Com-Ply Board Properties Made from Oil Palm Trunk Bonded with

Isocyanate, Phenol Formaldehyde and Urea Formaldehyde

Apri Heri Iswanto, Irawati Azhar, Tito Sucipto and Fazila Oktaviani Tarigan

Department of Forest Product, Faculty of Forestry, Universitas Sumatera Utara, Padang Bulan, Medan 20155, Indonesia

Keywords: Oil palm trunk, Com-Ply, PF, UF, Isocyanate.

Abstract: Problem of Indonesian wood industry is lack of wood as raw material. Need alternative materials to solve that

problem. Oil palm trunk is one of non-wood lignocellulosic material that potential to develop for material

substitution in the wood industry, especially of biocomposite industry. The objective of this research was to

evaluate of physical and mechanical properties of com-ply made from oil palm trunk bonded with UF, PF,

and isocyanate resin. The results showed that isocyanate resin produced the best properties of the board. All

parameters fulfill the requirement of JIS A5908 (2003). For all resin type, 7% adhesive level resulted in the

best properties of the board.

1 INTRODUCTION

The general problem of the Indonesiaan wood

industry is the lack of wood as raw material. Many

research had been done to find alternative material

from non-wood lignocellulosic materials. Oil palm

trunk is one of lignocellulose non-wood materials that

abundant in Indonesia. Sumatra islands are the

biggest plantations of oil palm in Indonesia. In the

plantation area, non-productive oil palm plant after

cutting process only became waste. This research

would try to utilize of oil palm trunk for biocomposite

materials, especially of the com-ply board.

Com-ply is biocomposite made from a

combination of particleboard for the core layer and

veneer for the surface layer (Tsoumis, 1991; Forest

Product Laboratory, 1999; Haygreen and Bowyer,

1985). Com-ply had better strength compared to

particleboard. Iswanto et al. (2017) reported that

utilization of veneer as a surface layer in

particleboard can improve the bending strength of

non-wood particleboard. In the producing of Com-

ply, adhesives have an essential role to result ining the

right product. Forest Product Laboratory (1999)

classified the adhesive into three types namely

exterior type (Phenol Formaldehyde-PF, Resorcinol

Formaldehyde-RF, Phenol Resorcinol

Formaldehyde, Isocyanate Emulsion, and Melamine

Formaldehyde-MF), limited exterior type (Melamine

Urea Formaldehyde-MUF, Isosianat, and Epoxy) and

interior type (Urea Formaldehyde and Casein). The

objective of this research was to evaluate properties

of com-ply made from oil palm trunk bonded with

Isocyanate, Phenol-Formaldehyde and Urea

Formaldehyde.

2 MATERIALS AND METHODS

2.1 Materials

Materials were used in this research consisted of oil

palm trunk (Elaeis guineensis Jacq.) was collected

from a plantation in North Sumatra, Meranti wood

veneer and Isocyanate, Phenol-Formaldehyde (PF)

and Urea Formaldehyde (UF) resin.

2.2 Methods

The com-ply board was fabricated in size of 25 by 25

cm with density and thickness target of 0.7 g/cm3 and

1 cm respectively. Resin variation in that determined

in this research was 3, 5, and 7%. Com-ply board

composition consisted of veneer used as a surface

layer (face and back) and particle of oil palm trunk

used as a core layer. Detail manufacturing process

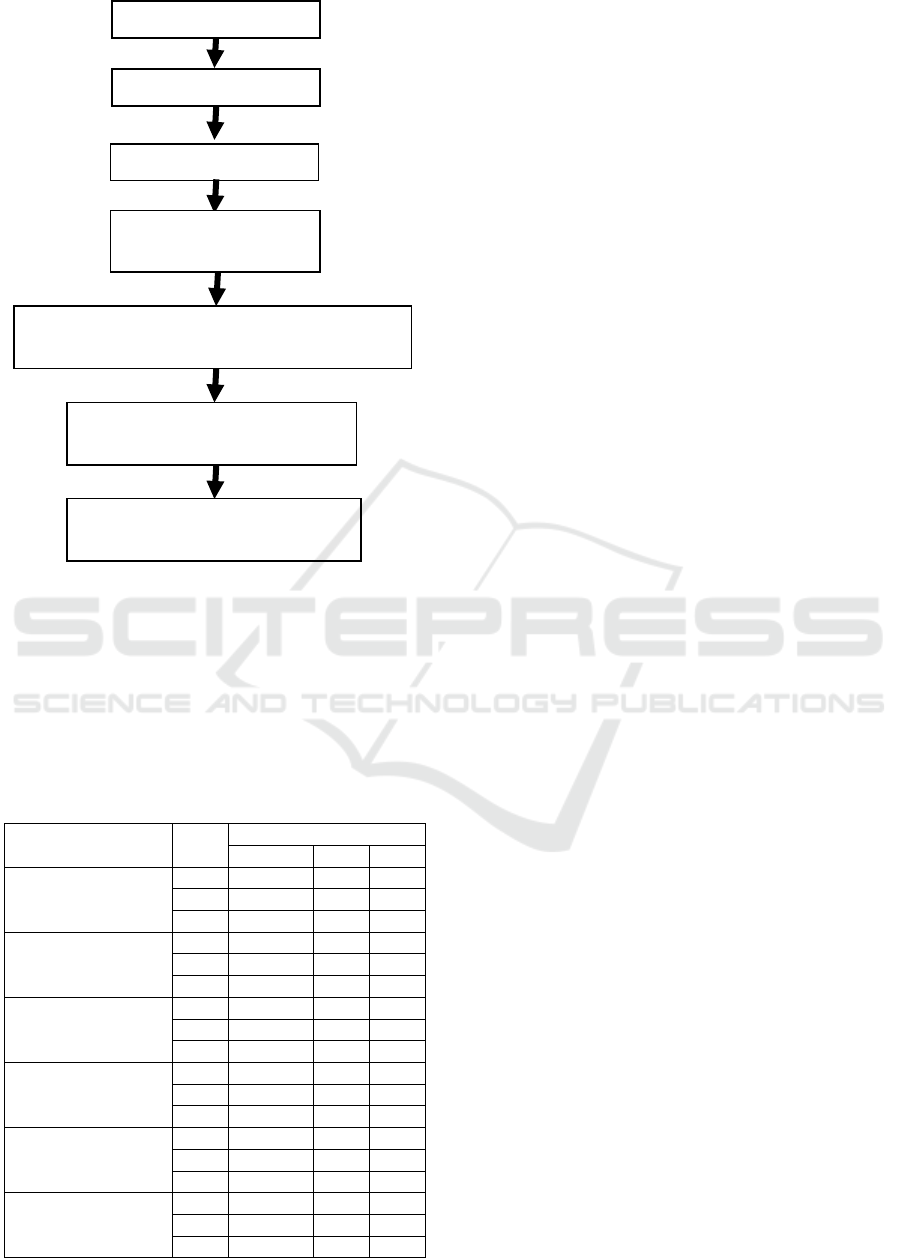

showed in Fig.1.

Iswanto, A., Azhar, I., Sucipto, T. and Tarigan, F.

Com-Ply Board Properties Made from Oil Palm Trunk Bonded with Isocyanate, Phenol Formaldehyde and Urea Formaldehyde.

DOI: 10.5220/0008386500050007

In Proceedings of the International Conference on Natural Resources and Technology (ICONART 2019), pages 5-7

ISBN: 978-989-758-404-6

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

5

Figure 1: Diagram of com-ply manufacturing.

3 RESULT AND DISCUSSION

The properties of com-ply results of this research

shown in Table 1.

Table 1: Data of physical and mechanical properties com-

ply board.

Parameters

Resin

Level

Resin Type

Isocyanate

PF

UF

Thickness Swelling

(%)

3

25.17

43.73

61.60

5

21.94

32.65

60.88

7

17.80

25.56

59.93

Water Absorbtion (%)

3

50.51

141.03

105.97

5

57.94

90.86

98.14

7

51.43

71.67

88.87

Modulus of Elasticity

(kg/cm

2

)

3

63,644

65,116

26,254

5

55,291

76,101

38,227

7

60,653

78,020

40,886

Modulus of Rupture

(kg/cm

2

)

3

626

475

195

5

625

505

192

7

639

548

234

Internal Bond

(kg/cm

2

)

3

3.38

2.73

0.31

5

5.05

3.03

0.57

7

5.76

3.98

0.62

Screw Withdrawl

(kg/cm

2

)

3

37.9

27.50

20.98

5

51.6

33.19

25.57

7

54.8

41.21

35.76

3.1 Physical Properties

3.1.1 Thickness Swelling (TS) and Water

Absorption (WA) of Board

Thickness swelling values of the board were varied

from 17.80%

to 61.60%. Isocyanate resin resulted in

the lowest value of TS. Chemical bonding of

isocyanate resin resulted in good bonding compared

to PF and UF resin. Isocyanate group (–N=C=O) will

react with the hydroxyl group (OH) from wood

resulted in urethane (Teco, 2005 and Mara, 1992).

Combination factors such as a non-polar, aromatic

compound of Isocyanate more resistant to hydrolysis.

Furthermore, the trend of the data showed that a high

level of resin resulted in decreasing of TS value for

all resin type. It similar research that conducted by

Iswanto et al. (2018a, 2018b, 2019), They reported

that effect of increasing adhesive level on decreasing

the TS of passion fruit hulls particleboard bonded

with UF resin. JIS A 5908 (2003) requiring of

maximum TS value is 12%, all adhesive types in this

research did not fulfill of standard. UF resin had the

highest value of TS. It is worst resin in order to

dimensional stability because UF more easy

hydrolysed of the hidrogen bond as a result of

humidity, strong acid, especially in medium to a high

temperature so UF (Pizzi 1994).

Water absorption values of the board were varied

from 50.51%

to141.03%. Similar trend data with TS

value also shown in WA, isocyanate resin resulted in

lowest WA value. Even though in the lowest resin

level (3%), isocyanate produced better dimensional

stability compared to PF. Teco (2005) and Mara

(1992) stated that compared to PF and UF, the

adhesive bond of isocyanate resin is chemical bond,

so that results of stable bond and strong.

3.2 Mechanical Properties

3.2.1 Modulus of Elasticity (MoE) and

Modulus of Rupture (MoR)

The MoE values of board were varied from 26,254.42

to 78,020.03 kg/cm

2

. PF resin produced by hihgest

MoE value. Generally, PF and isocyanate resin had

fulfilled JIS A 5908 (2003) that requirement the

lengthwise of MoE minimum of 40,000 kg/cm

2

. The

adhesive level had a linier correlation with MoE

value. The increasing of adhesive level produced of

higher MoE value. Maloney (1993) stated that MoE

affected by amount and adhesives type, adhesive

bond, and fiber length of particle. The difference of

Oil Palm Trunk

Sawdust

Drying (MC~ 5-7%)

Blending

Sawdust+Resin

Mat Forming

Surface: Veneer; Core: Particleboard

Conditioning

(1 week)

Physical and Mechanical Testing

(JIS A 5908 – 2003)

ICONART 2019 - International Conference on Natural Resources and Technology

6

resin level had a significant effect on mechanical

properties.

The MoR values of the board were varied from

192.56 to 639.43 kg/cm

2

. JIS A 5908 (2003) that

requirement the lengthwise of MoR minimum of 300

kg/cm

2

. Similar with MoE value, PF and Isocyanate

resin resulted in higher MoR value, and the higher

level of adhesive produced of greater MoR value.

Bowyer et al. (2003) stated that the increasing of resin

up to optimum condition resulted in the rise of MoR

value, the excess of resin did not result significant

effect on MoR value.

3.2.2 Internal Bond (IB) and Screw

Withdrawl (SW)

Internal bond values were varied from 0.31 to 5.76

kg/cm

2

. JIS A 5908 (2003) that requirement of IB

minimum of 3 kg/cm

2

. Board bonded with UF resin

did not fulfill standard, meanwhile of PF and

isocyanate resin overall meet the standard excepted of

3% level for PF resin. Data trend showed that higher

resin level resulted in better IB value for all resin type.

Haygreen and Bowyer (1985) stated that the internal

bond would be perfect as the adhesive level increases.

Screw withdrawal values were varied from 20.98

to 54.82 kg. JIS A 5908 (2003) that requirement SW

minimum of 51 kg. According to the standard, only

isocyanate resin at 5 and 7 level that fulfill the

requirement of JIS A 5908 (2003). Similar to the

previous mechanical properties, the increasing of

adhesive level caused of increasing of SW value.

4 CONCLUSIONS

Over all com-ply bonded with isocyanate resin fulfill

JIS A 5908 (2003). For UF and PF adhesives, resin

level 7% produced the best of physical and

mechanical properties of com-ply. While for

isocyanate resin, 3% level can be produced of com-

ply that fulfill of standard.

REFERENCES

Bowyer J. L., Shmulsky, Haygreen J. G. 2003. Forest

Products and Wood Science: an Introduction. Lowa

State University Press, 4

th

edition.

Forest Product Laboratory. 1999. Wood Hand Book: Wood

as an Engineering Material. Agric Handbook 72.

Washington DC. US department.

Iswanto, A. H., Aritonang, W., Azhar, I., Fatriasari, W.

2017. The physical, mechanical and durability

properties of sorghum bagasse particleboard by

layering surface treatment. Journal of the Indian

Academy of Wood Science 14(1): 1-8.

Iswanto, A. H., Sucipto, T., Adlina E., Prabuningrum D. S.

2018a. Passion fruit hulls particleboard: the effect of

urea formaldehyde level on physical and mechanical

properties. In IOP Conf. Series: Earth and

Environmental Science, International Conference on

Agriculture, Environment, and Food Security (AEFS)

2017. 122: 012138

Iswanto, A. H, Anjarani, H. D. 2018b. The Properties of

Sandwich Particleboard (SPB) Made From Bamboo

Belangke and Corn Stalk Bagasse Bonded With

Isocyanate in Various Levels. In IOP Conf. Series:

Earth and Environmental Science, International

Conference on Biomass 2018. 209: 012031

Iswanto, A. H, Sucipto, T., Suta, T. F. 2019. Effect of

Isocyanate Resin Level on Properties of Passion Fruit

Hulls (PFH) Particleboard. In IOP Conf. Series: Earth

and Environmental Science, The 1st Biennial

Conference on Tropical Biodiversity 2018. 270:

012021

Japanese Standard Association. 2003. Japanesse Industrial

Standard Particle Board JIS A 5908. Japanese

Standard Association. Jepang.

Haygreen, J. G., Bowyer, J. L. 1985. Forest product and

wood science: an introduction. Lowa State University

Press, 3

rd

Edition.

Maloney, T. M. 1993. Modern Particleboard and Dry

Process Fiberboard Manufacturing. Miller Freeman

Inc. San Francisco.

Marra, A. A. 1992. Technology of Wood Bonding

Principles in Practise. New York: Van Nostrand

Reinhold.

Pizzi, A. 1994. Advanced Wood Adhesives Technology.

Marcel Dekker, Inc. New York. USA

Teco. 2005. Resins Used In The Production of Oriented

Strand Board. Tech tips No. 14. USA.

Tsoumis, G. 1991. Science and Technology of Wood:

Structure, Properties, Utilization. Van Nostrand

Reinhold, New York.

Com-Ply Board Properties Made from Oil Palm Trunk Bonded with Isocyanate, Phenol Formaldehyde and Urea Formaldehyde

7