Furfural Synthesis from Mile-a-Minute Weed (Mikania micrantha)

using Roselle Petal Extract as Catalyst

Taslim

1*

, Iriany

1,2

, Okta Bani

1

, and Apri Wardiana Sinaga

1

1

Department of Chemical Engineering, Faculty of Engineering, Universitas Sumatera Utara, Jl. Almamater - Kampus USU,

Padang Bulan, Medan 20155, Indonesia

2

Center of Excellence for Natural Resources Based Technology, Universitas Sumatera Utara, Medan 20155, Indonesia

Keywords: Hydrolysis, mile-a-minute weed, roselle petal extract, furfural yield

Abstract: Mile-a-minute weed (Mikania micrantha) contains a large fraction of pentosan, and thus, is suitable as a

precursor of furfural. Generally, furfural production from biomass requires inorganic acids, such as sulfuric

acid and hydrochloric acid, as catalyst. However, the use of inorganic acid is not environmentally benign

and causes equipment corrosion. In this study, 50 g dry mile-a-minute weed was reduced to 100 meshes and

mixed with 50 g sodium chloride. Then, this mixture was added into roselle petal extract at a ratio of 1:6

(w/v) in a three-neck flask. The flask was then connected to a Liebig condenser and an erlenmeyer was

placed at the other end of the condenser to collect the furfural. The reaction was carried out at 100-120℃

and for 0-330 min. The resulting furfural was separated from water by extraction using chloroform. Two

layers of liquid were formed during extraction. The top layer was rich in water and the bottom layer was

rich in chloroform and furfural. The lower layer was distilled to purify furfural. The purified furfural was

identified by aniline acetate color test, Fourier-Tranform Infrared Spectrocopy (FTIR) and Gas

Chromatography–Mass Spectrometry (GCMS). The results suggested that organic acids from roselle petal

extraction can be used as a catalyst in furfural systhesis.

1 INTRODUCTION

The mile-a-minute weed has been known as one of

the most rampant invasive species in the world. This

plant has pentosane content reaching 56% and is

widespread throughout the Asia-Pacific region,

especially in Southeast China since 1980 (Ko et al.,

2013). It is listed as introduced, invasive, and

noxious plant according to United States Department

of Agriculture (USDA). For newly established

plantations such as those of tea, coffee, cocoa,

coconut, and palm oil, mile-a-minute is a threat to

the plant growth (Anderson et al., 2012). Control of

mile-a-minute is difficult and time-consuming, the

methods are also limited and expensive. It was

recommended cutting plants that grow on the ground

periodically to control their growth (Kuo, et al.,

2003). Thus, this plant needs to be utilized to reduce

the loss to many aspects of human life. One of its

utilization is as precursor of furfural (Taslim et al.,

2018).

Furfural is a furan derivative originating from

hemicellulose fraction of lignocellulose, which is

considered a promising biochemical based

commodity because its use allows production of

several products such as antacids, paints, fuel

additives, and fertilizers, as well as various other

products usually produced from non-renewable

resources (Guche et al., 2017).

Furfural is usually produced by hydrolysis with

aid of acid catalyst. Pentose dehydration is shown in

the following equation.

(C

5

H

8

O

4

)

n

+ nH

2

O → nC

5

H

10

O

5

(1)

pentosan pentose

nC

5

H

10

O

5

→ nC

5

H

4

O

2

+ 3nH

2

O (2)

pentose furfural

Furfural production and utilization will be useful

for reducing energy and environmental crises, as

well as increasing benefits of biorefinery economy

(Zhu et al., 2017).

Taslim, ., Iriany, ., Bani, O. and Sinaga, A.

Furfural Synthesis from Mile-a-Minute Weed (Mikania micrantha) using Roselle Petal Extract as Catalyst.

DOI: 10.5220/0008838400210025

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 21-25

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

21

Furfural synthesis from various biomass had

been reported in several literature using phosphoric

acid (Lenihan et al., 2010), sulfuric acid (Lacerda et

al., 2012), and hydrochloric acid (Hernandez-Salas

et al., 2009) as catalysts. The use of inorganic acids

can cause corrosion in the equipment used, and also

not environmentally benign. To overcome these

problems, organic catalysts is considered. The use of

organic acids derived from bilimbi as a catalyst in

furfural production had been carried out, in which

the yield reached 7.2% at 100℃ (Taslim et al.,

2018).

Until now, the use of organic acids from roselle

petals has never been reported. In fact, roselle flower

extract contains high organic acids including citric

acid, hydroxycitric acid, hibiscus acid, malic acid

and tartrate acid as the main compound, and oxalic

and ascorbic acid as minor compounds (Da-Costa-

Rocha et al., 2014). Therefore, this study aimed to

investigate the use of organic acids derived from

roselle petals as catalysts in furfural synthesis from

mile-a-minute weed, and compare it with sulfuric

acid catalyst.

2 MATERIAL AND METHOD

Mile-a-minute weed and roselle petals were obtained

from Medan Tuntungan, Indonesia. Chemicals used

such as sodium chloride, sulfuric acid, aniline, acetic

acid, and chloroform were purchased from Rudang

Jaya, Medan.

2.1 Sample Preparation

Sample preparation was carried out using a

procedure reported in the literature (Taslim et al.,

2018). A mix of mile-a-minute weed stems and

leaves were washed with water until free of dirt.

They were cut to ±1 cm using a knife. Then, they

were dried in the oven for 2 h at 100C. After

drying, mile-a-minute weed was milled in a ball

mill, and sieved to 100 meshes. Afterwards, the

sample was stored in a sealed plastic box at room

temperature and ready to be used for furfural

synthesis.

2.2 Extraction of Roselle Petals

Roselle extraction followed a procedure reported by

Taslim et al., (2008). Roselle petals were cleaned

using water to a constant pH, then grounded using a

commercial blender to get roselle extract. The

extract was filtered using Whatman paper number

41. Roselle filtrate was analyzed for its pH,

normality, acid number, and stored in a refrigerator

at 0C.

2.3 Synthesis of Furfural

Furfural synthesis followed a procedure reported

by Taslim et al., (2018) with modifications. As much

as 50 g mile-a-minute weed powder, 600 ml roselle

extract and 50 g sodium chloride were placed in a

three neck flask. The volume of the reaction mixture

was adjusted to 750 ml by adding distilled water.

The mixture was heated on a hot plate and stirred

using a magnetic stirrer. The flask was connected to

a long vertical pipe to provide sufficient length for

furfural steam passages. The long tube was

connected to a condenser to condense furfural vapor.

The reaction was carried out at 100, 110 and 120C

for 30, 60, 90, 120, 150, 180, 210, 240, 270, 300 and

330 min. The collected furfural-water mixture were

then extracted by adding 50 ml chloroform. After

extraction, two layers were formed, the top layer

was rich in water and the bottom layer was rich in

furfural and chloroform. The lower layer was

distilled at 60-70C to separate furfural from

chloroform. The purified furfural was collected and

its volume was recorded.

For comparison, the same procedure was carried

out using a 20% sulfuric acid catalyst. The furfural

obtained from these two types of catalyst were

identified by color assessment, FTIR, and GCMS.

3 RESULTS AND DISCUSSION

3.1. Preliminary Analysis

3.1.1. Preliminary Analysis of Mile-a-Minute

Weed

Preliminary analysis of mile-a-minute weed included

water content and pentosan content analysis. From

the results, mile-a-minute weed has an average

moisture of 80% and average pentosan content of

46%. These pentosan level is very close to the levels

reported in the literature (Ko et al., 2013; Taslim et

al., 2018).

3.1.2. Preliminary Analysis of Roselle Petal

Extract

Initial analysis of petal roselle catalyst extract

included pH, normality, and acid number. From the

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

22

results, the pH was 2.4, normality was 0.15 N, and

acid number was 6.93 g/g. For comparison, the 20%

sulfuric acid catalyst has pH of 0.2, normality of

2.27 N, and acid number of 222.83 g/g.

3.2. Effect of Reaction Temperature and

Reaction Time on Furfural Yield

The effect of reaction temperature and reaction

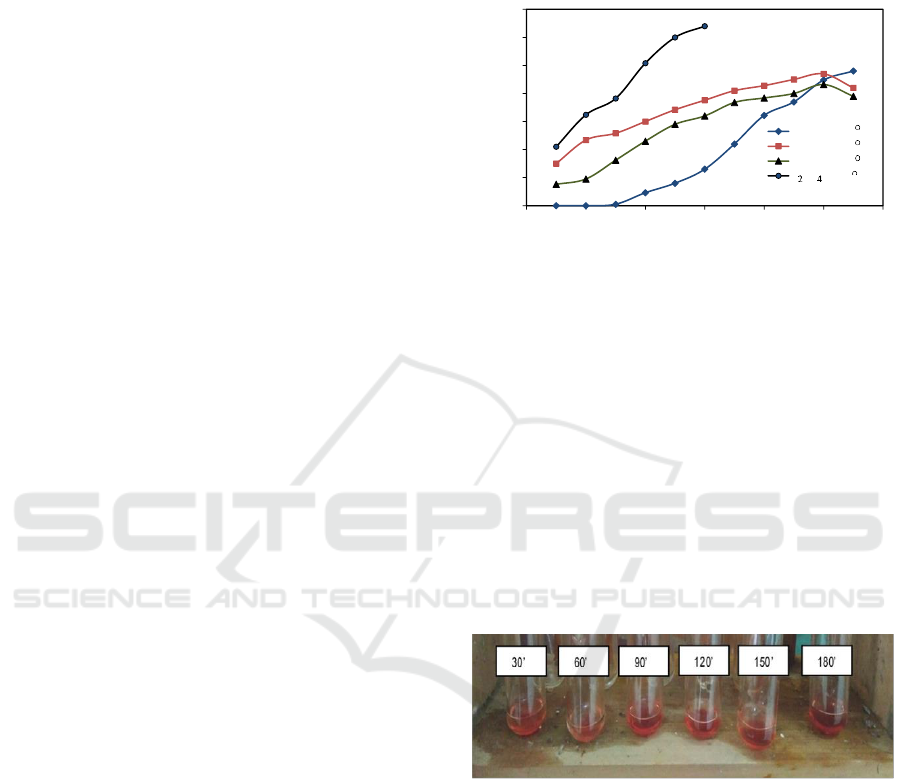

time on furfural yield is shown in Figure 1. In Figure

1, furfural formation catalyzed by roselle petal

extract was first observed at 30 min for reaction

temperature of 110 and 120

o

C. While for reaction

temperature of 100

o

C, furfural formation occurred at

reaction times above 90 min. However, after 300

min, the furfural yield at 100

o

C rivaled those of the

other temperatures. At 110 and 120

o

C, evaporation

rate of water was greater than furfural formation.

Pentosan in mile-a-minute weed was hydrolyzed to

pentose under acidic condition by the help of H

+

from roselle petal extract, then pentose dehydration

produced furfural as shown in equations (1) and (2).

Pentosan hydrolysis requires water while pentose

dehydration releases water. If water was evaporated

too quickly, hydrolysis will be incomplete and

pentose yield decreased. As a result, the furfural

yield may also decrease with increasing reaction

time and temperature. This causes furfural yield to

decrease at 330 min reaction time and reaction

temperatures of 110 and 120

o

C. Thus temperature

control is very necessary in this reaction to ensure

that these two stages of reaction take place well.

From figure 1, furfural yield produced using

roselle petal extract catalyst is still lower than that

using sulfuric acid catalyst. This is because the acid

number of sulfuric acid is 32 times greater than the

acid number of roselle petal extract, which means

that H

+

ions in sulfuric acid are more concentrated

than H

+

ions in roselle petal extract. The highest

furfural yield of 4.8% was obtained at reaction time

of 330 min, and reaction temperature of 100

o

C. The

optimum temperature reported by previous

researchers was 100

o

C, both for furfural formation

from pentose sugar using formic acid (Kim et al.,

2016) and for furfural formation from mile-a-minute

weed using organic acid catalysts from bilimbi

Taslim et al ., 2018).

At constant temperatures, increasing reaction

time increases furfural yield due to longer contact

times. The use of roselle petal extract in furfural

production does not require high temperatures, but

requires a long time of around 300 min.

In this study, furfural yield obtained using a 20%

sulfuric acid catalyst was up to 6.4%. This yield is

lower than the yield reported by other researcher at

8.3% under similar condition, but using corn cobs as

precursor (Shaffeeq et al., 2015).

0

1

2

3

4

5

6

7

0 60 120 180 240 300 360

Yield (%)

Time (minute)

Roselle, 100 C

Roselle, 110 C

Roselle, 120 C

H SO , 120 C

Figure 1: Effect of reaction time on furfural yield at

various temperatures

3.3. Furfural Analysis

3.3.1. Identification of Furfural by Colour

Assessment

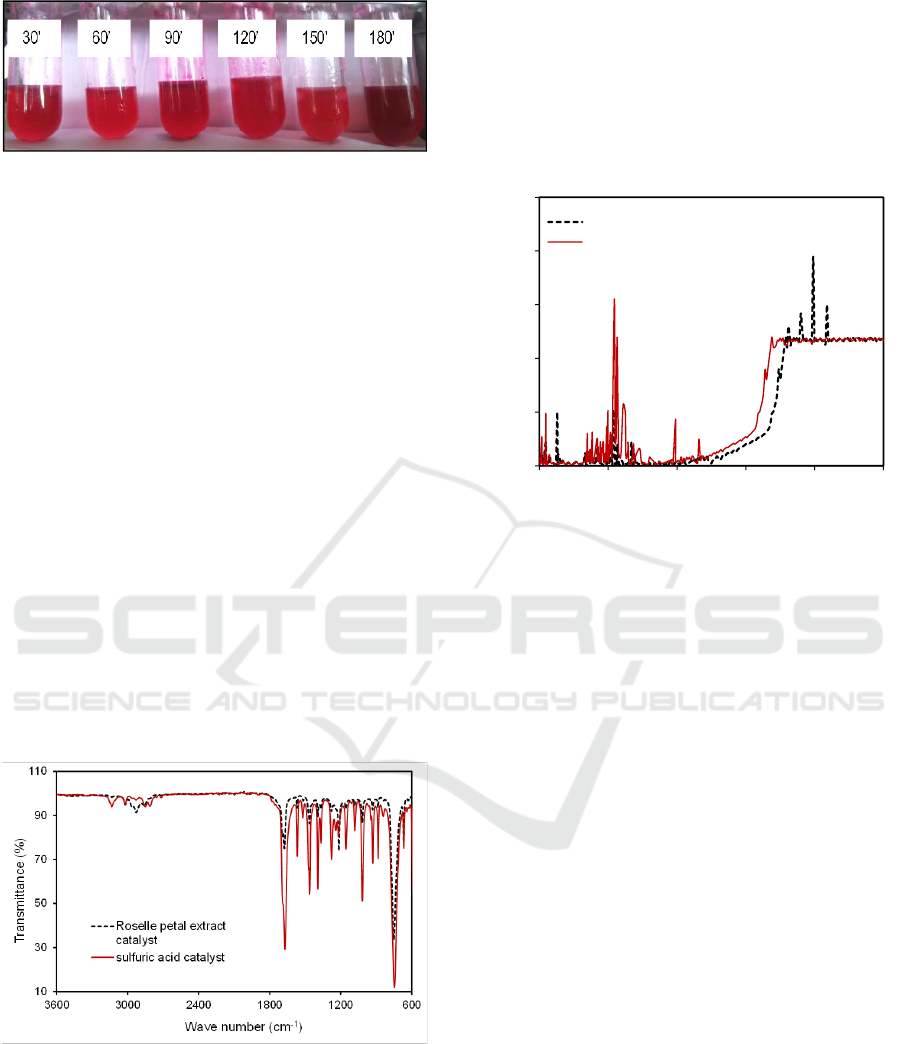

In this study, the qualitative identification of furfural

was done using aniline acetate reagent at aniline and

acetate ratio of 1:1 (v/v). The change in sample color

from clear to red indicates the presence of furfural.

In figure 2, the red color is still pale, indicating that

furfural formed using a roselle petal extract catalyst

was not much.

Figure 2: Colour assessment of furfural produced using

roselle petal extract catalyst at 120

o

C, at different reaction

time

In figure 3, the darker red color indicates that

more furfural was formed using sulfuric acid

catalysts. Sample at 180 min (3 h) appears darker,

indicating more formation of furfural. As shown in

figure 3, all samples became dark red after reaction

time of 30 min. This suggests that for sulfuric acid

catalyst, a long reaction time is not required. Similar

result was also reported in the literature (Taslim et

al., 2018).

Furfural Synthesis from Mile-a-Minute Weed (Mikania micrantha) using Roselle Petal Extract as Catalyst

23

Figure 3: Colour assessment of furfural produced using

sulfuric acid catalyst at 120

o

C, at different reaction time.

3.3.2. FTIR Analysis

The result of furfural analysis using FTIR is

shown in figure 4. Based on IR spectra (Figure 4)

aldehyde group in furfural was observed as

evidenced by C=O stretching vibration (1700-1600

cm

-1

) and CH aldehydes (2860-2800 cm

-1

) refleted

by the peak at 1674.52 cm

-1

and 2851.07 cm

-1

respectively for sulfuric acid catalyst and roselle

petal extract catalyst. The apearance of C=C

aromatic stretching vibration (1600-1475 cm

-1

) was

evidenced in the area around 1521.45 cm

-1

.

Stretching vibration peak at around 1166.00 on

sample using roselle petal extract catalyst indicated

C-O-C bonds (1200-1100 cm

-1

) within the molecular

structure of furfural, while for sulfuric acid catalyst,

same occurrence was observed at vibration peak of

1176 cm

-1

. The spectra of the compound produced

from mile-a-minute weed hydrolysis was virtually

identical to standard vibrations of furfural (Ong and

Sashikala, 2007). Therefore, it can be stated that the

compound was furfural.

Figure 4: FTIR spectra of furfural produced using roselle

petal extract and sulfuric acid catalyst

3.3.3. GCMS Analysis

Figure 5 shows the results of analysis using GCMS.

These results confirm that furfural has been formed

as a result of mile-a-minute weed ahydrolysis. For

the roselle petal extract catalyst, furfural compound

was identified at peak 2 (retention time of 3.37 min)

as 2,5 furandione, 3-ethyl-4-methyl. For sulfuric

acid catalyst, furfural compound was identified at

peak 3 (retention time of 3.28 min) as 2,5

furandione. Furandione belongs to the furfural

group, which proves that the samples contained

furfural.

27

22

1

2

3

14

12

30

11

31

34

20

4

13

6

5

9

7

41

20

44

23

21

24

47

8

35

46

40

10

0

5

10

15

20

25

3 8 13 18 23 28

Intensity x 10

4

minute

Roselle petal extract catalyst

Sulfuric acid catalyst

Figure 5: GCMS analysis of furfural produced using

roselle petal extract and sulfuric catalyst

4 CONCLUSIONS

Roselle petal extract can be used as a catalyst in

furfural synthesis from mile-a-minute weed. The

highest furfural yield of 4.8% using the roselle petal

extract was obtained at reaction temperature of

100

o

C and, reaction time of 330 min. This yield is

still lower than that using a sulfuric acid catalyst

which reached 6.4% in 150 min. Colour assessment,

FTIR, and GCMS analysis indicated the presence of

furfural as a result of mile-a-minute weed

hydrolysis.

REFERENCES

Anderson, P.J., Weaver, R.E., Neubig, K.M., Frank, M.S.,

Dixon, W.N., 2012. Which mikania: Native nine or

noxious weed? Botany Circular 37, 1-6.

Da-Costa-Rocha I., Bonnlaender B., Sievers H., Pischel I.,

Heinrich M., 2014. Hibiscus sabdariffa L. – A phyto-

chemical and pharmacological review. Food

Chemistry 165, 424-443.

Guche, J.E.O., Ameh, A.O, Tanimu, Y., Egu. S.A., 2017.

Determination and optimization of effect of process

parameters on furfural yield from microalgae. FUW

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

24

Trends in Science and Technology Journal 2(2), 782-

787.

Hernandez-Salas, J.M., Villa-Ramirez, M.S., Veloz-

Rendon, J.S., Rivera-Hernandez, K.N., Gonzalez-

Cesar, R.A., Plascencia-Espinosa, M.A., Trejo-

Estrada, S.R., 2009. Comparative hydrolysis and

fermentation of sugarcane and agave bagasse.

Bioresource Technology 100, 1238–1245.

Ko, C.H., Shih, T.L., Jhan, B.T., Chang, F.C., Wang,

Y.N., Wang, Y.C., 2013. Production of xylo-

oligosaccharides from forest waste by membrane

separation and Paenibacillus xylanase hydrolysis.

BioResources 8, 612-627.

Kuo, Y.L., 2003. Ecological characteristics of three

Invasive Plants (Leucaena leucocephala, Mikania

micrantha, and Stachytarpheta) in Southern Taiwan.

In: Oka, M., Matsui, M., Shiomi, T., Ogawa, Y.,

Tsauchiya, K (Eds), Biological invasions-

environmental impacts and the developments of a

database for the Asia-Pacific region. Proceeding of the

NIAES-FFTC Joint International Seminar, Tsukuba,

Japan, 177-191.

Kim, T. H., Ryu H.J., Oh K.K., 2016. Low acid

hydrothermal fractionation of giant miscanthus for

production of xylose-rich hydrolysate and furfural.

Bioresource Technology 218, 367–72.

Lacerda, T.M., de Paula, M.P., Zambon, M.D., Frollini, E.

Saccharification of Brazilian sisal pulp: evaluating the

impact of mercerization on non-hydrolyzed pulp and

hydrolysis products. Cellulose 19, (2012): 351–362.

Lenihan, P., Orozco, A., O’Neill, E., Ahmad, M.N.M.,

Rooney, D.W., Walker, G.M., 2010. Dilute acid

hydrolysis of lignocellulosic biomass. Chemical

Engineering Journal 156, 395–403.

Ong, H K, Sashikala M., 2007. Identification of furfural

synthesized from pentosan in rice husk. Journal of

Tropical Agriculture and Food Science 35 (2): 305–

12.

Shafeeq, A., Muhammad, A., Sarfaraz S., Akram Z.,

H.M.U. Saeed H.M.U., Farooq U., 2015. Effect of

acid concentration on the extraction of furfural from

corn cobs. International Journal of Chemical

Engineering and Application 6, 381-386.

Taslim, Mirnandaulia M., Iriany, Tambun R., 2018.

Furfural production from mile-a-minute weed

(Mikania micrantha) using organic acid from bilimbi

(Averrhoa bilimbi). Asian Journal of Chemistry 30(5):

1007-1011.

Zhu, Y., Li, W., Lu Y., Zhang T., Jameel H, Chang H.M.,

Ma, L., 2017. Production of furfural from xylose and

corn stover catalyzed by a novel porous carbon solid

acid in -valero lactone. Royal Society of Chemistry

Advances 7: 29916-29924.

Furfural Synthesis from Mile-a-Minute Weed (Mikania micrantha) using Roselle Petal Extract as Catalyst

25