Motif Design Cow Leather for Handbag

Nur Ottidilia Laily

1

, Eri Nahrani Ustadzah

1

1

Industrial Design, Faculty of Architecture, Design and Planning, the Institute of Technology (ITS)

Keywords: Leather, Quality, Design Motif, Indonesia.

Abstract: Quality leather in Indonesia has been recognized by the world as the skin with best quality. The statement

could not be separated from the freeing Indonesia from the skin and mouth disease being the biggest factor

declining quality of animal skins in the world. Even so, Indonesia has several problems being faced, namely

the lack of supply of quality leather to meet the needs of domestic leather. In fact, some industries are still

imported materials (chemicals and raw materials) from the outside, so the effect on the price and availability

of materials. Mostly, the low quality of the skin on the market thus lowering the image of products made of

leather. Therefore, the authors sought to raise the image of a low-quality leather into a high value product at

home and abroad.

1 INTRODUCTION

Leather industry in Indonesia entered the round

priorities become the focus of government in

Indonesia. Through the National Industrial

Development Master Plan (RIPIN) from 2015 to

2035, the leather industry to be part of the six

segments of the mainstay industries and 10 industry

segments priority for developed countries during the

period 2015-2035. It is considered as the leather

industry has a high international competitiveness and

high labor intensive than most other industry

segments.

Even so, in fact, jacket industry in Indonesia still

face many obstacles, such as there are many damaged

skin resulting in lower quality. Skin damage is caused

by several factors, namely the outside and inside

factors. Factor in, the damage to the skin gained

during the life of the animal. For example, because

wounds from fighting or tearing of the skin because

of a sharp object during life. Skin wounds during an

animal life will harden and can not be cured back. In

addition to injuries, the animal can be exposed to the

disease or parasite that settle on the animal's body for

life. For example, the ticks that cause the animal's

skin has a lot of bumps and hardened skin. Lumps and

hardening of the skin for ticks, also can not be

restored. Or from larvae into the animal's body,

causing the animal skin perforated.

The external factors that lead to decreased quality

of tanned animal skin is of human resources (HR)

skinning the animal or the treatment of humans

during the process leading to leather. The lack of

human skills as an operational force, it is possible to

make the skin is damaged or defective.

Indonesia skin quality with competitiveness

International, in fact, is not accompanied by the

availability of adequate skin to skin with good

quality, so the price of leather in Indonesia is higher

than any other country. In addition, a variety of tools

and chemicals for tanning purposes, the majority

coming from the Chinese State, where not all of the

tools able to buy the leather industry in Indonesia,

especially for the leather industry based home

industry.

Therefore, various treatments have been

undertaken to improve the quality of the leather back

has been sorted. Through this research, the authors

conducted a variety of experiments and treatments in

order to improve the quality of leather that has been

declining.

2 MANUSCRIPT PREPARATION

2.1 Step of Data Collection

The data collection method was obtained from

interviews and book Kajan obtained from journals,

books, and scientific work of the research that has

been there. Sources of primary data collection include

deep interview with local and collector bag designer

206

Laily, N. and Ustadzah, E.

Motif Design Cow Leather for Handbag.

DOI: 10.5220/0008561702060210

In Proceedings of the 1st International Conference on Interdisciplinary Arts and Humanities (ICONARTIES 2019), pages 206-210

ISBN: 978-989-758-450-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

branded leather bag. While the secondary data

includes data obtained by the authors through

scientific journals, books, articles, and so forth. While

data is data obtained tertiary author of the internet,

magazines, and newspapers.

2.2 Phase Studies and Analysis

2.2.1 User Analysis

Deep user analysis conducted by interview on one of

the collector bag international brands.

Table 1: Prospective Users

A

g

e 20

y

ears - 65

y

ears

Gende

r

woman

Wor

k

Em

p

lo

y

ers,

Government officials,

official Compan

y

,

CE

O

Companies, Owner of the

company

Income

Rp 20,000,000 and Rp

150,000,000 /

month

S

p

endin

g

Rp 15,000,000 and Rp

150,000,000 /

month

Status Married, Widow, Not Marrie

d

Reli

g

ion all reli

g

ions

2.2.2 Existing Analysis

Existing were used in this study, using a local brand

has worldwide bags, namely Kalyana Indonesia:

a. On the type of engraving and colouring manual

issued by Kalyana, a lead time 4-5 days with the

majority of the work by hand (almost 70%,

ranging from skin folding, stitching, staining

birthday (which takes the longest, ie 2-3 days),

and others so)

b. On the type of bag that uses the printing and

dyeing, Work 3 days old (making patterns,

printing, dyeing (2-3 days) to finish).

2.2.3 Material Analysis

The main material which is used in this research

cowhide with a grade B or C. There are three kinds of

treatments to create motifs in this study, among

others:

a. Recolour / Recolour

Material used: Pigment (red, blue, mustard,

white, black), Binder (ML 2806), Addesion (UR

1020), Sponges.

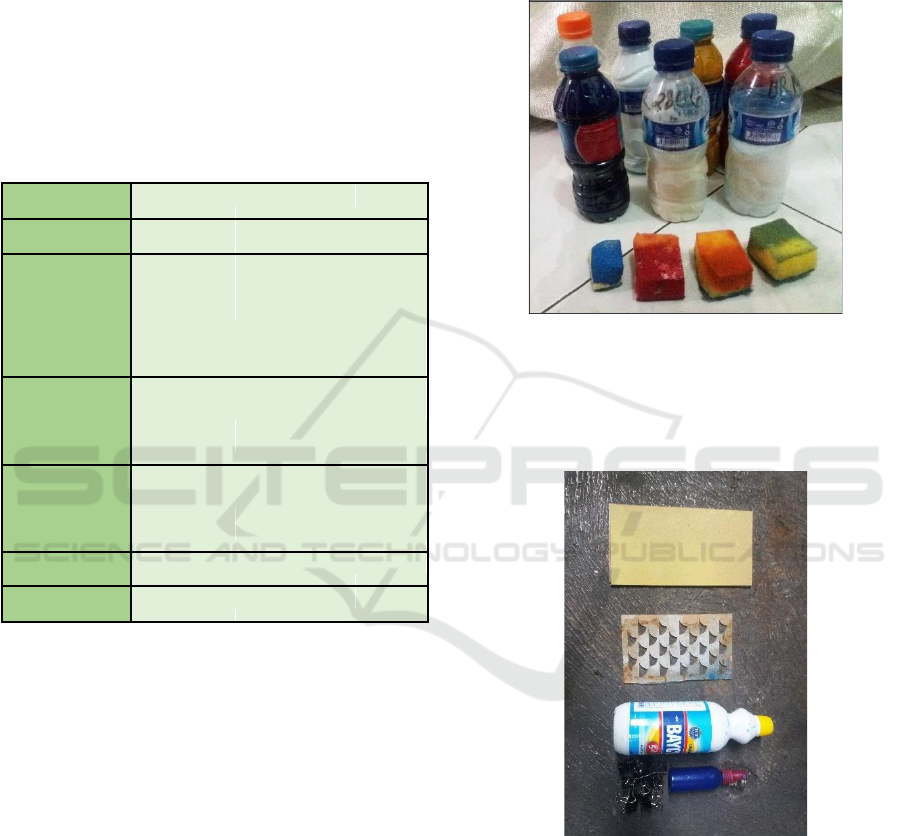

Figure 1: material and tools used in engineering repeated

staining. Source: author

b. Bleaching

Material used: plate mould, bleach, paper clip, a

board the size of a plate.

Figure 2: Materials and tools used to bleaching techniques.

Source: author

c. Pull Yarn

Material used: Yarn mattress, pigments, glass

stirrer.

Motif Design Cow Leather for Handbag

207

Figure 3: Materials and tools used in pull technique thread.

Source: author

2.2.4 Material Experiment

Some of the techniques used in the experiment

materials, among others:

a. Recolouring / Recolour

Techniques such as using or setting pour paint

motif pattern using dishwashing sponge foam.

Figure 4: Results of Experiments recolouring to pour paint

and sponges. Source: author

b. Bleaching

Techniques such as erosion of the coating color to

the outer shell. This uses printing plates are

sprayed with bleach regularly.

Figure 5: Results of Experiments with bleaching

techniques. Source: author

c. Pull Yarn

Mechanical pull the thread using basic material

cowhide crust (60%) and the use of skin pigment.

Figure 6: Results of Experiments with pull technique yarn.

Source: author

2.3 Phase Model Studies

Stage model studies in this study using a model class

1. In class model 1, the product model is made of

rubber material models

Figure 7: Bag design and development results application

to the bag. Source: author.

2.4 Production Process

The production process in the form of phase pattern

making, sewing bags and accessories finishing

processes such as elections, and so forth.

ICONARTIES 2019 - 1st International Conference on Interdisciplinary Arts and Humanities

208

Figure 8: Bag production process. Source: author

3 DISCUSSION / RESULTS OF

DESIGN

This research theme ladies handbag as the

implementation of the experimental media. The

concept of adaptation of the theme that is elegant,

long lasting, and unique. The following types of

handbag into implementation:

Figure 9: Implementation of experiments on the type of

hand bag ladies handbags. Source: author

For the mutual benefit and protection of Authors and

Publishers, it is necessary that Authors provide

formal written Consent to Publish and Transfer of

Copyright before publication of the Book. The signed

Consent ensures that the publisher has the Author’s

authorization to publish the Contribution.

The copyright form is located on the authors’

reserved area.

The form should be completed and signed by one

author on behalf of all the other authors.

4 CONCLUSIONS

The output of this design are three types of bag, office

bag, hand bag, and a sling bag. The three types of

these bags represent user needs in daily life. Users

designated in this peranjangan is a career woman or

women who are very influential in their environment

(officials, official wife, influencers, and so forth).

Office bag that used to work, with the features of

a laptop bag, pocket cards, kanong document, and the

main pouch container various purposes such as make-

up pouch, pouch worship equipment, wallets,

medicines, and so forth. For Hand Bag, normally used

for everyday life, such as shopping, meeting with

colleagues, visited the homes of friends or relatives.

Features in the form handbag zipper bags for coins,

pocket cards, and the main bag fit for wallets and

mobile phones only. As for the sling bag, used for a

very casual event, such as self shopping. In sling bag,

there is a long rope in the operation and three bags,

with the main bag only fit wallets and mobile phones

only.

Accessory or ornament used on bags using

premium quality. For example, zippers and zipper

head using YKK brand, using a metal ring with a

thickness of 3-4 mm, and Furing (insert bag) using

goat skin lining. We hope you find the information in

this template useful in the preparation of your

submission.

ACKNOWLEDGEMENTS

Author(s) thank you to Allah, the Rector of ITS has

provided amenities education for lead lectures,

People have provided support for undergoing Tasks

End, professors always guide during the research,

friends that provide mental support to writers can

undergo this Final smoothly.

REFERENCES

Industry, the Ministry of Public Communication Center

Industry. 2015 Master Plan development of national

industry 2015-2035. Taken from http://

www.kemenperin.go.id/ripin.pdf

Motif Design Cow Leather for Handbag

209

Sharphouse, JH 1995. leather Technician`s handbook.

Preparation For tannage

Sharphouse, JH 1995. Leather Technician`s handbook.

tanning Process

Sharphouse, JH 1995. Leather Technician`s handbook.

Quality Control Standards

Sharphouse, JH 1995. Leather Technician`s handbook.

Mechanical Action of Drums

Suharyadi. 2012. Process Technology Industry

tannery Skin. http://suharyadi.blogspot.com/proses-

technology-industry-tanning leather /

Heidemann E. 1993. Fundamental sof Leather

Manufacturing. Eduard Roether KG, Darmstadt.

ICONARTIES 2019 - 1st International Conference on Interdisciplinary Arts and Humanities

210