Development of Implementation Guidelines for Maintenance and

Treatment Work of Electrical Components in University of Indonesia

Buildings and Area based on Work Breakdown Structure (WBS)

Tito Tegar Irawan and Yusuf Latief

University of Indonesia, Jl. Margonda Raya, Kota Depok, Indonesia

Keywords: Guidelines, Maintenance, Treatment, Electrical Work, Work Breakdown Structure.

Abstract: Maintenance and treatment work of buildings is important in maintaining the reliability of buildings. the the

absence of standards for the implementation of electrical maintenance and treatment work in buildings at the

University of Indonesia is also one of the causes of building fires, electrical short circuit, and damage to

building transformers in the last 4 years. The purpose of this study is to develop standards for the

implementation of maintenance and treatment work of electrical components in buildings at the University

of Indonesia based on Work Breakdown Structure (WBS) using literature studies and the Delphi method.

The independent variable in this study is Work Breakdown Structure (WBS) includes the work type, work

package, alternative design, implementation requirements, activities, resources, and material specifications,

while the dependent variable in this study is the implementation standard. The results of this study are in the

form of developing an implementation standard based on Work Breakdown Structure (WBS) which can be

used as a reference for the maintenance and treatment of electrical components in buildings at the

University of Indonesia, which is expected to increase building user safety and convenience as well as

effectiveness and efficiency in building management.

1 INTRODUCTION

Based on the Regulation of the Minister of Public

Works No. 24 / PRT / M / 2008, maintenance of the

building is the activity of maintaining the reliability

of the building along with the infrastructures and the

ingredients so that the building is always worthy

function. While the treatment is an activity building

treatment replace parts of buildings, components,

construction materials, and / or infrastructure and

facilities in order to remain eligible buildings

function. Building maintenance is defined as work to

maintain, restore or repair every part of the building,

to maintain the performance of building and service

fabric and its surroundings, meet standards and

maintain the utility and value of buildings. This

includes repairs, improvements, and repairs to works

from existing facilities (Plavina & Geipele, 2013).

Building performance can be measured from 4 (four)

requirements, namely: functional requirements,

performance requirements, legality requirements and

compliance with regulations, and user requirements

(Son & Yuen, 2002). In the case of maintaining

function-worthy requirements, maintenance,

maintenance and inspection work must be carried

out on building buildings on a regular basis

(Republik Indonesia, 2002)

The University of Indonesia must have a source

of funds and resources are sufficient and reliable for

research activities and community services so that

research activities and community services can

generate new discoveries that benefit humanity and

contribute to the accumulation of knowledge

(BPMA, 2007), Buildings used to support the

achievement of the objectives and main functions of

an organization optimally users, and is expected to

follow the changes that may occur in its organization

(Achmada, 2013).

Based on an interview with Mr. Budi Prayitno as

Head of Management of Energy Saving Sustainable

UI and Mr. Beny Rahman, Head of Section for

Planning and Care and Maintenance of Mechanical,

Electrical, and Transportation UI in October 2018,

there were 5 phenomenon of fire, short circuit, as

well as damage to substations and transformers in

the last 4 years on the job of maintenance and

Irawan, T. and Latief, Y.

Development of Implementation Guidelines for Maintenance and Treatment Work of Electrical Components in University of Indonesia Buildings and Area based on Work Breakdown Structure

(WBS).

DOI: 10.5220/0008428801650173

In Proceedings of the 2nd International Conference on Inclusive Business in the Changing World (ICIB 2019), pages 165-173

ISBN: 978-989-758-408-4

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

165

upkeep of buildings and electrical components of the

University of Indonesia region which causes

kerugaian material up to 40 billion rupiah.

Besides avoiding damage incidents that may

occur, maintenance and treatment work of electrical

component can also increase the level of satisfaction

of building occupants (Au-Yong, 2014), Research

This will produce guidelines for the implementation

of maintenance and treatment of electrical work in

the building at the University of Indonesia based

Work Breakdown Structure (WBS) to be structured,

managed, measured, and scheduled.

The novelty of this research is the

implementation guidelines are made based on Work

Breakdown Structure and the addition of the

University of Indonesia area components to

electrical maintenance and treatment work package

such as power house, telephone, and backup power

generators. This research will contribute to the

University of Indonesia in the hope that it will

impact the implementation guidelines so the

guidelines become structured, complete, and avoid

all components mistakes of maintenance and

treatment electrical work, where electrical work is

very important because of all building facilities

supported by electrical components. Also become a

reference in making guidelines for maintenance and

treatment work of buildings, especially for electrical

components for other institution. For academic

purpose, this provides knowledge about the process

of making WBS-based implementation standards.

2 RESEARCH OBJECTIVES

The objectives of this research are:

To identify the work section, work type, and

work package of WBS for maintenance and

treatment work of electrical components in

buildings and areas at Univesitas Indonesia.

To identify alternative design/method and

activity in each package of maintenance and

treatment work of electrical components in

buildings and areas at Univesitas Indonesia.

To identify resources for each activity in the

maintenance and treatment work of electrical

components in buildings and areas at the

University of Indonesia.

To identify technical specifications used in each

activity of maintenance and treatment work of

electrical components in buildings and areas at

the University of Indonesia.

To identify ways to develop guidelines based on

the WBS (Work Breakdown Structure) for the

maintenance and treatment work of electrical

components in buildings and areas at the

University of Indonesia

3 LITERATURE STUDY

3.1 University of Indonesia Buildings

and Area

The University of Indonesia certainly has sufficient

and reliable sources of funds and resources for

research and community service activities so that

research and community service activities can

produce new findings that are beneficial to humanity

and contribute to the accumulation of knowledge

(BPMA, 2007). The building is used to support the

achievement of the main goals and functions of a

user organization optimally, and is expected to be

able to follow changes that can occur in the user

organization (Achmada, 2013). The University of

Indonesia consists of 85 buildings located in an area

of 320 hectares (Prayitno, 2018). To support this,

good maintenance and treatment need to be done,

one of which is in the electrical components of the

building.

3.2 Maintenance and Treatment Work

There are four aspects that need to be considered and

become the requirements for the success of

maintenance and treatment of building buildings,

namely the safety of buildings, the health of

buildings, the comfort of buildings, ease of building

(Direktorat Jenderal Cipta Karya, 2008).

3.2.1 Maintenance Work

Maintenance of building is an activity to maintain

the reliability of buildings and infrastructure and

facilities so that buildings are always functional.

Maintenance work includes several activities such as

cleaning, tidying, inspecting, testing, repairing, and

replacing building materials or equipment

(Direktorat Jenderal Cipta Karya, 2008).

3.2.2 Treatment Work

Treatment of building is an activity to repair and / or

replace parts of a building, components, building

materials, and / or infrastructure and facilities so that

the building remains functionally feasible.

Treatment work includes repairing and / or replacing

building materials, components, building materials,

ICIB 2019 - The 2nd International Conference on Inclusive Business in the Changing World

166

and / or infrastructure and facilities based on the

technical plan for maintenance of buildings. There

are three types of building maintenance work,

rehabilitation, renovation and restoration.

Building damage is the non-functioning of

buildings or building components due to shrinkage /

expiration of the age of the building, or due to

human behavior or natural behavior such as

excessive functional load, fire, earthquake, or other

similar causes. Based on the intensity of the damage,

damage to buildings can be divided into three levels,

minor damage, medium damage, and high damage

.Minor damage is damage mainly to non-structural

components, such as roof cover, ceiling, floor

coverings and fills walls. The maximum

maintenance cost is 35% of the highest unit price of

the new building construction that applies, for

buildings with the same class. Medium damage is

damage to some non-structural components, and or

structural components such as roof structures, floors.

The maximum maintenance cost is 45% of the

highest unit price of the new building construction

that applies, for buildings with the same class.

Heavy damage is damage to most building

components, both structural and non-structural,

which, after a repair, can still function properly. The

maximum maintenance cost is 65% of the highest

unit price of the new building construction that

applies, for buildings with the same class (Direktorat

Jenderal Cipta Karya, 2008).

3.2.3 Electrical Maintenance and Treatment

Work

Regarding the Guidelines for maintenance and

treatment of buildings, it is explained about the

scope of building maintenance for electrical

components as follows (Direktorat Jenderal Cipta

Karya, 2008):

Conduct periodic checks and maintain backup

power plants.

Conduct periodic checks and maintain on

lightning protection equipment.

Conduct periodic checks and maintain electrical

installation systems, both for electric power

supply and for room lighting.

Conduct periodic checks and maintain a network

of sound and communication (telephone)

installation and data.

Conduct periodic checks and maintain a network

of alarm systems and alarms.

3.3 Work Breakdown Structure (WBS)

The WBS is a structured decomposition of the entire

scope of work that must be done by the project team

to achieve project objectives and complete the

required results. The main benefit of the WBS

process is to provide a framework for what needs to

be done or done (Project Management Institute,

2013).

3.3.1 Power Source System

An electricity source system is an electrical system

that produces, processes or temporarily stores

electrical energy, and its protection so that it can be

used by electrical equipment. Some of the

components included in this system are a

transformer, uninterruptible power supply, backup

power source, and renewable power source.

3.3.2 Distribution System

This system functions to channel electrical energy so

that it can be used by the electric load. The

distribution system consists of several components,

namely medium voltage panels and low voltage

distribution panels.

3.3.3 Electric Load

The components included in this work package are

equipment that consumes electrical energy for the

operation of the building and its accessories. The

electrical load components are load panel panels,

cabling, lighting control systems, lightning rod

systems, artificial lighting systems, land systems,

sockets and switches, and under floor duct.

3.3.4 Electronic System

The system included in this component is equipment

installed in buildings whose parts consist of

electronic components such as CCTV systems, fire

alarm systems and detectors, computer and internet

network systems, signal amplifier systems, sound

systems, and telephones.

3.4 Alternative Design/Method

The method chosen or used in each component and /

or work package depends on the requirements of the

building. In this study will consider the requirements

of the Ministry Regulation of PUPR No. 24 of 2008,

Ministry Regulation of PUPR no. 45 of 2007, DKI

Development of Implementation Guidelines for Maintenance and Treatment Work of Electrical Components in University of Indonesia

Buildings and Area based on Work Breakdown Structure (WBS)

167

Governor Regulation no. 38 of 2012. Alternative

designs are chosen based on literature studies.

3.5 Activities

Forms of activities related to systems and electrical

equipment that are in a building, in principle, are

divided by phase. The phase is divided into

development phases with maintenance and treatment

phases. In the development phase there are two main

activities, namely design, installation and testing. In

design activities, electronic equipment is determined

by specifications and performance. The installation

aims to install equipment and systems in accordance

with their specifications while testing functions to

ensure that the system and equipment work in

accordance with the desired performance. While in

the maintenance and treatment phase there are

activities of inspection, service, replacement of

parts, and testing.

3.6 Resources

Every maintenance and treatment work requires

resources to complete its objectives. The resources

needed can be grouped into human resources, tool

resources, and material resources. Each resource

must be fulfilled both in terms of quantity and

quality.

4 METHODOLOGY

To answer questions in research and determine the

method used, it is recommended to use a strategy

(Yin, 2013). According to the form, there are several

kinds of instruments that can be used in general

research, namely Questionnaire / Questionnaire,

Interview, Observation, Documentation, Test

(Arikunto, 2000).To achieve the research objectives,

a qualitative method was used with inputs consisting

of primary data there are ministerial regulations,

Explanation of General Requirements for Electrical

Installation document, SNI, and previous research.

As for secondary data, researchers used

questionnaire instruments, expert judgment, and

interviews. Validity test is a step of testing carried

out on the content or content of an instrument

(Sugiyono, 2006). Validity is divided into three,

namely content validity, construct validity, and

criterion-related validity (Kerlinger, 1973).

Data analysis is the most important part of the

scientific method, because data analysis is used to

solve research problems (Basrowi & Suwandi,

2012). After that the data is analyzed, processed and

validated again by experts using the Delphi method.

The delphi method is a systematic method of

gathering opinions from a group of experts through a

series of questionnaires, where there is a feedback

mechanism through a round of questions held while

maintaining the anonymity of respondents' responses

(Foley, 1972). There are 10 steps to the theory of the

Delphi method (Hills & Fowles, 1975). The

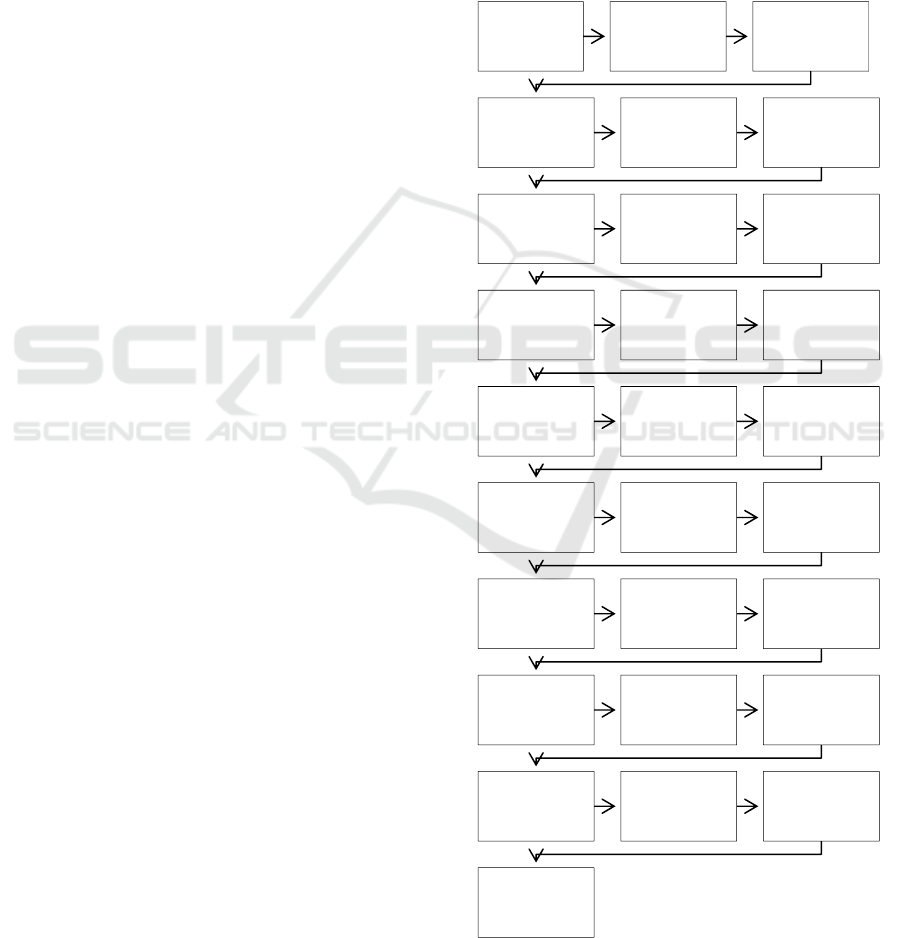

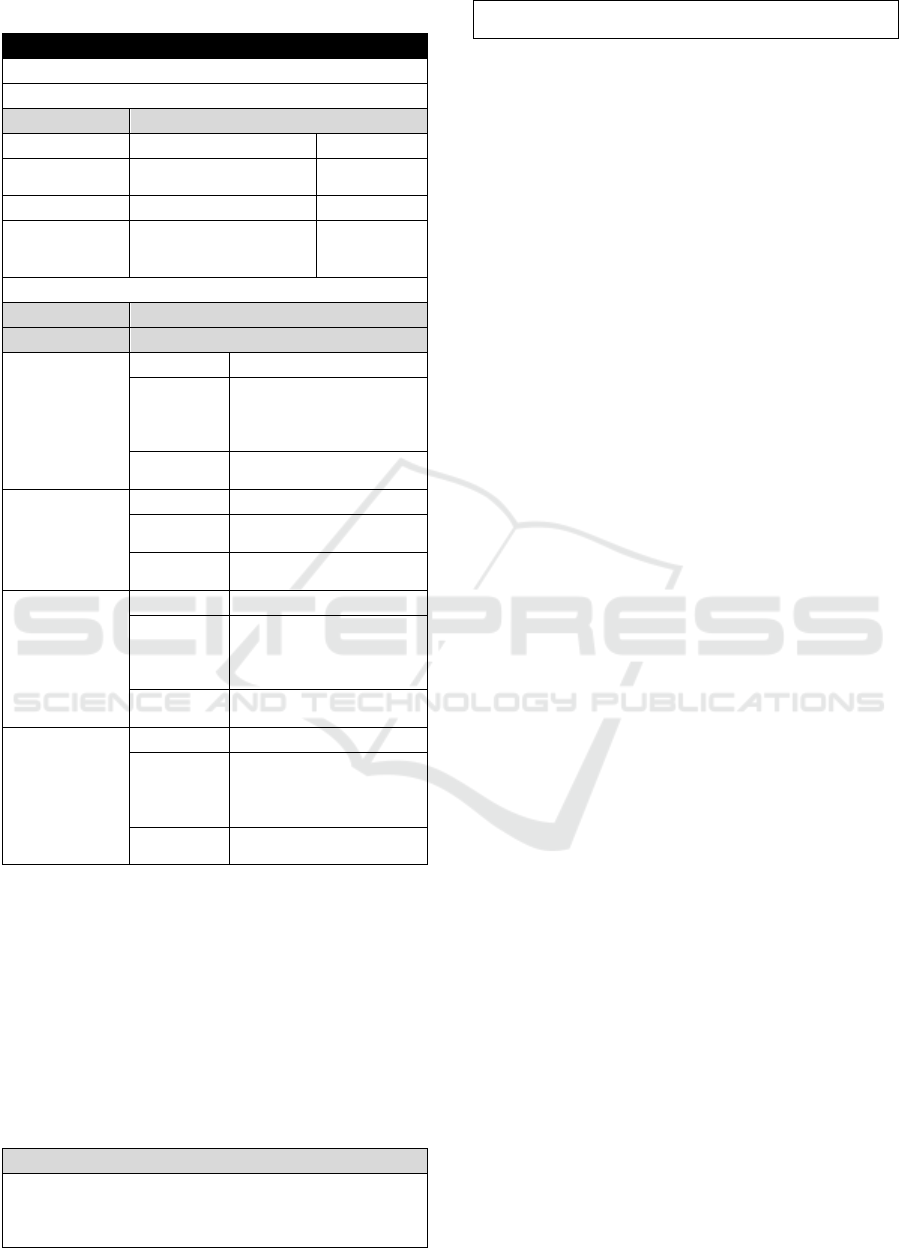

following figure is a flow diagram that shows the

stages of how this research will be carried out:

Figure 1: Research Process.

Start

Problems

identification

Research

questions

Literature Study

Research

methodology

identification

Research

variables

identification

Archive Analysis

Expert Validation

1

(Interview &

Questionnaire)

Data Analysis 1

(Descriptive

Analysis)

Forms, types, and

work packages of

WBS

Literature study

and archive

analysis

Expert Validation

2

(Interview &

Questionnaire)

Data Analysis 2

(Descriptive

Analysis)

Alternatives

Design

Literature study

and archive

analysis

Expert Validation

3

(Interview &

Questionnaire)

Data Analysis 3

(Descriptive

Analysis)

Resources and

implementation

requirements

Literature study

and archive

analysis

Expert Validation

4

(Interview &

Questionnaire)

Data Analysis 4

(Descriptive

Analysis)

Material

spesifications

Literature study

and archive

analysis

Expert Validation

5

(Interview &

Questionnaire)

Data Analysis 5

(Descriptive

Analysis)

Implementation

guidlines of

maintenance and

treatment work

Conclusion

End

ICIB 2019 - The 2nd International Conference on Inclusive Business in the Changing World

168

5 RESULT AND DISCUSSION

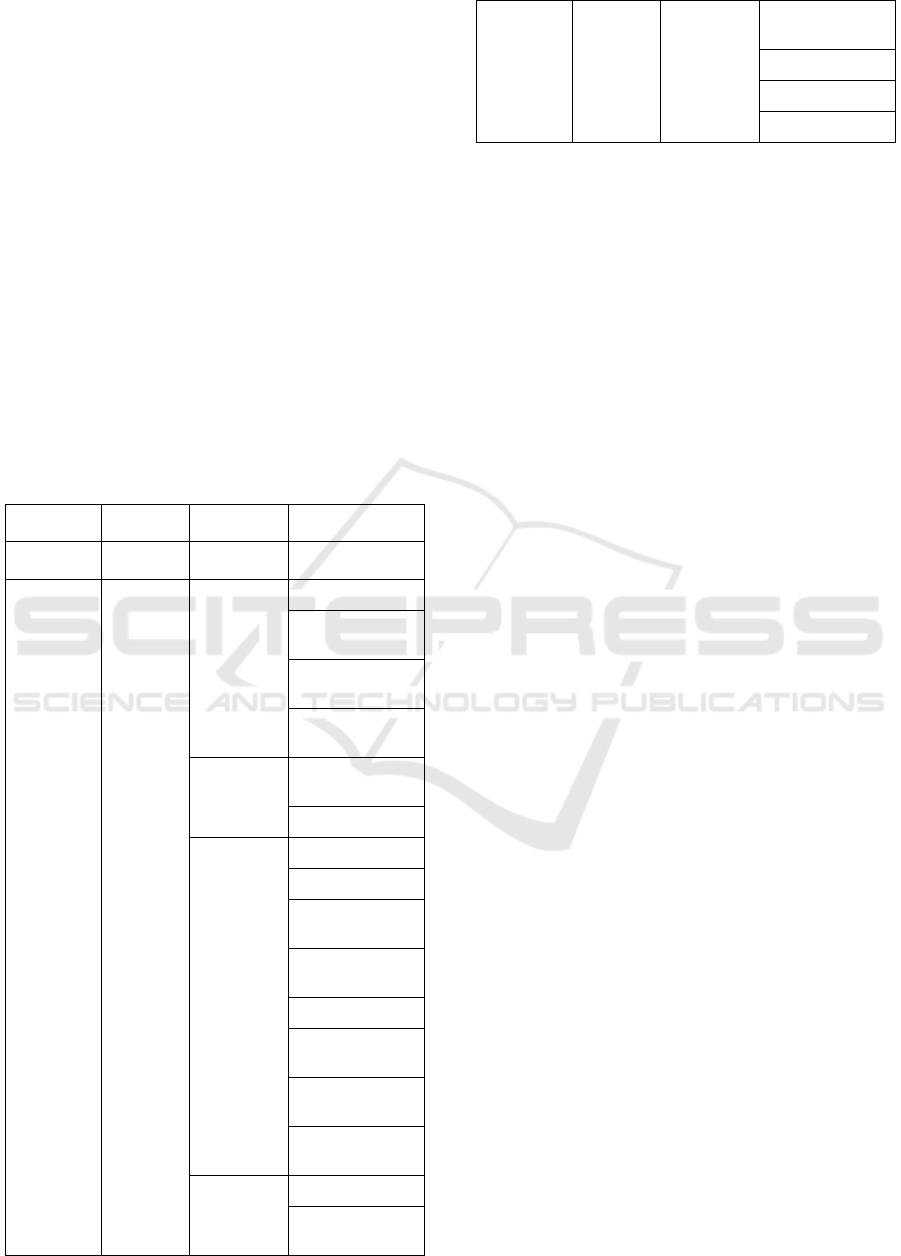

5.1 Level 1 to 4 WBS

To get the results in the first phase, the researcher

used SNI 0225:2011, Ministry Regulation of PUPR

no.24 of 2008, electrical WBS, and literature study

for inputs. Then for the analysis, I used the delphi

method to collect opinions from several experts

using questionnaires. After expert validation, Work

Breakdown Structure in table 1 is detailed every

work package concerning the work and maintenance

of electrical components in dungung and regional

buildings at the University of Indonesia. The

difference in WBS between office buildings and

University of Indonesia buildings is in the electricity

sources that are power house consisting of three

work packages. There are liquid transformers,

LVMDB, and medium voltage chambers.

Table 1: Work Breakdown Structure Level 1-4.

Project Name Work

Section

Work Type Work Package

Level 1 WBS Level 2

WBS

Level 3 WBS Level 4 WBS

Maintenance

and

Treatment

Work of

University of

Indonesia

Buildings and

Area

Electrical

Electrical

Sources

Power house

Backup Power

Generator

Renewable Power

Uniterruptable

Power Supply

Distribution

System

LVMDB Panel

MV Panel

Electrical

Load

Load Panel

Cable

Lightning Control

System

Lightning

Protection

Lightning

Grounding System

Receptacle and

Switch

Under Floor Duct

Electronics

CCTV System

Fire Alarm and

Detector

Internet and

Computer

Signal Repeater

Sound System

Telephone

From table 1, there are 4 components at WBS

level 3 and 19 components on WBS level 4.

Furthermore the work package will be more detailed

in alternative designs / methods and activities. The

implementation of the work package can be a

control account. Control accounts are a control point

for management where scope, budget, and schedule

are compared with earned values for performance

measurement.

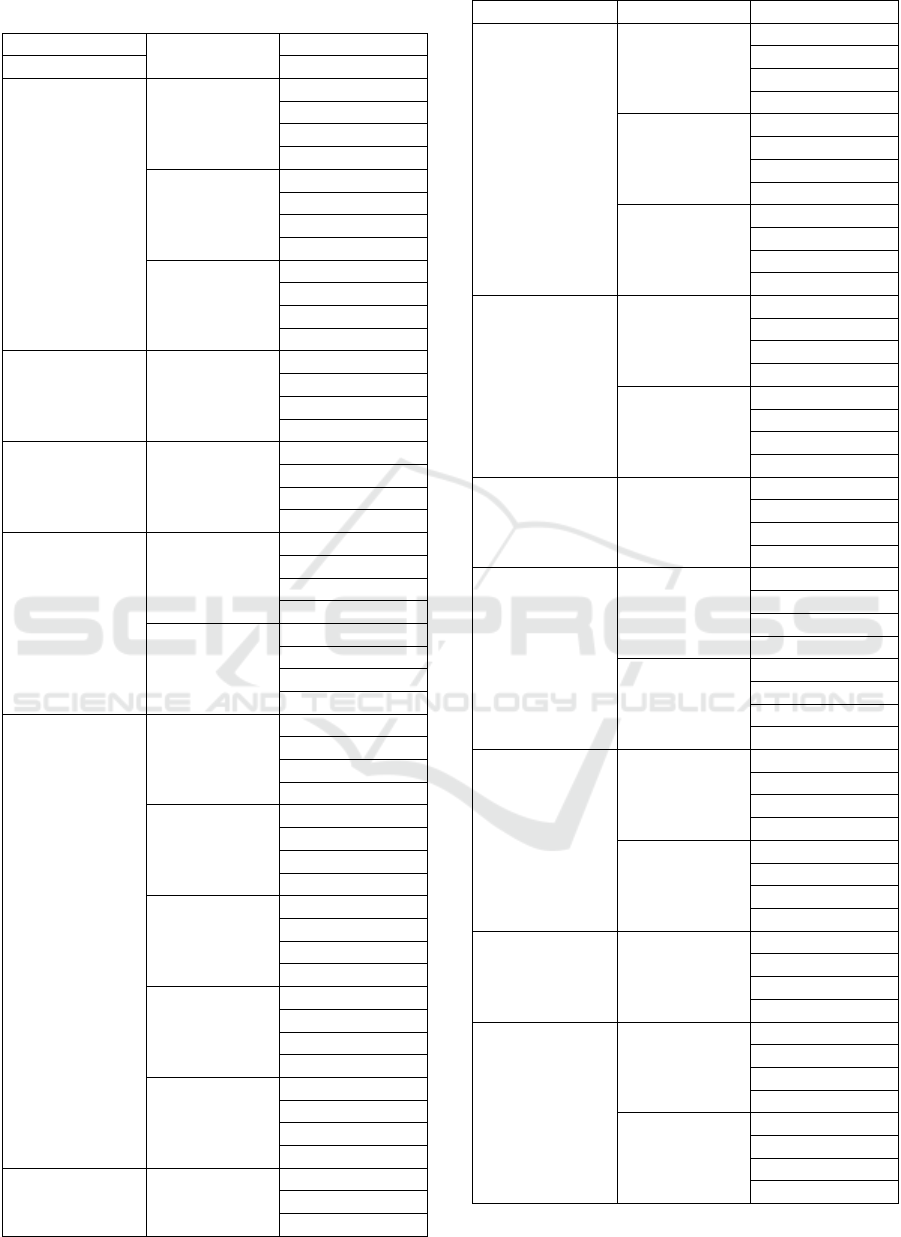

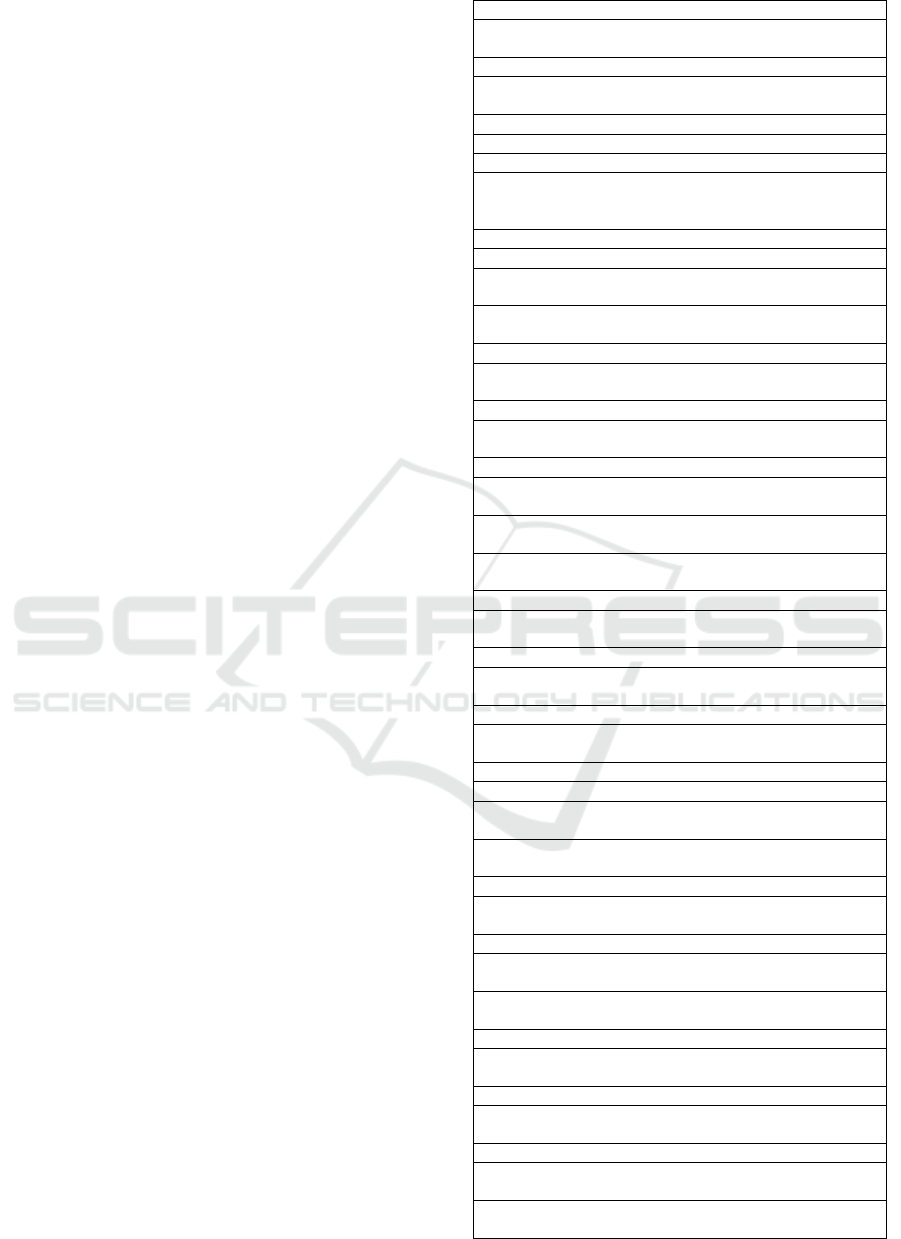

5.2 Alternatives Design/Method and

Level 5 WBS

To get the results in the second phase, the researcher

used Ministry Regulation of PUPR no.24 of 2008,

electrical WBS, and literature study for inputs. Then

for the analysis, I used the delphi method to collect

opinions from several experts using questionnaires.

The list of alternative design / method in table 2

covers all the scope of the work package in electrical

work. Then each alternative design / method is

implemented into more specific activities which

consist of inspection, maintenance, treatment, and

testing.

Inspection is cover surveillence and monitoring

the device to find a defect or anomaly during normal

operation. Maintenance work includes several

activities such as cleaning, tidying, inspecting,

testing, repairing, and replacing building materials

or equipment. While the treatment is an activity

building treatment and / or replace parts of

buildings, components, construction materials, and /

or infrastructure and facilities in order to remain

eligible buildings function. Testing is a process that

aims to ascertain whether all devices functions work

properly and look for errors that might occur in the

system.

From table 2, there are 41 components in

alternative designs/methods and 61 components in

activities. Furthermore, alternative designs/methods

will be more detailed in the resources. The

implementation of alternative designs/methods is a

method used to select alternative types of use of

work functions such as transformers, diesel

generators, and solar panels.

Development of Implementation Guidelines for Maintenance and Treatment Work of Electrical Components in University of Indonesia

Buildings and Area based on Work Breakdown Structure (WBS)

169

Table 2: Alternatives Design / Method.

Work Package

Alternative Design /

Method

Activity

WBS Level 4 WBS Level 5

Power House

MV Cubicle

Inspection

Maintenance

Treatment

Testing

LVMDB

Inspection

Maintenance

Treatment

Testing

Transformer

Inspection

Maintenance

Treatment

Testing

Backup Power Generator Diesel Generator

Inspection

Maintenance

Treatment

Testing

Renewable Energy Solar Panel

Inspection

Maintenance

Treatment

Testing

Uniterruptable Power

Supply

UPS Central

Inspection

Maintenance

Treatment

Testing

UPS Lokal

Inspection

Maintenance

Treatment

Testing

LVMDB Panel

LVMDB

Inspection

Maintenance

Treatment

Testing

Sub Distribution Panel

Inspection

Maintenance

Treatment

Testing

Connecting Board

Inspection

Maintenance

Treatment

Testing

Mini Circuit Breaker

Inspection

Maintenance

Treatment

Testing

Molded Case Circuit

Breaker

Inspection

Maintenance

Treatment

Testing

MV Panel

Vaccum Circuit

Breaker

Inspection

Maintenance

Treatment

Testing

Load Panel

AC Panel

Inspection

Maintenance

Treatment

Testing

Lighting Panel

Inspection

Maintenance

Treatment

Testing

Utility Panel

Inspection

Maintenance

Treatment

Testing

Cable

Medium Voltage

Cable

Inspection

Maintenance

Treatment

Testing

Low Voltage Cable

Inspection

Maintenance

Treatment

Testing

Lightning Control

System

Time Sensor

Inspection

Maintenance

Treatment

Testing

Lightning Protection

Lightning Rod -

Tight Wire

Inspection

Maintenance

Treatment

Testing

Lightning Rod -

Meshed Cage

Inspection

Maintenance

Treatment

Testing

Lightning

LED Lamp

Inspection

Maintenance

Treatment

Testing

Fluorescent Lamp

Inspection

Maintenance

Treatment

Testing

Grounding System Solid Grounding

Inspection

Maintenance

Treatment

Testing

Receptacle and Switch

Switch

Inspection

Maintenance

Treatment

Testing

Receptacle

Inspection

Maintenance

Treatment

Testing

ICIB 2019 - The 2nd International Conference on Inclusive Business in the Changing World

170

Table 2: Alternatives Design / Method. (cont.)

Under Floor Duct Under Floor Duct

Inspection

Maintenance

Treatment

Testing

CCTV System

DVR

Inspection

Maintenance

Treatment

Testing

CCTV Camera

Inspection

Maintenance

Treatment

Testing

Recorder

Inspection

Maintenance

Treatment

Testing

Fire and Alarme

Detector

Smoke Detector

Inspection

Maintenance

Treatment

Testing

Heat Detector

Inspection

Maintenance

Treatment

Testing

Fire Panel

Inspection

Maintenance

Treatment

Testing

Fire Alarm

Inspection

Maintenance

Treatment

Testing

Internet and Computer

Ethernet Server

Inspection

Maintenance

Treatment

Testing

Wifi

Inspection

Maintenance

Treatment

Testing

Signal Repeater

Telephone Signal

Repeater

Inspection

Maintenance

Treatment

Testing

Sound System

Mic

Inspection

Maintenance

Treatment

Testing

Speaker

Inspection

Maintenance

Treatment

Testing

Tape Recorder

Inspection

Maintenance

Treatment

Testing

Telephone PABX

Inspection

Maintenance

Treatment

Testing

While the implementation of activities is to

identify and document specific actions that will be

carried out to produce a deliverable project. The

main benefit of this process is the decomposition of

work packages into activity schedules that provide

the basis for estimating, scheduling, implementing,

monitoring and controlling project work. This

process is carried out throughout the project.

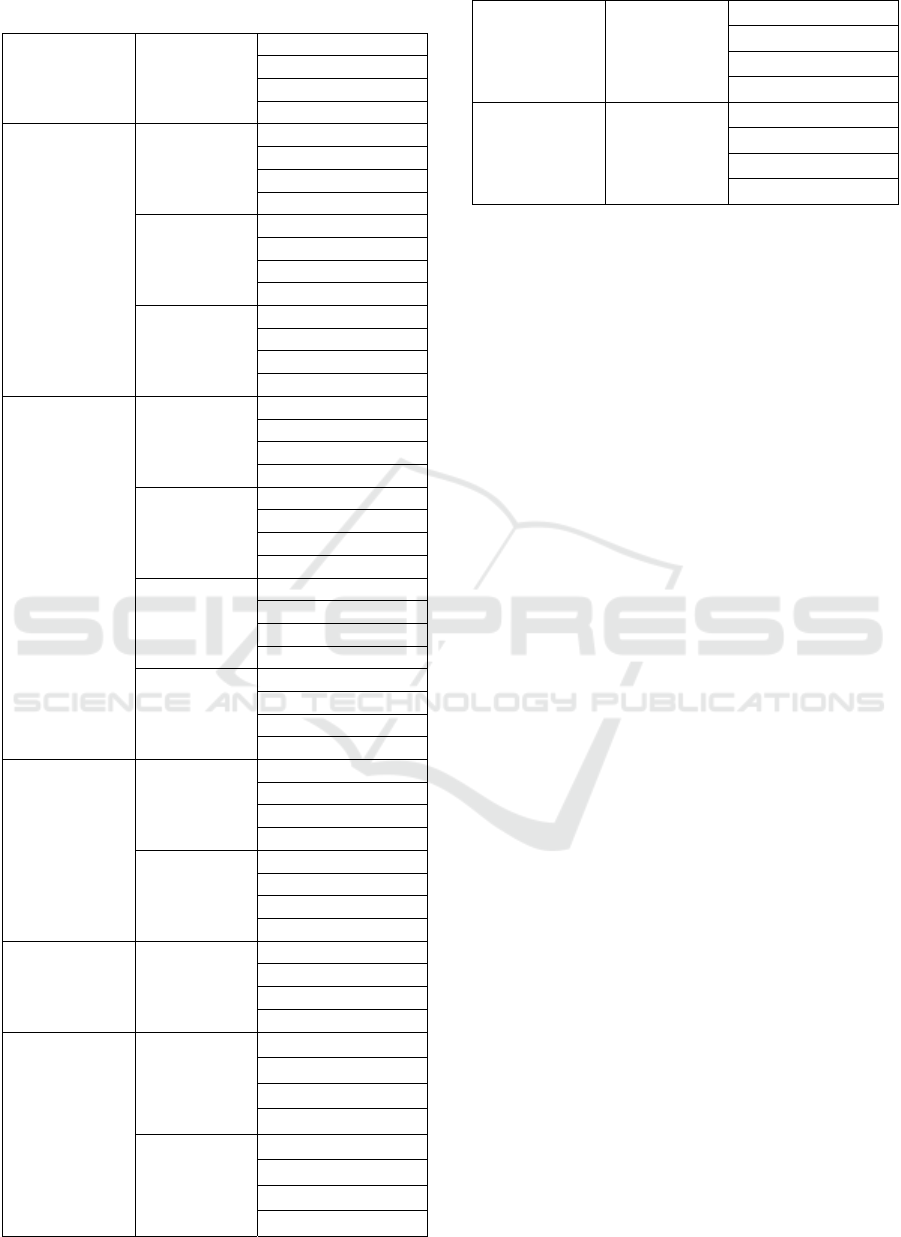

5.3 Level 6 WBS

To get the results in the third phasethe, the

researcher used Ministry Regulation of PUPR no.24

of 2008, PUIL documents about Electrical

Instalation, and Standard for Maintenance Testing

Spesification for inputs. Then for the analysis, I used

the the delphi method to collect opinions from

several experts using questionnaires. Every

maintenance and treatment activity requires

resources to complete its objectives. Resources

consist of materials, equipment, and men. In this

case, the researcher took the example of the work

package and transformer alternative design.

The implementation of good resource planning is

in accordance with the logical needs of the project

that will help achieve project suggestions and

objectives maximally.

5.4 Technical Specification

To get the results in the fourth phase, the researcher

used Ministry Regulation of PUPR no.24 of 2008,

PUIL documents about Electrical Instalation, and

Standard for Maintenance Testing Spesification for

inputs. Then for the analysis, I used the the delphi

method to collect opinions from several experts

using questionnaires. Technical specifications are

needed so that all materials used in maintenance and

treatment work are of equal quality. This makes it

easy for workers to choose the material used.

Technical specifications can also be used as

inspection activities and tested back to initial

performance.

Development of Implementation Guidelines for Maintenance and Treatment Work of Electrical Components in University of Indonesia

Buildings and Area based on Work Breakdown Structure (WBS)

171

Table 3: Work Breakdown Structure Level 5 & 6.

POWER HOUSE

TRANSFORMER

CODE DESCRIPTION

WBS LEVEL 2 WORK SECTION Electrical

WBS LEVEL 3 WORK TYPE

Electrical

Sources

WBS LEVEL 4 WORK PACKAGE Power House

DESIGN

ALTENATIVES/METH

OD

Transformer

LEVEL 5 WBS LEVEL 6 WBS

ACTIVITIES RESOURCES

Inspection

Materials -

Equipments

Personal protective

equipment, multimeter,

torque wrench, light tools,

temperature gun

Man

Electrical technician,

superviso

r

Maintenance

Materials Patchwork

Equipments

Personal protective

equipmen

t

Man

Electrical technician,

superviso

r

Treatment

Materials Spare parts

Equipments

Personal protective

equipment, multimeter,

torque wrench, special

tools

Man

Electrical technician,

superviso

r

Testing

Materials -

Equipments

Personal protective

equipment, multimeter,

torque wrench, special

tools

Man

Electrical technician,

superviso

r

The implementation of technical specifications is

to ensure the accuracy of measurement results

obtained in accordance with what has been

determined. In addition, the specifications are also

arranged in a complete and clear manner

regarding items, methods or final results of work

that can be purchased, built or developed by other

workers so that it can fulfill the wishes of all

stakeholders involved.

Table 4: Technical Specification.

TECHNICAL SPECIFICATION

1. Meets the SNI 0225: 2011 standards or the latest on

"General Requirements for Electrical Installations"

2. Meets the SNI IEC 60076: 2012 standards or most

recently on "Power Transformers"

3. Meets the ISO 14001: 2015 standards or the latest on

"Environmental Management"

5.5 Guideline Development

To get the results in the fifth phase, the researcher

used the previous project name, work section, work

package, work type, alternative design/method,

activity, resources, and technical spesification for

inputs. Then for the analysis, I used the delphi

method to get experts approval using questionnaires.

Then after expert validation on how to develop

guidelines based on the WBS (Work Breakdown

Structure) for maintenance and treatment work of

electrical components in buildings and areas at the

University of Indonesia, there are seven stages in

developing implementation guidelines. Starting from

knowing the project name, work section, work type,

work package, alternative design / method,

resources, and technical specifications.

With the development of WBS-based guidelines,

these guidelines become structured, measurable,

scheduled, and complete as well as to avoid the

failure to fulfill all components of maintenance and

treatment of electrical components because all

building facilities are supported by these

components. The use of electrical components can

be harmful to humans and the environment if not

done carefully so that these electrical components

must be safe and in their use must be in accordance

with the applicable provisions and standards so that

no damage can endanger the user (Suyono, et al.,

2011).

6 CONCLUSION

WBS-based guidelines of maintenance and treatment

electrical work are structured, complete, and can

avoid the mistakes of all work components so it can

make easier for users to easier and better understand

the steps of each process, so the process can be more

effective and efficient.

ACKNOWLEDGEMENTS

The Authors would like to thank the financial

support provided by the University of Indonesia

through PIT 9 funding scheme under Grant number

NKB-0087/UN2.R3.1/HKP.05.00/2019 managed by

the Directorate for Research and Public Services

(DRPM) University of Indonesia.

ICIB 2019 - The 2nd International Conference on Inclusive Business in the Changing World

172

REFERENCES

Achmada, A., 2013. Manajemen Perawatan dan

Perbaikan Bangunan Gedung Utama Rumah Sakit

Umum Daerah (RSUD). Pekanbaru: Titoti Press.

Arikunto, S., 2000. Manajemen Penelitian Jakarta.

Jakarta: Rineka Cipta.

Au-Yong, C., 2014. Preventive Maintenance

Characteristics Towards Optimal Maintenance

Performance: A Case Study of Office Buildings. Kuala

Lumpur: University of Malaya.

BPMA, 2007. Penjaminan Mutu Akademik Universitas

Indonesia. Depok: BPMA.

B. & S., 2012. Memahami Penelitian Kualitatif. Jakarta:

Rineka Cipta.

Direktorat Jenderal Cipta Karya, 2008. Peraturan Menteri

Pekerjaan Umum Nomor 24 Tahun 2008 Tentang

Pedoman Pemeliharaan dan Perawatan Bangunan

Gedung. Jakarta: Departemen Pekerjaan Umum.

Foley, R., 1972. Dairy Cattle Principles, Practices,

Problems, Profit.. Philadelphia: LEA & Febiger.

Hills, K. & Fowles, J., 1975. The Methodological Worth

of The Delphi Forecasting Technique Technological.

Technological Forecasting and Social Change, pp.

179-192.

Kerlinger, F., 1973. Foundations of Behavioural

Research. 2nd penyunt. New York: Holt, Rinehart, &

Winston.

Plavina, B. & Geipele, I., 2013. Chances For The

Development of Multiapartment Dwelling Houses'

Policy in Latvia. Latvia, Jelgava, LLU, EF, pp. 43-47.

Prayitno, B., 2018. Kepala Pengelolaan Penghematan

Energi Berkelanjutan Universitas Indonesia

[Wawancara] (4 October 2018).

Project Management Institute, 2013. Project Management

Body of Knowledge. Fifth penyunt. Pennsylvania:

Project Management Institute, Inc..

Republik Indonesia, 2002. Undang - Undang Nomor 28

Tahun 2002 tentang Bangunan Gedung. Jakarta:

Sekretariat Negara.

Son, L. & Yuen, G., 2002. Building Maintenance

Technology. London: Palgrave.

Sugiyono, 2006. Metode Penelitian Kuantitatif, Kualitatif,

dan R&D. Bandung: Alfabeta.

Suyono; Prasetyo, M.T.; Assafat, L, 2011. Tingkat

Keandalan Utilitas Kelistrikan Bangunan Gedung

Bertingkat di Kota Semarang. Semarang: Media

Elektrika.

Yin, R., 2013. Case Study Research. 4th penyunt. London:

SAGE.

APPENDIX

Indicators for Each Construct:

I

nspection

Get a permit and work permit related to the activities that

will be carried out

Conduct risk studies to find out the dangers that might occu

r

Use personal protective equipment according to the type of

wor

k

Check physical and mechanical conditions

Check anchorage, alignment and grounding

Check the condition of equipment parameters

Check the electrical bolt connection using a low-impeded

ohmeter, torque-wrench and / or conduct a thermographic

survey

Check the operation of the cooling fan

Check the surge arrestor condition

Check the condition of the alarm, function of the dick, trip

from the observer / protection equipmen

t

Record all findings and anomalies as further maintenance

activities

M

aintenance

Get a permit and work permit related to activities that will be

carried out

Conduct risk studies to find out the dangers that might occu

r

Use personal protective equipment according to the type of

wor

k

Secure equipment, turn off equipment or use LOTO

Clean the outside of the transformer (body and floor) from

dus

t

Adjust the temperature and air condition of the transformer

room

Tighten all cable strings on the terminal in the correct and

strong position

Perform calibration of measuring and protection devices

Record all the troubles or anomalies as further treatment

activities

Treatmen

t

Get a permit and work permit related to the activities that

will be carried out

Conduct risk studies to find out the dangers that might occu

r

Use personal protective equipment according to the type of

wor

k

Prepare all parts and materials needed

Secure equipment, turn off equipment or use LOTO

Replace parts (electrical, mechanical, measuring, and

protective equipment) that are damaged, obsolete or expired

Conduct testing activities to ensure that the installed parts

have the desired performance

Testing

Get a permit and work permit related to the activities that

will be carried out

Conduct risk studies

t

o find out the dangers that might occu

r

Use personal protective equipment according to the type of

wor

k

Measure resistance through the condition of a low-impeded

ohmeter bolt

Test coil insulation to coils and coils to groun

d

Get a permit and work permit related to the activities that

will be carried out

Conduct risk studies to find out the dangers that might occu

r

Use personal protective equipment according to the type of

wor

k

Perform turn-ratio tests at each tap position

Exitation-current test on each phase

Test the surge arresters

Record all test results and plan maintenance and

maintenance activities if there are inappropriate results.

Development of Implementation Guidelines for Maintenance and Treatment Work of Electrical Components in University of Indonesia

Buildings and Area based on Work Breakdown Structure (WBS)

173