The Effect of Improvement on Work Facility of Coco Bristle Process

to Occupational Health and Safety

Listiani Nurul Huda

1

, A. Rahim Matondang

1

and Indra Nasution

2

1

Department of Industrial Engineering, Universitas Sumatera Utara, Kampus USU, Medan City, Indonesia

2

Department of Mechanical Engineering, Universitas Sumatera Utara, Kampus USU, Medan City, Indonesia

Keywords: Work Facility, REBA, Working Posture, Machine Redesign, Coco Bristle.

Abstract: One of improvements on health and safety can be carried out by the improvement on work facilities used by

workers during the production process. This research was conducted in one of manufacture of coco bristel

which the machines are not designed ergonomically. Work posture of the worker are in standing position

during the processing of coco bristle and the body position is bending that can causes fatigue at the back and

spine. On the other hand, the coco bristle machine is not ergonomically designed to maintain security as

workers shrink the outer shell of coir. Pulling velocity of coconut husk by spinning pliers may result in hand

drawn towards the nail. Therefore, this research is needed to carried out in order to re-design the coco bristel

machine so that workers can work more healthily and safely. The method used in this research is work posture

asessment by Rapid Entire Body Assessment (REBA) and anthropometric concept to re-design coco bristle

machine. The results show that the actual machine design gives a REBA score of 6 indicating that

improvement of work posture is in need of improvement. The improvement is carried out by redesign of the

machine through consideration to the most dominant body dimension influenced the work of making coco

bristel. These dimensions are the height of the elbows at standing position, hand reach, and hand grip. This

improved machine design resulted in a smaller REBA score by two points than before which means that the

spinal position tends to be in a more healthier position than before. As for the safety of using the machine,

hand protection is added based on the dimension of hand grip. The results of this study indicate that there is

a strong relationship between the machine design and size dimensions of the worker's body with the level of

security and health in the work.

1 INTRODUCTION

Indonesia is able to produce 18.3 million tons of

coconut per year and is the largest producer of

coconuts in the world. Exports of Indonesia's coconut

derivative products also ranked first in the world in

terms of quantity, but only ranked second in terms of

profit. This is because the selling value of Indonesian

coconut derivative products is still lower compared to

rival countries such as the Philippines and Sri Lanka

(Burton, 2013). In addition to the different types of

coconuts produced in each country, other causes are

due to the fact that coconut derived production in

Indonesia is still experiencing a lack of research

development for both product development and the

development of production system and other support

systems. It can be seen from the data that 72.16% of

Indonesia's copra is exported to the Philippines, while

the Philippines sells copra that has been processed

into coconut oil and copra meal for export (Herlinda,

2014). This is why the export earnings of Philippine

coconut derived products are higher than in

Indonesia. While Indonesia exports most of its

products in the form of copra, the Philippines sell

them in the form of oil and copra meal which certainly

has a higher selling power.

The same is true of coco bristle products or better

known by name bristle fibre. Although Indonesia is

the largest coconut producing country in the world, its

coconut fibre processing products are still far behind

compared to India and Sri Lanka. Based on the

average data from international trade, a coconut can

produce 0.15 kilograms of coco fibre and 0.39

kilogram coco peat. Based on data from the

association of Indonesian coconut husk industry

(AISKI), the selling price of coco fibre and coco peat

in the domestic market consecutively ranges between

Rp 2,000 - Rp 2,500 per kilo and Rp 1,000 - Rp 1,500

358

Huda, L., Matondang, A. and Nasution, I.

The Effect of Improvement on Work Facility of Coco Bristle Process to Occupational Health and Safety.

DOI: 10.5220/0008554403580364

In Proceedings of the International Conference on Natural Resources and Technology (ICONART 2019), pages 358-364

ISBN: 978-989-758-404-6

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

per kilogram. Coconut production in Indonesia

reaches fifteen billion pounds per year and which can

be processed only reach to 480 million grains or 3.2

percent, it is estimated that Indonesia loses Rp 13

Trillion per year from unprocessed coconut husk

(Nara, 2014). Therefore it is necessary to research the

development of coconut processing business, one of

which can be done with the design of work systems.

The design of work system aims to produce a

comfortable working system, safe, and healthy for

workers and produce output in accordance with the

desired. The design of the work system has three

variables, namely the use of the human body,

preparation and workplace conditions, as well as the

design of tools and equipment’s. The improvement of

the work system design should pay attention to

these three variables well (Niebel, 2007).

This study focuses on the improvement of two

aspects in the design of the work system, which are

the design of equipment and the use of the human

body to increase the production of one of the coconut

derivatives, namely coco bristle. One coconut can

produce 35% coconut husk. From this coconut husk

can be processed into coco fibre products i.e coconut

husk that has been decomposed into fibres.

This coco fibre products can be processed into

coco bristle and coco peat. Coco fibre can be

processed into tiles, coco charcoal, coir carpet which

called Mourzouks, coir belts, and others. While coco

bristle can be used to make products such as sofa,

motorseat, brush, doormat, etc. While coco peat is

generally used as a medium for planting and organic

fertilizer (Kavitha, 2015).

(a) (b)

(c)

Figure 1: (a) Coco Fiber (b) Coco Bristle (c) Coco Peat.

At the research location, coco bristle processing is

done by using machine called coco bristle machine.

This machine has two parts, where the first part serves

to destroy the outer coconut skin. The production

process is the operator pinning the tip of the coir then

put it into the machine so that the coconut outer shell

is destroyed and leaves the long fibers called coco

bristle. This step is done repeatedly for both sides. The

second part serves to destroy the tip of the coir that is

still there to get a clean coco bristle from the outer

skin. The steps taken are the operator holding the

finished coco bristle part and pinning the remaining

heads, and done repeatedly. Such parts may be

dangerous to the operator if the operator's hand is

drawn into it. The operator does not use any safety

device to protect his hand from the machine. This

shows that the design of the machine still does not pay

attention to the safety of the workers.

Research on coconut coir machine design has been

done before in (Widananto, 2015) and (Villa, 2016),

but there is no further research especially on the design

of coco bristle machine. Therefore, the improvement

of coco bristle engine design is expected to increase

the amount of production so that the company can

meet the demand while increasing the comfort and

security of the operator.

In this research there will be designing coco bristle

machine with anthropometry approach. The machine

will be designed to fit the worker's body dimensions

and will be designed to get a safer and more

convenient way of working.

2 METHODS

This research was conducted on a coconut processing

SME but the research object focused on coco fiber

making. The research procedures conducted in this

research are:

1. Preliminary Research

This stage is used to diagnose the problems found

in coco bristle making work stations. At this stage,

the data on the initial machine specifications are

also collected as the design basis.

Figure 2: Condition of Coco Bristle Initial Machine.

The Effect of Improvement on Work Facility of Coco Bristle Process to Occupational Health and Safety

359

2. Assessment of Operator Posture

Field studies are conducted to obtain data on the

operator's body posture while working. This data

is collected in the REBA (Rapid Entire Body

Assessment) method of valuation table. REBA is

used to evaluate the work posture and muscle of

operators where repetitive work is associated with

abnormalities throughout the body. The REBA

assessment covers the whole body and legs

(Bhandhare, 2013). The REBA assessment was

performed using REBA worksheets conducted by

researchers.

Figure 3: REBA Worksheet.

Each of the worker's (top and bottom) body parts

is scored by its appropriateness to the points on the

worksheet. The total value of all points is the desired

end value. This final value is an indication of the risk

of the work posture examined. The REBA rating

category is divided into five categories as shown in

Table 1.

Table 1: REBA rating categories.

REBA

Score

Risk Level

Action

Level

Action

1

Negligible

0

No action required

2-3

Low

1

May need action

4-7

Medium

2

Action required

8-10

High

3

Needs immediate

action

11-15

Very high

4

Needs action right now

3. Anthropometry Data Processing

Dimensions of operator’s body are measured and

processed statistically (mean, standard deviation,

and uniformity data) to obtain data on required to

find the percentile dimensions for designing tools.

Instruments used for the measurement of body

dimensions include:

a. Goniometer

This instrument is used to measure the angle

of the operator body. Example of goniometer

can be seen from Figure 4.

Figure 4: Goniometer Tool.

b. Length Gauge

This instrument is used to measure operator

body dimensions. The sample of length gauge

used can be seen in Figure 5.

Figure 5: Length Gauge.

The anthropometric data used are:

a. Elbow at Standing Position

Elbow height at standing position is used to

determine the height of the work surface. This

is in accordance with the principle of the

workplace, where the height of the working

surface should be determined from a

convenient work posture for the operator.

Generally, this means that the upper arm is

hanged naturally and the elbow is bent at 90

o

(Burton, 2013). This may reduce the score on

the operator's work posture assessment.

b. Hand Reach

Hand reach is incorporated into the design of

the new engine so that the operator is more

comfortable when picking or placing the coir

into the container.

c. Handheld Diameter

Handheld diameter used to determine the grip

diameter used when the operator clamps

coconut coir. The corresponding handheld

diameter will allow the operator to grasp the

handle.

4. Machine Redesign

The new coco bristle machine is designed with

consideration of anthropometry and safety. The

design of the tool will be done in the form of 3D

commuter graphics using AutoCAD.

5. Machine Testing

ICONART 2019 - International Conference on Natural Resources and Technology

360

Machines that have been designed and

manufactured will be trials and then REBA

assessments will be conducted again made to see

the effects of new machines on worker posture.

3 RESULTS

3.1 Working Posture Rating

The posture examined is the operator working posture

when standing using coco bristle machine. The work

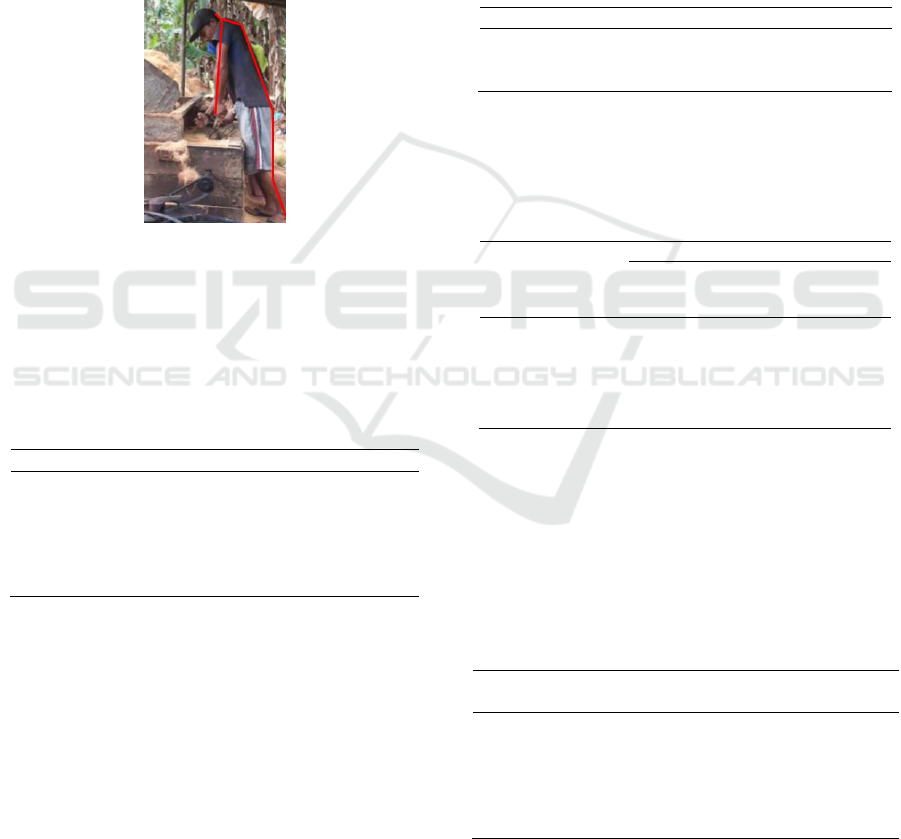

posture is shown in Figure 6.

Figure 6: Operator’s working posture of workers at coco

bristle machine.

The work posture is assessed by the REBA

method of six operators working on coco bristle

machine. The results of the REBA assessment

recapitulation are shown in Table 2.

Table 2: REBA assessment recapitulation.

Operator

Score

Information

1

6

Action required

2

6

Action required

3

5

Action required

4

5

Action required

5

6

Action required

6

6

Action required

In accordance with the REBA scoring criteria, the

mean six scores obtained for each operator indicate

there is a need for corrective action. An improvement

made is to do a new machine design because the

current work posture is problematic because of the

shape of the machine that requires as such.

3.2 The New Design of Coco Bristle

Machine

The design of the new machine is done by considering

the anthropometry dimension of the worker and the

user safety. Improvement made is also a response to

the weaknesses in the old machine as described

below:

1. Aspects of Anthropometric Dimension of New

Coco Bristle Machine

The initial coco bristle machine dimension can be

improved by designing a machine with

dimensions that match the operator's body

dimensions. Therefore, it is necessary to calculate

the anthropometric data of the operators. There

are three body dimensions used in the design of

the new engine coco bristle. The body dimensions

used can be seen in Table 3.

Table 3: Body dimensions used.

No

Body Dimensions

Percentiles

1

Elbow at Standing Position (TSB)

P50

2

Hand Range (JT)

P50

3

Handheld Diameter (DG)

P50

There are six measurement results according to the

number of operators. The results of these

measurements can be seen in Table 4.

Table 4: Operator body dimensions.

No

Operator

Body Dimension (cm)

Elbow at

Standing

Position

Hand

Range

Handheld

Diameter

1

Operator 1

103.0

74.0

4.4

2

Operator 2

102.6

73.3

3.9

3

Operator 3

103.3

75.0

4.6

4

Operator 4

103.1

73.9

4.5

5

Operator 5

103.0

74.1

4.3

6

Operator 6

102.9

73.6

3.8

The measurements of body dimensions were then

analyzed statistically. The mean values, standard

deviations, as well as upper and lower control

limits are calculated to see if the data obtained are

uniform. The result of uniformity test of the data

for the calculation result of body dimension is

shown in Table 5.

Table 5: Uniformity test of body dimensions data.

N

o

Measuremen

t

x̅

S

N

Informatio

n

1

TSB

102,9

8

0,2

3

6

In Control

2

JT

73,98

0,5

8

6

In Control

3

DG

4,25

0,3

3

6

In Control

The results of the statistics test show that all data

is within the limits, which means the data can be

further processed data. The next processing is to

The Effect of Improvement on Work Facility of Coco Bristle Process to Occupational Health and Safety

361

calculate the percentile of data. Percentile used for

elbow height at standing position is fifty

percentile, hand reach is fifty percentile, and

handheld is also fifty percentile.

a. Calculation of dimension percentile of Elbow

at Standing:

= 102,98 cm

b. Calculation of dimension percentile of Hands

Reach:

= 73,98 cm

c. Calculation of percentile dimension of

Handheld Diameter:

= 4,25 cm

2. Security Aspect of New Coco Bristle Machine

The safety aspect of the coco bristle machine is

required in the design of the new machine, in

accordance with the results of the open

questionnaire asked to the respondent. New

machine security can be realized by adding some

detail to the new machine to improve the security

of the machine compared to the old machine.

The addition is the addition of a layer of wood on

the lid when clamping the tip of the coir. This is

done to reduce the risk of work accidents in the

form of the operator's hand pull into the wooden

scroll when pinning the tip of the coir. The

clamping section of the coir tip of the starting

machine can be seen in Figure 7.

Figure 7: Coir Tip Clamp on the Initial Machine.

The addition of wood coating on coco bristle

machine design can be seen in Figure 8.

Figure 8: The Addition of wood coating on new coco

bristle machine.

Besides that, the addition is also done on rubber

pads at the end of the hole at the tip of the coir

clamp. The addition of this rubber pad can be seen

in Figure 9.

Figure 9: Rubber pads addition on the new coco bristle

machine.

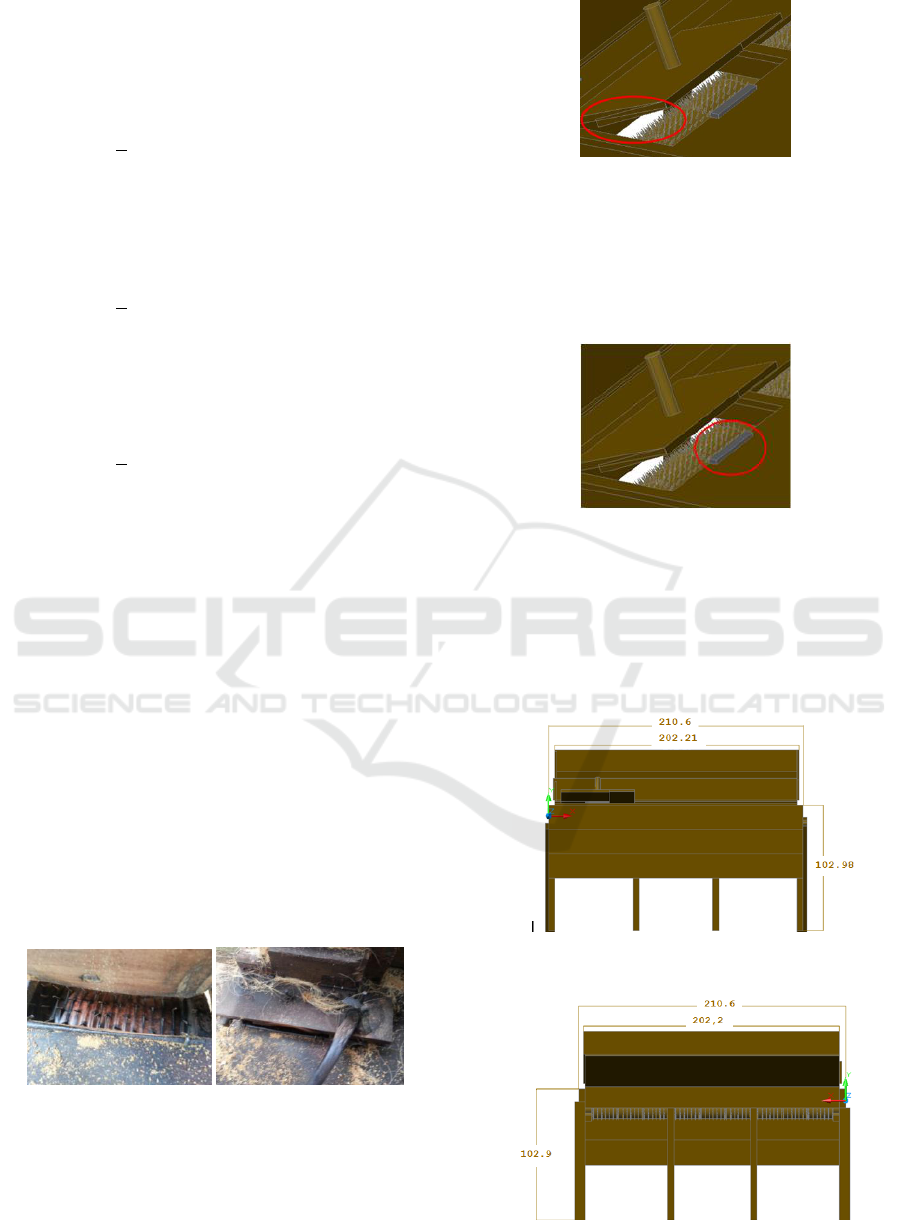

Based on the characteristics, dimensions, and

safety aspects wanted, a new Coco Bristle machine

was designed. The 3D AutoCAD design and

original New Coco Bristle machine product can be

seen in Figure 10 through Figure 16.

Figure 10: Front view of new coco bristle machine design.

Figure 11: Back view of new coco bristle machine design.

ksxP

50

)23,0(098,102

ksxP

50

)58,0(098,73

ksxP

50

)33,0(025,4

ICONART 2019 - International Conference on Natural Resources and Technology

362

Figure 12: Right view the new coco bristle machine design.

Figure 13: Left view of new coco bristle machine design

Figure 14: Top view of new coco bristle machine design.

Figure 15: Bottom view of new coco bristle machine design.

Figure 16: New coco bristle machine products.

3.3 Machine Testing

Machine testing is performed to assess machine

performance. The main purpose of designing this new

machine is to create a machine that is more secure and

comfortable to use. Therefore, testing should be done

to assess whether the desired goal has been achieved.

Testing is done by assessing the worker's posture

when using a new machine using REBA. The

assessment results show an average score of four,

which means the score has dropped two points from

the REBA calculation on the initial machine. This

indicates that this machine is more secure and

comfortable to use in work. The safety level of the

new machine is considered safer and easier to use by

the workers, especially the handheld security that has

been designed in accordance with the dimensions of

the hand grip is safer to use than the old machine.

Figure 17: Results of the calculations of REBA for new

coco bristle machine.

4 CONCLUSIONS

The results showed that there is a close relationship

between the design and the dimensions of the tool

with the level of security and health in work. This can

be seen from the decrease in REBA scores up to two

points and machine design that has been made is more

The Effect of Improvement on Work Facility of Coco Bristle Process to Occupational Health and Safety

363

secure. This finding is not only found in this study.

Some other studies such as (Meena, 2015) who

designed the hand tool for screen textile printing also

found that there was a decrease in pain in the lower

back area by 29% from 75%, pain in the shoulder was

also reduced to 33% from 74% by using the new tool.

This study used a different approach from

previous research (Widananto, 2013) which also

redesigned coconut coir machine. The study uses a

more focused participatory approach to make

improvements related to the utilization and use of

tools. However, such an approach can be considered

for further research given that the design of Coco

Bristle machine with ergonomic principles has not

been done before this research.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge that the present

research is supported by Talenta Research Grant of

Research Institution, University Sumatera Utara on

Contact Number of 5338/UN5.1.R/PPM//2017, date

of 22 Mei 2017. The gratitude is also intended for

Asty and Ratih Sulastri students for the help and

support provided for this research.

REFERENCES

Bhandhare, A., 2013. Postural analisis and quantification of

fatigue by using rula and reba techniques, IJMPE, Vol.

1(3).

Burton J., 2013. The world leaders in coconut production,

cited from https://www.worldatlas.com/articles/the-

world-leaders-in-coconut-production.html

Herlinda, W. D., 2014. Ekspor kelapa RI kalah dari

Filipina, cited from http://industri.bisnis.com/read/

20140421/12/220920/ekspor-kelapa-ri-kalah-dari-

filipina [In Indonesia]

Kavitha, M., Production process of coir and coir products,

IMPACT: IJRBM, Vol. 3(3), pp.39-47

Meena, M. L., 2015. An ergonomic approach to design

hand tool dor screen textile printing, IJMECH, Vol. 4,

No. 2, pp. 59-67.

Nara, N., 2012. Bakar sabut kelapa, Rp 13 triliun menguap,

cited from http://ekonomi.kompas.com/read/2012/11/

11/04331576/Bakar.Sabut.Kelapa.Rp.13.Triliun.Meng

uap [In Indonesia]

Niebel, B., Freivalds, A., 2007. Methods standards and

work designs, New York: McGraw-Hill.

Villa, F. T., 2016. Coconut husk mini-chipper machine,

IJERGS, Vol 4(1):611-623.

Widananto, H., Purnomo, H., 2013. Rancangan mesin

pengupas sabut kelapa berbasis ergonomi parsipatori,

presented at National Seminar IENACO, unpublished.

[In Indonesia]

ICONART 2019 - International Conference on Natural Resources and Technology

364