Development of Implementation Guidelines for Maintenance and

Treatment Work of Mechanical Components in Universitas Indonesia

Building and Area based on Work Breakdown Structure (WBS)

Kallista Alsadila and Yusuf Latief

Civil Engineering Department, Universitas Indonesia, Depok, Indonesia

Keywords: Guidelines, Maintenance, Mechanical, Building, Work Breakdown Structure.

Abstract: In maintaining the quality and reliability of buildings in accordance with standards that apply during their

useful life, regular maintenance and treatment work are required. With these activities, various aspects can be

fulfilled during building utilization, such as safety, health, comfort, convenience, and efficiency. At the

University of Indonesia, several phenomena have resulted in building damage and other losses such as costs

and time. The poor maintenance activities due to the absence of complete guidelines, causing damage to the

mechanical components. In fact, the mechanical component is the most influential component in determining

building performance. The purpose of this study is to develop a standard implementation guideline based on

a proven decomposition technique, the Work Breakdown Structure (WBS). The independent variables used

are WBS level, from work types until technical specifications. The research method used is the study of

literature, Delphi’s techniques, and validation with various experts. The results of this study are the

establishment of standard guidelines for the implementation of maintenance and treatment work of

mechanical components for Universitas Indonesia that cover several type buildings and environment, that can

be used as references and applied in other buildings.

1 INTRODUCTION

According to The Committee on Building

Maintenance, in maintaining a building facility to

remain in a condition that is in accordance with

applicable standards, an activity called maintenance

is required (Usman & Winandi, 2009, p. 2). In

addition, maintenance activities are carried out to

maintain the usefulness and value of the building,

which includes updating and repairing activities

(Usman & Winandi, 2009, p. 2). In 1987, Redlin

explained the purpose of this maintenance and

treatment activity was to minimize repair costs,

increase user satisfaction, increase activity efficiency,

minimize energy use costs, and minimize potential

safety problems (Aditya, 2018). Wimala (2000)

states, with good building maintenance activities, it

will give each individual a feeling of being

comfortable, safe, calm and clean so as to increase

work productivity (Handayaniputri, 2009, p. 1).

In 2014, there was a fire phenomenon that caused

damage to buildings that occurred in Universitas

Indonesia (UI). As a result, one of the faculty building

was burned down entirely, along with important

documents stored in it. In addition, total costs

incurred, reaching approximately 40 billion Rupiah

(Prayitno, 2018). After tracing, the cause of the fire

was damage to the mechanical component, which was

shorted to the air conditioner (Anshari, 2014).

Another phenomenon occurred in 2017, namely an air

conditioner short circuit that caused a fire in the

Faculty of Pharmacy Building, and caused losses of

up to 25 million Rupiah (Prayitno, 2018).

One effort that can be done to overcome the

phenomenon that occurs, is to carry out the good

maintenance and treatment work of mechanical

components. According to Wimala (2000), a

guideline is needed in achieving effective and

efficient management in carrying out maintenance

and treatment activities (Handayaniputri, 2009). With

the existence of clear guidelines, it is expected to

reduce the risk of expenditure due to damage to

buildings (Handayaniputri, 2009). According to (the

United States Environmental Protection Agency,

2017, p. 1), the operational standard procedure or

standard of implementation is a set of written

instructions about the routine activities followed by

an organization. The use of standard operating

Alsadila, K. and Latief, Y.

Development of Implementation Guidelines for Maintenance and Treatment Work of Mechanical Components in Universitas Indonesia Building and Area based on Work Breakdown Structure

(WBS).

DOI: 10.5220/0008435406930701

In Proceedings of the 2nd International Conference on Inclusive Business in the Changing World (ICIB 2019), pages 693-701

ISBN: 978-989-758-408-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

693

procedures can reduce the possibility of differences

and improve quality through consistent procedures.

With the use of guidelines for maintenance and

treatment work, the utilization of buildings that meet

the requirements of safety, health, comfort and ease

and efficiency can be realized, in harmony with the

environment (Permen PU No. 24, 2008).

The Work Breakdown Structure (WBS) is a

process of detailing project work deliverables into

smaller and more manageable components (Project

Management Institute, 2013). Garcia-Forniels et al.

(2003) emphasize that, WBS may be the most

important tool for project management because it

provides the basis for planning, scheduling, control,

assigning responsibility and information management

(Ibrahim et al. 2009, p. 389). In making guidelines or

implementation standards, each element has different

characteristics, so it requires special handling.

Making standard implementation based on WBS, can

avoid missing an element in a component to be

maintained.

According to The Government Accountability

Office / GAO (1990) states that, the WBS helps in the

process of estimation there are no forgotten items and

also helps to make comparisons with several similar

projects (Fitriadi, 2017). This is a preventive action

taken, in order to reduce the possibility of a bad

phenomenon, due to the presence of elements that are

not maintained.

This study will discuss how to develop

implementation guidelines for maintenance and

treatment based on WBS, in this study focusing on

mechanical components in Universitas Indonesia

building and area scope. There are several previous

studies that also discussed the maintenance and

treatment work of mechanical components namely,

(Aditya, 2018) for a government building, and

(Aryaningrum, 2018) which is also for government

buildings, but more specifically for green buildings.

The difference in this study is the scope which is not

only intended for buildings, but also the area. The

area used as the object of research, Universitas

Indonesia, has a variety of building types. That way

this study covers a wider and more complete range of

maintenance and treatment related to mechanical

components.

This guideline can be used as a reference and later

can be modified and applied to similar buildings or

areas. Not only the results, the steps taken in the

process based on WBS, the proven decomposition

technique, will show more structured steps, thus

minimizing the missed work packages. The technique

used in making the results guidelines are expected to

be applied in making all types of guidelines without

exception.

2 RESEARCH OBJECTIVES

The objectives of this research are :

1. To identify the work type and work package of the

WBS for the maintenance and treatment work of

mechanical components in the buildings and areas

of the University of Indonesia.

2. To identify design alternatives and activities in

each work package of maintenance and treatment

work on mechanical components in the buildings

and areas of the University of Indonesia.

3. To identify resources and implementation

requirements for each activity in the maintenance

and treatment work of mechanical components in

the buildings and areas of the University of

Indonesia.

4. To identify technical specifications used in each

activity of maintenance and treatment work of

mechanical components in the buildings and areas

of the University of Indonesia.

5. To identify ways to develop implementation

guidelines based on the WBS (Work Breakdown

Structure) for the maintenance and treatment work

of mechanical components in the buildings and

areas of the University of Indonesia.

3 LITERATURE REVIEW

3.1 Universitas Building and Area

Universitas Indonesia is one of the largest educational

institutions in Indonesia. According to the QS World

University Rankings, the University of Indonesia

ranked first as the best university in Indonesia

(Quacquarelli Symonds Limited, 2018). The

Universitas Indonesia campus, located in Depok, has

a land area of 320 hectares and there are 85 buildings

that have been built on the land, (Prayitno, 2018).

The Universitas Indonesia area, is a unique area

because it consists of various multi-disciplines.

Therefore, there are various types of buildings in the

University of Indonesia areas such as lecture

buildings, administrative buildings, hospitals, library

and others.

3.2 Maintenance and Treatment Work

Maintenance of the building is an activity to maintain

the reliability of building buildings and infrastructure

ICIB 2019 - The 2nd International Conference on Inclusive Business in the Changing World

694

and facilities so that building is always functional

(preventive maintenance) (Permen PU no. 24 2008).

Building maintenance is also an effort to avoid

damage to components / building elements due to

obsolescence before their age ends.

Whereas, treatment is an activity to replace parts

of buildings, components, building materials,

infrastructure and facilities so that buildings are

curative maintenance (Ministry of Public Works,

Directorate General of Cipta Karya, 2008). There are

three types of building treatment work, namely,

rehabilitation, renovation and restoration.

Other sources state that building maintenance is

defined as "work" to maintain, restore or repair every

part of the building, to maintain the performance of

building and service fabric and its surroundings, meet

standards and maintain the utility and value of

buildings. This includes improvements and repairs to

works from existing facilities (Pļaviņa & Geipele,

2013).

In Undang-undang (UU) No. 28 of 2002

concerning building, it was explained that the

building utilization was carried out by the owner or

user of the building after the building was declared to

have fulfilled the requirements of function

worthiness. In terms of maintaining function-worthy

requirements, periodic maintenance, maintenance

and inspection work must be carried out on buildings

(UU No. 28, 2002).

Based on the guidelines for the operation and

maintenance of the building, maintenance work

includes several activities as follows; cleaning,

tidiness, inspection, testing, repair, replacement of

building materials or equipment (Ministry of Public

Works, Directorate General of Cipta Karya, 2008).

Maintenance and treatment work of building is

done to maintain the requirements achieved by a

building, namely; safety of the building, building

health, the comfort of the building, and ease of

building (Ministry of Public Works Directorate

General of Cipta Karya, 2008).

3.2.1 Scope of Maintenance and Treatment

Work of Mechanical Components

Based on the Minister of Public Works Regulation

No. 24 of 2008, regarding the Guidelines for

Maintenance of Buildings, it is explained about the

scope of building maintenance for mechanical

components as follows:

a. Maintain and carry out periodic inspection of the

air system, so that the air quality in the room still

meets the technical and health requirements

required including maintenance of the main

equipment and air ducts.

b. Maintain and carry out periodic inspections of

water distribution systems which include the

provision of clean water, sewage installation

systems, hydrant systems, sprinklers and septic

tanks and waste treatment units.

c. Maintain and carry out periodic inspection of the

transportation system in the building, both in the

form of lifts, escalators, travelators, stairs and

other vertical transportation equipment.

3.3 Mechanical Components

Facilities and infrastructure found at the building in

the form of important components, are interrelated

with each other in order to achieve the function of the

building to provide comfort and security for its users

(Suyono, Prasetyo, & Assafat, 2011). One important

component in the building is a mechanical

component. Where this component becomes very

vital because all facilities contained in the building

are supported by these components. The mechanical

component accounts for 46.2% as the most influential

component in determining building performance

(Juarti, Marlailana, & Noorlaelasari, 2015, p. 57). In

handling, if not done carefully, mechanical

components can be harmful to humans and their

environment. So, the applicable provisions and

standards are needed, so that they are safe and there

is no damage that can endanger the users (Suyono,

Prasetyo, & Assafat, 2011).

3.4 Work Breakdown Structure (WBS)

According to Norman, Brotherton & Fried (2008), the

WBS is a tool for monitoring and control that defines

the scope of a project (Ajizah, 2018). Work

Breakdown Structure (WBS) is a hierarchical

decomposition of the scope of work that must be

completed by the project team to achieve the

objectives and deliver the expected results (Project

Management Institute, 2013). Decomposition is a

technique used to divide the project scope and project

results into divisions and sub-divisions, making it

easier to manage (Project Management Institute,

2013). The decomposition process is carried out from

the highest level, namely the project itself, to the

lowest level, namely the work package. With this

decomposition technique, it is expected to cover all

existing mechanical elements, thereby reducing the

risk of building damage.

Development of Implementation Guidelines for Maintenance and Treatment Work of Mechanical Components in Universitas Indonesia

Building and Area based on Work Breakdown Structure (WBS)

695

3.5 Implementation Guidelines

Implementation standards or guidelines for

maintenance and treatment work are intended to be a

reference in carrying out the work activities, in this

case the maintenance and treatment of mechanical

components of buildings in the University of

Indonesia. This guideline aims to realize the use of

buildings that meet the requirements of safety, health,

comfort and convenience and efficiency, harmonious

and in harmony with the environment (Permen PU

No. 24, 2008). According to Amare (2012), the

existence of guidelines can reduce errors in the

implementation process. Based on (Permen PU No.

24, 2008), the scope of this guideline includes

management of maintenance and treatment,

procedures, systems and programs, equipment,

equipment and performance standards for building

maintenance and treatment, as well as guidance.

4 RESEARCH METHODOLOGY

4.1 Research Process

In looking for results to answer each research

question, qualitative methods were used in this study.

Beginning with literature review and archive analysis,

expert validation, analyzing data to results for each

research question. After all the data is obtained then

the implementation guideline for maintenance and

treatment work of mechanical components is made

and followed by final validation. Figure 1 is a flow

diagram that shows the stages of how this research

will be carried out.

4.2 Data Collection Method

There are two types of data collected in this study,

namely, primary data and secondary data. According

to (Kusmayadi & Sugiarto, 2000, p. 80), primary data

is data collected directly from the object of research

by researchers. While secondary data is data that is

the result of gathering people or agencies in the form

of research, reports, and publications.

In this study, the primary data is obtained from

interviews with experts who are experts in their fields,

assisted by questionnaires as research instruments.

For this study, experts asked for validation amounted

to three to five people for each research question, with

five questionnaires used, in total. While secondary

data is obtained through literature studies of Undang-

undang, government regulations, previous research,

UI archives, standards such as ISO, SNI and other

supporting documents.

For each research question begins with secondary

data collection. Then proceed with making a

questionnaire based on the collected secondary data.

After that the Expert is asked to validate, give

opinions and provide improvements that must be

done, through interviews and filling out

questionnaires. The results of the questionnaire were

then used as primary data in this study. Finally, the

primary and secondary data obtained is processed and

validated back to the experts using Delphi’s method,

to produce the implementation guidelines.

5 RESULTS

Based on (Rajasa, 2017), (Supriadi et.al, 2018) and

(Aryaningrum, 2018), the WBS used in this study

consisted of 6 levels. Level 1 is for the project name,

level 2 is for work sections, level 3 is for the type of

work, level 4 is for work packages, level 5 is for

activities, and level 6 is for resources. All levels of the

WBS will be developed to serve as the

implementation guidelines for maintenance and

treatment work of mechanical components.

5.1 Work Type and Work Package

Based on validation at the data collection stage, type

of work is divided into five items; gases, plumbing,

fire protection systems, air conditioning systems, and

vertical transportation systems. The results obtained

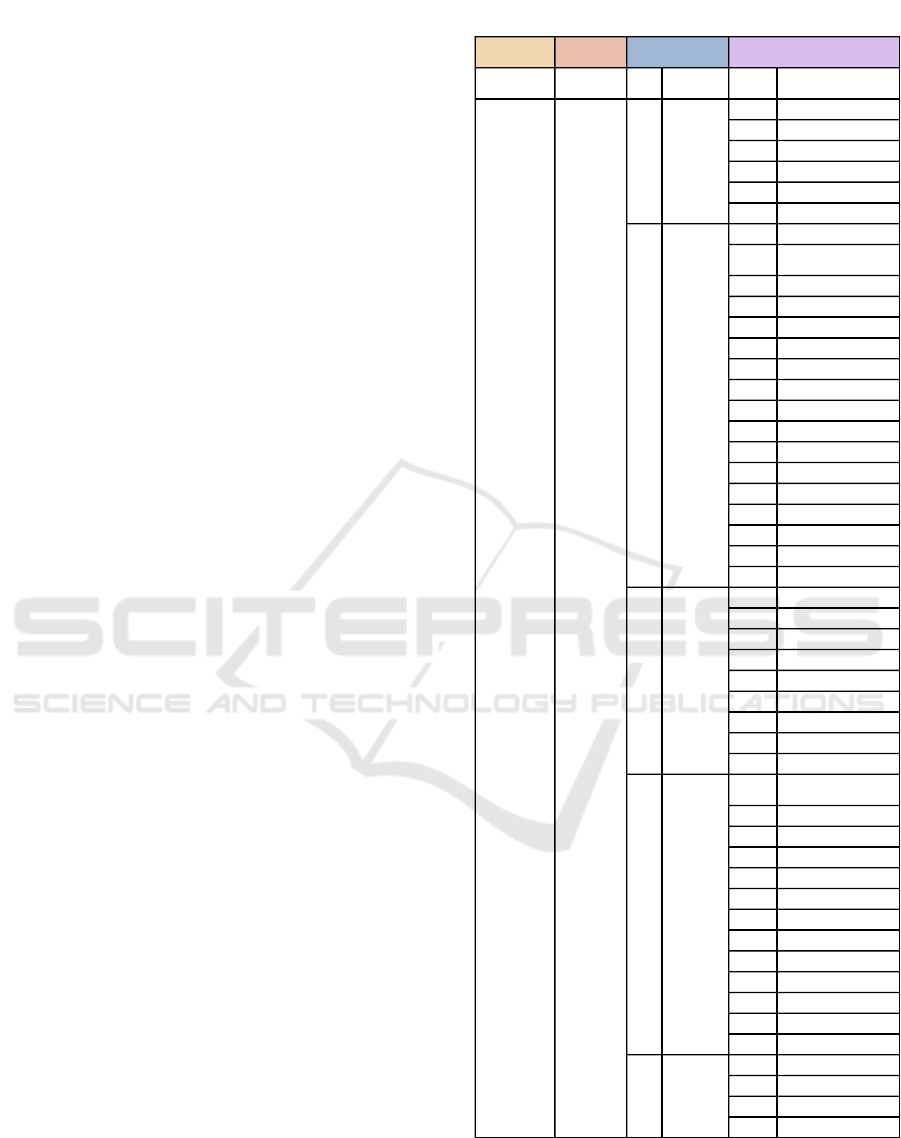

for research question one, can be seen in Table 1.

WBS level 4 consists, of 49 work packages

which are decomposition from the upper level, the

work type. In its application, the WBS used can be

different, adjusting to the needs based on the object

(building and area).

5.2 Design Alternatives/Method and

Activities

The alternative design or method referred to in this

study becomes a shadow level that is found between

levels 4 and 5. Its function is to provide information

related to alternatives that might be found for the

design and method used, from each work package that

is available. In developing this guideline, each

alternative design and method will be lowered to the

next level, thus that it has each different activity.

Activities at level 5 are derived from each

alternative a . Each alternative design / method will

have four typical activities consist of; inspection,

ICIB 2019 - The 2nd International Conference on Inclusive Business in the Changing World

696

maintenance, treatment and testing. Inspection is an

activity carried out at any time, in the form of

checking the existing condition of an object.

Maintenance is an activity carried out periodically to

maintain the reliability of an object. Treatment is an

activity in the form of object repair if damage occurs.

The last, testing is an activity to check whether after

repairing the object has been functioning optimally

again, after repairs are made.

5.3 Work Type and Work Package

Based on validation at the data collection stage, type

of work is divided into five items; gases, plumbing,

fire protection systems, air conditioning systems, and

vertical transportation systems. The results obtained

for research question one, can be seen in Table 1.

WBS level 4 consists, of 49 work packages

which are decomposition from the upper level, the

work type. In its application, the WBS used can be

different, adjusting to the needs based on the object

(building and area).

5.4 Design Alternatives/Method and

Activities

The alternative design or method referred to in this

study becomes a shadow level that is found between

levels 4 and 5. Its function is to provide information

related to alternatives that might be found for the

design and method used, from each work package that

is available. In developing this guideline, each

alternative design and method will be lowered to the

next level, thus that it has each different activity.

Activities at level 5 are derived from each

alternative a . Each alternative design / method will

have four typical activities consist of; inspection,

maintenance, treatment and testing. Inspection is an

activity carried out at any time, in the form of

checking the existing condition of an object.

Maintenance is an activity carried out periodically to

maintain the reliability of an object. Treatment is an

activity in the form of object repair if damage occurs.

The last, testing is an activity to check whether after

repairing the object has been functioning optimally

again, after repairs are made.

5.5 Resources & Implementation

Requirements

Resources contained in level 6 WBS consist of

tools, materials and labor resources for each activity.

Based on ILO Encyclopaedia (2011), tools are

primarily used to put things together or to take them

apart, furthermore the usage lasts for many years.

Materials are items that can be finished product.

Labor is the man power who execute the

process/activity.

Implementation requirements are the stages

carried out at each activity at level 5 WBS. The goal

Table 1: WBS Level 1 – 4.

WBS Level 1

WBS Level 2

Name of

Project

Work

Section

Code

Work Type Code Work Package

Mechanical

X1.1.1 Evaporator

X1.1.2

Meter Gas

X1.1.3

Gas Pipe

X1.1.4

Riser Pipe

X1.1.5

Gas Tank

X1.1.6

Accessories

X1.2.1

Carbon Filter

X1.2.2

Filter Pump Rain

Harvesting Tank

X1.2.3

Floor Drain

X1.2.4

Clean Water Pipe

X1.2.5

Rain Water Pipe

X1.2.6

Dirty Water Pipe

X1.2.7

Swimming Pool Pipe

X1.2.8

Pump Booster

X1.2.9

Pump Deep Well

X1.2.10

Pump Filter

X1.2.11

Swimming Pool Pump

X1.2.12

Dewatering Pump

X1.2.13

Sampit Pump

X1.2.14

Transfer Pumps

X1.2.15

Roof Tank

X1.2.16

Sewage Treatment Plant

X1.2.17

Water Treatment Plant

X1.3.1

Accessories

X1.3.2

Detector

X1.3.3

Hydrant Pillar

X1.3.4

Fire Pipe

X1.3.5

Riser Pipe

X1.3.6

Fire Pump

X1.3.7

Siamese Connection

X1.3.8

Sprinkler

X1.3.9

Solar Tank

X1.4.1

Air Handling Unit

(AHU)

X1.4.2

Ducting

X1.4.3

Evaporator

X1.4.4

Fan Coil Unit (FCU)

X1.4.5

Filter Dryer

X1.4.6

Filter Expansion

X1.4.7

Indoor Fan

X1.4.8

Outdoor Fan

X1.4.9

Compressor

X1.4.10

Condenser

X1.4.11

Cooling Tower Cooling

X1.4.12

Cooling

X1.4.13

Refrigerant

X1.5.1

Freight Elevator

X1.5.2

Passenger Elevator

X1.5.3

Escalator

X1.5.4 Gondola

Maintenance

and Treatment

Work of UI

Buildings and

Area

X1.5

Vertical

Transportati

on System

X1.4

Air

Conditionin

g System

Fire

Protection

System

WBS Level 3

WBS Level 4

X1.1

Gas System

X1.2

Plumbing

X1.3

Development of Implementation Guidelines for Maintenance and Treatment Work of Mechanical Components in Universitas Indonesia

Building and Area based on Work Breakdown Structure (WBS)

697

is that the implementation process is in accordance

with the standards and the results obtained have the

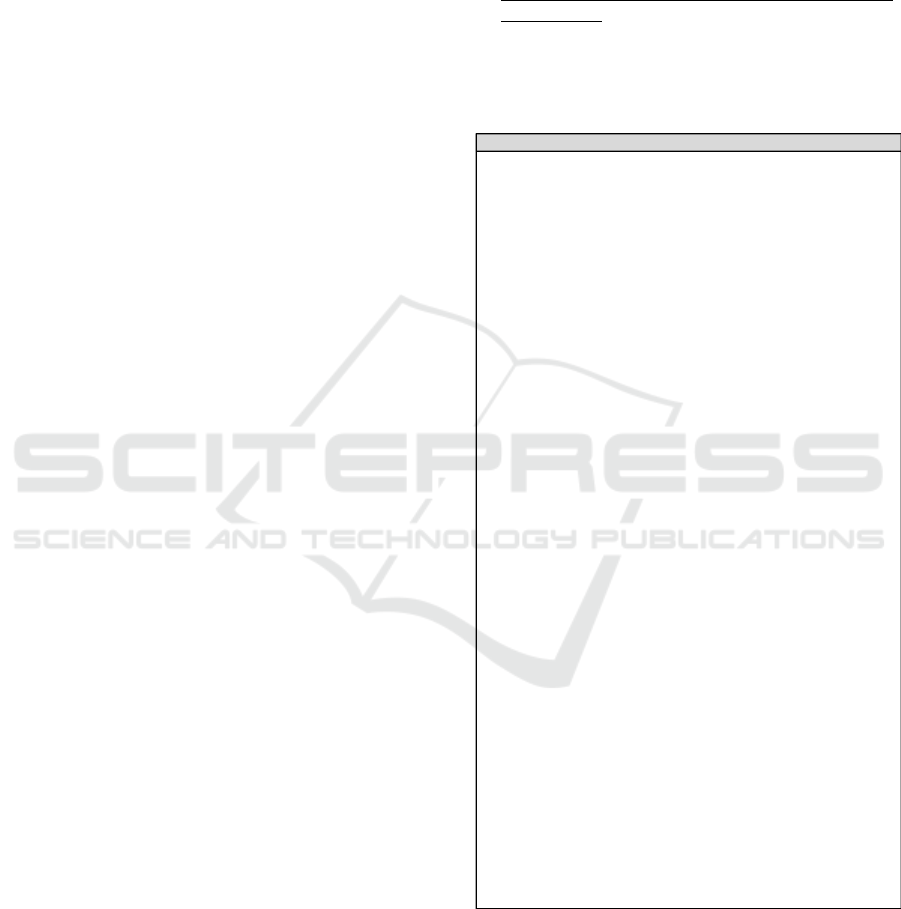

quality as expected. Table 3 showing the example of

Table 2: Alternative design/method.

resources used for one package, in this case for the

vertical transportation system and the example of

implementation requirements can be seen on the

appendix.

5.6 Technical Specification

According to Aryaningrum (2018), technical

specifications are needed to meet certain quality

standards. Another goal is to ensure the achievement

of accurate measurement results, according to what

has been determined. The example of the technical

specification is presented in table 4. To obtain the

technical specification used in this guideline, several

standards are used related to mechanical components

such as SNI, ISO, ASME, PUIL and applicable

government standards.

Table 3: Resources.

WBS Level 4

Work Package

Evaporator

Evaporator

Meter Gas

Meter Gas

Gas Pipe

Gas Pipe

Riser Pipe

Riser Pipe

Gas Tank

Gas Tank

Accessories

Accessories

Carbon Filter

Carbon Filter

Filter Pump Rain Harvesting Tank

Filter Pump Rain Harvesting Tank

Floor Drain

Floor Drain

Clean Water Pipe

Clean Water Pipe

Rain Water Pipe

Polyvinly Chloride

Dirty Water Pipe

Dirty Water Pipe

Swimming Pool Pipe

Swimming Pool Pipe

Pump Booster

Pump booster

Pump Deep Well

Submersible

Filtter Pump

Filtter Pump

Pump Swimming Pool

High-density polyethylene

Dewatering Pump

Dewatering Pump

Sampit Pump

Sampit Pump

Transfer Pump

Transfer Pump

Roof Tank

Roof Tank

Sewage Treatment Plant

Activated Sludge

Water Treatment Plant

Water Treatment Plant

Fire Alarm

Alarm Bell

Break Glass Emergency

Check Valve

Gate Valve

Disposal Valve

HydrantBox

Light Indicator

Pipe Mouth

Socket Emergency Phone

Fire Detector

Smoke Detector

Hydrant Pillar

Two-way type

Black Steel

High-density polyethylene

Wet Riser System

Dry Riser System

Diesel Pump

Electric Pump

Pump Jockey

One Way Type

Two Way Type

Pendant

Upright

Sidwalls

Solar Tank

Solar Tank

Air Handling Unit (AHU)

Air Handling Unit (AHU)

Horizontal Ducting

Vertical Ductiing

Split Duct, Ceiling Cassette, Floor Standing, VRV

Wall Mounted

Fan Coil Unit (FCU)

Fan Coil Unit (FCU)

Filter Dryer Filter Dryer

Accessories

Detector

Alternative Design / Method

Siamese Connection

Sprinkler

Ducting

Fire Pipe

Riser Pipe

Fire Pump

Evaporator

Filter Dryer

Filter Dryer

Filter Expansion

Filter Expansion

Split Duct, Ceiling Cassettes, Floor Standing, VRV

Wall Mounted

Split Duct, Ceiling Cassettes, Floor Standing, VRV

Wall Mounted

Split Duct, Ceiling Cassete, Floor Standing, VRV

Wall Mounted

Split Duct, Ceiling Cassette, Floor Standing, VRV

Wall Mounted

Cooling Tower Cooling

Tower

Air cooled chiller

Water cooled chiller

Refrigerant Pipe

Refrigerant Pipe

Freight Elevator

Freight Elevator

Passenger Elevator

Passenger Elevator

Escalator

Escalator

Gondola Gondola

Compressor

Condenser

Chiller

Indoor Fan

Outdoor Fan

Mechanical

Vertical Transportation System

Passenger Elevator

Passenger Elevator

Materials

Tools

Labor

Materials

Tools

Labor

Materials

Tools

Labor

Materials

Tools

Labor

Treatment

Testing

WBS LEVEL 6

RESOURCES

-

Checklist Form

Mechanical Technician

oil, greas, accu water, cleaning liquid

1 set of elevator maintenance equipment

Mechanical Technician

WO RK SECTION

WO RK TYPE

WO RK PACKAGE

Inspection

Maintenance

DESIGN ALTENATIVES/METHOD

-

1 set of elevator testing equipment, all instalation

operations requirements testing form, equipements testing

form, cable testing form

Mechanical Technician

accumulator, floor buttons, emergency switches, steel straps,

tire handles, anvils and combplates

1 set of elevator treatment equipment

Mechanical Technician

WBS LEVEL 5

ACTIVITY

WBS LEVEL 3

WBS LEVEL 4

VERTICAL TRANSPORTATION SYSTEM

PASSENGER EL EV ATOR

WBS LEVEL

DESCRI PTI ON

WBS LEVEL 2

ICIB 2019 - The 2nd International Conference on Inclusive Business in the Changing World

698

Table 4: Technical specification.

6 DISCUSSION

After all results are obtained from stage one to four,

all elements are compiled to form a guideline for each

work package. Can be seen for work type, the results

obtained are in accordance with the research

(Aryaningrum, 2018). In this study, there is a slight

difference, namely the addition of one work type,

namely gas work type. For work packages, there are

several items omitted from the literature study based

on Permen PU No. 24 Tahun 2008, Aryaningrum

(2018) and Rajasa (2017). This adjusts to the needs of

the UI based on the results of expert validation. In the

alternative design / method section, show the type that

might appear for each work package. For example,

the detector is divided into a smoke detector and fire

detector. This aims to ensure that implementation

requirements are specific and can eliminate errors.

For the guideline format used, it can be adjusted

based on user needs. In this study, the sample format

used for each work package can be seen in table 3 and

the appendix. The format used can show each

component for each WBS level clearly, so that all the

information needed can be summarized properly.

It can be concluded to obtain a guideline based

on the WBS consisting of 8 stages. These stages

consist of; determining work types, determining work

packages, determining alternative designs/methods,

determining activities, determining resources,

determining implementation requirements,

determining technical specifications and compiling

all the guidelines components. The determination that

occurs at each stage depends on the project carried

out, so it needs a little modification if it is made or

applied in a different place. Furthermore, for a

smaller scope project, adjustments can be made to the

number of levels used in the guideline making the

process.

7 CONCLUSION

The guidelines produced from this study are very

important and needed to be used as a reference for

maintenance and treatment work. The goal is to

achieve maximum quality results, so that it can

minimize building damage that occurs. This can be

achieved by using a WBS as a technique in the

making process. By decomposing the scope of work

to the smallest part, it is expected to cover all existing

elements to the smallest part, without any exception.

By applying the guidelines correctly as a preventive

action, it will reduce the possibility of a bad

phenomenon occurred.

This guideline can be used as a reference and

later can be modified and applied to similar buildings

or areas. Not only in the construction field, but the

WBS technique used can also be applied to make

guidelines in other fields.

ACKNOWLEDGEMENTS

The Authors would like to thank the financial support

provided by Universitas Indonesia through PIT 9

funding scheme under grant number NKB -

0087/UN2.R3.1/HKP.05.00/2019 managed by the

Directorate for Research and Public Services

(DRPM) Universitas Indonesia.

REFERENCES

Aditya, R. (2018). Pengembangan Prosedur Teknis

Pelaksanaan Pemeliharaan dan Perawatan Komponen

Mekanikal dan Elektrikal pada Bangunan Gedung

Pemerintah di Jakarta untuk Perencanaan K3. Depok,

Indonesia: Universitas Indonesia.

Ajizah, N. (2018). Perencanaan Sumber Daya pada

Pekerjaan Mekanikal dan Elektrikal Bangunan Gedung

Apartemen Berbasis WBS (Work Breakdown

Structure). Depok, Indonesia: Universitas Indonesia.

Alsadila, K. and Prayitno, B. (2018). Fenomena Kerusakan

Gedung Akibat Komponen Mekanikal.

Amare, G. (2012). Reviewing the Value of Standard

Operating Procedure. Ethiopan Journal of Health

Science, 22 (3), pp. 205-208.

Anshari, D. F. (2014). Kronologi Kebakaran di Gedung C

Fisip UI. Kompas, [online]. Available at:

https://megapolitan.kompas.com/read/2014/01/07/092

1022/Kronologi.Kebakaran.di.Gedung.C.FISIP.UI

[Accessed 16 May. 2018].

Aryaningrum, D. E. (2018). Pengembangan Pedoman

Pelaksanaan Pekerjaan Pemeliharaan, Perawatan dan

Penentuan Spesifikasi Material untuk Desain

a.

b.

c.

d.

e.

f.

Technical Specification

Meet the regulations of Electric Lift, Aircraft Lift, and Transportation from the

Ministry of Manpower of the Republic of Indonesia, the latest edition

Meet the SNI-03-2190-1999 standard or the latest on Passenger Lift

Construction with Traction Motor.

Meet ASME A Standards 17.1 - 1996 regarding "Safety Code for Elevators

and Escalators", or the latest edition.

Meet the PUIL standard (General Electrical Installation Regulations) that

applies or the latest edition.

All equipment from the material and components must be new according to

the brochure, published and in accordance with the specifications as

described as well as on the plan drawings and are products that are still

outstanding, produced regularly and must attach a letter of support.

Must be produced by the same factory (brand), so as to provide the

possibility of being exchanged.

Development of Implementation Guidelines for Maintenance and Treatment Work of Mechanical Components in Universitas Indonesia

Building and Area based on Work Breakdown Structure (WBS)

699

Komponen Mekanikal Bangunan Hijau pada Gedung

Pemerintah Berbasis Work Breakdwon Structure.

Depok, Indonesia: Universitas Indonesia.

Fitriadi, R. (2017). Pengembangan Standar WBS (Work

Breakdown Structure) untuk Estimasi Biaya pada

Pekerjaan Konstruksi Jembatan Beton Precast

Berbasis Risiko. Jakarta: Universitas Indonesia.

Handayaniputri, A. (2009). Pengembangan Konsep

Standar Operasional Prosedur pada Proses

Manejemen Pemeliharaan dan Perawatan Bangunan

Gedung (Bagian X Lembaga Y). Jakarta: Universitas

Indonesia.

Ibrahim, Y. M., Kaka, A., Aouad, G., & Kagiouglou, M.

(2009). Framework for a generic work breakdown

structure for building projects (Vol. IX). United

Kingdom: Emerald Group Publishing Limited.

Juarti, E. R., Marlailana, R. R., & Noorlaelasari, Y. (2015).

Penentuan Indikator Kinerja Bangunan Gedung

Pendidikan (Vol. IV). Bandung, Indonesia: Politeknik

Negeri Bandung.

Manager, I. C. (2011). Tools. Encyclopaedia of

Occupational Health & Safety, [online]. Available at:

http://www.iloencyclopaedia.org/part-xvi-

62216/construction/content/tools-equipment-and-

materials [Accessed 18 Feb. 2018]

Pļaviņa, B., & Geipele, I. (2013). Chances of the

development of multiapartment dwelling houses policy

in Latvia. 14th Annual International Conference

“Economic Science for Rural Development” Latvia,

Jelgava: LLU, EF, pp. 43–47.

Project Management Institute. (2013). A Guide to The

Project Management Body of Knowledge (PMBOK

Guide) (5th Edition ed.). Newtown Square,

Pennsylvania, USA: Project Management Institute,Inc.

Supriadi, L. S., Biruni, R. Y., Latief, Y. (2018).

Development of Work Breakdown Structure (WBS)

Dictionary for The Construction Works of Precast

Concrete Bridge. IOP Conf. Ser.: Mater. Sci. Eng. 420

012004. [online]. Available at:

https://www.researchgate.net/publication/328004550

[Accessed 1 Oct. 2018].

Supriadi, L. S., Latief, Y., Susilo, B., & Rajasa, M. (2017).

Developement of Risk-Based Standardized WBS

(Work Breakdown Structure) for Cost Estimation of

Aparment's Project. International Journal of Civil

Engineering and Technology (IJCIET), 8(10), pp. 822-

833.

Suyono, Prasetyo, M. T., & Assafat, L. (2011). Tingkat

Keandalan Utilitas Kelistrikan Bangunan Gedung

Bertingkat di Kota Semarang. Media Elektrika 4.1, 2.

Republik Indonesia. (2008). Peraturan Menteri Pekerjaan

Umum Nomor 24/PRT/M/2008 tentang Pedoman

Pemeliharaan dan Perawatan Bangunan Gedung.

Jakarta, Indonesia: Departemen Pekerjaan Umum

Direktorat Jenderal Cipta Karya., pp. 1-122.

Republik Indonesia. (2002). Undang-undang No. 28 Tahun

2002 tentang Bangunan Gedung. Sekretariat Negara.

Jakarta, Indonesia.Usman, K., & Winandi, R. (2009).

Kajian Manajemen Pemeliharaan Gedung (Building

Maintenance) di Universitas Lampung. Universitas

Lampung, Jurusan Teknik Sipil - Fakultas Teknik,

[online]. Available at: http://ft-

sipil.unila.ac.id/ejournals/index.php/jrekayasa/article/v

iewFile/8/pdf [Accessed 6 Oct. 2018].

Quacquarelli Symonds Limited. (2018). QS Top

Universities. QS Top Universities, [online]. Available

at:

https://www.topuniversities.com/universities/universit

as-indonesia [Accessed 6 Oct. 2018].

APPENDIX

1.

Elevator checks are carried out routinely every 1 (one) week.

2.

Checking is done as follows:

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

k.

l.

m.

n.

o.

3.

Analyze whether maintenance / maintenance needs to be done.

Checking the floor of the lobby of the elevator, which includes

checking the condition of the floor door (hoistway entrance) with

the requirements not ringing, not vibrating and the position is not

tilted for door leaf meetings, the functions of the buttons, the

function of indicator lights on each floor and the emegency key

Check the cleanliness of the elevator room and the condition of

the elevator machine.

Check the condition of the gear box oil if there is a leak or not.

Check the condition of the main shave and alternating whether it

is functioning properly or not.

Check whether the shave cover is open / closed.

Checking cleanliness conditions Slow down car switch rail, CWT

rail, car door mechanic and outside door, hosway and elevator

door seel and rail and its functions.

Check the condition of the installation of the air phone, reset

button, earthquake detector, lift control from BAS and the

elevator door sensor, whether it works properly or not.

Check the battery conditions, is it still functioning properly or need

to add water batteries or not.

Check the roof of the train (Top of Car), which includes inspection

of emergency door access on the train (emergency exit),

inspection of more speed safety switches (safety operated

switches), inspection of broken tape switches, inspection of

emergency stop switches, inspection limit switch at the top end of

the launch room and inspection of door contacts (door contacts).

Checking the engine room, which includes checking the value of

the fuse (ampere), motor power rating (kW), motor rotation (rpm),

frequency (Hertz), temperature rise motors and motor insulators.

Check the pits, which include a counter weight check, monkey

ladder inspection, basic pit cleaning checks, final limit switch

checks, and directional limit switch checks.

INSPECTION

check the condition of the passenger elevator is functioning

properly or there is damage.

check the availability of oil and grease and rail oil.

check the cleanliness condition of the door motor, casting, roof

governor and CWT chain and its functions.

Check the man save deflector sleave whether it works properly or

not.

IMPLEMENTATION REQUIREMENTS

ICIB 2019 - The 2nd International Conference on Inclusive Business in the Changing World

700

1.

a.

Repair elevator repair if damage occurs.

b.

Add oil and grease and rail oil if it is reduced or empty.

c.

d.

e.

f.

g.

h.

i.

j.

k.

l.

m.

Repairing If there is a leak in the gear box oil

1.

a.

b.

c.

d.

e.

a.

Prepare equipment and materials needed for testing elevators.

b.

c.

Test upwards without load.

d.

Do testing below without load.

e.

Perform testing above with full load.

f.

Perform testing below with full load (magnetic switch) open.

g.

h.

Carry out testing with full load (magnetic switch) closed.

Testing the brakes, left and right rails, r steel cables, steel cable governor

tensioning, cage safety brakes, safety switches, governor and governor

switches.

TESTI NG

Test cage speed, cage current and speed, current and voltage of the

elevator motor.

2.

Treatment is carried out as follows:

Change batteries if they don't work according to the

specifications specified.

Replacing damaged floor switches and emergency switches in

accordance with specified specifications.

Replace steel straps that show signs of cracking, breaking or

breaking on some wire or rusting components and diametrnya

shrinkage of more than 10% of the original size, in accordance

with the specified specifications.

Replace the tire handle that shows signs of cracking or breaking

in accordance with the specified specifications.

Replace damaged or broken / cracked runway and combplate

according to specified specifications.

Lubricating dry steel ropes your data shows signs of corrosion

with special lubricating oils.

TREATMENT

Prepare equipment and materials needed for elevator maintenance.

Perform cleaning Slow down car switch main rail, CWT rail, car

door mechanic and outside door, hosway and elevator door seel

and rail and make repairs if damage occurs.

Repairing the air phone installation, reset button, earthquake

detector, elevator control from BAS and elevator door sensor in

case of damage.

Add water batteries if needed.

Repair floor buttons and emergency switches if they are not

functioning properly.

Cleaning the engine room, sliding and pit chambers from

garbage, dust and oil spills.

Regularly lubricate guide rails, governors, pesawawt, trains,

doors, machines, buffers and equipment with the type of lubricant

that suits the type and brand.

MAINTENANCE

Prepare equipment and materials needed for elevator maintenance

2.

Maintenance carried out as follows:

Perform dirty cleaning of the motorbike and make repairs if there

is damage (jam).

Perform cleaning clearance, roof governors and dirty CWT chains

/ comensstarting and make repairs if damage occurs.

Manages to save save deflector sleave in case of damage and

does not function properly.

Development of Implementation Guidelines for Maintenance and Treatment Work of Mechanical Components in Universitas Indonesia

Building and Area based on Work Breakdown Structure (WBS)

701