Power Supply Meshes based Line Routing for Urban MV

Distribution Network Planning

Ning Luo

1, a

, Hua Gao

1, b

, Zhuding Wang

2, c

, Molin He

1, d

1

Power grid planning research centre of Guizhou Power Grid Co., Ltd,Chongqing, 550000, China

2

State Key Laboratory of Power Transmission Equipment & System Security and New Technology, Chongqing University,

Chongqing 400044, China

Keywords: MV line routing planning, power supply mesh, shortest path algorithm, two-step algorithm, trunk line.

Abstract: Considering that it is difficult to determine the load points or the locations of user access facilities in urban

areas for the planning years, an optimization method for the routing planning of urban medium - voltage

(MV) trunk lines is proposed based on power supply meshes. Firstly, based on the results of load forecasting

and high voltage substation planning, power supply meshes are generated in the entire planning area

according to the principle of selecting standby substations close to loads. Then, based on the thinking line of

“trunk firstly, branch then”, a shortest path based two-step algorithm is proposed to find the shortest trunk

lines for the load centres of power supply meshes and the shortest trunk tie-line be-tween the load centres of

each mesh. A numerical example shows that the method is practical and feasible, which can provide a

reference for the reasonable routing scheme of medium voltage trunk lines.

1 INTRODUCTION

At present, most of the medium-voltage line routing

planning methods need to know the layout of load

points or the locations of user access facilities (such

as distribution transformers, switching stations or

ring network units) for the planning years (

Song

Meng, Liu Jian, Liu Gongquan, 2005; LI You, CHANG

Xianrong, 2013; LU Zhi-ying, TIAN Shuo, CHENG

Liang, et al, 2014; GE Shaoyun, WU Qing, et al, 2005;

Koutsoukis N C , Georgilakis P S, 2017

). Those

methods may be suitable for the rural distribution

network planning, but are not effective enough for

the urban distribution network planning because of

the difficulty in determining the locations of user

access facilities for the planning years. In recent

years, the power supply meshes based MV

distribution network planning has been carried out

successively in power grid enterprises (

Ming Xu,

Wang Zhuding, Wang Jingyu, etc, 2018; Wang Jingyu,

Wang Zhuding, Zhang Yongbin, et.al, 2018; Gu yuan,

2018)

. For the large-scale MV distribution net-work

planning, the main purpose of power supply meshes

based planning is to transform the large-scale

complex network planning of whole planning area

into relatively simple and independent network

planning for much smaller power supply meshes

with the mesh generation being satisfying the

technically feasible and economically optimal

principle for the whole network planning.

In this paper, the power supply meshes are firstly

generated in the entire planning area according to

the principle of selecting standby substations near

loads, and then based on the thinking line of “trunk

firstly, branch then”, a shortest path based two-step

algorithm is proposed for MV line routing planning

to find the shortest power supply trunk lines for the

load centres of power supply meshes and the

shortest trunk tie-line between the load centres of

each mesh. It is shown through a numerical example

that the thinking line and method presented in this

paper are of great practical value for MV line

routing planning.

2 MESH OPTIMIZATION

GENERATION

In this paper, a mesh is defined as the moderately

sized area supplied by the two substations (i.e., the

main supply one and standby one). Based on the

layout of main channels, the standby substations

310

Luo, N., Gao, H., Wang, Z. and He, M.

Power Supply Meshes based Line Routing for Urban MV Distribution Network Planning.

DOI: 10.5220/0008386403100316

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 310-316

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

(a) inter-substation mesh

Inter-substation mesh

Load A1 Load B1

Substation A Substation B

Power supply area A1

Power supply area B1

(b) intra-substation mesh or radiation mesh

intra-substation mesh

radiation mesh

Power supply

area A3

Power supply

area A1

Power supply

area A2

Substation

A

Figure 1. Diagrams of tie-line mode based mesh classification.

close to loads are selected in the whole planning

area, resulting in the optimized meshes. The specific

steps of mesh optimization generation are as follows

(

Ming Xu, Wang Zhuding, Wang Jingyu, etc, 2018):

(1) Determining the main supply substation for

each load

Firstly, the power supply area of each substation

is obtained according to the substation optimization

planning (

Wang Yujin, 2011; HUO Kailong, WANG

Zhuding, ZHANG Daihong, et al, 2017)

, and then each

substation is called the main supply substation of the

loads in its power supply area. Taking the simplified

system shown in Fig.1 (a) as an example, if loads A1

and B1 respectively are located in the power supply

areas of substations A and B, the main supply

substations of loads A1 and B1 are respectively

substation A and substation B.

(2) Determining the standby substation for each

load

Based on the layout of main channels and an

allowable power supply radius, the possible standby

substation close to a load is found. Taking Fig.1 (a)

as an example, the standby substations of loads A1

and B1 are respectively identified as substation B

and substation A because they are closest to loads

A1 and B1 except for the loads’ main supply ones.

(3) Generating inter-substation meshes

In this paper, the inter-substation mesh is defined

as the area whose power supply substations can be

transferred between two substations. The inter-

substation mesh generation method is to firstly d

classify the loads of the same main supply substation

and the same standby substation into one supply

area, and to then merge the two supply areas with

opposite main and standby substations into one

inter-substation mesh.

Taking Fig.1 (a) as an example, the main and

standby substations of all loads (e.g. load A1) in

supply area A1 are respectively substation A and

substation B, and the main and standby substations

of all loads (e.g. load B1) in supply area B1 are

respectively substation B and substation A. Since the

main and standby substations of supply area A1 and

supply area B1 are opposite, they can be merged into

an inter-substation mesh involving substations A and

B.

(4) Generating intra-substation meshes and

radiation meshes

In this paper, an intra-substation mesh is defined

as the power supply area whose supply feeders can

be transferred between the different feeders from the

same substation, and a radiation mesh is defined as

the power supply area with no standby supply

substation or tie-line.

Power Supply Meshes based Line Routing for Urban MV Distribution Network Planning

311

For the loads which cannot be classified into

inter-substation meshes and are within the power

supply area of a certain substation, they are

classified into moderately sized areas based on

expert experience or a load clustering method. Then,

according to actual demand and the principle of

selecting standby feeders close to load centres, the

intra-substation meshes or radiation meshes are

generated with the main channel layout and the

power supply radius being satisfied, as shown in Fig.

1 (b).

(5) Manual intervention

Other issues of a power supply mesh may

include clear physical geography and management

boundaries, the same or close load classification

levels, the same power supply reliability

requirement, and the approximate same load sizes of

supply areas. Planners need to use their experience

to first analyse and then further adjust a mesh

generation scheme through manual intervention.

3 NETWORK MODEL

Based on an urban road network, the network model

of candidate channels for line routing and

corresponding network node types are defined.

3.1 Channel Network

With an urban road network being regarded as the

candidate channels for line routing, a channel

network can be represented by the weighted

undirected graph

,,

g

ggg

GVEW

()

, where

12

, ...

g

gg gn

VVVV()

and

g

E

respectively represent channel

nodes and the set of edges between channel nodes

(i.e., the segments of candidate channels),

g

W

is the

set of comprehensive costs for the corresponding

edges in

g

E

.

As in (

WANG Zhuding, QIU Jun, 2002), all

network edges (or segments) can be divided into two

subsets: 1) branches and 2) links. The branches are

the edges constituting the graph tree of network

along with the nodes, and the other network edges

are the links.

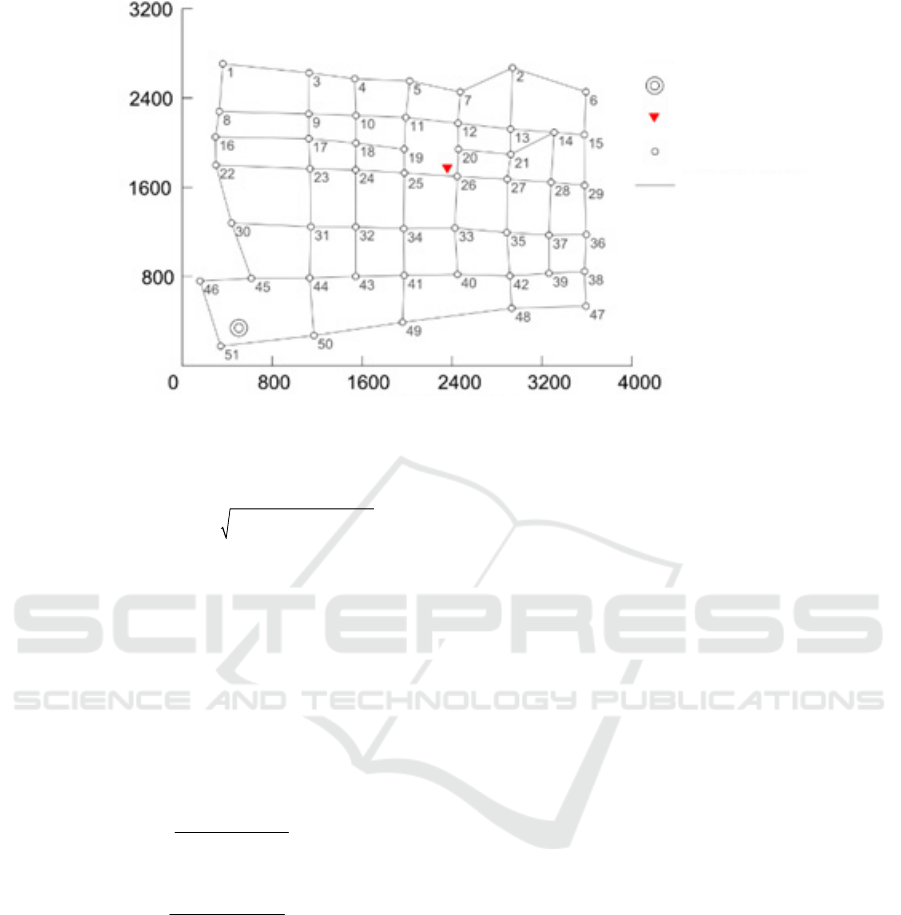

3.2 Node Classification

Channel network nodes are geographically divided

into three types: high voltage substation nodes, load

centre nodes and common nodes. In Fig.2, node #51

is a substation node, and node #26 is a load centre

node.

4 OPTIMIZATION MODEL OF

TRUNK LINE ROUTING

4.1 Optimization Model

For each of relatively independent meshes, the

optimization planning of trunk line routing is carried

out with the objective of minimizing the overall cost

of trunk lines with the connectivity of trunk line

channels being satisfied and the supply areas’ load

centres being passed through by trunk line channels

(hereafter abbreviated as a load centre constraint).

The corresponding routing optimization model can

be expressed as follows.

,

,g,

MV ,

MV ,

min , 1, ,

()1

..

()1

gi

g

ib m

bE

gi

gi

f

CiN

E

st

E

…

(1)

Where,

m

N

is the total number of all power

supply meshes,

,gi

E

is the set of channel segments

(or edges) for the trunk line in mesh i,

,gb

C

is the

comprehensive line cost of channel segment (edge)

i,

MV ,

()

gi

E

and

MV ,

()

gi

E

are respectively the

judgment functions of load centre constraint and

connectivity of trunk line channels corresponding to

,gi

E

(Being equal to 1 represents that the load centre

constraint or the connectivity is satisfied).

4.2 Determining of Load Centres

Let the coordinates of load point j in power supply

area i be (xj, yj). Considering that a load moment

(i.e., a load power multiplied by the distance

between the load and its supply substation) is

approximately proportional to the corresponding

voltage loss, investment and operation cost, the

selection of load centre position (xA,i, yA,i) for

supply area i should minimize the sum of all load

moments for the load points within power supply

area i,. Thus, we have

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

312

Abscissa of channel nodes / m

Ordinate of channel nodes / m

substation site

load center

channel nodes

candidate

channel path

Figure 2. Diagram of node classification.

,,

22

,,,

min - -

LP i LP i

Ai j j Ai Aiij

jS

j

j

j

S

fL xyyPxP

(2)

Where

j

P

is the active power of load point j,

,

L

Pi

S

is the set of all load points within power supply

area i,

,ij

L

is the distance between the load centre of

supply area i and load point j.

Let

,,

/0

Ai Ai

df dx

and

,,

/0

Ai Ai

df dy

, the load

centre coordinates of power supply area i can be

given by

,

,

,

,

,

,

/

/

/

/

LP i

LP i

LP i

LP i

jj ij

jS

Ai

jij

jS

jj ij

jS

Ai

jij

jS

Px

x

P

Py

y

P

L

L

L

L

()

,

()

()

()

(3)

Given the initial load centre location of a power

supply area, the final load centre location can be

obtained iteratively by an alternating method of

location and power allocation (

Wang Yujin, 2011).

5 SHORTEST PATH BASED TWO-

STEP ALGORITHM

If the load centres of supply areas are known, based

on the shortest path algorithm (

Gong Qu, 2009), the

routing of trunk lines from the load centres to their

main supply substations is performed firstly, and

then the routing of the trunk lines between the two

load centres in a mesh is carried out.

(1) Routing from a load centre to its main supply

substation

Firstly, a virtual node is created and the

comprehensive costs between the virtual node and

all main supply substations are assumed to be zero,

while the comprehensive costs between the virtual

node and the other channel network nodes are

assumed to be a large number. Then, taking the

virtual node as the root node of a shortest path tree,

all other channel network nodes are added to the

shortest path tree one by one according to the

adjacent relationship between the nodes and the

comprehensive line costs of paths between them and

the root node by using a shortest path algorithm,

until the shortest path tree contains all load centre

nodes. Based on the parent node information, the

shortest path from a load centre node to its main

supply substation node is obtained (i.e., the trunk

line path).

(2) Routing between load centres

Firstly, a virtual node is created and the

comprehensive costs between the virtual node and

all load centres are assumed to be zero, while the

comprehensive costs between the virtual node and

the other channel network nodes are assumed to be a

large number. Secondly, taking the virtual node as

the root node of a shortest path tree, all other

channel network nodes are added to the shortest path

Power Supply Meshes based Line Routing for Urban MV Distribution Network Planning

313

tree one by one according to the adjacent

relationship between the nodes and the

comprehensive line costs of paths between them and

the root node by using a shortest path algorithm,

until the shortest path tree contains all channel

network nodes. Then, the basic loop of a link is

identified based on the information of its end nodes

and parent nodes (

WANG Zhuding, QIU Jun, 2002).

Finally, the shortest inter-substation or intra-

substation path is extracted from the basic loop with

the smallest comprehensive cost for each inter-

substation or intra-substation mesh (i.e., the trunk

tie-line path).

6 A NUMERICAL EXAMPLE

The following example is to perform the routing of

10kV trunk lines in an urban area where there are 16

110kV substations, 387 channel segments, 227

network nodes and 58 supply areas.

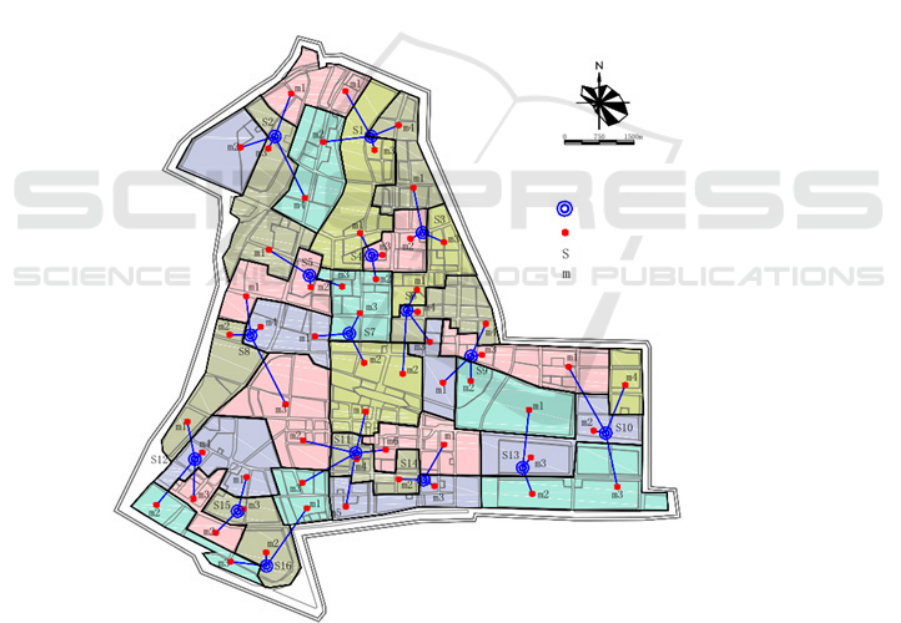

The meshes produced by the presented method

are shown in Fig.3 (a). The adjacent patches with the

same filling colour belong to the same mesh, and

only two of them are radiation meshes for which

only the trunk line paths need to be found.

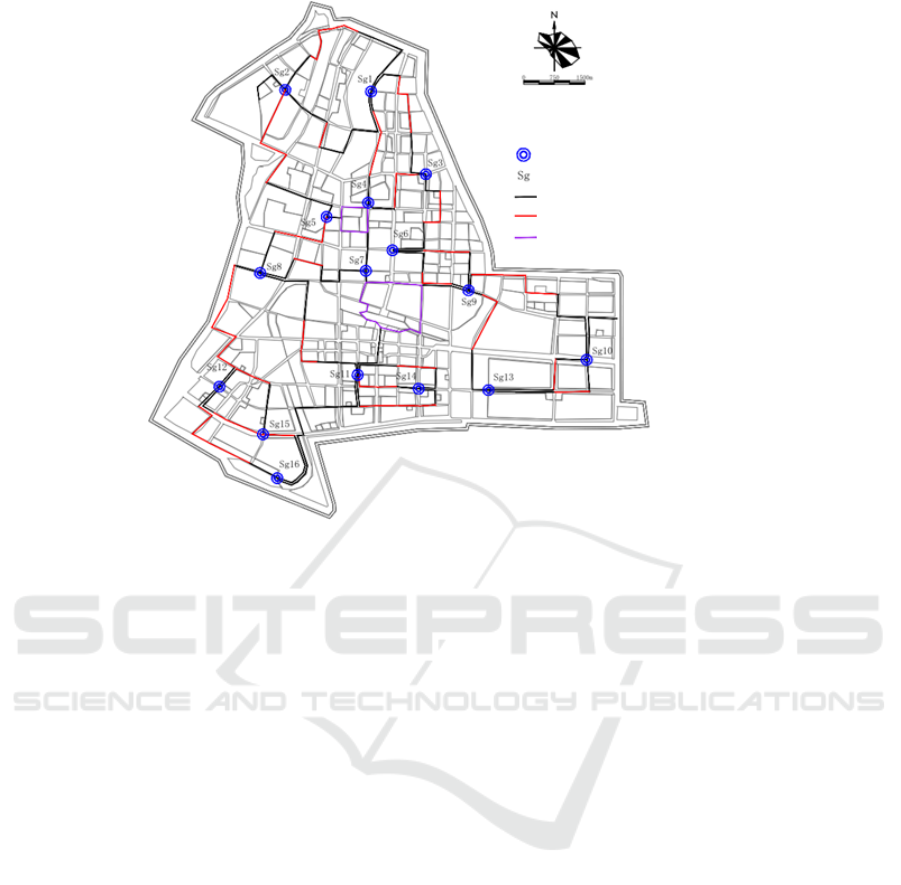

According to the generated meshes and the load

centres of supply areas, the routing results of trunk

lines are shown in Fig.3 (b) where the purple

channels contain 2 feeders, and the other channels

contain 4 feeders. For the line wiring modes of

different meshes, the typical modes such as double

loops, N-supplies and one-backup and multi-

segment moderate tie connection can be selected

according to the actual situations (such as the load

density, power supply capacity, economy and

operability).

Load center

Substation node

Supply area

(a) Generated power supply meshes

110kV substation site

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

314

110kV substation site

Substation node

Trunk tie line path (4 feeders)

Trunk tie line path (2 feeders)

(b) Trunk line routing scheme

Trunk line path (4 feeders)

Figure 3. Generated power supply meshes and trunk line routing scheme.

7 CONCLUSIONS AND

DISCUSSIONS

A new method is proposed for the trunk line routing

for urban medium voltage distribution network

planning.

(1) A new thinking line is proposed for line

routing in this paper: based on generated meshes, the

routing of trunk lines is firstly performed along the

channels of a road network, and then the specific

scheme of user access to the trunk lines will be made

in the future when the locations of user access

facilities are known.

(2) To simplify the problem solution, the supply

areas are taken as the basic units of a power supply

mesh, and a power supply mesh may be taken as the

basic unit to carry out the trunk line routing. With

the constraints of channel resources and load centres

being satisfied, the shortest trunk line paths for all

supply areas and the shortest trunk tie-line paths for

all supply meshes are determined by a shortest path

algorithm.

(3) The proposed method results in a planning

scheme of clear power supply areas, reasonable

power supply radii and simple tie-lines, showing that

the method is practical and can provide a reference

for the trunk line routing of urban medium voltage

distribution network planning.

REFERENCES

GE Shaoyun, WU Qing, et al. Study on optimization of

the tie lines for urban medium voltage distribution

network [J]. Proceedings of the CSU-EPSA, 2005,

17(06): 43-49.

Gong Qu, Graph theory and network optimization

algorithm [M]. Chongqing: Chongqing University

Press, 2009.

Gu yuan, Guiding principles for grid planning of

distribution network[S], State Drid Corporation of

China, 2018.

HUO Kailong, WANG Zhuding, ZHANG Daihong, et al.

Practical Method of Multi-stage Planning

Optimization for Large-scale Substation [J].

Proceedings of the CSU-EPSA, 2017, 29(5): 122-128.

Koutsoukis N C, Georgilakis P S, Hatziargyriou N D.

Multistage Coordinated Planning of Active

Distribution Networks [J]. IEEE Transactions on

Power Systems, 2017:1-1.

LI You, CHANG Xianrong. Distribution network

intelligent planning consider feeder line automatic

layout and tie-line wiring investment [J]. Automation

of Electric Power Systems, 2012, 36(14): 30-35.

LU Zhi-ying, TIAN Shuo, CHENG Liang, et al.

Automatic planning about single loop distribution

Power Supply Meshes based Line Routing for Urban MV Distribution Network Planning

315

network based on improved ACO [J]. Proceedings of

the CSU-EPSA, 2014, 26(06): 47-53.

Ming Xu, Wang Zhuding, Wang Jingyu, etc. Medium-

voltage Distribution Network Planning Based on Mesh

Optimization Generation [J]. Automation of Electric

Power Systems, 2018, 42(22):232-242.

Song Meng, Liu Jian, Liu Gongquan. Urban distribution

network planning based on optimal partition-ing [J].

Relay, 2005, 33(23): 31-35.

Wang Jingyu, Wang Zhuding, Zhang Yongbin, et.al.

Three Layer Macro Network Constraint Based

Precision Planning of Middle Voltage Distribution

Networks [C]. Proceedings of 2018 3rd International

Conference on Electrical Engineering, Mechanical

Engineering and Automation (ICEEMEA2018), 2018:

13.

Wang Yujin. Substation Planning through Decreasing

Initial Redundant Substation in Meshes. [D].

Chongqing: College of Electrical En- gineering of

Chongqing University, 2011.

WANG Zhuding, QIU Jun. An efficient algorithm for

assessing reliability indexes of general distribution

sys-tems. IEEE Transactions on power systems, 2002,

17 (3): 608-614.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

316