Value Engineering of Coco Peat Product to Increase Productivity

Listiani Nurul Huda

1

, A. Rahim Matondang

1

and Indra Nasution

2

1

Department of Industrial Engineering, Universitas Sumatera Utara, Kampus USU, Medan City, Indonesia

2

Department of Mechanical Engineering, Universitas Sumatera Utara, Kampus USU, Medan City, Indonesia

Keywords: Coco Peat, Productivity, Value Engineering, Ergonomics Design

Abstract: Coco peat is a scrap from the process of sweeping coco fiber and coco bristle fibers in the form of fine

granules. The selling value of coco peat block is more expensive compared to coco peat fine grain, hence

why value engineering is needed. In this paper the process of making the coco peat block press machine is

ergonomically described. Productivity of coco peat block fine grain and coco peat block will be compared.

The method used for ergonomic design uses anthropometric data and Rapid Entire Body Assessment

(REBA) analysis, while productivity measurement uses total productivity. The results obtained showed that

the design using anthropometric data of workers resulted in an improvement of 4 points of work posture

from conditions that needed to be improved to be safe. The total productivity of technological engineering

changes carried out shows an increase in index of around 0,41. There is an increase in selling value between

fine grain coco peat with 3 times coco peat block. These findings indicate that the procurement of press

machines that are ergonomically designed to add the value of coco peat is a viable solution to increase the

productivity of the company.

1 INTRODUCTION

Coconut is one of the most agricultural products has

many derivatives. Not only from the flesh of the

fruit, even coconut husk which is classified as scrap

can be utilized as a product that is worth selling. The

derivative of coconut husk can be divided into three,

namely coco fibre, coco bristle, and coco peat.

Figure 1: Industry Tree of coco peat

Coco fiber and coco bristle are fibers of coconut

husk which has been combed to separate from one

another (not sticking together). The granules

resulting from the sweeping process is called coco

peat. The difference in selling price of these three

products are shown in Table 1.

Table 1: The selling price of the products.

No.

Product

Selling Price (Rp) / kg

1

Coco Bristle

14,000

2

Coco Fibre

2,700

3

Coco Peat

600

Coco peat has the lowest sales value. But if you

consider the ratio of the proportion of the quantity

produced by the coconut husk for each product,

where the coco fiber, coco bristle, and coco peat in a

row, namely 20%, 10% and 70%, then it would be

very unfortunate if the coco peat not utilized. Mainly

because of coco peat also has a good resale value

because it can be used as a fertilizer and growing

media such as hydroponics, vegetables, also flowers

and trees nursery.

Coco peat has a mild nature, it can absorb large

volumes of water, the acceptable pH, and have

oxygention propertieswhich make coco peat suitable

as planting media for root growth (Awang, 2009).

Such properties make the coco peat to be one good

alternative in lieu of the land, because the amount of

land is increasingly limited.

Huda, L., Matondang, A. and Nasution, I.

Value Engineering of Coco Peat Product to Increase Productivity.

DOI: 10.5220/0008554303510357

In Proceedings of the International Conference on Natural Resources and Technology (ICONART 2019), pages 351-357

ISBN: 978-989-758-404-6

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

351

The compny that become the object of study has

a production capacity of 4,500 kg per day. Coco

peat, packed into 30 kg sacks, deposited into the

warehouse and sold to the local market for Rp

18,000 per sack. Process undertaken to acquired

coco peat products, namely:

1. Combing: Coconut coir parsed using a machine

to separate Crasher coco fibers and CCO bristle

fiber and coco peat granules.

2. Sieving: Beads of coco peat granules then

filtered three times with sifting machine to obtain

fine granules according to the standard of the

company.

3. Packaging: Sieving results then packed into 30

kg sacks sized manually by workers.

Sales of coco peat in bulk form is the simplest

way of selling. Generally coco peat is sold in the

form of blocks, especially for countries that are more

developed in their agribussiness like India, Europe,

and America. The block form is easier to handle in

terms of transportation because it has a smaller

volume than the bulk form.

(a)

(b)

Figure 2: (a) Coco peat bulk in sacks (b) Coco peat

pressed into block.

Value engineering (VE) is an organized effort to

analyze the function of the product or service so that

the company can find a way of generating the

required functionality of the essential characteristics

that users want while achieving the target set fee.

Value engineering is widely used in target costing,

product design and / or development, quality control,

etc. In this research, value engineering done for

product development. Value added activities carried

out by changing the shape of the packaging of bulk

into blocks which have a higher selling value, at Rp

23,000 / 10kg. Cost engineering is done on

designing products by considering the option

ofbuilding a new machine design with ergonomic

principles or buy the machine available in the

market.

Value addition of coco peat bulk into blocks can

be done with the procurement of a press machine.

Thus in this study will be a comparison of

productivity of sales coco peat with a bulk form and

block. They will also do a comparison of

productivity between the use of the press machine

individually designed with ergonomic considerations

with engines purchased from the market.

2 METHODS

Stages of the research conducted in this study

include the ergonomic design of the press machine,

productivity calculations, and the analysis of the

value added.

Manually packing Method is analyzed by using

Rapid Entire Body Assessment (REBA) to look at

risk due to work postures that are not good. This

method is chosen because the workers use almost

entire body part to work. Then the machine will be

designed with consideration of workers

anthropometry so that in addition to having better

productivity, health and work comfort is also

obtained in the presence of the press machine.

Productivity calculation method used in this

study is total productivity. This method compares

the magnitude of the overall output of the input

used. Input factors are taken into account include

labour, materials, capital, energy, and others while

the output factor is the revenue earned from the sale

(Sinulingga, 2014). Productivity on the conditions

before and after value engineering is compared to

see which options are most profitable productivity.

The formula used to calculate the total productivity,

namely:

Total productivity = Output / Input

(1)

An option with the best productivity index is

submittedas the best proposal of this study. To find

out how much value is actually done in the

ICONART 2019 - International Conference on Natural Resources and Technology

352

engineering of this value then the calculation of

added value is done. This calculation is performed in

a way to calculate the necessary costs (materials,

labour, packaging, depreciation, etc.) to make one

kilo of product. Then the value of the product sales

will be reduced by the value of the production cost.

The result of these reductions is actual profit earned

by the manufacturer.

Calculation of profit per kilo product is done for

the condition before and after engineering. Then the

difference of thevalue of the two is the added value

that has been done. The larger the value, the better

the added value that has been done.

3 RESULTS

3.1 Ergonomic Design Press Machine

Packaging method performed before the value

engineering is manually done by workers. Activity

of manual packaging is done by using a shovel to

move the coco peat located on the production floor

into the sack.

95

25

10

60

50

15

Figure 3: Method of manual packaging.

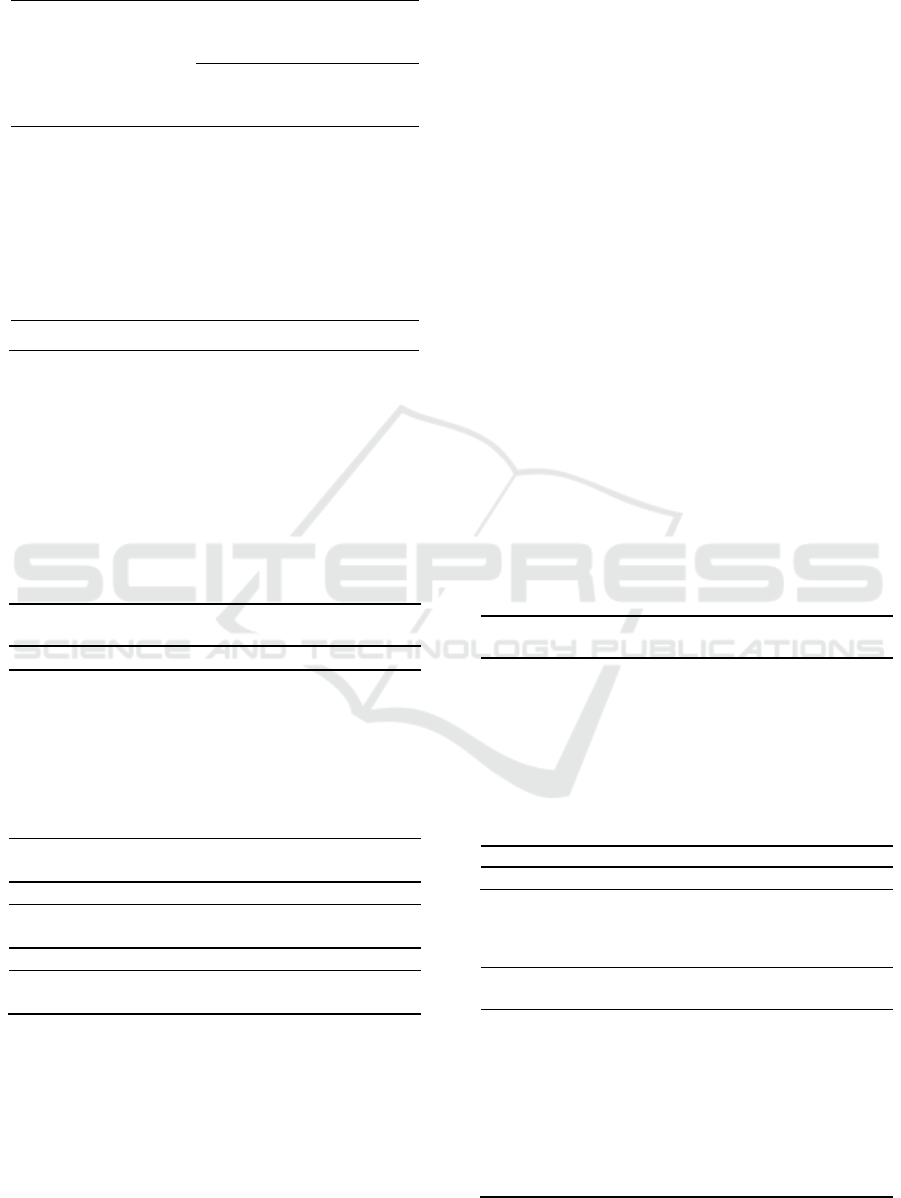

Figure 3 shows that the worker bent to 95

o

repeatedly for a long time. The manual method is

then analyzed posture using REBA method (see

Figure 4). REBA assessment results show the value

of nine which indicated that necessary action as soon

as possible. This means that the procurement of a

new working method or an ergonomic press machine

is required in terms of packaging.

The design of the press machine is done by using

the worker's body dimensions (five workers) as

consideration of the dimensions of the press

machine. Body dimensions used were High Standing

Elbow, Hand Reach and Height Upright.

Figure 4: REBA sheet assessment before value

engineering.

Theresults of the collected anthropometric data

are then processed statistically by calculating the

average, standard deviation, and uniformity test.

Then the dimensions used is the 95th percentile

results in accordance with the principle of upper

extreme.

The costs necessary to make the press machine is

shown in Table 2.

Table 2: Cost of each component machine press.

No.

Component

Unit price

(Rp 000)

Quantity

(Unit)

Total Price

(Rp 000)

1

Iron Plate

8-10 mm

8,750 / m

15

8.242

2

Iron Plate

12-20 mm

8,750 / m

15

16.485

3

diesel

engines

4.770 / unit

1

4.770

4

hydraulic

Valve

123 / unit

1

123

5

hydraulic

Pump

950 / unit

1

950

6

Working

cylinder

9,000 / unit

1

9,000

7

oil Filter

428 / unit

1

428

Total

39.998

The costs in Table 2 was obtained by interviews

with experts of construction machinery. This

machine is able to suppress the bulk 4 kg coco peat

coco peat into one unit block. The cost of

construction of this machine is much cheaper when

compared to the cost of purchasing the press

machine of the market for Rp 65,000,000 per unit

with the same capacity. Figure 5 shows the

appearance of the proposed draft press machine.

1. Raw materials

- Aluminum - Bentonite

- Wood - Cat Pilox

- Silica Sand - Graphite

- Powder Cooper 108 - Kerosene

- Nail

2. Equipment

- Mixer -

GayungPenuang

- Mal - Grinding

machine

- Hose - Furnace

- Shovels - Palu

- Pressure Equipment - Sand Paper

- Scoop nets

- Oil Drum

3. Capital

4. Labor

5. Information

6. Managerial

7. Land

Value Engineering of Coco Peat Product to Increase Productivity

353

200 cm

3

4

2

1

5

97,26 cm

120

cm

69

,

25

cm

154,53 cm

(a) (b)

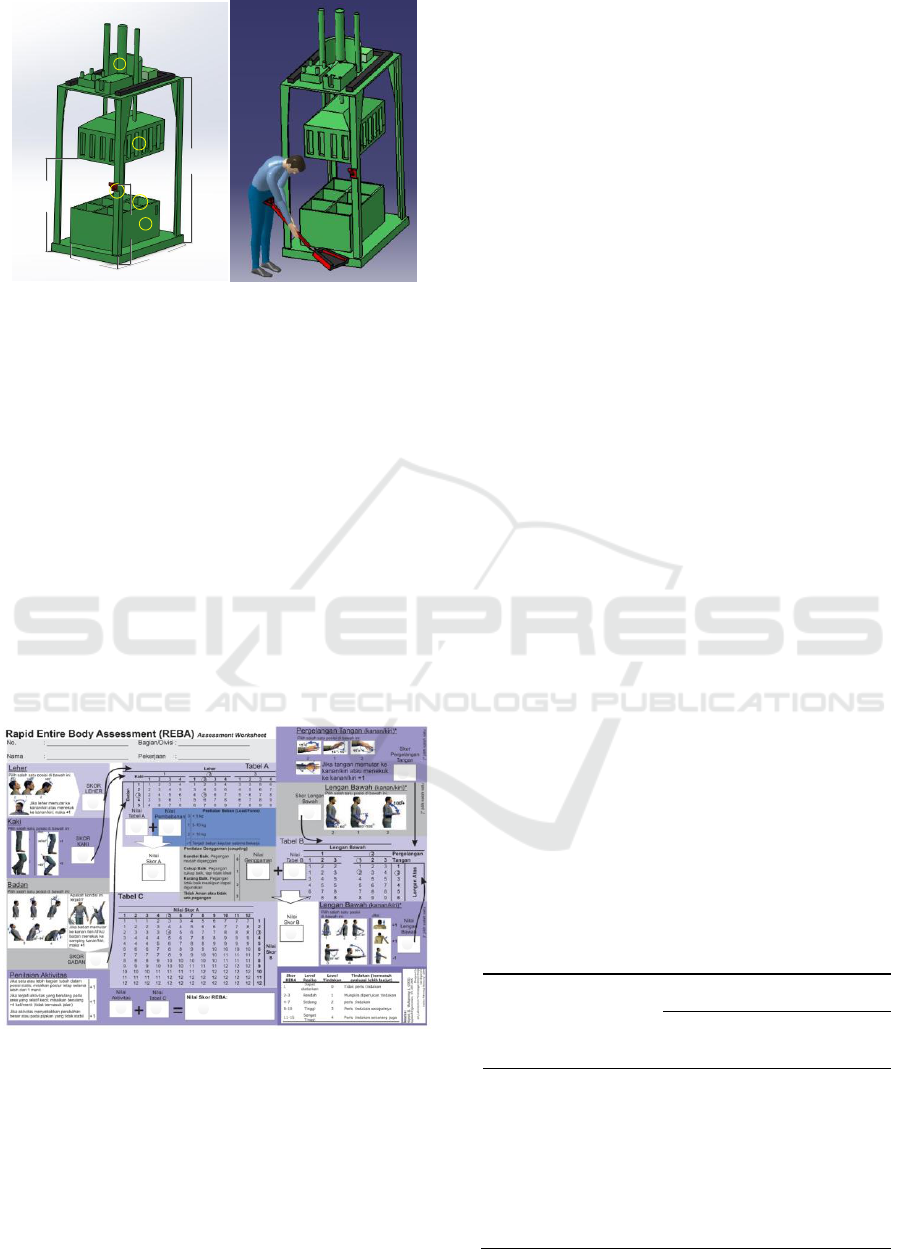

Figure 5: (a) Draft of the press machine (b) How to use.

Information:

1. Container as a place to put coco peat

2. Control valve as a means of controlling the lowering

and raising the working cylinder.

3. Cylinder as a means to lower and raise the mould

presses.

4. Mold presses as a tool that puts pressure on coco peat

into blocks.

5. Door as a place to put out the coco peat that has been

printed.

In Figure 5 (b) is shown posture coco peat bulk

of workers when inserting bulk coco peat into the

machine. Posture thus already looks much better

when compared with the posture before the press

machine. Posture assessment work on the use of the

press machine shown in Figure 6.

2

2

3

5

0

5

1

2

3

1

2

4

1

5

2

Figure 6: REBA sheet assessment after value engineering.

REBA assessment results show the value of five,

which indicates that the working posture is safe to

do in the long term.

3.2 Calculation of Productivity

Productivity calculations carried out for before and

after value engineering. Factors taken into account

the inputs and outputs include:

1. Raw material costs namely the costs required in

the acquisition of raw materials (Rp 7 / kg)

2. Telaborcost which consist of salaries to

employees (five workers with a salary of Rp

50,000 / day / person before value engineering

and Rp 75,000 / day / person after value

engineering).

3. The energy cost which consist of electric power

costs for machinery and other production

purposes.

4. Transportation cost is the transportation cost to

the consumer (Rp 283 / kg prior to value

engineering and Rp 373 / block after value

engineering).

5. The cost of packaging ie the cost of procurement

of sacks for bulk coco peat or plastic / cardboard

for products coco peat block (Rp 1,500 for sacks

and an assumed amount of Rp 6,708,000 for

plastic and cardboard)

6. Depreciation costs of equipment and machinery.

7. Machinery maintenance costs.

8. The output is the result of revenues from product

sales (Rp 600 / kg for bulk and Rp 2,300 / kg for

the block). Each of the coco peat block is made

of 4 kg of coco peat bulk.

To see a comparison of productivity of prior to

value engineering and after value engineering, then a

simple simulation is done using historical data. The

production data with press machine designed

ergonomically and the ready to use purchased

machine is considered the same as the specification

is also considered as the same engine capacity. Coco

peat production data 2016-2017 period are shown in

Table 3.

Table 3: Comparison of production data before and after

value engineering.

Month

Raw material

(Kg)

Prior to Value

Engineering

After Value

Engineering

(A)

(Ton)

(B)

(Rp

000)

(A)

(000

Blocks)

(B)

(Rp 000)

2016 Aug'

99.400

71

2.3

17.75

6,708

2016 Sept'

105,000

75

2.5

18.75

6,708

2016, Oct'

106.400

76

2.5

19:00

6,708

2016, Nov'

105,000

75

2.5

18.75

6,708

2016 Dec’

96,600

69

2.3

17:25

6,708

2017, Jan'

96,600

69

2.3

17:25

6,708

ICONART 2019 - International Conference on Natural Resources and Technology

354

Table 4: Comparison of production data before and after

value engineering (continued).

Month

Raw material

(Kg)

Prior to

Value

Engineering

After Value

Engineering

(A)

(Ton)

(B)

(Rp

000)

(A)

(000

Blocks)

(B)

(Rp 000)

2017, Feb'

109,200

78

2.6

19:50

6,708

2017, Mar'

105,000

75

2.5

18.75

6,708

2017, Apr'

105,000

75

2.5

18.75

6,708

2017, May

109,200

78

2.6

19:50

6,708

2017, June

'

109,200

78

2.6

19:50

6,708

2017 July '

100,800

72

2.4

18:00

6,708

Total

1,247,000

891

29.7

223

80,496

Information:

(A) The raw material is processed and sold

(B) Costs incurred for packaging

Based on production data on Table 3 the

productivity of each condition can be calculated.

Comparison of productivity before and after value

engineering can be seen in Table 4.

Table 5: Productivity comparison before and after value

engineering.

No

Description

(A)

(Rp 000)

(B)

(Rp 000)

(C)

(Rp 000)

1

Output (Income) (Rp)

534.600

683.100

683.100

2

Input (Rp)

Raw material

8.731

8.731

8.731

Labor

74.250

111.375

111.375

Energy

16.375

60.106

60.106

Packaging

44.550

80.496

80.496

Transportation

252,000

110.820

110.820

Depreciation

1,450

5,050

7,300

Maintenance

60

1,800

2,400

Total Cost of

Production

397.958

378.379

381.230

3

Gross Revenue (Rp)

136.641

304.720

301.869

4

Corporate Income

Tax 15%

20.496

45.708

45.280

5

Net income

116.145

259.012

256.589

6

Productivity Total

(D)

1:34

1.81

1.79

Information:

(A) Prior to the engineering value

(B) After engineering value with the press machine design

results

(C) After engineering value with the press machines

purchased in the market

(D) Calculated by a formula (1)

Total productivity index for the condition before

value engineering and after value engineering with

designed machine and purchased machine

successively 1.34, 1.81, and 1.79. This figure means

that every US $ 1 generate Rp 1.34 to conditions

prior to engineering, and so on for the other options.

This means the condition after the value engineering

with designed machine is the best option because it

has the highest index value.

3.3 Added Value

,

Added value calculation is performed to see how

much profit is obtained by producers as compared to

prior to value engineering. This calculation will be

done by comparing the value of profits after value

engineering using the press machine which is

ergonomically designed, with the profit before value

engineering. The option of after value engineering

with designed machine is chosen to be analyzed

because this option has the highest value. Tables 5

and 6 respectively show the cost of production and

the selling value of the condition before and after

value engineering.

Table 6: Production cost and income before value

engineering.

No.

Production

description

Amount

(kg)

Price

(Rp)

Total

(Rp)

1

Income

1

2,300

2,300

2

Production cost

Raw material

4

7

29

Labor

375

Energy

202

Packaging

271

Depreciation

17

Transportation

373

Maintenance

6

Total Production Costs

434

Profit per kg (Rp)

166

Table 7: Cost of production and income after value

engineering.

No.

Production

description

Amount

(kg)

Price

(Rp)

Total (Rp)

1

Income

1

600

600

2

Production cost

Raw material

1

7

10

Labor

83

Energy

15

Packaging

50

Depreciation

1

Transportation

283

Maintenance

1

Value Engineering of Coco Peat Product to Increase Productivity

355

Total Production Costs

434

Profit per kg (Rp)

166

It can be concluded that by using the system of

bulk sales, manufacturers have lost Rp 860 per kg or

Rp 766,260,000 per year. This figure is quite large

because the value has exceeded the value of sales of

bulk per year that is Rp 534,600,000. In other words

there is an increase of 143% of income compare to

prior of value engineering.

4 DISCUSSION

There are three options on this study to be

considered. Option 1 is the condition without VE,

option 2 is VE with the designed machine, and

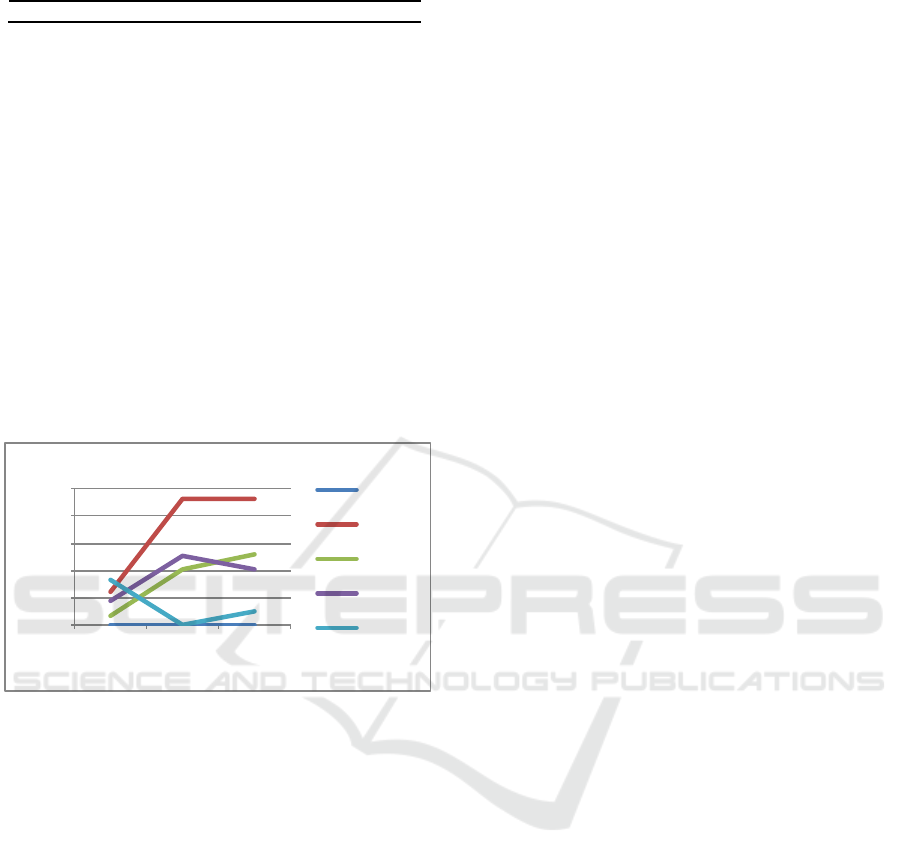

option 3 is VE with purchased machine. Productivity

values of the three options can be seen on Figure 7.

Figure 7: Options comparison.

From productivity point of view, the added value

for option 1 and 2 are above the production cost

which means both option is giving better cost to

income ratio than option 3. From the opportunity

cost which means the loss that gain by choosing

other option, the base value is the option 2 because it

has the best added value. If option 1 is chosen

company would lost the income of Rp 840 per

kilogram and if option 3 is chosen then company

will lost Rp 257 per kg.

Basically the option 2 is the best option to

choose. But there is also some disadvantage of it

such as a necessary of an expert machine constructor

to deliver the design into real life in the right way.

This option will need some adjustment for the

workers to get used to it. The period of adjustment,

there will be a slight deviation in the productivity

due to learning curve. A sensitivity analysis also has

not been done. So we cannot make sure the

reliability of the investment against various

scenarios.

Generally this method of value added is not

something new in the development of coco peat. But

there is still limited study which discussed about the

economic value of coco peatfor most of them are

discussing about the usage of coco peat as growing

media such as done in (Yahya, A, 1997 and Trivedi,

Darshini R., 2014)

The kind of coco peat discussed in this study is

the kind that needs a further treatment before use.

Especially if it is to be used as growing media. Coco

peat has a chemical property name tanin which is

harmful for plants for it can prevent them to grow.

Hence why, coco peat need to be soaked in water for

several hours before used. This process is meant to

reduce or eliminated the tanin in the coco peat by

rinsing it off with water (Ramadhan, Dimas, 2018,

Arif, 2014).

This study is only discussing the press machine

because for now it is the only required condition to

fulfil the market demand. The current local market

preferred a low cost rather than a quality product. If

needed, a further research can be done to develop

further the value of coco peat such as making a

ready to use coco peat which has already labelled

and standardized quality parameters such as weight,

size, impurities, moisture, electrical conductivity,

pH, phytosanitary test (Plant Quarantine Certificate),

salinity, fibre content, cation exchange capacity

(CEC), etc.

This standardization is necessary if we want to

expand our business internationally. In Netherland,

there are already many coco peat producers which

has been certificated by European Certification body

for Agricultural Sector (ECAS). These companies

not only provide a standardized coco peat, they are

also selling a customized coco peat-based media

mixtures for each type of plant. So buyer can buy the

most suitable type to increased the success rate in

growing plants (trubus online, 2009).

In India, they even have a Coir Board which has

a lot of information about coconut derivatives

products and control the regulations and the

development of coco peat industry. Not only for

growing media coco peat even used for a living lawn

that can be rolled up, as a raw material to make

briquettes, bio oil, insulator, production of vanillin,

activated carbon, even textiles (Ministry of MSME

India, 2016).

1,34 1,81 1,79

600

2300 2300

166

1026

1283

434

1274

1017

840

0

257

0

500

1000

1500

2000

2500

Option 1 Option 2 Option 3

Rupiah

Rupiah

Options Comparison per kg Product

Productiv

ity index

Selling

price

Productio

n cost

Added

Value

Opportun

ity cost

ICONART 2019 - International Conference on Natural Resources and Technology

356

5 CONCLUSIONS

In conclusion, this study indicates that the value

engineering done by transforming the form of coco

peat from bulk to block can increase the productivity

and income to the company. The added value is not

only the increase of productivity, but also the

healthy and comfort while working for the chosen

option is to make the ergonomically designed press

machine rather than the ready to use machine that

can be purchased from the market.

ACKNOWLEDGMENTS

The authors gratefully acknowledge that the present

research is supported by Talenta Research Grant of

Research Institution of Universitas Sumatera Utara

on Contact Number of 5338/UN5.1.R/PPM//2017,

date of 22 Mei 2017. The gratitude is also intended

for Leni and RatihSulastri for the help and support

provided for this paper.

REFERENCES

Awang., Yahya, et al, 2009. Chemical and Physical

Characteristics of Cocopeat-Base Media Mixtures and

Their Effect on the Growth and Development of

Celosia cristata, AJABS 4 (1):63-71.

Arif, I., Hanif, N.H., 2014. Suitability of cocopeat as a

transplanting media in the polytube of Magnolia

elegans (blume.) H. Keng seedlings, WASIAN Journal

1(2): 73-76.

Ministry of Micro, Small & Medium Enterprises of India,

2016. Coir Pith Wealth from Waste, Coir Board. India.

Ramadhan, D., Riniarti, M., Santoso, T., 2018.

Pemanfaatan Cocopeat sebagai Media Tumbuh

Sengon Laut (Paraserianthes falcataria) dan Merbau

Darat (Intsi palembanica), Jurnal Sylva Lestari

6(2):22-31.

Sinulingga, S., 2014, Rekayasa Produktivitas

(Productivity Engineering), USU Press.Indonesia.

Soekartawi, 2002. AnalisisUsahatani (Farming Analysis),

Universitas Indonesia. Jakarta.

Trivedi, D., Aruna, G.J., 2014. Studies on seed

germination of Stereospermumsuaveolens with respect

to different parameters, Environmental and

Experimental Biology 12: 33–37.

Yahya, A., H. Safie, H., Kahar, S.A., 1997. Properties of

cocopeat-based growing media and their effects on

two annual ornamentals, JTAFS 25(2): 151-157.

Trubus online, 2009. Henk van Staalduinen Pada

Cocopeat Belanda Bersandar. (Accessed from

http://www.trubus-online.co.id/henk-van-staalduinen-

pada-cocopeat-belanda-bersandar/ on February 25

th

,

2019).

Value Engineering of Coco Peat Product to Increase Productivity

357