Mangan Coated N-Graphene for Good Performance Electrode in

Primary Battery Anode

Rikson Siburian

1*

, Sabarmin Perangin-angin

1

, Helmina Sembiring

1

, Crystina Simanjuntak

2

and Yopi Sihombing

1

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1 Kampus USU, Medan, Indonesia

2

Postgraduate Chemistry Study Program, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1 Kampus USU, Medan, Indonesia

yopivani17@gmail.com

Keywords: N-Graphene, Mn/N-Graphene, Alternative Electrode, Primary Battery.

Abstract: Even though lithium is expected to remain the dominant battery technology for the next decade, new battery

technologies are on their way. N-Graphene and Mn/N-Graphene have the potential to be used as an alternative

electrode on primary battery anode. The results showed that the N-Graphene diffraction showed a weak and

wide peak at 2θ = 26.5

o

which indicates that N-Graphene was formed. The data is consistent with EDX data,

where the abundance of N atoms in N-Graphene (4.68%). At the Mn / N-Graphene electrode a sharp peak

appears at 2θ = 31

o

, indicating that Mn is deposited in N-Graphene. The EDX data also shows that Mn atoms

are deposited in graphene (0.15%). Mn / N-Graphene has the highest conductivity value (1250 μS/ cm)

compared to primary battery anodes (10 μS / cm), Graphite/N-Graphene (350 μS / cm) and N-Graphene

(1157.33 μS / cm).

1 INTRODUCTION

Graphene, the type of carbon in the form of

monolayer graphite, has a specific surface area of

2,600 m

2

/g (Stoller et al., 2008) with a honeycomb-

shaped structure that has the potential to produce

higher lithium ion storage capacity (Eriksson, 2001),

high electron mobility of 15,000 cm

2

/Vs (Geng et al,

2011), extraordinary thermal conductivity of 3000

W/mK (Netro et al, 2009) and has good chemical

stability and mechanical properties (Bolotin et al.,

2008). The advantages of graphene is an interesting

thing to form a composite material that is used as an

electrode material on lithium ion batteries. However,

pure graphene has poor pore affinity, low coulomb

efficiency, high charge-discharge platform and low

cycle stability so that it cannot be a direct substitute

for carbon-based commercial electrode material in

lithium ion batteries (Atabaki and Kovacevic, 2013).

To overcome the poor pore affinity of graphene a

doping is needed to fix it (Yang et al, 2015). A doping

agent suitable for improving the pore affinity of

graphene is nitrogen (Yu et al, 2013; Sun et al, 2012).

Nitrogen will modify the graphene structure so that it

will strengthen the stability of graphene in each bond

and improve porosity (Xing et al, 2016). Depositing

Pt metal to graphene will improve the electrical

properties and catalytic activity of Graphene (Rikson,

2014). Therefore, research is needed to improve the

quality of primary batteries by combining Mn metal

with N-graphene. The Mn metal used has an electrical

conductivity of 6.2. 105 (S / m).

2 MATERIALS AND METHODS

2.1 Synthesis Graphite/N-Graphene

About 1 g of graphite was added to the glass beaker

is then added 200 mL Ethanol Absolute, stirred for 1

hour. Then, 1 g of N/graphene was added with 200

mL of absolute Ethanol, stirred for 1 hour. The

graphite-ethanol mixture was added into N/graphene-

ethanol, and then stirred for 2 hours. Filtered using

Whatmann no.42, then the precipitate was dried with

an oven at 80

o

C and characterized by XRD.

18

Siburian, R., Perangin-angin, S., Sembiring, H., Simanjuntak, C. and Sihombing, Y.

Mangan Coated N-Graphene for Good Performance Electrode in Primary Battery Anode.

DOI: 10.5220/0008838300180020

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 18-20

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2.2 Synthesis Mn/N-Graphene

About 1 g of MnCl

2

was added to the glass beaker is

then added 200 mL Ethanol Absolute, stirred for 1

hour. Then, 1 g of N/graphene was added with 200

mL of absolute Ethanol, and then stirred for 1 hour.

The MnCl

2

-ethanol mixture was added into

N/graphene-ethanol then stirred for 2 hours. Filtered

using Whatmann no.42, then the precipitate was dried

with an oven at 80

0

C and characterized by XRD.

3 RESULTS AND DISCUSSIONS

3.1 Diffractogram of Zinc Anode,

Graphite, Graphene and

N-Graphene

X-ray diffraction data from primary battery anodes,

graphite, graphene and N-graphene are shown in

Figure 1.

Figure 1: Diffractogram of Zinc anode, graphite, graphene

and N-graphene.

The data above shows the XRD diffraction pattern

of commercial primary battery anodes where there are

sharp peaks and densities which are at 2θ = 43

o

Zn

(101), graphite and graphene show peaks at 2θ = 26.5

o

which correspond to diffraction lines C (002) , where

the sharp and tight peaks on the graphite diffraction

pattern indicate that the particle size of graphite is

large and overlapping and graphene has a weak and

wide peak which indicates the particle size of nano-

sized graphite and stacked on the interlayer of

graphene. The occurrence of peak changes from the

diffractogram is due to the bonding of graphite and

oxidation and the entry of oxygen into the interlayer

space in graphite (Jeong et al, 2008).

X-ray diffraction pattern of N-graphene which

shows the peak at 2θ = 10

o

there is a fairly sharp but

wide peak indicating that N from ammonia (NH

3

) has

been deposited into graphene. The above diffraction

pattern also shows a peak that is at 2θ = 26.5

o

which

corresponds to the diffraction line C (002), which has

a tightly sharp peak and is surrounded by widened

peaks which indicate that the particle size is nano-

sized and stacked graphene on the interlayer of

graphene which has been successfully synthesized.

This data explains that N-graphene has been produced

which is a modification of a graphene by doping N

from ammonia into graphene.

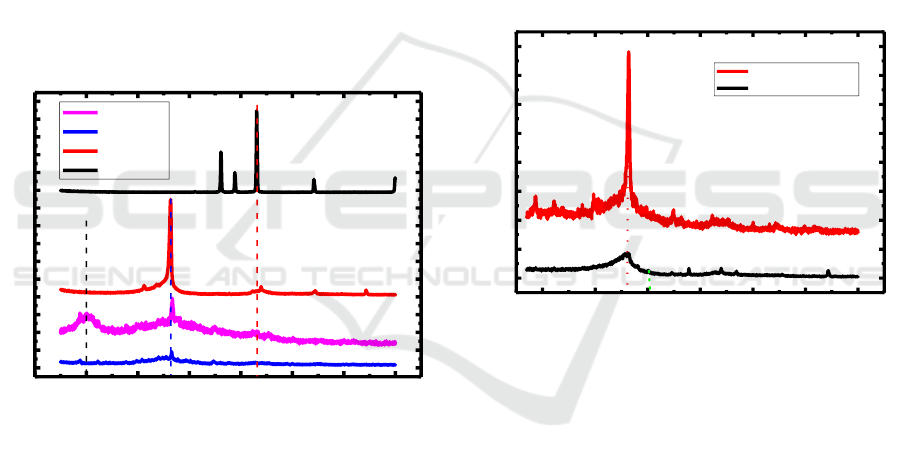

3.2 Diffractogram of Graphite/

N-Graphene and Mn/N-Graphene

X-ray diffraction data from primary graphite/N-

graphene and Mn/N-graphene are shown in Figure 2.

Figure 2: Diffractogram of Graphite/N-Graphene and

Mn/N-Graphene.

The XRD diffraction pattern of graphite / N-graphene

shows sharp and tight peaks at 2θ = 26,5

o

C (002)

which are specific to the intensity of carbon atoms

which are still dominated by hexagonal graphite

phases. Diffractogram changes indicate that N-

graphene has been deposited into graphite. The XRD

diffraction of Mn / N-Graphene shows a broad and

weak peak at 2θ = 26.5

o

C (002) which is specific to

the intensity of carbon atoms which is still dominated

by the hexagonal phase and diffraction at 2θ = 31

o

Mn

(100) which indicates that Mn is deposited into N-

graphene (Jeong et al, 2008).

4 CONCLUSIONS

The electrode synthesis in the primary battery anode

with graphite becomes graphene into N-graphene

0 10 20 30 40 50 60 70

Intensity (a.u)

2 Theta

N-Graphene

Graphene

Graphite

Zinc Anode

43

o

Zn (101)

10

o

N

26,5

o

C (002)

10 20 30 40 50 60 70

Intensity (a.u)

2 Theta

Grafit/N-Grafena

Mn/N-Grafena

31

o

Mn (100)

26

o

C (002)

Mangan Coated N-Graphene for Good Performance Electrode in Primary Battery Anode

19

using a modified Hummer method followed by

depositing Manganese metal on the N-graphene

compound. Where N-graphene is produced by

deactivating graphene using ammonia (NH

3

) so that

graphene is reduced. The deformed graphene is

modified and forms N-graphene which has a good

catalyst activeness value and has a high conductivity

value.

ACKNOWLEDGEMENTS

Authors would like to thankful to Ministry of

Research, Technology and Higher Education,

Republic of Indonesia who supported funding of our

research by the research grant: DRPM research,

Universitas Sumatera Utara No.

157/UN5.2.3.1/PPM/KP-DRPM/2019.

REFERENCES

Atabaki dan Kovacevic, 2013, The electronic Properties of

Graphene, Rev. modern Physic Journal of the American

Physical Society.

Bolotin, K.I, Sikes, K.J, Jiang, Z., Klima, M., Fudenberg,

G., Hone, J., Kim, P. dan Stormer, H.I., 2008, Ultrahigh

Electron Mobility in Suspended Graphene, Solid State

Commun, 146 (1) : 351-355.

Eriksson, T., 2001, LiMn2O4 as a Li-Ion Battery Chatoda

from Bulk to Electrolyte Interfase. Uppsala University,

Sweden

Geng., D., Songlan Y., Yong Z., Jinli Y., Jian L., Ruying

L., Tsun K. S., Xuenliang S., Siyu Y. and Shanna K.,

2011, Nitrogen Doping Effects on the Structure of

Graphene, Applied Surface Science 257 (2011) : 9193–

9198.

Jeong, K-Hae. Lee, P.Y. Lahaye, R. J. W. E. Park, H-Min.

An, K. H. Kim, I. J. Yang, Woong-Cheo. Park, C.Y.

Ruoff, R. S. Lee, Y. H. 2008. Evidence of Graphitic AB

Stacking Order of graphit oxides. J. AM. Chem. SOC.

American chemical society.

Netro, C.A.H., Guinea, F,. Peres, N.M.R., Novoselov, K.S.

dan Geim, A.K., 2009, The Electronic Properties of

Graphene Rev. Modern Physics, Journal of The

American Physical Society, 81 (1): 109-162.

Siburian, RA.F. 2014. Support Material Effect For Pt

Catalytic Activity at Cathode. University of Nusa

Cendana. Kupang

Stoller, M.D., Park, S.J., Zhu, Y.W., An, J.H. dan Ruoff,

R.S., 2008, Graphene-Based Ultracapacitors, Nano

Lett, 8 (1): 3498-3502.

Sun, L., Lei W., Chungui T. Taixing T., Ying X., Keying

S., Meitong L. and Honggang F., 2012, Nitrogen-

Doped Graphene With High Nitrogen Level Via A One-

Step Hydrothermal Reaction of Graphene Oxide with

Urea for Superior Capacitive Energy Storage, RSC

Advances, 2 (1) : 4498–4506.

Xing, Z., Zhicheng J., Yulong Z., Jialu W., Yabo Z.,

Yinghuai Q. and Yitai Q., 2016, One-pot hydrothermal

synthesis of Nitrogen-doped graphene as

highperformance anode materials for lithium ion

batteries, Scientific Reports, 6 (26146):1-10.

Yang, S., Yuan L., Xuefeng S., Peng Z. and Lian G., 2015,

Covalently Coupled Ultrafine H-TiO2

Nanocrystals/Nitrogen-Doped Graphene Hybrid

Materials for High-Performance Supercapacitor, ACS

Applied Materials & Interfaces, 1 (1) :1-26

Yu. F., Lo S. T., Lin J. C., Zhang W., Lu J. Y., Liu F. H.

and Li L. J., 2013, Nitrogen Doped Graphene Sheets

Grown by Chemical Vapor Deposition: Synthesis and

influence of nitrogen impurities on carrier transport,

ACS nano, 7(8) : 6522-6532.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

20