Research on the New Woodleaf Glaze in Celadon

Feng Shanxin

Faculty of Decorative, Silpakorn Talingchan University, Bangkok, Thailand

Keywords: New wood leaf glaze, Lead content, Celadon decoration effect, Edible utensils.

Abstract: Since the emergence of celadon, there have been thousands of years of history. The glaze of celadon is also

diversified by a single, and there is a lot of geographical features of the kiln. The innovation of glaze has an

important influence on the development of celadon. The main research of this paper is a rich wood-leaf glaze.

At first, this kind of wood-leaf glaze can only be applied to the black jizhou kiln porcelain. The material is

generally mulberry leaf directly attached to the surface of the green body after being processed and fired.

After the porcelain is formed, the composition of the leaf is golden and has a high ornamental effect[2].

Because of the uncertainty of the blade itself during the firing process, the success rate of firing is very low,

and the yield cannot be predicted at all. In this project, a kind of glaze that resembles metal glaze with golden

color, simple color and no obvious luster is prepared by researching and analyzing the chemical composition

of mulberry leaf.This type of glaze can greatly reduce the problem of high lead content in metal glazes. The

wood glazes studied in this topic are fired at high temperatures and can be applied not only to celadon

decoration but also to various daily-use ceramics and the decoration[1].

1 INTRODUCTION

It is a fusion of natural with nature, and the

production of wood-leaf cup is entirely a result of the

wisdom of nature and the ancients. There have been

more than 1,200 years of baking history since then, of

which black glaze porcelain was the most

representative. Because of the uncertainty of the

leaves in the firing process, each samovar will have a

different shape, and the yield is very low, and the

wood-leaf cup have been loved by the public. Then,

after the burning of the wood-leaf cup, people

continuously carried out research experiments to

complete the re-burning of wood-leaf cup[3]. The

golden leaf color of the wood-leaf cup is consistent

with the contemporary rustic style. This study

prepared a wood leaf glaze with golden wood leaf

color by analyzing the composition of the wood leaf

glaze and firing experiments[4]. The traditional

wood-leaf cup is only shown by the black undercoat.

This study will use traditional celadon as the

experimental object[5]. By controlling the content of

iron and rare metals in the glaze, the wood-leaf glaze

can be incorporated into the celadon to make it more

vivid and beauty. The research results of the project

can be widely applied to more porcelain decorations,

and can also be used as a glaze with metallic color.

The wood leaf glaze is burned at a high temperature

and is different from the low lead glaze containing

high lead content. Glazes need to be fired at high

temperatures, so they are lead-free and non-toxic and

can be widely used in the processing of daily-use

ceramics. The research has a high research value and

has huge market potential

Be advised that papers in a technically unsuitable

form will be returned for retyping. After returned the

manuscript must be appropriately modified.

2 EXPERIMENTAL STEPS AND

CONCLUSIONS

The color of the glaze needs to be matched with the

use of high iron content mud, which helps the hair

color of the leaves. The thickness of the glaze layer is

about 0.5-0.8mm, and it is fired in an oxidizing

atmosphere. The firing temperature is about 1250-

1300℃. Too high a temperature is not good for the

emergence of the of leaves color. The electric kiln is

in full compliance with its firing standards, so it is

possible to abandon the traditional firewood kiln and

gas kiln. The electric kiln is easy to operate, easy to

operate, the heating curve and atmosphere are

relatively stable, and the finished product rate is high.

202

Shanxin, F.

Research on the New Woodleaf Glaze in Celadon.

DOI: 10.5220/0008561502020205

In Proceedings of the 1st International Conference on Interdisciplinary Arts and Humanities (ICONARTIES 2019), pages 202-205

ISBN: 978-989-758-450-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2.1 The Data Collection

The wood leaf glaze is prepared by replacing the

chemical components in the mulberry leaf with

mineral chemical substances. The data of Table 1 can

be obtained by examining the chemical composition

of the glazed glaze minerals in the wood leaf aphid

product at different temperatures:

Table 1: The energy spectrum analysis of the glaze surface

after decorative wood leaves.

According to studies, we can choose the specific

gravity of raw materials at 800℃ to calculate the

specific gravity of each component of the wood leaf

glaze. Calculation of wood-leaf glaze type. Through

the energy spectrum analysis of the wood leaf glaze

in Table 1, the wood leaf glaze type can be calculated.

a. Calculate the number of constants for each

chemical formula in the glaze. The analytical values

of each component are divided by their corresponding

molecular weights to obtain their respective

quotients. Each quotient is divided by S (the sum of

basic component quotients to be added) to calculate

that each component is in glaze type Constant

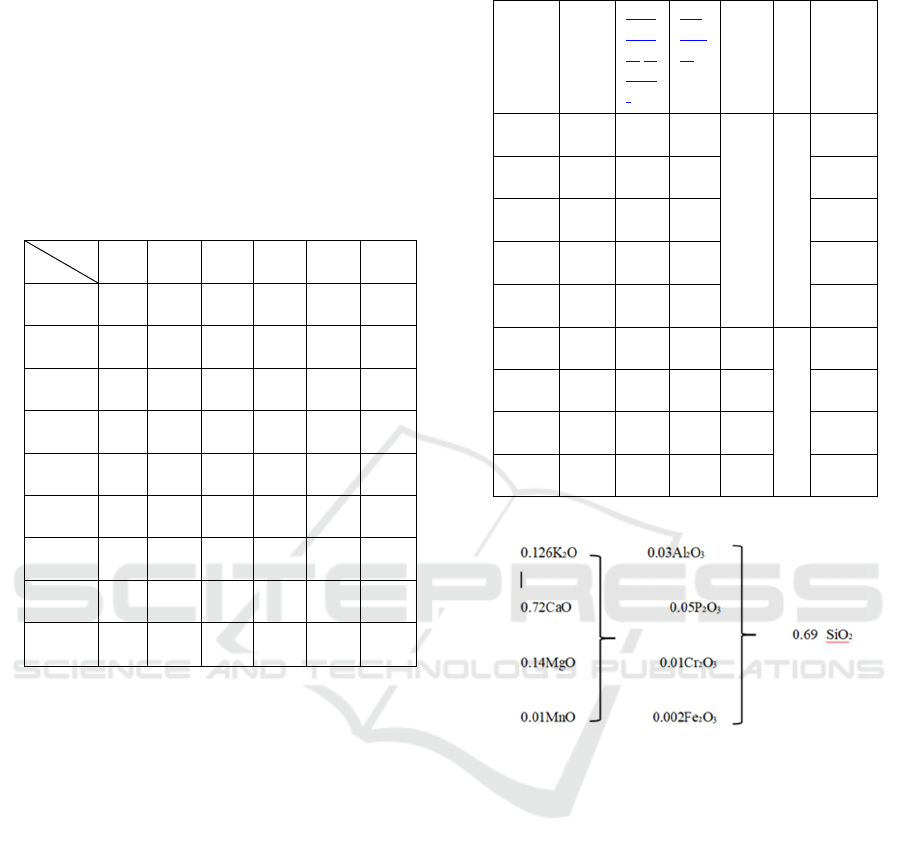

number. (Table 2). b. According to the calculated

number of constants, the wooden leaf glaze type is

listed. (figure 1)

Table 2: Reference Values (Values Rounded):

Name Ass

ay

valu

e

Mol

ecul

ar w

eigh

t

Qu

otie

nt

Bas

e

ele

men

t

S The

const

ant

numb

er

SiO

2

35.8

8

60.1 0.5

97

0.69

P

2

O

3

6.29 142.

3

0.0

4

0.05

Fe

2

O

3

0.32 159.

7

0.0

02

0.002

Al

2

O

3

2.69 102 0.0

3

0.03

Cr

2

O

3

1.95 294.

2

0.0

1

0.01

MnO 0.84 70.9 0.0

1

0.01

0.

8

7

0.01

MgO 4.98 40.3 0.1

2

0.12 0.14

CaO 35.2

0

56.1 0.6

3

0.63 0.72

K

2

O 9.97 94 0.1

1

0.11 0.126

Figure 1: wood - leaf glaze type.

Calculate the weight percentage of each

ingredient in the recipe. a. According to the glaze data

format of Figure.1, the weight percentage of raw

materials used for preparing the wood leaf glaze was

calculated. In view of the cost, all oxides cannot be

used in glazes, and there are many sources of raw

materials for the same chemical composition. In order

to replace glaze, a suitable compound is used instead

of oxides, for example, Al2O3 is replaced by

orthoclase (Al2O3∙6SiO2). Since ortho-feldspar

contains elements such as K, Al, and Si, the use of

K2O, Al2O3, and SiO2 can be reduced during

glazing. After determining the raw materials, use the

constant number in Figure 1 to equalize the number

of constants for each raw material, as shown in Table

3.Multiplicity of each constant and each molecular

weight to obtain the blend amount of each raw

material. b. Calculate the weight percentage of raw

materials by the sum of the blended amounts.

T/℃

CE

800 950 105

0

115

0

120

0

125

0

SiO

₂

35.

88

42.7 49.

30

57.9

3

58.1

0

58.3

5

P

2

O

3

6.2

9

5.80 4.5

1

2.72 2.62 2.54

Fe

2

O

3

0.3

2

0.49 1.0

0

2.49 3.76 4.64

Al

2

O

3

2.6

9

3.78 7.5

8

10.8

6

13.3

5

15.4

6

Cr

2

O

3

1.9

5

1.61 1.0

8

0.74 0.66 0.58

MnO 0.8

4

0.72 0.6

9

0.68 0.63 0.59

MgO 4.9

8

3.20 3.0

1

2.74 2.39 2.28

CaO 35.

20

30.0

1

22.

17

15.5

8

11.8

7

10.1

1

K

2

O 9.9

7

8.89 7.3

7

6.01 4.39 4.26

Research on the New Woodleaf Glaze in Celadon

203

Table 3: Reference Values (Values Rounded).

Name Co

nst

an

t

nu

m

be

r

Chemical

Formula

(Alternati

ve)

Con

stan

t

nu

mb

er

Mole

cular

weig

ht

Har

mo

ny

Wei

ght

(%)

SiO

2

0.

69

SiO

2

0.5

1

60.1 30.6

51

21

P

2

O

3

0.

05

CaO∙P

2

O

5

0.0

5

310.

3

15.5

15

11

Fe

2

O

3

0.

00

2

Fe+O

3

0.0

02

159.

7

0.31

94

0.2

Al

2

O

3

0.

03

K

2

O∙Al

2

O

3

∙6SiO

2

0.0

3

556 16.6

8

12

Cr

2

O

3

0.

01

K

2

Cr

2

O

7

0.0

1

294.

2

2.94

2

2

MnO 0.

01

MnO 0.0

1

70.9 0.70

9

0.5

MgO 0.

14

MgCO

3

0.1

4

84.3 11.8

02

8

CaO 0.

72

CaCO

3

0.5

7

100 57 40

K

2

O 0.

12

6

K

2

O 0.0

86

94 8.08

4

5.6

2.2 Ball Grinding Glaze and Test Strip

Test

The grammage of each raw material was precisely

weighed, and the ingredients and water were put into

a ball mill for ball milling according to the specific

gravity of 1:0.7. The balls in the ball mill tank must

not exceed one-half of the tank solvent. The ball

milling time is about 30 minutes to ensure that the ball

mill particles can pass through a 120 mesh screen.

The longer the ball-grinding time, the finer the glaze.

But, if excessive ball mill, the glaze material is easy

to crack when the glaze is dry, it easy to produce

shrinkage glaze, jump glaze and so on.

Combine with celadon's mud glaze to make no

less than 6 sets of test pieces, respectively placed in

different directions of the upper and middle three

floors of the kiln in order to observe whether the glaze

color has the stability and best firing position. The

thickness of the glaze of each test piece must be thin

and thick. Only the upper half of the test piece is

glazed, which can facilitate observation of the color

and flow of glazes of different thicknesses. Each test

piece must be etched with different depths of scribes

using tools to observe the effects of different layers of

glaze.

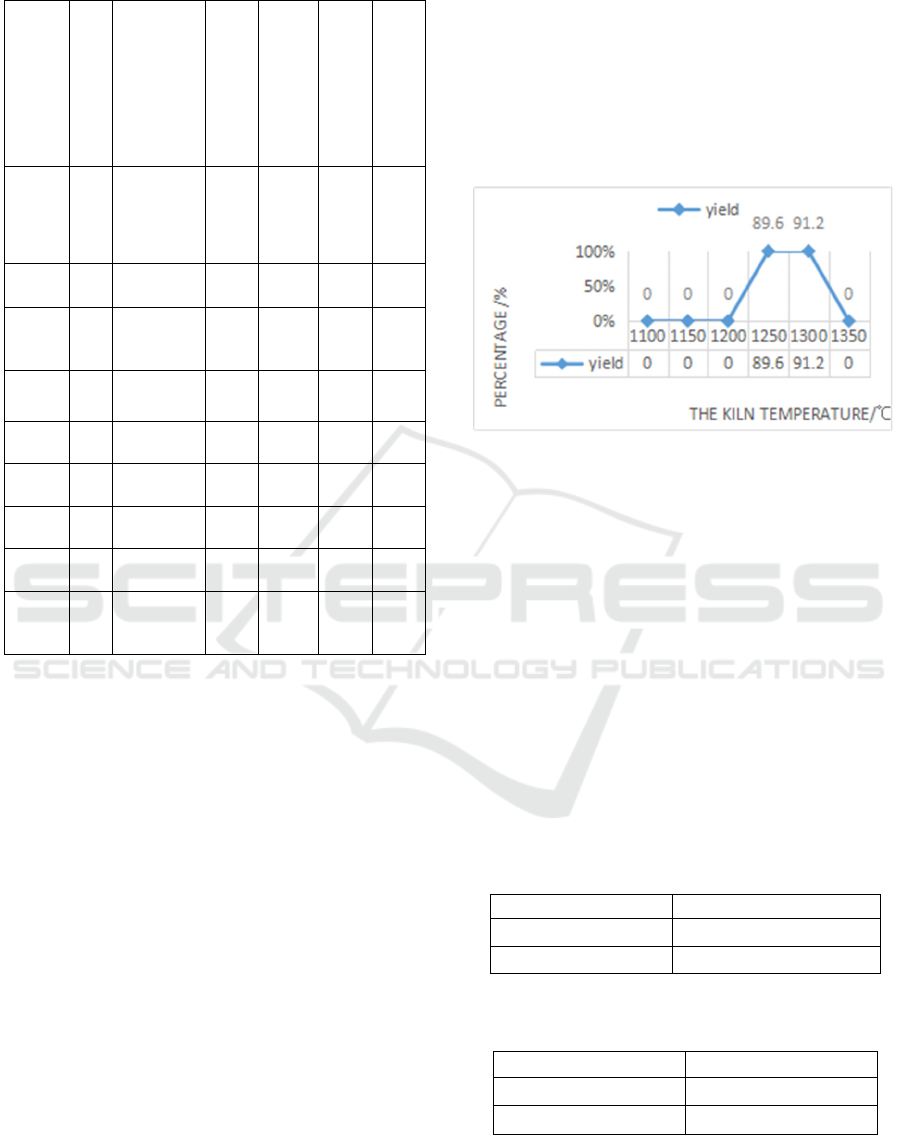

2.3 The Effect of Temperature on Yield

Kiln: electric kiln, Test pieces: 6 sets of 6 pieces

The kiln temperature 1100℃, 1150℃, 1200℃,

1250℃and 1300℃

Figure 2:influence of kiln temperature on yield

2.4 The Effect of Temperature on Yield

Glaze processing temperature: 850℃and 1250℃.

Sample: 200g low temperature metal glaze, 200g

wood leaf glaze is melted into powder.

a (pre-low temperature metal glaze of lead)

b (low-temperature metal glaze after lead analysis)

c (before lead wood leaf glaze)

d (wood leaf glaze after lead analysis)

Equipment: ball mill, scanning electron

microscope (produced by philips of the Netherlands),

energy spectrometer (produced by idax, USA).

Accelerate precipitation lead placement environment:

temperature 70℃, relative humidity 75%

Table 3: comparison of lead quantity of low temperature

metal glazes.

N

ame Pb

a 67.6

b 73.1

Table 3: comparison of lead quantity of low temperature

metal glazes.

Name Pb

c 0

d 0

ICONARTIES 2019 - 1st International Conference on Interdisciplinary Arts and Humanities

204

3 CONCLUSIONS

By analyzing the experimental data, the best firing

temperature of the wood leaf glaze is between 1250-

1300℃.The color rendering effect of the wood leaf

glaze in the celadon test piece is compared with that

of the traditional wood leaf figurine. The color

stability of the wood leaf glaze has been significantly

improved, and it is not necessary to treat the

chlorophyll in the leaf blade with a reagent, which is

convenient to use and has a high success rate. The

new wooden leaf glaze course was decorated with

ceramic paintings to enhance the controllability of the

decoration. The wood leaf glaze studied in this paper

can be fired at high temperature to ensure that no lead

element is harmful to the user's health. It can be

clearly seen from Table 4 that the glaze a prior to the

lead expulsion contains high lead itself, and the lead

content becomes higher after the treatment.

Compared with the low-temperature metal glaze, the

cost of the wood leaf glaze is low, and the use range

is large, and the high cost of multiple reburning can

be saved by burning at a high temperature once. This

study has achieved new breakthroughs in both food

safety and decorative effects.

REFERENCES

Patris P. Decorative surface finishes: Bronzing, patina‐

antiqua, verd‐antique in NY furniture 1810–1830: New

York workshops practices 1810–1830[J]. Color

Research & Application, 2016, 41(3): 232-240.

Nan P N. Searching and preserving lanna palm leaf

scriptures of temples for creating a learning source of

the northern thailand[J]. Journal of MCU Buddhapanya

Review, 2017, 2(3): 57-66.

Sheridan S. Musings: From the garden of greens and

blues[J]. Ceramics Art and Perception, 2017 (106): 117.

Britt J. The quest for the illusive leaf bowl[J]. Ceramics

Technical, 2014 (38): 84.

Newman R. A compositional and microstructural study of

Korean celadon glazes of the 11th to 15th centuries[J].

MRS Online Proceedings Library Archive, 1990, 185.

Smith, J., 1998. The book, The publishing company.

London, 2

nd

edition.

Research on the New Woodleaf Glaze in Celadon

205