Comparation Study of Color Reading Method

in Gambier Extract Dyed Batik Fabric

Vivin Atika

1

, Agus Haerudin

1

and Zohanto Widyantoko

1

1

Centre for Handicraft and Batik, Ministry of Industry, 7

th

Kusumanegara Street, Yogyakarta

Keywords: spectrophotometer, mathematics counts, digital image, colour difference.

Abstract: Colour reading has an important role in the study of natural colours on batik, because it is one of few methods

in determining the quality of a dye performance in batik fabric. The commonly used method is using visible

ultra violet spectrophotometer that requires substantial cost and complicated operation system. This study

aims to determine the performance method comparison between visible ultra violet spectrophotometer and

mathematical count from digital images as colour difference test method to evaluate the quality of batik's

natural colours from Gambier extract. We have done sample dyeing from previous research and doing colour

difference test by spectrophotometer. Then we take the sample picture by scanner and measure the L*a*b*

values. We count the colour difference from L*a*b* values using mathematics equation. The L*a*b* and ΔΕ

values from both method are compared by statistical t test and ANOVA test. From the results it was found

that the colour difference value of both methods differ significantly, but each method gave good performance

to measure the colour difference. However, it should be noted that the RGB space model depends on the input,

so the more accurate the digital image with the original sample, the value will be closer to the colour difference

values of laboratory measurements.

1 INTRODUCTION

Natural dyes batik is favourite because of its

unique, exotic and tender, yet classic nuance

colouring. Dewi (2006) in Setiawan, et al (2018) said

that dyeing is also take part in determining the quality

of the batik. Colour reading has a colouring quality

on natural dyes of batik fabric. In batik the colour

reading is there are a few methods such as colour

intensity and colour different test. Colour intensity

and colour different tests were conducted using an

ultraviolet visible spectrophotometer. Colour is

calculated using reflectance data (%R) that is

converted into (K/S) score. The (K/S) score is

approximately amount of colour absorbed in the batik

fabric. In colour measurement methods using the

colour reading method of L*a*b* colour space with

the results hue and chrome.

Digital images are taken by electronic media such

as digital cameras, scanners, smartphones, etc. The

used colour space models are RGB and L*a*b*. RGB

colour model space is using transmitted light to

perform colour. Vary compositions and intensity of

three prime colours, green and blue are used to make

colours cyan, magenta, yellow, and white. This model

is applied by television and computer screens, where

coloured pixels are produced by red, green and blue

electron shots on screen. It really depends on the

apparatus performer.

Colour space models International standards

developed by Commission International d'Eclairage

(CIE) on 1976. L*a*b* is composed by luminance

component or lightness (L score = 0-100) with two

chrome components (-120 to +120): component a,

from green to red and component b, from blue to

yellow. L*a*b* colour space is independent from the

apparatus, but the result is the input or apparatus that

produces images (Yam and Papadakis, 2004).

Besides, in L*a*b* colour space the colour

perception is uniform, so the Euclidean distance

between two colours approximately equal to the

colour difference accepted by human eyes. This

model has a wider coordinates compared to RGB or

CMYK.

The use of digital images as an analytical tool has

been widely used, such as in the fields of health (Tam

and Lee, 2012) and food (Tahir, et al., 2007; Larrain,

et al, 2008, Magdić, et al., 2009; Trinderup and Kim,

2015). Digital image of objects are taken using digital

cameras with certain specifications. RGB data is

18

Atika, V., Haerudin, A. and Widyantoko, Z.

Comparation Study of Color Reading Method in Gambier Extract Dyed Batik Fabric.

DOI: 10.5220/0008525500180023

In Proceedings of the 1st International Conference on Intermedia Arts and Creative Technology (CREATIVEARTS 2019), pages 18-23

ISBN: 978-989-758-430-5

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

taken from digital images in JPEG format and

converted into L*a*b* values using sequential

transformation from RGB to CIE L*a*b* (Konica

Minolta, 1998).

Natural colours come from the extracts of plant

parts, animal waste, and minerals. Natural colour is

obtained by extraction using solvents, either by

heating or not (Pujilestari, et al., 2016). The

compound content in it is very complex, so the colour

distribution is not broad and tends to be uneven. In

addition, it is very difficult to reproduce the same

colour using single natural dyes. So to produce a

good colour, repeated inspections are needed.

Commercial colour measurement involves certain

instruments that require high costs and are not easy to

operate. Natural colouring still experiences problems

in colour uniformity, so that practical methods are

needed in colour reading that can be carried out

repeatedly. Batik optical signals from natural

colouring can be used as digital images using various

devices such as colour sensors, cameras and ordinary

scanners.

The purpose of this study is to determine the

performance method comparison between visible

ultra violet spectrophotometer and mathematical

calculation from digital images as colour difference

test method to evaluate the quality of batik's natural

colours from Gambier extract.

2 RESEARCH METODOLOGY

2.1 Experimental Design and Sampling

Samples used in this study were 12 pieces. They

were cotton and silk dyed with Gambier extract.

Gambier extract obtained by heat extracting at

temperature of 100°C for 2 hours using water and

cold soaking with alcohol for 4 days. The extract was

then used to dye the fabric by 6 times dipping. The

dyed fabric were putting into post-mordant using

fixative agent alum, ferrous sulphate and limestone.

2.2 Colour Measurements

Existing samples were measured for colour

reading using spectrophotometry to determine the

value of the lightness (L*), redness (a*) and

yellowness (b*). This value will be the real L*a*b*

value. Digital image of the samples were taken using

canon LiDE 120 scanner with optic resolution

specification 2400 x 4800 dpi and 16 bit deep for each

colour. The estimated L*a*b* value were obtained

from digital image of samples using mathematical

calculation approach.

RGB colour measured from digital image, then

converted into CIE L*a*b* colour space using the

sequential transformation from sRGB to XYZD

65

to

XYZ

C

(Pascale, 2003 in Larrain et al., 2008) and from

XYZ

C

to CIE

C

L*a*b* (Konica Minolta, 1998 in

Larrain et al., 2008). The subscript letter referring to

illuminator used.

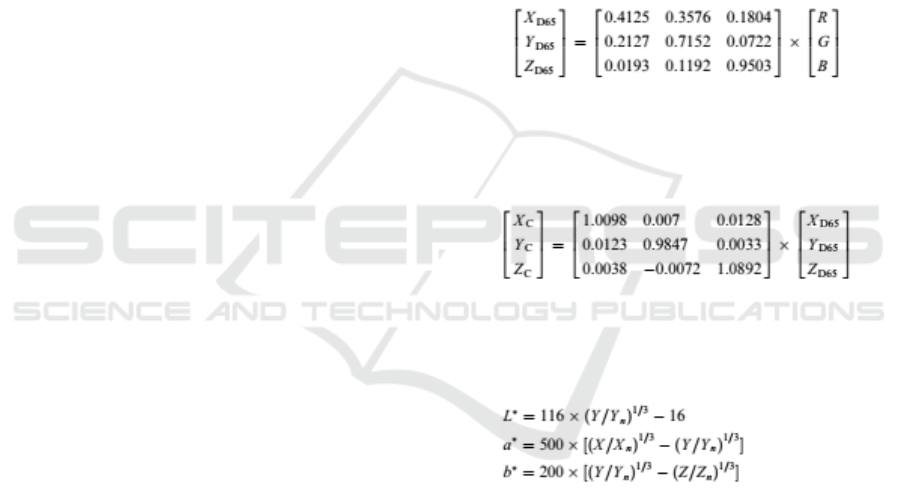

Referring to Larrain et al. (2008), sRGB value

were linearized by dividing with 255 and then

applying a decoding exponent of 2.2. This decoding

exponent corresponded to 1/γ using a simple

encoding γ of 0.45. Then, linear sRGB was converted

to XYZD65 using the matrix transform (Pascale,

2003):

(1)

Then XYZD65 was converted to XYZC using the

Bradford matrix transform (Pascale, 2003)

:

(2)

Finally, the following equations were used to

convert XYZC to CIEC L*a*b* (Konica Minolta,

1998):

(3)

Where Xn, Yn, and Zn are the values for X, Y,

and Z for the illuminator used, in this case 0.973,

1.000, and 1.161 respectively. Also, (X/Xn)1/3 was

replaced by [7.787 x (X/Xn) + 16/116] if X/Xn was

below 0.008856; (Y/Yn)1/3 was replaced by [7.787 x

(Y/Yn) + 16/116] if Y/Yn was below 0.008856; and

(Z/Zn)1/3 was replaced by [7.787 x (Z/Zn) + 16/116]

if Z/Zn was below 0.008856 (Konica Minolta, 1998).

The real and estimated value of L*a*b* from the

sample are then calculated for colour difference (ΔE)

using the following formula:

∆

√

(4)

Comparation Study of Color Reading Method in Gambier Extract Dyed Batik Fabric

19

All values were collected in form of data group to be

used for further analysing.

2.3 Statistical Calculation

Statistical analysis was performed using the t-test

and ANOVA using α = 0.05, with the hypothesis that

there were no significant differences between groups

of real and estimated data of each value of L*, a*, b*

and ΔE also the measuring tool were giving the same

effect on calculated values.

Data was then plotted to find out the linear

regression equation and provided a correlation

coefficient (R). Thus we could find how much the

relationship/correlation between treatment, real and

estimated value of L*, a*, b*, and ΔE. The relation of

each data were used to described the comparison of

performance colour reading method by

spectrophotometry and digital image analysis using

mathematical calculation.

3 RESULTS AND DISCUSSIONS

3.1 L*a*b* Scores

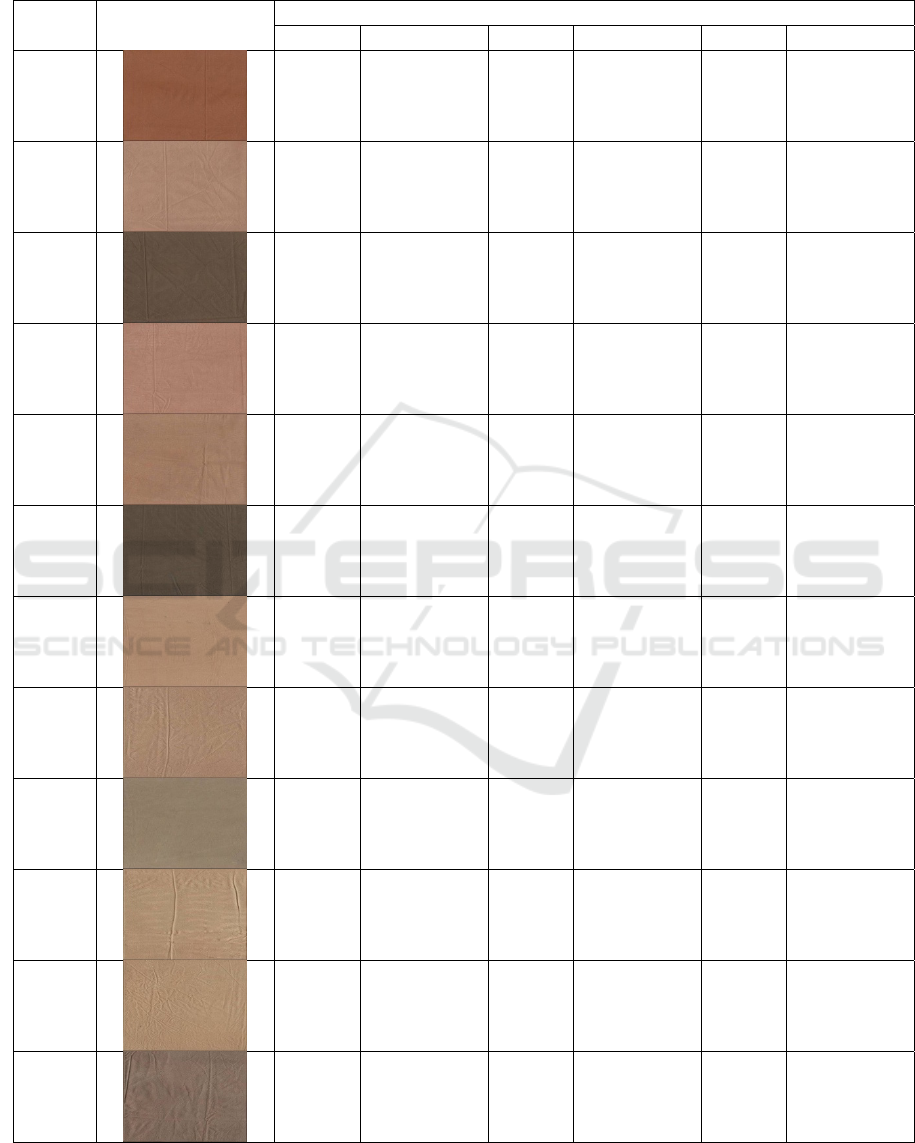

The measurements results are in the form of real and

estimated data groups from 12 fabric samples and

digital images. Data images and each data group

consists of L*, a*, b* values are presented in Table 1.

3.2 ΔΕ Score Analysing

The value of ΔΕ obtained from 12 samples were

amount to 66 pieces of data. The analysis was carried

out by the t-test and ANOVA statistical method. The

t-test hypothesis used is that there is no difference

between the real and estimated ΔE value, with the H

0

starting criterion when t count < t table. The result is

t count = 8.10 > from t table = 2.39, H

0

is rejected.

Statistical calculations ANOVA test with α = 0.05

and hypothesis that there are no significant different

effect between measuring tools and calculated data.

The result of ANOVA test is, P value = 1.9072 E-11

< α = 0.05, H

0

is rejected. The two statistical analysis

results means that the real data is different from the

estimation, so the results of direct measurements from

the fabric using spectrophotometers and

measurements using digital images are significantly

different. Moreover the both measuring tools were

giving different effect on data.

The data are then plotted to find out its linear

regression equation, by giving a correlation

coefficient (R) = 0.94, so that between treatment, real

and estimation value of ΔΕ, there are quite

relationship/correlation. This is in accordance with

Figure 1, which in the graph shows the same trend

between real and estimated ΔΕ.

Figure 1: Graphic of real versus estimated ΔE

3.3 Lightness Score Analysing

Lightness (L*) single scores are analysed with

statistical t-test and ANOVA calculations. From t-test

results, obtained t score = 0.32 > from t table = 2.72,

so that H

0

is accepted. From ANOVA test with α =

0.05, giving P value = 0.76 > α = 0.05. So, H

0

is

accepted. Both t-test and ANOVA doesn’t show any

significant differences between real and estimated L*

value.

The data are plotted to find out the linear regression,

by giving correlation coefficient (R) = 0.97, so that

between variables, real and estimated L* there are

relation/correlation. This is in accordance with Figure

2, which is in the graphic showing the same trend

between real and estimation.

Figure 2: Graphic of real versus estimated L*

-

10.00

20.00

30.00

40.00

50.00

1 5 9 1317212529333741454953576165

ΔE

samples

real estimated

-

10.0

20.0

30.0

40.0

50.0

60.0

70.0

ABCDE FGH I JKL

L*

Samples

real

CREATIVEARTS 2019 - 1st International Conference on Intermedia Arts and Creative

20

3.4 a* Score Analysing

The value of redness (a*) is analysed statistically by

the t test. From the results of the t test, the value of t

= 6.68 > from t table = 2.72, so that H

0

is rejected.

From ANOVA test with α = 0.05, giving P value =

0.000035 < α = 0.05. So, H

0

is rejected. Both test

result shows that there is a difference between real a*

and estimated a*. The two colour measuring tool also

gives difference effect to form data results.

The data plotted to find out the linear regression

equation, providing R = 0.97. Between treatment, real

and estimated a* value is having correlation or

showing the same trend, in accordance with Figure 3.

Figure 3: Graphic of real versus estimated a*.

3.5 b* Score Analysing

The value of yellowness (b*) is analysed using the t

test. From the results of the t test, the value of t count

= 6.19 > from t table = 2.72, so that H

0

is rejected.

ANOVA test with α = 0.05, giving P value =

0.000068 < α = 0.05. So, H

0

is rejected. This also

shows that there are any significant difference

between real and estimated b* value. Both measuring

tool also gives difference effect on resulting the data.

Linear regression from data provides R = 0.91.

Treatment, real and estimation value of b* are having

correlation. This is in accordance with Figure 4,

where the real and estimated data both shows the

same trend on the graphic.

Figure 4: Graphic of real versus estimated b*.

From the statistical calculation t-test and ANOVA for

ΔE, a* and b*, there are significantly difference

performance on two measuring tool in resulting

colour reading data but highly correlated.

The difference on data results can be caused by

difference source of subject that are measured.

Spectrophotometer measure directly from existing

dyed fabric and mathematical calculation estimate

colour reading value from digital image. There are

bias in measurement because of few factors. Digital

image are RGB based. The L*a*b*'s colour space

cover larger gamut compared to RGB. So that L*a*b*

readings from RGB digital images cannot show

precise colour coordinates location (Yam &

Papadakis, 2004). The use of image converter as

input/input for reading RGB values to the sample lab

also has an effect. Light source of the measuring tool

can also give effect on measuring data results.

Illuminator C in colorimeter puts more emphasis on

the red portion of the light spectrum than cool white

fluorescent light in digital image converter (Larrain,

et al., 2008).

In this study, L* statistical calculation shows no

difference performance. Yet in linear regression

plotting, all data give high R. Means that both

measuring tools are correlated. O’Sullivan, et al.

(2003) and Larrain, et al. (2008) said that in their

study instrumental colour measurements taken from

digital images were more highly correlated than

colorimeter values. This is due to possibility of full

surface evaluation of digital images will get more

representative sampling.

From the result, even though there are bias, digital

image can be used as simple and easy method to

predict or estimate L*a*b* and colour difference

value for natural batik dyed fabric inspection. The

choice of the right digital image converter also

influence the result of measurement. The more it can

convert closely to real image, the more precise the

value obtained.

-

5.0

10.0

15.0

20.0

25.0

ABCDE FGH I J KL

a*

samples

real estimated

-

10.0

20.0

30.0

40.0

ABCDE FGH I J KL

b*

samples

real

Comparation Study of Color Reading Method in Gambier Extract Dyed Batik Fabric

21

Table 1: Group of real and estimated L*a*b* scores of cotton and silk dyed with Gambier extract.

Samples Digital Image

Value of measurements

Real L* Estimated L* Real a* Estimated a* Real b* Estimated b*

A

43.46 43.43 23.16 18.58 32.30 23.24

B

62.34 57.69 15.21 10.92 29.32 17.88

C

38.32 35.43 5.89 5.02 11.04 11.66

D

55.51 57.14 21.09 13.44 33.96 17.15

E

56.39 54.49 16.02 10.58 31.24 18.49

F

31.85 33.67 4.34 3.14 10.81 9.72

G

58.15 60.10 13.11 9.56 29.76 18.98

H

59.10 58.18 12.29 8.13 29.20 17.93

I

50.95 53.99 7.16 3.87 21.90 14.12

J

66.23 62.09 10.56 6.58 32.13 19.47

K

60.03 61.01 11.55 6.79 31.04 20.77

L

44.29 46.46 7.42 6.18 15.14 10.40

CREATIVEARTS 2019 - 1st International Conference on Intermedia Arts and Creative

22

4 CONCLUSIONS

From the results it was found that the colour

difference value of both methods differ significantly,

but each method gave good performance to measure

the colour difference. However, it should be noted

that the RGB space model depends on the input, so

the more accurate the digital image with the original

sample, the value will be closer to the colour

difference values of laboratory measurements. The

colour measurement method using spectrophotometer

and mathematical calculations from digital images

can be used. However, these two methods cannot

replace each other because RGB is very dependent on

the input produced by the scanner.

ACKNOWLEDGEMENTS

This research was established by funding from Centre

for Handicraft and Batik, Ministry of Industry. We

also give high appreciation for all supported partners

in this research.

REFERENCES

Dewi, S.T., 2006. Analisis Pengaruh Orientasi Pasar dan

Inovasi Produk Terhadap Keunggulan Bersaing

Untuk Meningkatkan Kinerja Pemasaran (Studi

pada Industri Batik di Kota dan Kabupaten

Pekalongan). Universitas Diponegoro. Available at:

http://eprints.undip.ac.id/15810/.

Larrain, R.E., Schaefer, D.M. & Reed, J.D., 2008. Use of

Digital Images to Estimate CIE Color Coordinates of

Beef. Food Research International, 41, pp.380–385.

Magdić, D. et al., 2009. Impact analysis of different

chemical pre-treatments on colour of apple discs

during drying process. Croatian Journal of Food

Science and Technology, 1(1), pp.31–35. Available

at: https://hrcak.srce.hr/58696.

Minolta, K., 1998. Precise color communication: Color

control from perception to instrumentation. Konica

Minolta Sensing, Inc.

O’Sullivan, M. G., Byrne, D. V., Martens, H., Gidskehaug,

L.H. & Andersen, H. J., & Martens, M., 2003.

Evaluation of pork colour: Prediction of visual

sensory quality of meat from instrumental and

computer vision methods of colour analysis. Meat

Science, 65(2), pp.909–918.

Pascale, D., 2003. A review of RGB color spaces from xyY

to R’G’B’. The Babel Color Company.

Pujilestari, T. et al., 2016. Pemanfaatan Zat Warna Alam

Dari Limbah Perkebunan Kelapa Sawit dan Kakao

Sebagai Bahan Pewarna Kain Batik. Dinamika

Kerajinan dan Batik, 33(1), pp.1–8.

Setiawan, J. et al., 2018. Kesesuaian Batik Tulis IKM

Berdasarkan SNI 08-0513-1989. Jurnal

Standardisasi, 20(1), pp.69–76. Available at:

http://js.bsn.go.id/index.php/standardisasi/article/vie

w/618/pdf_1.

Tahir, A.R. et al., 2007. Evaluation of the effect of moisture

content on cereal grains by digital image analysis.

Food Research International, 40, pp.1140–1145.

Tam, W.K. & Lee, H.J., 2012. Dental Shade Matching

Using a Digital Camera. Journal of Dentistry, 40(2),

pp.e3–e10. Available at:

https://www.sciencedirect.com/science/article/pii/S

0300571212001492?via%3Dihub.

Trinderup, C.H. & Kim, Y.H.B., 2015. Fresh Meat Color

Evaluation Using a Structured Light Imaging

System. Food Research International, 71, pp.100–

107.

Yam, K.L. & Papadakis, S.E., 2004. A Simple Digital

Imaging Method For Measuring and Analyzing

Color of Food Surfaces. Journal of Food

Engineering, 61, pp.137–142.

Comparation Study of Color Reading Method in Gambier Extract Dyed Batik Fabric

23