A Review of Green Supply Chain Management

as a Need for Company’s Continuous Improvement

Nurhayati Sembiring, Muhammad Haikal Karana Sitepu

Industrial Engineering Department, Engineering Faculty, Universitas Sumatera Utara, Medan, 20155 Indonesia.

Keywords: Environment, green, supply chain management

Abstract: Nowadays, there is an increasing need to pay attention to environmentally sound choices in all fields. The

competitive market that has taken place in the millennial era requires companies to have strategic plans,

critical attitudes and attention to the role of the environment. The company's business strategy must be

revised, for example supply chain activities. Supply Chain activities focus to achieve a greener

environmental. The focus of improvement is on minimizing the environmental damage. Minimization of

environmental impacts is carried out from starting the process of industry until the finishing step. Activities

carried out include green design, saving resources, reducing hazardous materials and recycling or reusing

products. With helping of Green Supply Chain Management (GSCM) integrating action will activates all of

the manufacturing process in an industry more safe and healthy and safe for environment and human life.

Many factors that become the drivers of GSCM. Based on reports from companies in various countries of

the world, those who have implemented GSCM have proven that there is an increase in company profits.

1 INTRODUCTION

Environmental awareness is currently increasing,

and there is increasing recognition that

environmental pollution due to industrial

development needs to be addressed. This was

reinforced by Conference in Stockholm, and in Rio

de Janeiro.(H’Mida and Lakhal, 2007).Through

Kyoto Protocol held in 1997, supervision of

emissions caused by the activities of manufacturing

companies became increasingly tightened.

In this era of openness, many customers asking

everything that are more safe and healthy. The same

thing is demanded by local communities, and non-

governmental organizations (NGOs). They requested

that companies provide reports on company

activities. If these demands are not met, the

claimants will disseminate the bad things. and can

damage the company’s image (Tuni, Rentizelas, and

Duffy, 2018) Supply Chain helping management to

faced increased attention to adverse environmental

impacts due to company through the healthy

environment. Any world communities feel the

effects of global warming. This causes the people

who are consumers of marketed products,

demanding the government's attention to issue

regulations on environmental management that are

implemented on a world scale. (Kim, Youn, and

Roh, 2011). Environmental reports from world

companies experience positive growth. A forum

formed in the US, the Global Environmental

Management Initiative, based on published research

data, there are many companies who are members of

them have reported their competitive advantage after

considering environmental aspects in supply chain

management.

Consumers who have felt the effects of global

warming are demanding to issue environmental

management regulations that are applied on a world

scale. (Kim, Youn, and Roh, 2011). Initially, many

considered this to be difficult for the company, but

based on {Lakhal and Mida, 2007) it can be seen

that companies that have complied with regulations

regarding environmental management experience

positive growth. This competitive advantage is also

experienced by companies incorporated in a forum

formed in the US, the Global Environmental

Management Initiative. In China, the government

produces many environmental regulations and strict

tax policies. Through the determination of taxes and

water quota prices, the community must save on

water use. The same is done for other resources. The

aim is to make efficient exploitation and use of all

resources (Zhu, Sarkis, and Geng, 2005).

The general term used in connection with this

policy is known as “Rs (Reduce, Re-use, Rework,

96

Sembiring, N. and Sitepu, M.

A Review of Green Supply Chain Management as a Need for Company’s Continuous Improvement.

DOI: 10.5220/0008506700960099

In Proceedings of the International Conference on Natural Resources and Technology (ICONART 2019), pages 96-99

ISBN: 978-989-758-404-6

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Refurbish, Reclaim, Recycle, Remanufacturing,

Reverse logistics, etc.)”.(Srivastava, 2007). All of

this policy if used in human’s life will make the

environment cleaner and healthy (Büyüközkan and

Ifi, 2012).

2 METHODS

To explore information about green supply chain

that has been published from previous studies, some

literature was reviewed. As a literature review , the

reference journals is chosen to be analyzed (Winter

and Knemeyer, 2013) From Figure 1, could be seen

all of the step clearly.

Step 1 – choosing period of paper publication

Several studies in the Period between 2005 and

2018 have been chosen as the main references. The

selection of this period of time is considered to have

sufficiently represented thinking that is a developing

science.

Step 2 – choosing journal

Some journal are chosen such as: International

journals such as international journal of managing

value and supply chains, resources, conservation

and recycling, international journal of production

economics, international journal of sustainable

engineering, environmental technology, journal of

purchasing and supply management, journal of

cleaner production. These journals contain

management, social science, operations/production,

and social/environmental.

Step 3 – choosing article

The main criterion for selecting paper is

relationship of the content of the article to the

framework of the previously defined text.

Step 4 – analysis

The next step is to study and examine selected

articles to find out how research has developed over

time. This analysis also provides the manufacturing

industry that research was conducted. Figure 1

shows the methodology of research.

3 RESULTS AND DISCUSSION

3.1 Green Supply Chain Management

(GSCM)

Supply Chain is a flow of the entire physical process

needed starts from the fulfillment of raw materials

from suppliers that contain all steps of the process to

produce finished products, directly or indirectly, so

that this product finally arrives at the end user. In

order to achieve competitive advantage, increase

company profits and expand market share, it is

necessary to integrate environmental management

practices into overall supply chain management so

that a greener supply chain is achieved. Based on the

literature that used as references there are various

definitions about Green Supply Chain Management

(GSCM). The following table shown principle of

GSCM (Epoh and Mafini, 2018).

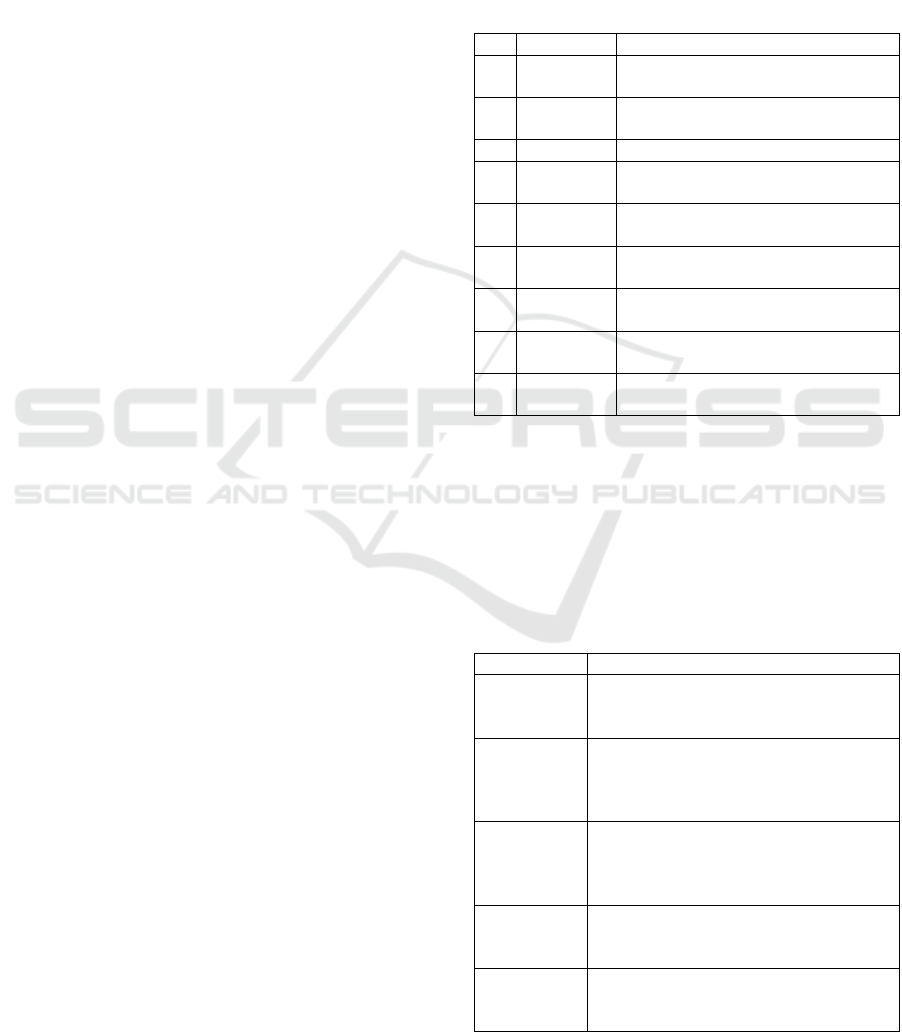

Table 1: Some definitions of GSCM

Year

Author

Definition

2001

Gilbert

Concerns into Greening the supply

chain

2001

Zsidisin and

Siferd

Response to the natural safety

environment

2007

Srivastava

Integrating environment for useful life

2007

Davies and

Hochman

holistic effort to acheive

environmental performance

2008

Rettab and

Ben Brik

minimise impacts or footprint.

2008

Zhu et al

Life-cycle or the entire of product in

management supply chains

2008

Walker et al

Analysed raw materials, process until

end costumer.

2011

Large and

Gimenez

GSCM to improve the performance

2012

De Giovanni

and Esposito

a green company objective is

environmentally friendly.

There is a close and integrated relationship

among suppliers, ,manufacturers, wholesalers,

retailers, and end-users of the product/ consumers)

(Tay, Rahman, Aziz, and Sidek, 2015). In Table 2.

can be seen the activities carried out by each part

contained in the GSCM chain.

Table 2: The activities carried out by each part contained

in the GSCM

Part of GSCM

Activities

Suppliers

All of product from wholesalers

manufacturers, retailers and consumers are

Supplied reverse supply

Manufacturers

Suppliers, wholesalers, retailers and

consumers need distribution to and

reverse distribution the design for

disassembling of products and services,

Wholesalers

Retailers, consumers, manufacturers and

suppliers need distribution to

retailers/consumers and reverse

distribution

Retailers

Distribution to consumers and reverse

distribution from consumers, wholesalers,

manufacturers and suppliers

Consumers

Acquisition and consumption of

products/services; disposal of

products/services and packages

A Review of Green Supply Chain Management as a Need for Company’s Continuous Improvement

97

GSCM focuses on delivering green knowledge

applications and realizing the standardization of

production and delivery processes. The GSCM

activities will be successfully implemented among

supply chain partners if there is a close relationship

of trust, good and intense communication and

collaboration , complete information about products

and safe risks among partners..(Srivastava, 2007).

Problems will not occur much if the company works

well together efficiently and there is commitment

among business partners to produce the best output

(De Giovanni and Esposito Vinzi, 2012)

3.2 Drivers to GSCM

Many companies plan to implement the green supply

chain concept because of the issuance of

environmental laws. At first they felt hard to do it

because a lot of changes had to be made. Based on

(Diabat and Govindan, 2011) the following are some

of the important drivers in implementing GSCM

practices such as: Environmental partnership with

ISO 14001 certification , suppliers, , etc.

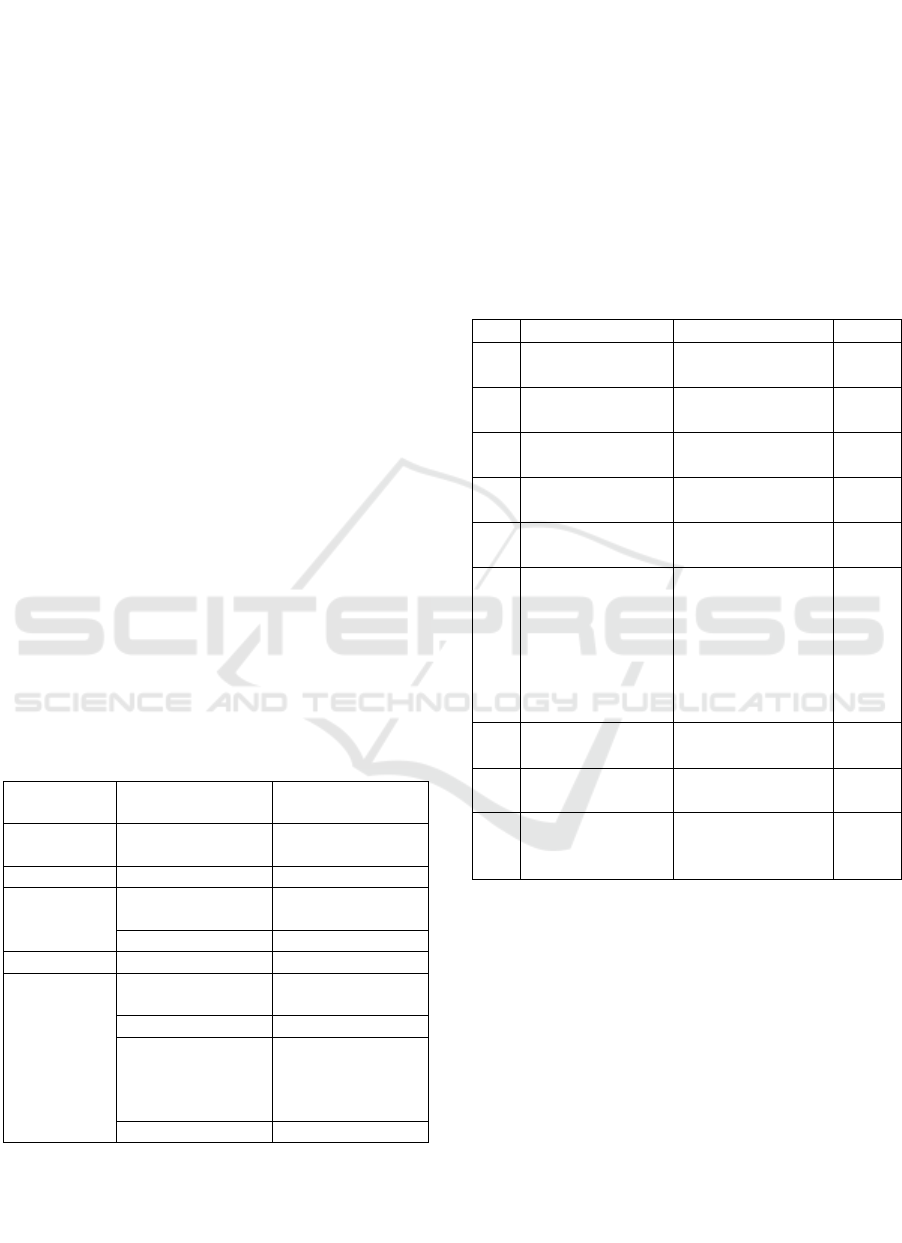

3.3 Methodological Approaches

There are some techniques analysis and model types

in GSCM performance measurement. According to

(Tuni et al., 2018) Modelling approaches in

quantitative GSCM research could be seen in Table

4.

Table 4: Modelling approaches in quantitative GSCM

research

Type of the

method

Technique

Solution

Mathematical

programming

Single objective

Multi objective

Goal , linear and non

linear programming

Simulation

System dynamics

-

Heuristic

Artificial intelligence

Bayesian network

Fuzzy logic

Metaheuristics

Memetic algorithm

Hybrid models

-

-

Analytical

models

MCDM

AHP/ANP

DEA

Game theory

Stackelberg model

Systemic

I.O analysis

Metrics

LCA

Energy methods

Statistical

Probabilistic model

3.4 Some Studies in Manufacturing

Area

Industry is widely known to be a major cause of

environmental problems such as produce of

machinery; gadget; aeroplane; printing; materials of

building and others. Traditional pollutant industries

such as producers in the chemical, electricity and

paper industries generally experience higher

environmental pressures. Some studies can be seen

in Table 5.

Tabel 5: Some studies of GSCM in manufacturing area

Time

Paper by

Industrial Sectors

Place

2005

Zhu, Q., Sarkis, J.,

and Geng, Y

Manufacturing and

processing industries

China

2007

H’Mida, S., and

Lakhal, S. Y

Oil refinery

companies

Canada

2010

Shang, K. C., Lu, C.

S., and Li, S

Electronic

companies

Taiwan

2011

Diabat, A., and

Govindan, K

Aluminium sector

India

2011

Yeh, W. C., and

Chuang, M. C

Electronic products

Taiwan

2011

Kim, J. H., Youn, S.,

and Roh, J. J

Global Korean

companies such as

Samsung

Electronics, POSCO,

LG Electronics,

Hyundai

Automotive, and SK

Korea

2012

Büyüközkan, G., and

Ifi, G

Ford corporation

US

2012

De Giovanni, P., and

Esposito Vinzi, V

1400 organizations

among Italy’s firms

Italy

2018

Zainuddin, A., and

Kuzaiman, N. A

Malaysian

Automotive

Company

Malaysia

4 CONCLUSION

Green supply chain management is needed in terms

of competitive industrial commercialization. There

are many incentives to create green supply chains,

including pressure from global warming and

environmental problems. The implementation of

effective and green supply chains will apply

throughout the world. GSCM helping company to

make better achievement in all aspect.

ICONART 2019 - International Conference on Natural Resources and Technology

98

ACKNOWLEDGEMENTS

The author like to give big appreciate to students

who have helped the author to edit the template for

this paper.

REFERENCES

Abu Seman, N. A. 2012. Green supply chain management:

a review and research direction. International Journal

of Managing Value and Supply Chains, 3(1), 1–18.

Andiç, E., Yurt, Ö., Baltacioǧlu, T. 2012. Green supply

chains: Efforts and potential applications for the

Turkish market. Resources, Conservation and

Recycling, 58, 50–68.

Basiri, Z., Heydari, J. 2017. A mathematical model for

green supply chain coordination with substitutable

products. Journal of Cleaner Production, 145, 232–

249.

Büyüközkan, G., Ifi, G. 2012. A novel hybrid MCDM

approach based on fuzzy DEMATEL, fuzzy ANP and

fuzzy TOPSIS to evaluate green suppliers. Expert

Systems with Applications, 39(3), 3000–3011.

https://doi.org/10.1016/j.eswa.2011.08.162

De Giovanni, P., Esposito Vinzi, V. 2012. Covariance

versus component-based estimations of performance

in green supply chain management. International

Journal of Production Economics, 135(2), 907–916.

https://doi.org/10.1016/j.ijpe.2011.11.001

Diabat, A., Govindan, K. 2011. An analysis of the drivers

affecting the implementation of green supply chain

management. Resources, Conservation and Recycling,

55(6), 659–667.

https://doi.org/10.1016/j.resconrec.2010.12.002

Epoh, L. R., Mafini, C. 2018. Green supply chain

management in small and medium enterprises: Further

empirical thoughts from South Africa. Journal of

Transport and Supply Chain Management, 12, 1–12.

https://doi.org/10.4102/jtscm.v12i0.393

H’Mida, S., Lakhal, S. Y. 2007. A model for assessing the

greenness effort in a product supply chain.

International Journal of Global Environmental Issues,

7(1), 4. https://doi.org/10.1504/IJGENVI.2007.012074

Kim, J. H., Youn, S., Roh, J. J. 2011. Green supply chain

management orientation and firm performance:

evidence from South Korea. International Journal of

Services and Operations Management, 8(3), 283.

https://doi.org/10.1504/IJSOM.2011.038973

Srivastava, S. K. 2007. Green supply chain management:

A state-of-the-art literature review. International

Journal of Management Reviews, 9(1), 53–80.

https://doi.org/10.1111/j.1468-2370.2007.00202.x

Tay, M. Y., Rahman, A. A., Aziz, Y. A., Sidek, S. 2015. A

Review on Drivers and Barriers towards Sustainable

Supply Chain Practices. International Journal of

Social Science and Humanity, 5(10), 892–897.

https://doi.org/10.7763/IJSSH.2015.V5.575

Tuni, A., Rentizelas, A., Duffy, A. 2018. Environmental

performance measurement for green supply chains: A

systematic analysis and review of quantitative

methods. International Journal of Physical

Distribution and Logistics Management, 48(8), 765–

793. https://doi.org/10.1108/IJPDLM-02-2017-0062

Winter, M., Knemeyer, A. M. 2013. Exploring the

integration of sustainability and supply chain

management: Current state and opportunities for

future inquiry. International Journal of Physical

Distribution and Logistics Management, 43(1), 18–38.

https://doi.org/10.1108/09600031311293237

A Review of Green Supply Chain Management as a Need for Company’s Continuous Improvement

99