Design and Power Generation of a Vermiculture-Based Microbial

Fuel Cell Assembly (VBMFC) with Eudrilus eugeniae

Kristopher Ray S. Pamintuan

1,3,*

, Rod Matthew P. Musni

2

, Alessandra Mae A. Buan

2

, Patricia Denise

R. Carlos

2

, and Donnel B. Tayam

2

1

School of Chemical, Biological, and Materials Engineering and Sciences, Mapua University, Manila, Philippines

2

Young Innovators Center, Mapua University, Manila, Philippines

3

Center for Renewable Bioenergy, Mapua University, Manila, Philippines

Keywords: Vermiculture, microbial fuel cells, Eudrilus eugeniae, waste management

Abstract: A Vermiculture-based Microbial Fuel Cell (VBMFC) is a novel concept combining vermiculture and

Microbial Fuel Cells (MFCs) to propose a solution to both solid waste management and non-renewable

energy problems. In theory, the earthworms would act as a biocatalyst, degrading the bulk of the waste to

simpler substances that can then be more readily available to electrogenic bacteria as substrate. For the first

time, a VBMFC was designed and constructed to process banana peels using Eudrilus eugeniae. The

assembly was kept at ambient conditions and was maintained by light watering and feeding every day. The

assembly was shown to generate increasing voltage, current, and power, until it plateaus and reaches an

equilibrium value of about 800 mV and 65 μA. A maximum power density of 5.60 mW/m

2

electrode

surface area was obtained. The effectivity of the VBMFC set-up was attributed to the differing degradation

rates of E. eugeniae and the microflora, wherein the role of the former is to degrade the bulk waste to make

it easier for microorganisms to degrade later. Overall, this preliminary study was able to demonstrate that a

functional VBMFC is possible. Further optimization studies are therefore recommended to allow for the

scale-up of this technology.

1 INTRODUCTION

Solid waste management and the prevailing use of

non-renewable sources for electricity generation has

been two of the most serious concerns haunting our

society today. As our population grows, the demand

for more energy and more space for waste disposal

also grows. In the Philippines alone, about 40,000

tons of solid waste is generated everyday, and about

57% of that is residential. Of the residential waste

fraction, 52% is biodegradable consisting of kitchen

scraps, food wastes, and other readily degraded

materials [1]. It is of interest if the biodegradable

fraction of the municipal solid waste can be utilized,

mainly as electricity, to lessen the burden on the

problems both posed by solid wastes and non-

renewable energy.

Vermiculture has long been known of its ability

to transform solid biodegradable waste to nutrient-

rich earthworm waste [2]. The earthworm species

used is vital in the success of this technology.

Eudrilus eugeniae, commonly known as the African

nightcrawler, has long been used in

vermicomposting in tropical temperatures [3]. The

vermicast produced can then be used as a nutrient-

rich soil additive as a fertilizer. The nutrient

recycling process of earthworms in vermiculture

also attracts a wide variety of microflora in the

vermicast, and the vast diversity in microorganisms

are proven to be beneficial to plants [4]. The

presence of a diverse group of bacteria, possibly

containing electrogens [5], makes the vermiculture

process an attractive system to integrate a Microbial

Fuel Cell (MFC). Thus, this study demonstrates the

first known attempt to generate electricity through a

Vermiculture-Based Microbial Fuel Cell (VBMFC).

In theory, the earthworms would act as a

biocatalyst, as their purpose in vermiculture is to

degrade the complex molecules of biodegradable

wastes to simpler structures, which can be used by

bacteria. If the bacteria present are electrogens,

electricity harvesting can be possible through

properly placed electrodes. This means that the

VBMFC can continually produce electricity as long

Ray S. Pamintuan, K., Matthew P. Musni, R., Mae A. Buan, A., Denise R. Carlos, P. and B. Tayam, D.

Design and Power Generation of a Vermiculture-Based Microbial Fuel Cell Assembly (VBMFC) with Eudrilus euginae.

DOI: 10.5220/0008656600370040

In Proceedings of the International Conference on Future Environment Pollution and Prevention (ICFEPP 2019), pages 37-40

ISBN: 978-989-758-394-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

37

as the earthworms are fed, and proper conditions

such as humidity and water content are maintained.

In this study, the main ojective is to design a

functional VBMFC and to measure its performance

in terms of power generation, using Eudrilus

eugeniae, and its organic matter degrading capacity.

This technology has the potential to simultaneously

solve both problems on electricity generation and

solid waste management if designed and studies

carefully.

2 METHODOLOGY

2.1. VBMFC Design

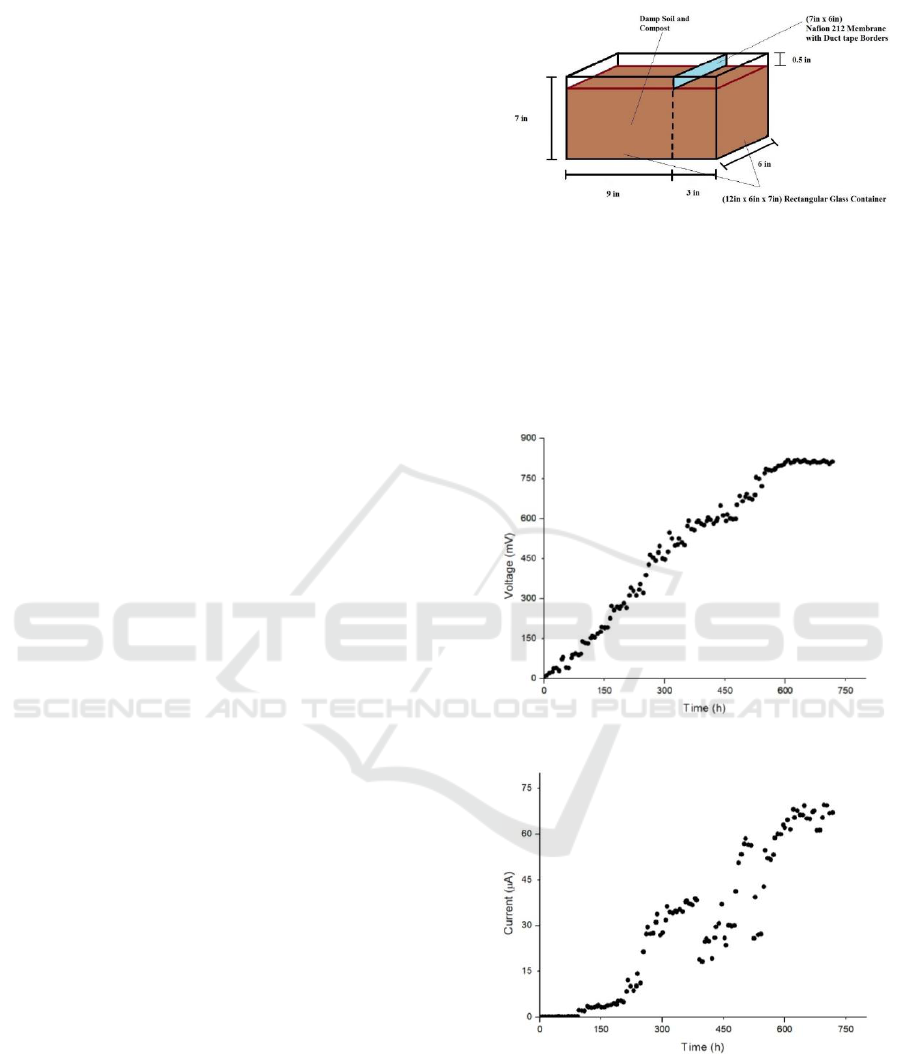

The VBMFC assembly is shown in Figure 1. The

larger portion serves as the anodic compartment, and

the smaller one is the cathodic compartment. The

two parts of the cell were divided by a proton-

exchange membrane (Nafion 212) attached flush to

the sides and bottom of the container, mainly to

conduct protons while preventing earthworms from

crossing compartments. Graphite electrodes (4 in x 4

in plates) were placed on both compartments, on

opposite sides, connected by copper wires. Moist

garden soil was placed on the compartments. A

plastic lid was used to loosely cover the top of the

set-up to minimize moisture loss and to prevent the

escape of earthworms.

2.2 Experimental set-up

E. eugeniae was obtained from a vermiculture farm

in Bulacan, Philippines. 80 adult worms were placed

in the anodic compartment at the start of the

experiment. The set-up was maintained by minimal

daily watering as to maintain moist soil but not

damp, and the worms were fed with one fresh

banana peel (67 g) every other day. The assembly

was kept in a dimly-lit place at room temperature

(25

o

C – 30

o

C) for majority of the experiment.

2.3 Data acquisition and analysis

The open circuit voltage and current of the VBMFC

was manually monitored four times everyday, for

thirty days, using a digital multimeter. From the

gathered data, power can be determined (P = I/V) as

well as power density (P

D

= P/A). All parameters

were plotted against time to analyse their evolution

as the assembly matures.

Figure 1: Vermicultue-based microbial fuel cell (VBMFC)

assembly

3 RESULTS AND DISCUSSION

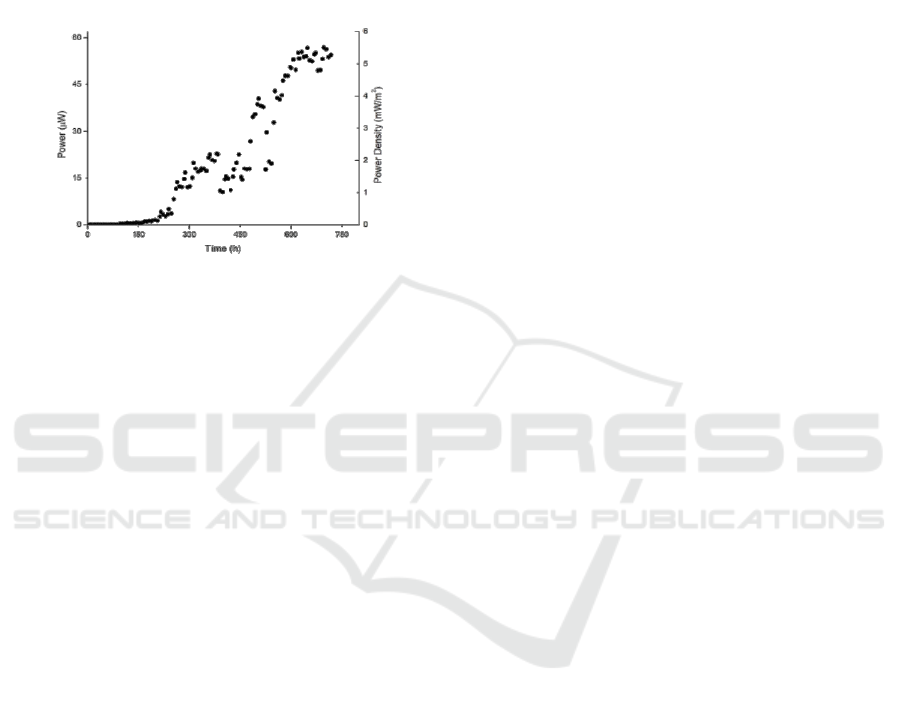

The measured voltage and current over the span of

30 days are shown in Figures 2 and 3.

Figure 2: Voltage measured from VBMFC

Figure 3: Current output of VBMFC

Both voltage and current steadily increased

through time, reaching a plateau at day 26. At this

point, the system is considered to be at equilibrium

and it will stay that way unless conditions were to

change. The equilibrium open circuit voltage of the

cell was about 800 mV; this value is significantly

ICFEPP 2019 - International conference on Future Environment Pollution and Prevention

38

higher compared to voltages generated by Plant-

Microbial Fuel Cells (PMFCs) [6] mainly because

PMFCs are reliant on the plant’s rhizodeposits to

produce electricity. The VBMFC is expected to

continuously generate power as long as feed is

continuously introduced to the system, and if the

worms will reproduce to compensate for the losses

along the way.

Figure 4: Power and power density of VBMFC

The obtained power and power density are

illustrated in Figure 4. As with both voltage and

current, power and power density were also

observed to increase through time as equilibrium is

being established. This increase in power generation

can be attributed to the breaking down of the banana

peels by the earthworms, giving bacteria an easier

access to the nutrients of the food. In a previous

study, it has been found that E. eugeniae working on

market waste as the substrate was able to increase

the organic carbon and nitrogen content of the soil

by 55.8% and 56.9%, respectively [7]. The

degrading action of the earthworm provided simpler

organic compounds for the bacteria to consume, thus

producing power. The maximum power density

generated was 5.60 mW/m

2

.

It has been observed that some of the worms

opted to crossover to the cathodic site due to

overcrowding in the anodic side. However, there is

no food available in the cathode compartment so the

worms inevitably went back to the anode

compartment where there is always food.

The consistent readings on all parameters were

attributed to the presence of a proton-exchange

membrane (PEM) which facilitated the orderly

transfer of protons from the anode to the cathode

while preventing oxygen crossover. However, the

PEM represents majority of the cost of the VBMFC

assembly. Without looking at costs of construction,

the PEM chosen is known to withstand degradation

in proton-exchange membrane fuel cells (PEMFCs)

and can be a valuable part of the VBMFC assembly

[8]. However, soil degradation of Nafion-212 as well

as its degradation under microbial influence should

be further studied, for it might behave differently.

The biodegradation capability of the VBMFC

was also seen in this study. The reactor was able to

process 33.5 g/day of banana peels, according to

what is fed. The value could be greater if more feed

is given to the earthworms. This can be a good

starting point for the design of larger and more

efficient VBMFCs.

As it stands, a hypothetical 1-hectare VBMFC of

the present design can process about 2632 tons of

biodegradable waste per year, while simultaneously

generating 490.56 kWh of electric energy. This can

be an effective low-cost solid waste treatment option

that can also yield useful by-products, mainly

vermicompost and earthworm biomass which can be

used as a high-protein feed for animals (such as

fishes).

The VBMFC can be treated as a continuous

reactor. Its input is solely biodegradable waste and

the outputs are biomass (earthworms), vermiculite,

and electricity. The solid waste acting as the feed is

converted to useful products. In conventional

vermiculture, only vermicompost and earthworm

biomass are produced. In the VBMFC, electricity

generation is added as another beneficial product.

With more development, this technology can soon

be used in larger scales for higher waste degradation

capacities.

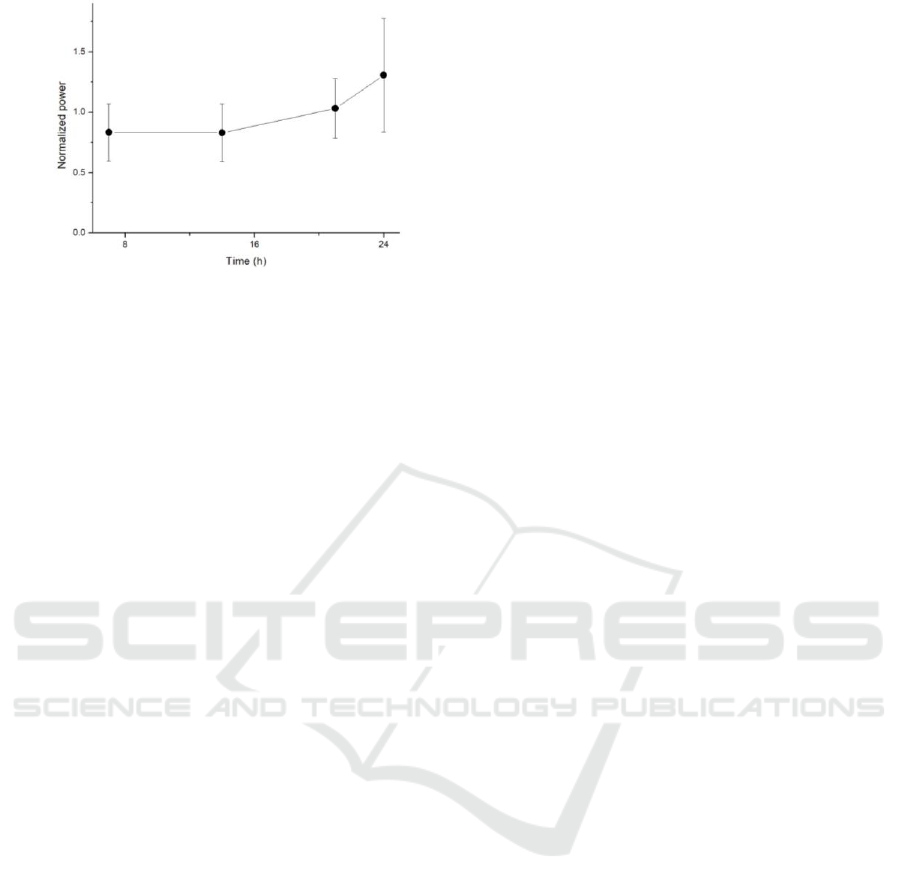

Daily periodicity in the power generation was

observed (Figure 5). As measurements were taken in

7-hour intervals (7:00 am, 2:00 pm, 9:00 pm, and

12:00 mn), the obtained power was observed to be

lower in the morning and afternoon, then would

shoot up to higher values in the evening. This can be

attributed to the nocturnal nature of E. eugeniae,

wherein it mainly feeds at night. Its motion churning

the soil and active waste production are the

hypothesized reason for the observed daily

periodicity of power output. Several t-tests at 95%

confidence interval confirmed that there is no

significant difference between normalized powers at

7:00 am and 2:00 pm, but they are lower than the

normalized power at 9:00 pm and 12:00 mn.

Design and Power Generation of a Vermiculture-Based Microbial Fuel Cell Assembly (VBMFC) with Eudrilus euginae

39

Figure 5: Daily averaged power output normalized against

daily average power

4 CONCLUSIONS

The presented study was a preliminary investigation

on the possibility of integrating electricity

generation while treating biodegradable solid waste

through the design of a VBMFC.

The observed values of voltage, current, power,

and power density were all increasing through time,

and indication that the substrate degraded by worms

was transformed to a more readily consumed organic

matter by electrogens. Power generation also

followed a daily periodic trend with lower power

during the day which then increases by night.

Furthermore, the generated power rivals those of

some plant-microbial fuel cells. With further

optimization studies, this technology could have the

potential for scale-up and industrialization.

In conclusion, it was demonstrated that a

VBMFC is capable of simultaneous solid

biodegradable waste treatment and electricity

generation with E. eugeniae as a biocatalyst.

REFERENCES

[1] National Solid Waste Management

Comission, “National Solid Waste

Management Status Report,” 2015.

[2] N. Soobhany, R. Mohee, and V. K. Garg,

“Recovery of nutrient from Municipal Solid

Waste by composting and vermicomposting

using earthworm Eudrilus eugeniae,” J.

Environ. Chem. Eng., vol. 3, no. 4, pp.

2931–2942, 2015.

[3] S. A. Viljoen and A. J. Reinecke, “Life-

cycle of the african nightcrawler, Eudrilus

eugeniae (Oligochaeta),” South African J.

Zool., vol. 24, no. 1, pp. 27–32, 1989.

[4] J. I. Fritz, S. Haindl, H. Insam, and R.

Braun, “Microbiological community

analysis of vermicompost tea and its

influence on the growth of vegetables and

cereals,” no. June, 2012.

[5] N. Chabert, O. Amin Ali, and W. Achouak,

“All ecosystems potentially host

electrogenic bacteria,” Bioelectrochemistry,

vol. 106, pp. 88–96, 2015.

[6] K. R. S. Pamintuan, J. A. A. Clomera, K. V.

Garcia, G. R. Ravara, and E. J. G. Salamat,

“Stacking of aquatic plant-microbial fuel

cells growing water spinach (Ipomoea

aquatica) and water lettuce (Pistia

stratiotes),” IOP Conf. Ser. Earth Environ.

Sci., vol. 191, 2018.

[7] S. Pattnaik and M. V. Reddy, “Nutrient

Status of Vermicompost of Urban Green

Waste Processed by Three Earthworm

Species — Eisenia fetida , Eudrilus eugeniae

, and Perionyx excavatus,” Appl. Environ.

Soil Sci., 2010.

[8] A. C. Fernandes and E. A. Ticianelli, “A

performance and degradation study of

Nafion 212 membrane for proton exchange

membrane fuel cells,” vol. 193, pp. 547–

554, 2009.

ICFEPP 2019 - International conference on Future Environment Pollution and Prevention

40