Effect of Cover Soil to Concentration of Ammonia, Nitrate and

Nitrite in Leachate with Bioreactor Landfill Simulation

Winny Laura C. Hutagalung, Rinaldi and Syarafina Sabilla

Environmental Engineering Study Program, Engineering Faculty, Universitas Jambi, Mestong, Pondok Meja 36364

Keywords: Bioreactor Landfill, Cover Soil, Ammonia, Nitrate, Nitrite.

Abstract: Leachate is one of the wastes from the waste processing site that must be handled appropriately so as not to

pollute the environment. One method of handling leachate is leachate recirculation. Ammonia contained in

leachate can pollute the environment. This study simulated landfills in two bioreactors with recirculation

leachate and the addition of water and distinguished them using (1) and without using cover soil (2). The

study was conducted for 30 days. The parameters analysed were ammonia, nitrate, and leachate nitrite. The

observations of the two bioreactors showed that the concentration of ammonia and nitrate in bioreactor 2

tended to be higher than in bioreactor 1. Nitrite concentrations did not show significant differences in the two

bioreactors. Ammonia, nitrate, and nitrite compounds in both bioreactors have been formed since the

beginning of the study even though they initially had relatively low values. The decrease in the height of the

organic waste is faster in bioreactor 1 with a percentage of final waste reduction of 79.03%. The highest waste

temperature occurs in bioreactor 2, which reaches 43

0

C. The pH of waste in both bioreactors tends to be

neutral, while the pH of leachate in both bioreactors tends to be acidic.

1 INTRODUCTION

Indonesia is a developing country with a population

that continues to increase every year. The impact of

population growth increases the amount of waste

generated. The problem that occurs in Indonesia is the

increasing number of waste generated every day,

while the land that can be used as disposal and

processing of waste is increasingly limited. Waste

generation has a direct impact on environmental

conditions, such as siltation of rivers, air pollution,

causing various diseases, and damaging aesthetic

values.

Jambi City is one city that is inseparable from the

problem of garbage. In 2015 the population of Jambi

City was 569.296 people with an annual waste

generation of 571.444 m

3

(Central Statistics Agency,

2015). The landfill used is the Talang Gulo landfill

which has a controlled landfill system. Many

problems occur in implementing this system, such as

limited land, methane gas production, and the high

volume of leachate produced. Leachate produced

contains various pollutants, including ammonia,

nitrate, and nitrite. Therefore, there must be a way to

accelerate the stabilization of waste to overcome the

problem of limited land and reduce the organic

content of leachate in a faster time. According to

Chan (2002) by conducting leachate recirculation can

improve leachate quality, accelerate the

decomposition of waste, and reduce leachate

processing costs.

Based on the above problems, the authors

conducted a study on the condition of leachate in

landfill modelling to be made with the type of organic

waste in two different reactors, namely using cover

soil and without cover soil. This study was conducted

to analyse the effect of cover soil on decreasing the

height of the waste, the temperature of the garbage,

the pH of the waste and the pH of leachate water in

each reactor. Determine the concentration of

ammonia, nitrate, and nitrite in leachate produced

from each reactor. The landfill is a physical facility

that is used as a place for final waste processing. The

landfill is a method of handling waste by storing

garbage into the soil. The most widely known final

disposal method is open dumping, controlled

landfills, and sanitary landfills (Tchobanoglous et al.,

1993).

Leachate is liquid waste arising from the entry of

external water into landfills, dissolving, and rinsing

dissolved materials, including organic matter

resulting from biological decomposition processes

292

Hutagalung, W., Rinaldi, . and Sabilla, S.

Effect of Cover Soil to Concentration of Ammonia, Nitrate, and Nitrite in Leachate with Bioreactor Landfill Simulation.

DOI: 10.5220/0008553402920299

In Proceedings of the International Conference on Natural Resources and Technology (ICONART 2019), pages 292-299

ISBN: 978-989-758-404-6

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

(Damanhuri, 2008). One of the characteristics in

leachate is ammonia, which, if excessive, is harmful

to the environment. Ammonia in leachate must be

removed because it is toxic, inhibits anaerobic

degradation and can affect human health (Dini, 2014).

Increasing the concentration of ammonia-

nitrogen will increase the level of toxicity in leachate

(Dini, 2014). High concentrations will potentially

inhibit the degradation process and require treatment

of leachate before being discharged into the water

body. In leachate, most ammonia-nitrogen is in the

form of ammonium (NH4 +) because the pH level is

less than 8 (Reinhart et al., 2002 in Dini, 2014).

Parameter of ammonia (NH

3

), nitrite (NO

2

-

) and

nitrate (NO

3

-

) produced in the bioreactors are formed

due to decomposition reactions of organic matter

containing nitrogen, such as proteins and amino acids.

Protein must undergo the process of hydrolysis into

amino acids so that it can be used as an energy source

by a microorganism. The process of protein

hydrolysis and fermentation by microorganisms

causes ammonia (NH

3

) to form in leachate.

The process of changing from amino acids to

ammonia is called ammonification, which helped by

microorganisms such as bacteria and fungi. In the

case of sufficient oxygen, ammonia will be converted

biologically through the nitrification process.

Nitrification is a two-stage process that also involves

two types of bacteria, Nitrosomonas and

Nitrosococcus, which can decompose ammonia into

nitrite, and Nitrobacter, which is able to decompose

nitrite compounds into nitrates.

2 MATERIALS AND METHODS

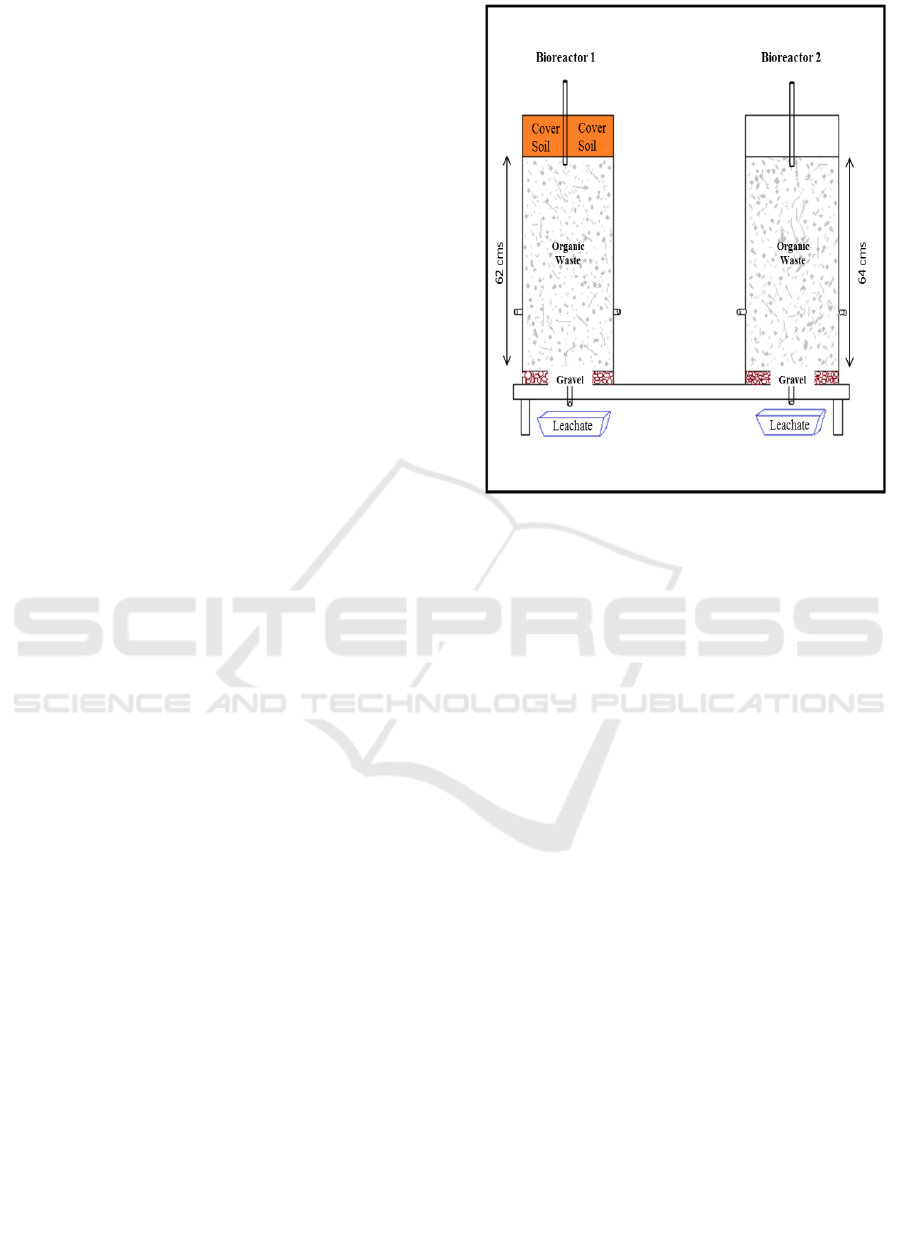

In this study, there were two different bioreactors

those are bioreactor 1, which used cover soil and

bioreactor 2 without cover soil. The cover soil used is

sandy clay soil. The bioreactor is made using 85 cm

tall drums with a diameter of 48 cm. Organic waste

filled into the bioreactors with weight 57 kgs. Organic

waste was taken from Talang Banjar Traditional

Market, Jambi City and was chopped in Makmur

Waste Bank, Eka Jaya.

The temperature of waste is carried out using a

thermometer. Waste temperature is measured at each

port that is in each reactor. The measurement pH of

leachate was carried out every day for 30 days of

study. Leachate water is taken from the reservoir of

leachate water from each reactor, which will then be

measured for its pH value using a pH meter. The

layout of bioreactors used is as follows:

Figure 1: Layout of Bioreactor.

This study was conducted for 30 days. The

parameters observed in this study were the decreased

of the height of waste, temperature, and pH of waste,

pH of leachate, the concentration of ammonia (NH

3

),

nitrite (NO

2

-

) and nitrate (NO

3

-

). Both bioreactors will

be treated with leachate recirculation and addition of

rainwater. Recirculation of leachate carried out will

redistribute nutrients needed by microorganisms in

landfills (Adam, 2015). The amount of water added

was 477 ml, with the calculation of rainfall in Jambi

City. Addition of water is carried out every day

during the study.

Recirculation of leachate is carried out in the first

week for seven days, then in week-2 to week-4 only

once a week. For the addition of water is done every

day. The method used to measure the concentration

of each parameter, like Ammonia is SNI 06-6989.30-

2005, Nitrite (NO

2

) is SNI 06-6989.9-2004, and

Nitrate (NO

3

) is SNI 6989-79-2011.

3 RESULTS AND DISCUSSION

3.1 Effect of Cover Soil to Reduction of

Organic Waste

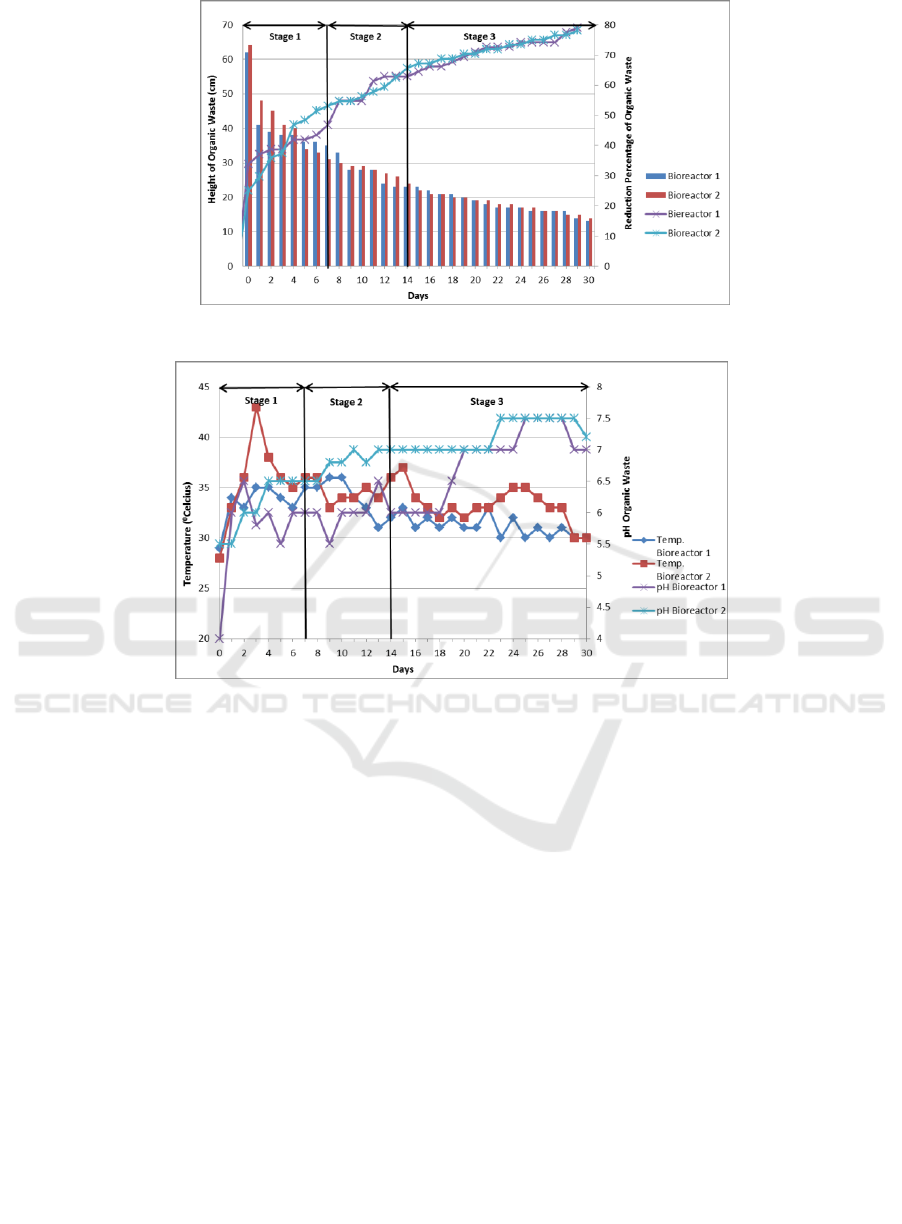

Decreasing the height of the waste is classified into 3

stages, namely the initial reduction of waste, the

decrease in primary waste, and the subsequent

Effect of Cover Soil to Concentration of Ammonia, Nitrate, and Nitrite in Leachate with Bioreactor Landfill Simulation

293

decrease in waste (El-Fadel, 2014). The reduction in

waste caused by the addition of external loads to the

waste is referred to as the initial reduction in waste.

The external load added above the layer of waste can

reduce the amount of space formed between the

surfaces of the waste (Adam, 2014). The initial

reduction of waste on the day-1 of the bioreactor 1

decreased to 33.87%, while in bioreactor 2 decreased

to 25%.

Furthermore, the reduction of waste height

continues and is observed at each stage. Stage 1 is a

decrease in waste height in the first week of the study.

At this stage, the decrease in the height of the waste

occurs as a result of the weight of the waste itself or

can be said as a primary decline (Elagroudy et al.,

2008). At this stage, the height of waste in bioreactor

1 decreased by 43.55%, while in bioreactor 2

decreased by 51.56%.

At the end of stage 2 on the day-14 of the study,

the height of bioreactor 1 decreased by 62.90%, while

in bioreactor 2 decreased by 62.50%. At the

beginning of stage 3 on the day-15, the height of

waste in bioreactor 1 decreased by 62.90%, while in

bioreactor 2 decreased by 65.63%. At the end of stage

3 on the day-30, the height of waste in bioreactor 1

was 13 cm, while in bioreactor 2 was 14 cm. Based

on the results, it was obtained that the percentage of

reduction of waste in bioreactor 1 was 79.03%, while

bioreactor 2 was 78.13%.

The reduction in waste that occurs from stage 2 to

stage 3 can be categorized as a secondary decrease in

waste. It occurs as a result of the physical and

biochemical decomposition processes that have

occurred (Elagroudy et al., 2008). Reduction in waste

will continue until it reaches a stable condition. As

shown in Figure 2, the accumulated percentage of

waste reduction. In this case, the initial decline in

waste and the decrease in primary waste is shown in

stage 1. While the secondary decrease in waste is

shown in stages 2 and 3.

3.2 Effect of Cover Soil to pH and

Temperature of Organic Waste

In general, the temperature of waste in bioreactor

tends to fluctuate because it is influenced by ambient

temperature or the temperature outside the bioreactor.

Besides that, the temperature is one indicator that

shows that the decomposition process of organic

compounds runs smoothly is the change in the

temperature of the waste. The heat generated from

organic waste is caused by the decomposition of

organic fractions from the waste mass. The heat

generated is influenced by the operating system

applied to landfills and climatic conditions (Yesiller

et al., 2011).

The temperature of waste becomes an important

parameter because it affects the solubility of organic

compounds and heavy metal compounds contained in

waste (Sethi et al., 2013). The measurement of waste

temperature is carried out every day for 30 days. The

results of the temperature of the waste in bioreactor 1

are in the range of 30-36

0

C, this is suitable for the

process of decomposition of waste. Meanwhile, the

temperature of waste in bioreactor 2 is in the range of

30-43

0

C. The condition of microorganisms or

mesophilic bacteria can grow optimally in the range

of 30-38

0

C.

The temperature of waste in each bioreactor has

increased during the first stage. The temperature

range of waste in bioreactor 1, which uses cover soil

during stage 1 is between 33-35

0

C, while the range of

temperature values of waste in bioreactor 2 during

stage 1 is 33-43

0

C. This is related to the phase of

aerobic waste degradation that is taking place at both

bioreactors. In this phase of aerobic waste

degradation, oxygen trapped in waste is consumed

very quickly by aerobic bacteria to degrade the

organic material contained in waste into carbon

dioxide, water, organic residues which are partially

degraded and also produce heat (Anindita, 2013).

The heat generated from the aerobic degradation

process is what causes the initial temperature of the

waste to be high — exothermic processes in waste

degradation caused by respiration and metabolism

microorganism. The metabolism of microorganisms

is closely related to the organic fraction so that if the

temperature of the waste gets higher, it is also the

metabolic process of microorganisms is high

(Rahmawati, 2017).

The value of the waste temperature for bioreactor

2 increased dramatically on the day-3, which was

43

0

C. This is due to an exothermic reaction in the

bioreactor. An exothermic reaction is a reaction that

experiences heat transfer from the system to the

environment or in that reaction can emit heat. In

exothermic reactions generally, the system

temperature will increase. With a waste volume of

0.115 m

3

, it can produce a maximum waste

temperature value of 43

0

C.

At stage 2, the value of the waste temperature

tends to fluctuate. The temperature range of waste

obtained during stage 2 in each bioreactor is between

31-36

0

C for bioreactor 1 and 33-36

0

C for bioreactor

2. The waste temperature during stage 3 is the same

as stage 2 because the temperature of the waste is

fluctuating, but the temperature the waste of the two

bioreactors decreased on the day-30 or at the end of

ICONART 2019 - International Conference on Natural Resources and Technology

294

Figure 2: Reduction of Organic Waste.

Figure 3: Temperature and pH of Organic Waste.

stage 3, the study was 30

0

C. According to Sahidu in

Anindita (2013), the optimum temperature for the

growth of anaerobic bacteria ranges from 30-35

0

C.

This indicates that the process of degradation of waste

in both bioreactors after entering the anaerobic

degradation phase does not take place optimally.

The results of pH waste in this study tend to be

neutral in each reactor. The process of recirculation

leachate does not change the pH value to acid. This is

because the process of adding water is done every

day. The process of adding water every day affects

bioreactor 2, in the absence of a layer of soil covering

the water that enters the organic waste, it will seep

faster to the bottom of the organic waste where the

bottom has a port or hole to check the pH of the waste.

The pH of waste in bioreactor 2 is more neutral.

Conversely, the pH of waste in bioreactor 1 is longer

to reach a neutral pH. This is because the addition of

water is done through the cover soil first, then it seeps

into the garbage. Graph of temperature and pH of

waste can be seen in Figure 3.

3.3 Effect of Cover Soil to pH of

Leachate

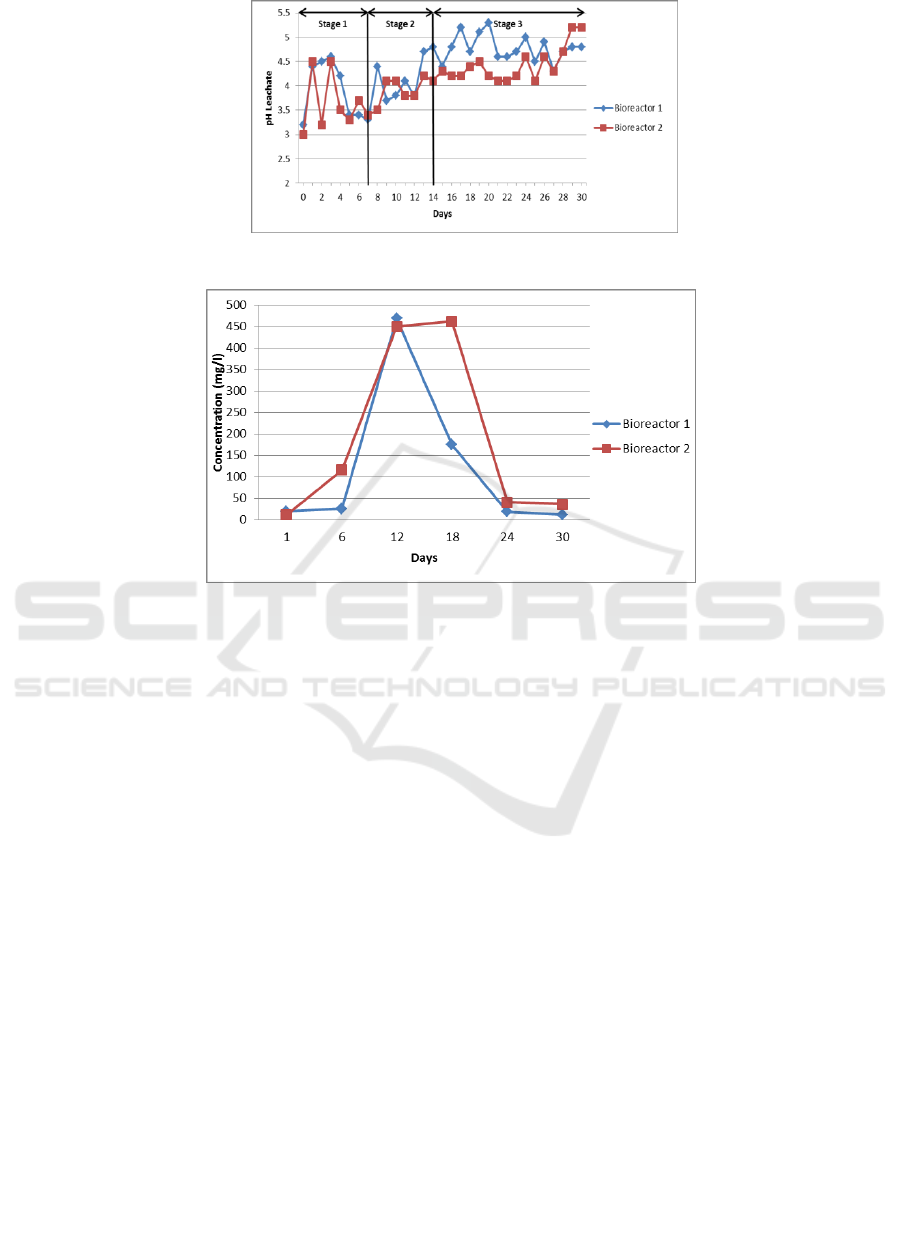

The pH of leachate is one of the most significant

parameters in influencing leachate concentration in

landfills. In Figure 4, we can see the change in pH of

leachate for 30 days. The pH of leachate is closely

related to the concentration of the material dissolved

in it. The pH of leachate can also provide an

illustration of the ongoing phases in the landfill

reactor. On day-1 until day-30, it was seen that the pH

of leachate tended to be acidic in both bioreactors.

The range of pH of leachate in bioreactor 1 was

ranged from 3.2 until 5.3, while in reactor 2 it was

ranged from 3 until 5.2. This is due to the formation

of organic acids and increased carbon dioxide in the

waste. The formation and accumulation of organic

acids also result in a small amount of methane

produced because acidogenic bacteria, not

methanogenetic bacteria dominated the bioreactor.

Effect of Cover Soil to Concentration of Ammonia, Nitrate, and Nitrite in Leachate with Bioreactor Landfill Simulation

295

The pH of leachate at both bioreactors tends to be

low, indicating that the degradation process that takes

place in the waste has entered the acid phase or

commonly called the acidogenesis phase. In the

acidogenesis phase, there is a decreasing of pH

leachate as a result of the formation of acetic acid and

hydrogen. The pH of leachate in the acidogenesis

phase ranges from 5-6.5 (McBean et al., 1995). If the

leachate has an acidic pH and it recirculates to the

waste without a pH adjustment and buffering, it will

increase the solubility of organic acid in the leachate,

so that the pH of the next produced leachate tends to

decrease due to the accumulation of organic acids

which dissolved in leachate. In this study the pH

value did not reach neutral pH, this was related to

Dini (2014) where the pH value began to enter the

normal stage on the day-35 of the study with a pH of

7.2.

3.4 Effect of Cover Soil to

Concentration of Ammonia, Nitrate

and Nitrite in Leachate

The results obtained from this study were that on the

day-1 of the study, the concentration of ammonia in

leachate was 20.6 mg/L for bioreactor 1 and 11.9

mg/L for bioreactor 2. On day-6, the concentration of

ammonia was increased to 26.4 mg/L for bioreactor 1

and 116.4 mg/L for bioreactor 2.

This increase in concentration occurs because the

process of decomposition of organic material that

contains protein has begun. Proteins are converted

into amino acids in the process of hydrolysis, and

amino acids are converted back to ammonia

(Ayuningtias, 2013). On the day-12, the

concentration of ammonia increased to 468.7 mg/L

for bioreactor 1 and 449.6 mg/L for bioreactor 2.

The concentration of ammonia increased on day-

12 due to leachate recirculation process carried out

for seven days, respectively in the first week of the

study. This result is in accordance with what was

stated by Vazquez (2008) that leachate recirculation

could increase ammonia concentration because the

process can make ammonia in the dissolved

bioreactor in leachate. On the day-18, the

concentration of ammonia in bioreactor 1 decreased

to 175.2 mg/L, but for bioreactor 2 was increased to

462.3 mg/L. On the day-24, the concentration of

ammonia decreased to 19.7 mg/L for bioreactor 1 and

41.3 mg/L for bioreactor 2. Furthermore, on the day-

30 of the study, the concentration of ammonia

continued to decrease to12.35 mg/L for bioreactor 1

and 37.12 mg/L for bioreactor 2.

This decreasing concentration of ammonia is

thought to be due to the recirculation process of

leachate, which is no longer carried out every day but

once a week. In this study, the measured ammonia

concentration tended not to be too high because of the

constant addition of water. Purcell et al. (1999) said

that one method of ammonia removal is by washing

by water. Graph of ammonia concentration can be

seen in Figure 5.

In this study, it can be seen that ammonia

concentration in bioreactor 1 was lower than

bioreactor 2. This is related to the system used at the

landfill.

A landfill that applies a controlled landfill system

which was modeled with bioreactor 1 and open

dumping system was modeled with bioreactor 2.

Comparison of ammonia concentrations from the two

landfill sites with different systems shows that low

ammonia concentrations are found in landfills that

implement a controlled landfill system.

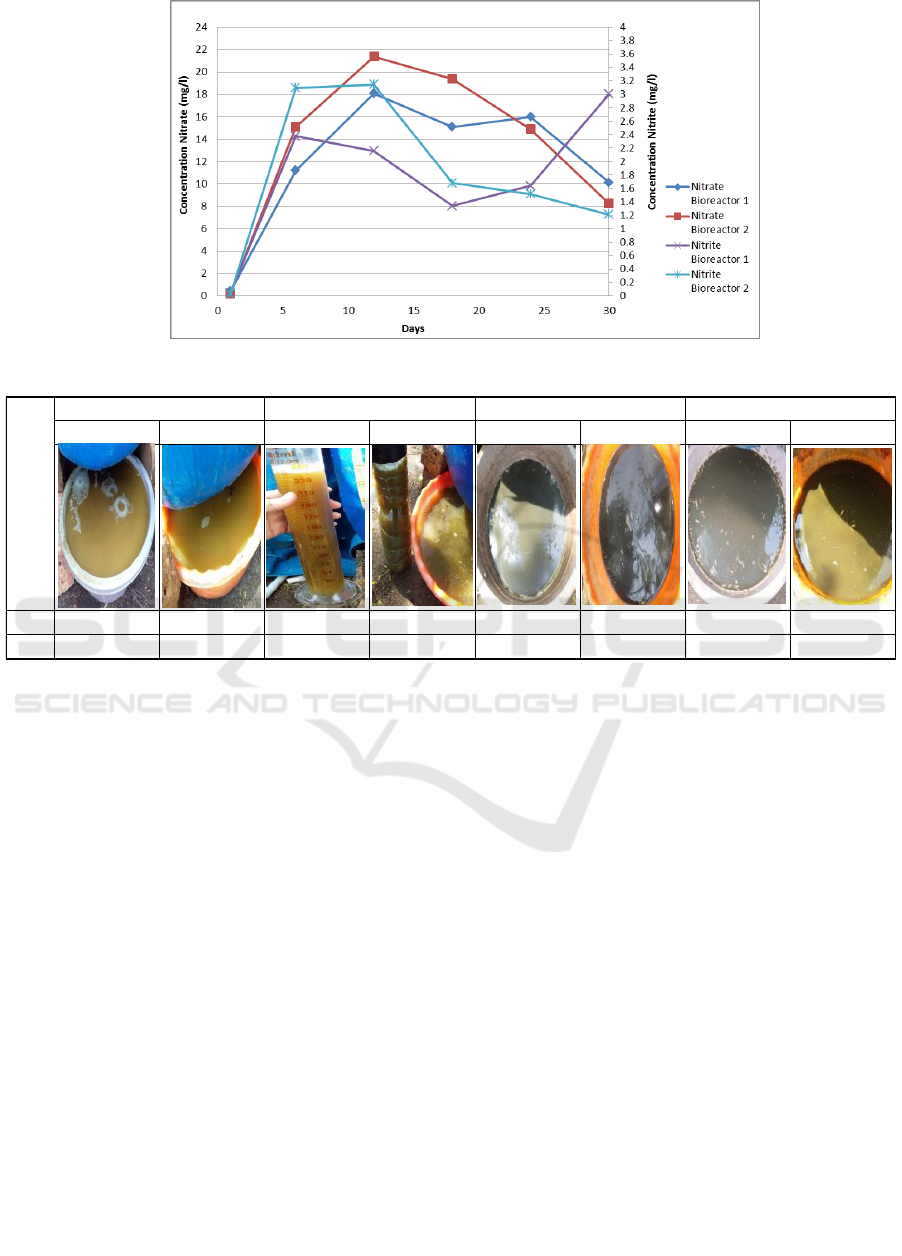

Furthermore, for concentrations of nitrite, there

was not too much difference in both bioreactors.

Concentrations of nitrite showed the nitrification

process in the bioreactor. The nitrification reaction is

triggered by the entry of oxygen due to leachate

recirculation and the addition of water. Besides, it is

estimated that the conditions in the bioreactor are

influenced by oxygen entering through several parts

of the bioreactor that are not tightly closed, such as

holes for testing pH and temperature of the waste. In

this study, the concentration of nitrite continued to

increase until day-12. After increasing, there was a

decrease in the concentration of nitrite in both

bioreactors until the last day of the study. However,

different things happened in bioreactor 1 because of

the concentration of nitrite, which had increased on

the last day of the study. Increase the concentration of

nitrite on day-30 in line with the decrease in ammonia

concentration because it has turned into nitrite

through the nitrification process.

In bioreactor 2, the concentration of nitrite tends

to be higher compared to bioreactor 1. This is because

the waste in bioreactor 2 is more quickly exposed to

the outside air or the waste inside the bioreactor is

readily reacted with oxygen; the nitrification process

will rapidly occur. Conversely, in bioreactor 1, air

from the outside is difficult to enter into the waste in

the bioreactor.

In addition to ammonia and nitrite concentrations,

nitrate concentrations were also examined to see the

association as one of the essential components in the

nitrification reaction. On the day-1 until day-18, the

concentration of nitrate was increased. Furthermore,

until the day-30, the concentration of nitrate was

ICONART 2019 - International Conference on Natural Resources and Technology

296

Figure 4: pH Leachate.

Figure 5: Concentration of Ammonia.

decreased. Nitrates can cause water to become

cloudy, reduce dissolved oxygen, and cause foul

odors. This was proven by organoleptic testing,

wherein this study the leachate produced tended to be

colored and foul-smelling. Graph concentration of

nitrate and nitrite can be seen in Figure 6.

3.5 Analysis of Recirculation Leachate

Recirculation of leachate is one of the factors to

accelerate the process of degradation of waste that

occurs in the reactor. Recirculation of leachate water

will trigger the stabilization process of reducing waste

in the reactor because it contains various substances

in leachate such as ammonia, nitrate, nitrite, methane,

carbon dioxide, sulfate, sulfite, water and

microorganisms (Damanhuri, 1993).

In this study, the recirculation of leachate was

carried out at both reactors with the frequency of

leachate administration in the first week of each day

and the following week only once a week. With the

provision of different recirculation in the first week

and the following week, the differences in the results

obtained in this study differ. Decreasing the height of

the waste in both bioreactors tended to occur faster in

the first week of the study, the height of the garbage

was reduced by around 1-21 cm in the first week. For

the pH value of the waste, the effect of recirculation

of leachate is not very visible because of the addition

of rainwater that is done every day so that in the two

reactors the organic waste pH tends to be neutral.

According to Priyambada in Anindita (2013), the

reactor which received leachate water recirculation

treatment experienced an increase in waste

temperature faster, because the content contained in

leachate can increase the rate of stability of waste

degradation. This is indicated by the temperature of

the waste at the two reactors is higher in the first week

compared to the following week. The pH value of

leachate in both reactors tended to be acidic, although

the recirculation of leachate water in the 2nd to the

fourth week was only done once a week.

Ammonia, nitrate, and nitrate concentrations on

the day-12 or at 2 weeks increased. This is due to the

provision of leachate recirculation carried out in the

first week every day. According to Vazquez (2008)

that leachate recirculation can increase ammonia

concentration because the process can make ammonia

in the dissolved reactor in leachate. Then the

concentration of ammonia, nitrate, and nitrite tends to

decrease in the following week.

Effect of Cover Soil to Concentration of Ammonia, Nitrate, and Nitrite in Leachate with Bioreactor Landfill Simulation

297

Figure 6: Concentration of Nitrate and Nitrite.

Table 1: Characteristics of Leachate.

Then the concentration of ammonia, nitrate, and

nitrite tends to decrease in the following week.

3.6 Organoleptic Testing to Leachate

Characteristics

Organoleptic test or also called physical test using

testing using sensory devices. In this study, the color

and smell of leachate in each bioreactor will be tested

using the sense of sight and sense of smell. On day-1

the bioreactor 1 produces brownish leachate with a

foul odor. Whereas in bioreactor 2 it produces

brownish yellow leachate and smells sour.

On the day-6 of the study, from bioreactor 1, leachate

was still brownish yellow and sour. Whereas in

bioreactor 2 the leachate is solid yellow and there is

much foam in the water, the smell of leachate at that

time stings foul. On the day-12 until day-30, on

bioreactor 1 the leachate was thick green with a

stinging smell.

While in bioreactor 2 the blackish leachate on the

day-12 of the study with the smell of very thin

leachate was also accompanied by the number of

maggot caterpillars that were accommodated in the

reservoir. For the day-18 until the day-30, the

leachate was thick green with a stinging smell.

According to Yatim and Mukhlis (2013), the odor in

leachate is produced from the process of overhauling

or decomposing organic matter, especially anaerobic

reformation of components will produce rancid and

foul-smelling compounds in the form of ammonia,

H

2

S and methane compounds.

In bioreactor 1, leachate produced better smell and

color of leachate than bioreactor 2. In bioreactor 1,

the odor produced did not smell rancid, but in

bioreactor 2, the odor produced was more stinging

and rancid. The color produced in each reactor is also

different. In the bioreactor 2 colors produced tend to

be darker.

4 CONCLUSIONS

Reduction of waste was faster in bioreactor 1, with

the percentage of final waste reduction was 79.03%.

The percentage of the reduction of waste in bioreactor

Bioreactor 1 Bioreactor 2 Bioreactor 1 Bioreactor 2 Bioreactor 1 Bioreactor 2 Bioreactor 1 Bioreactor 2

Color Brownish Brownish Yellow Brownish Yellow Yellow Green Blackish Green Green

Smell Foul Odor Smell Sour Smell Sour Stings Foul Stinging Smell Stinging Smell Stinging Smell Stinging Smell

Day-1

Day-6

Day-12

Day-30

Organoleptic Testing to

Leachate Characteristics

ICONART 2019 - International Conference on Natural Resources and Technology

298

2 was 78.13%. The pH of waste in both bioreactors at

the beginning was acidic. However, the next day until

the end of the study, the pH of the waste tended to be

neutral at both. The recirculation process of leachate

water in both reactors does not change the pH value

to acidic. This is because the process of adding water

is done every day.

The condition of microorganisms or mesophilic

bacteria that can grow optimally is in the range of 30-

38

0

C. The waste temperature in bioreactor 1 was in

the range of 30-36

0

C; this is suitable for the process

of decomposition of waste. Meanwhile, the

temperature of waste in bioreactor 2 was in the range

of 30-43

0

C. The pH value of leachate in both

bioreactors tended to be acidic for 30 days. In this

study, the pH value did not reach neutral. Ammonia,

nitrate, and nitrite in both bioreactors have been

formed since the beginning of the study, even though

they initially had relatively low values. Over time, the

concentration of the three experienced an increase in

the day-12 of the study, and then finally decreased on

the day-30.

REFERENCES

Adam, G. A., 2015. Influence of Physical-Chemical Waste

Properties on Waste Volume Reduction and Leachate

Characteristics of an Aerobic and Anaerobic

Bioreactor. Unpublished Master Thesis. Environmental

Engineering Study Program, Department of Civil

Engineering, Faculty of Engineering, Universitas

Indonesia (in Bahasa).

Anindita, Fathia. 2013. Effect of Recirculation Leachate to

Total Suspended Solid (TSS) and Total Dissolved

Solids (TDS) in Lysimeter. Unpublished Bachelor

Thesis. Environmental Engineering Study Program,

Department of Civil Engineering, Faculty of

Engineering, Universitas Indonesia (in Bahasa).

Ayuningtias, L., 2013. Analysis of Leachate Recirculation

Effect in Lysimeter on Ammonia, Nitrite, and Nitrate

Concentration in Leachate. Unpublished Bachelor

Thesis. Environmental Engineering Study Program,

Department of Civil Engineering, Faculty of

Engineering, Universitas Indonesia (in Bahasa).

Central Statistics Agency, 2015. Jambi City in Numbers.

Jambi: BPS Jambi City (in Bahasa).

Damanhuri, E., 2008. Leachate Management. Dictate of

Waste Landfilling-Version 2008, Bandung: FTSL ITB

(in Bahasa).

Dini, A., 2014. Leachate Recirculation Effect Analysis on

Bioreactor Landfill Towards Refuse Decomposition

and Concentration of Ammonia, Nitrate, Nitrite With

Continued Waste Filling Method. Unpublished

Bachelor Thesis. Environmental Engineering Study

Program, Department of Civil Engineering, Faculty of

Engineering, Universitas Indonesia (in Bahasa).

Elagroudy, S. A., Abdel-Razik, M. H., Warith, M. A. &

Ghobrial, F. H., 2008. Waste Settlement in Bioreactor

Landfill Models. Waste Management and Research,

0(0) 1-11.

El-Fadel, M., Fayyard, W., & Jihan, H., 2012. Enhanced

Solid Waste Stabilization In Aerobic Landfills Using

Low Aeration Rates and High Density Compaction.

Waste Management and Research, 0(0) 1-11.

McBean E. A., Rovers F. A., & Farquhar G. J., 1995. Solid

Waste Landfill Engineering and Design. Prentice-Hall,

Inc. A. Simon Schuster Company, Englewood Cliffs,

New Jersey 07632

Purcell, B. E., Butler, A. P., Sollars, C. J., & Buss, S. E.,

1999. Leachate Ammonia Flushing from Landfill

Simulators, J.CIWFM, 13

Rahmawati, H.N., 2017. Effect of Aeration on Leachate’s

Characteristic Results for Organic Vegetable Waste

with Biodrying Method (Case Study: Cabbage).

Environmental Engineering Journal, Vol. 6, No. 1

(2017) Universitas Diponegoro (in Bahasa).

Sethi, S. & Kothiyal, N.C. 2013. Stabilization of Municipal

Solid Waste in Bioreactor Landfills – An Overview.

International Journal Environment and Pollution, Vol.

51.

Tchobanoglous, G., Theisen & Vigil, S. A., 1993.

Integrated Solid Waste Management: Engineering

Principles and Management Issues. McGraw- Hill, Inc.

Singapore.

Vazquez, R.V., 2008. Enhanced Stabilisation of Municipal

Solid Waste in Bioreactor Landfills. Netherlands: CRC

Press/Balkema.

Yatim, E. M. dan Mukhlis. 2013. “Effect of Leachate to

Well Water Around Air Dingin Landfill.” Journal

Public Health 7:2(2013):54-59 (in Bahasa).

Yesiller, N., Hanson, J. L., Yoshida, H. 2011. Landfill

Temperature Under Variable Decomposition

Conditions. Conference Paper in Geotechnical Special

Publication, Geo-Frontiers 2011:1055-1065

Effect of Cover Soil to Concentration of Ammonia, Nitrate, and Nitrite in Leachate with Bioreactor Landfill Simulation

299