FIG. 3), you can see it clearly through the nine-

screen image, starting with the initial common

welding fixtures, the development of auxiliary

welding positioning device has gone through a long

evolutionary process. From the nine-screen diagram,

we can analyze that the clamping device and the

transmission device are one of the most compact

subsystems of the auxiliary welding positioning

device, so we think the design of clamping and

transmission device may become a research focus of

this design.

1.2.4 Analysis Summary

Through the above analysis method summary,

transform the difficult problems in the system design

process into two key problems A and B, Question A

- how to clamp the welding parts and adjust the

welding position to find the most suitable welding

station and Question B - how to design a welding

device suitable for welding parts of different sizes,

and simple operation of an auxiliary welding

positioning device, solving the above two problems

is very important for the design of the device.

1.3 Solutions to Design System

Problems

TRIZ theory has a clear classification for the

solution of quasi-analytical problems, as to this

specific problem for the design of this article, the "

Idea Final Result " is adopted to establish the

solution ideas of the related problems in the overall

design, then through the physical contradictions and

technical contradictions of design process to solve

one by one to improve the system design (Qin Han,

2009).

1.3.1 Idea Final Result

When using TRIZ tools to solve problems, we use

the "IFR" analysis method firstly (as shown in table

2).

Design of Welding Positioning Device for Big-Caliber Steel Tube based on TRIZ Theory

167

Fig 3. Nine-screen analysis diagram of auxiliary welding positioning device.

Table 2. Idea Final Result Analysis Method Table.

NO Question Analysis Results

1

What is the

ultimate goal

of the design?

Improve welding

efficiency of big-

caliber steel tube.

2

What is the

Idea Final

Result?

Easy operation,

clamp pipe diameter

welding parts of

different sizes,

continuous turning to

ensure that the

welding device.

3

What are the

obstacles to

reaching the

idea final

result?

Manual labor is

laborious and

inconvenient, poor

regulation of

clamping device

4

What is the

result of this

obstacle?

The welding process

requires hand-rolled

steel pipe, the device

is not suitable for all

pipe diameters.

5

What are the

conditions for

not having this

disorder?

Design the

mechanism for

turning steel pipes,

improved clamping

device.

6

What are the

available

resources to

create these

conditions?

Electrical energy,

personal experience

accumulation,

mechanical related

principles

From the above analysis, we can see that we

should give priority to our own advantages,

therefore, we will improve the structural design and

combine the electrical device to realize the final

ideal solution of an auxiliary welding positioning

device, it is concluded that the diameter of tube is

clamped electrically by the rotating device, by

improving the clamping device, it is suitable for all

Big-caliber welding parts, through the improvement

of the positioning device, the device can not only

complete the clamping positioning, but also can flip

and move.

1.3.2 Solution to Key Problem A - Physical

Contradiction

Key question A: how to clamp the welding parts and

adjust the welding position to find the most suitable

welding station? Through analysis, it is found that

the circular tube needs to be clamped and fixed in

the welding process to ensure the quality of welding.

The weld of circular tube needs to move to the front

of the welder to ensure the smooth welding, so we

use physical contradiction analysis.

Firstly, the problem is transformed into a

physical contradiction, which can be expressed as

follows: The circular tube needs to be clamped and

fixed to ensure the welding quality, and it needs to

be moved to the front of the welder to ensure the

smooth operation of welding.

TRIZ theory uses the separation principle to

solve physical contradictions (Guang Yang, 2004).

Based on the above description of physical

contradictions, the principle of space separation is

more reasonable. After analyzing the invention

principle, we believe that principle 7 may help solve

the problem. The specific scheme is shown in table 3

below.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

168

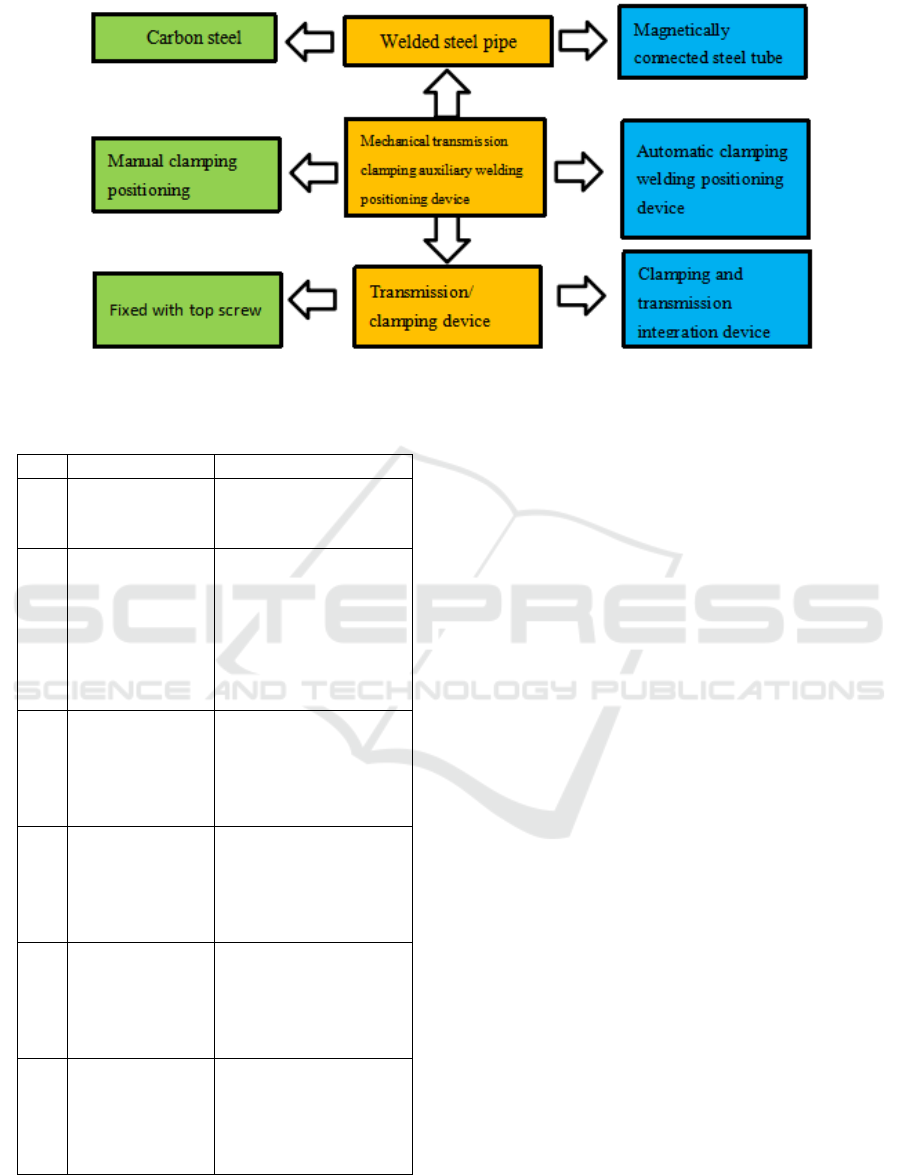

Table 3. Solutions to key problem A.

Inventive

Principle

No

Inventive

Principle

Concrete

Proposal

7

Nested

principle

Nest the tube

into the

positioning

fixture

1.3.3 Solution of Key Problem B - Technical

Contradiction

For the key question B, how to design an auxiliary

welding positioning device suitable for the welding

parts of different sizes with simple operation? The

analysis shows that:

Increasing the adjustability of the auxiliary

welding positioning device means that the stability

of the structure decreases.

Simplifying the operation method of auxiliary

welding positioning device means improving the

maneuverability of the equipment, but at the same

time the manufacturability of the equipment

becomes complicated.

We believe that this is a technical contradiction,

so we use technical contradiction analysis to solve

the problem, the specific operation is as follows:

Extraction technology contradiction

Table 4. Technical contradictions of key question B.

Technical contradiction

If

Want to fit the fixture of welding

positioning device to different sizes of

welding parts

Want to make welding positioning

device fixture easy to operate

Then

Increase the adjustability of positioning

fixture

Save operation time

But

It is necessary to control the clamping

strength of tube fittings with different

tube diameters

Equipment systems are more complex

Table 5. Corresponding contradiction matrix table.

Improved

parameter

Weakened

parameter

Force

System

Complexity

36

Adaptability,

Versatility

15,17,20

loss of time 6,29

According to the above contradiction matrix

table, the following solution table 6 is obtained.

Table 6. Solutions to key problem B.

Question

Inventive

Principles

Concrete Proposal

35-10

15 Dynamic

Principle

A telescopic joint is

installed in the

positioning

clamping device to

adjust the clamping

force

22-36

6

Multipurpose

principle

The clamping part

of the positioning

device is installed

with the

transmission part,

so that it has the

function of

positioning

clamping and

transmission

performance.

2 DESIGN OF WELDING

POSITIONING DEVICE FOR

BIG-CALIBER STEEL TUBE

2.1 The Final Design Scheme of

Auxiliary Welding Positioning

Device for Big-Caliber Steel Tube

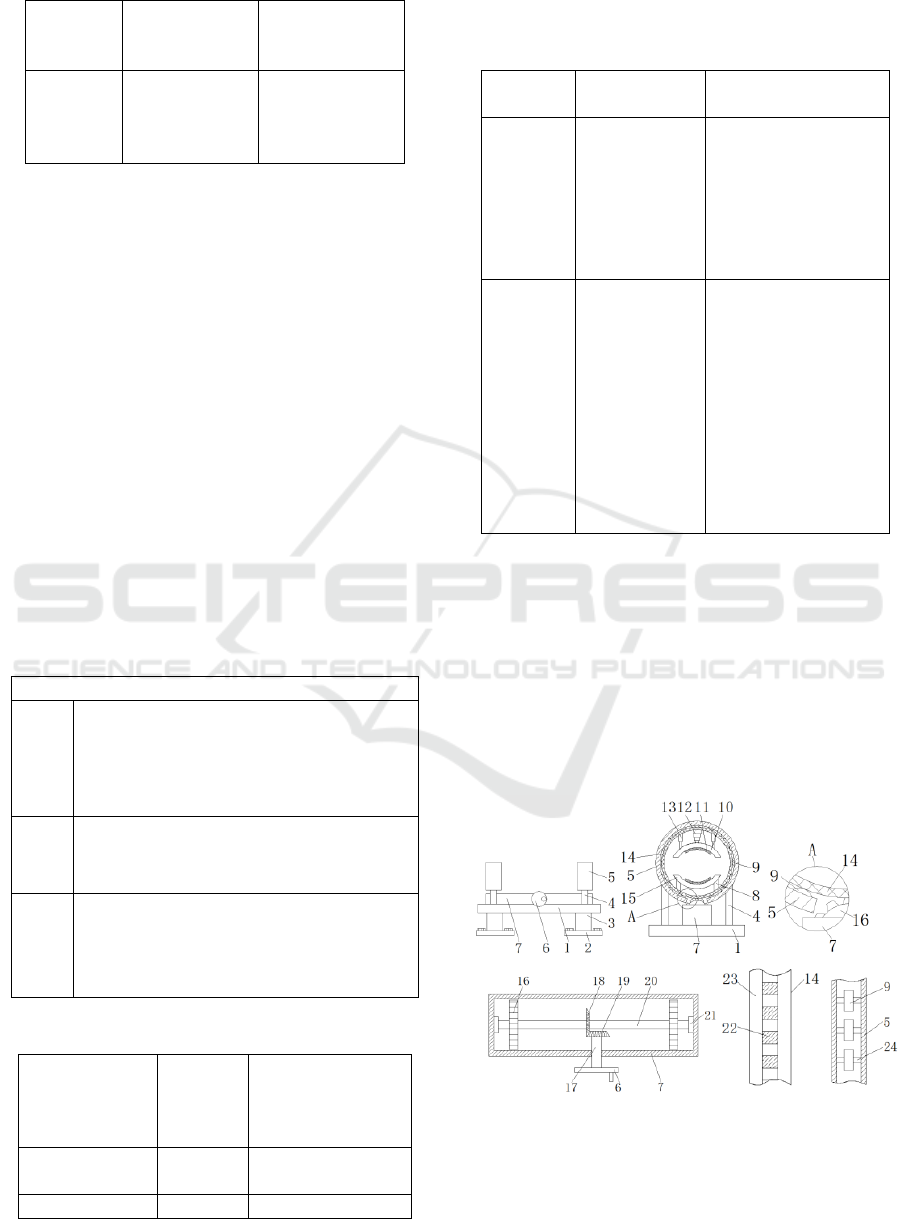

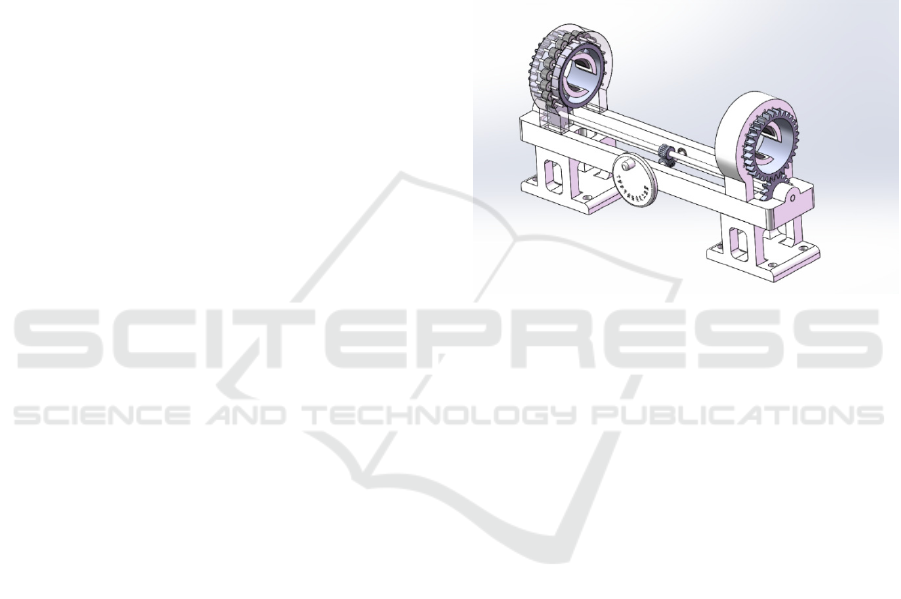

Fig 4. Overall schematic diagram of the device.

As shown in FIG 4, both sides of the bottom of base

plate 1 are fixedly connected with supporting leg 3,

the bottom of the supporting leg 3 is fixedly

Design of Welding Positioning Device for Big-Caliber Steel Tube based on TRIZ Theory

169

connected with the supporting plate 2, the

connection between the bottom of supporting plate 2

and the ground is fixed and connected by foundation

bolt, through the foundation bolt, the phenomenon of

shaking affecting welding operation can be

effectively avoided when the device is in use,

improved the stability of the device in use, the top of

the base plate on both sides are provided with fixed

collar 5, both sides of the bottom of the fixed collar

5 are fixedly connected with dead lever 4, the

connection between the bottom of dead lever 4 and

the base plate 1 is fixed, the inner cavity of the fixed

collar 5 is provided with loose collar 14, the inner

groove of the fixed collar 5 is provided with live

bearing 9, the inner sleeve of the live bearing 9 is

provided with fixed axis 24, both sides of the fixed

axis 24 are fixed connected with the joint of the

fixed collar 5, both sides of the surface of the loose

collar 14 are provided with inclined ramp 23 which

is used in combination with the live bearing 9, by

live bearing 9 and inclined ramp 23, it can

effectively avoid the stuck phenomenon of loose

collar 14 during rotation, improved the utility of the

device, the top of the inner cavity of the loose collar

14 is fixedly connected with electric telescopic rod

12, the bottom of the electric telescopic rod 12 is

fixedly connected with movable jaw 10, and both

sides of the top of the movable jaw 10 are fixedly

connected with auxiliary telescopic rod 13, the top

of the auxiliary telescopic rod 13 is fixed connected

with the joint of the loose collar 14, and through the

auxiliary telescopic rod 13, it can effectively avoid

the deviation phenomenon caused by uneven force

of movable jaw 10 when positioning the pipeline,

and improve the positioning effect of the device, the

bottom of the movable jaw 10 is provided with fixed

jaw 15, and both sides of the bottom of the fixed jaw

15 are fixed with joint lever 8, the bottom of joint

lever 8 is fixedly connected with the loose collar 14,

and the inner sides of movable jaw 10 and fixed jaw

15 are fixedly connected with soft pads 11, the top

of the base plate 1 is fixedly connected with the

drive box 7, the inner cavity of the drive box 7 is

provided with revolving bar 17, the bottom of the

revolving bar 17 runs through the drive box 7 and is

fixedly connected with the swivel plate 6, the top of

the revolving bar 17 is fixedly connected with the

active bevel gear 19, the left side of the top of the

active bevel gear 19 is engaged with the driven bevel

gear 18, the inner cavity of driven cone tooth 18 is

provided with crossbar 20, the two sides of the

crossbar 20 are movably connected with bearing 21,

bearing 21 away from the side of the crossbar 20 and

is fixedly connected to the connection of drive box

7, gear 16 is set on both sides of the surface of

crossbar 20, the top of gear 16 runs through drive

box 7 and extends to the outside of drive box 7, the

surface of the loose collar 14 is provided with tooth

ace 22 used in conjunction with the drive box 7, The

top of the inner cavity of the drive box 7 is provided

with straight slot used in concert with gear 16, the

bottom of the inner cavity of the fixed collar 5 is

provided with notch used in concert with gear 16,

through straight slot and notches, it can effectively

avoid the phenomenon of collision affecting the use

during rotation.

Fig 5. 3d Rendering of Device Structure.

3 CONCLUSIONS

The welding positioning device designed in this

article, the welding parts are clamped and adjusted

by electric transmission for easy operation and use

by the welder, the whole three-dimensional welding

of tube diameter can be completed in one clamping,

save time and labor, not easy to remove welding,

none of the auxiliary welding devices on the market

has this function. The TRIZ theory used in the

design process provides an efficient and practical

innovative method for this design. Great help has

been provided to the completion of this innovative

design, this method is of great benefit to innovative

design and is worth popularizing. We hope you find

the information in this template useful in the

preparation of your submission.

REFERENCES

Countinho J S. Failure-effect Analysis [J]. Transactions of

the New York Academy of Sciences, 1964, 26(2):

564-584.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

170

Gofuku A, Koide S, Shimada N. Fault Tree Analysis and

Failure Mode Effects Analysis Based on Multi-level

Flow Modeling and Causality Estimation[C]// SICE-

ICASE, 2006. International Joint Conference. IEEE,

2006:497-500.

The Development of Welding Automation in China from

the Application of Welding Auxiliaries in Gas

Shielded Welding [J].Qin Han. Welding. 20009 (10).

Present Situation and Prospect of Welding Automation

Technology [J] Guang Yang. Maschinen Markt. 2004

(11).

Design of Welding Positioning Device for Big-Caliber Steel Tube based on TRIZ Theory

171