Design and Characterization of Synthetic Biodegradable Films for

Soft Tissue Engineering

Sofia Ribeiro

1,2 a

, Emanuel M. Fernandes

4,5 b

, Manuela E. Gomes

4,5 c

, Rui L. Reis

4,5 d

,

Yves Bayon

1 e

and Dimitrios I. Zeugolis

2,3 f

1

Institute Medtronic, Sofradim Production, Trevoux, France

2

Regenerative, Modular & Developmental Engineering Laboratory (REMODEL),

National University of Ireland Galway (NUI Galway), Galway, Ireland

3

Science Foundation Ireland (SFI) Centre for Research in Medical Devices (CÚRAM),

National University of Ireland Galway (NUI Galway), Ireland

4

3B’s Research Group – Biomaterials, Biodegradables and Biomimetics, University of Minho Headquarters of the

European Institute of Excellence on Tissue Engineering and Regenerative Medicine, Guimarães, Portugal

5

ICVS/3B’s – PT Government Associate Laboratory, Braga/Guimarães, Portugal

1 RESEARCH PROBLEM

To repair soft tissue, it is vital to ensure that the

biomaterial is able to mimic the complex elasticity

and topography of the native tissue. Huge efforts have

been invested into the development and design of

appropriate elastomeric biomaterials to match the

tissue of choice. However most of past studies have

used non-degradable polymers as substrates. In order

to obtain an optimal tissue engineered approach it is

vital to study the effect of biodegradable polymers.

The goal of the present study is to characterize

extensively a set of biodegradable polymeric micro-

grooved films and to assess its effect on cell adhesion,

morphology and phenotype through optimal substrate

rigidities.

2 OUTLINE OF OBJECTIVES

Production of biodegradable polymeric films with a

range of different stiffness.

Characterization of the physico-chemical and

mechanical properties of the polymeric films.

Assessment of the impact of substrate rigidity on

cell adhesion, proliferation and differentiation

potential.

a

https://orcid.org/0000-0002-0265-0416

b

https://orcid.org/0000-0002-4296-2529

c

https://orcid.org/0000-0002-2036-6291

d

https://orcid.org/0000-0002-4295-6129

e

https://orcid.org/0000-0002-0232-3079

f

https://orcid.org/0000-0002-7599-5191

Optimization of imprinting of micro-sized

grooves in the polymeric films.

3 STATE OF THE ART

Current surgical interventions are based on tissue

grafts; synthetic/natural biomaterials; direct cell

injections; and combinations of cells and a carrier

system. However, preclinical and clinical trials

revealed that tissue grafts are characterised by

delayed remodelling and substandard mechanical

function (Zeugolis et al., 2011); natural/synthetic

biomaterial-based substitution yields thinner and

weaker neotissue (Zeugolis, Chan and Pandit, 2011);

direct cell injections offer little control over localised

retention and distribution of the injected cell

suspensions, leading to scattered therapeutic

efficiency; and the presence of the carrier in the

cell/carrier system hinders normal tissue remodelling

and function (Abbah et al., 2014). All in all, current

surgical repairs do not restore soft tissue function,

imposing the need for new functional and clinically

relevant/viable regeneration strategies.

Research efforts have been directed towards

reconstruction of more functional in vitro

microenvironments using biopolymers (Gomes et al.,

2017) with optimized surface topography

(Vermeulen et al., 2019) and substrate stiffness (Li et

28

Ribeiro, S., Fernandes, E., Gomes, M., Reis, R., Bayon, Y. and Zeugolis, D.

Design and Characterization of Synthetic Biodegradable Films for Soft Tissue Engineering.

In Doctoral Consortium (BIOSTEC 2019), pages 28-32

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

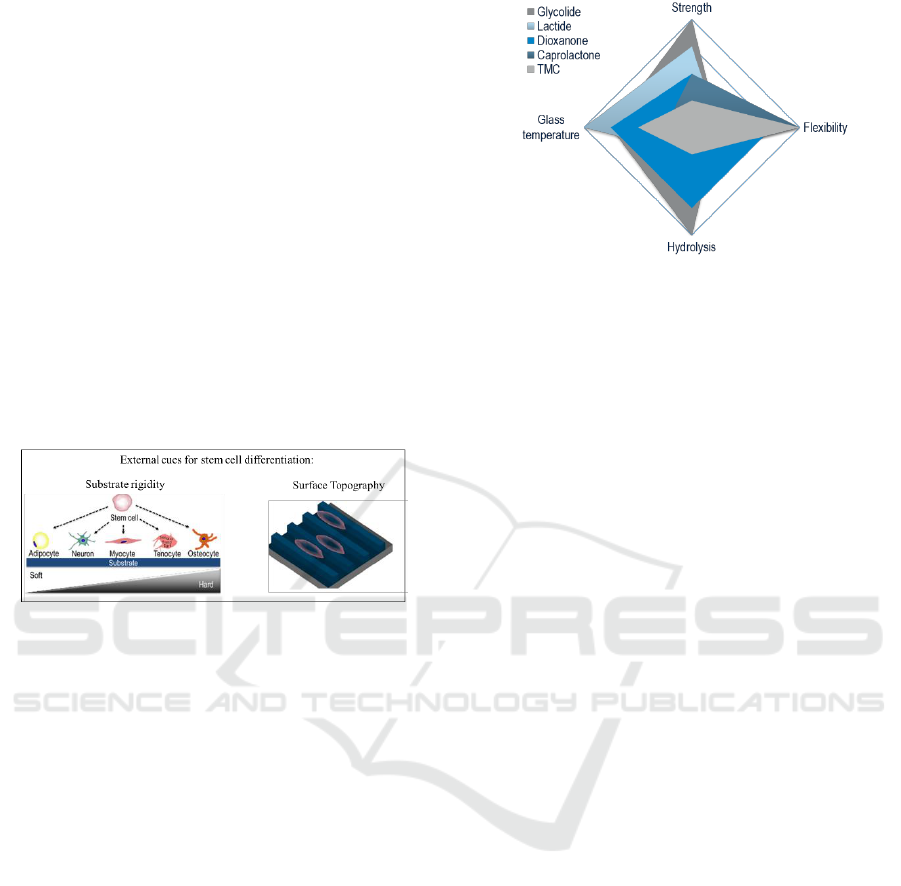

al, 2013) as means to control cellular growth, motility

and phenotype maintenance (Figure 1). The rationale

of using topographical features as means to control

cellular functions are based on the fact that

fundamental cellular substrata, the basement

membranes, are not smooth structures, but are

covered with the intertwined fibrillar meshwork of

the ECM (Jin et al., 2018). Similarly, rigidity plays a

crucial role in cell motility in vivo, as cells move from

regions of high ECM compliance to more stiff regions

(durotaxis) and in vitro studies have demonstrated

that stem cells commit to phenotype with extreme

sensitivity to elasticity; soft substrates that mimic

brain are neurogenic, whilst rigid substrates that

mimic bone are osteogenic (Engler et al., 2006; Lv et

al., 2015). Thus, it has been postulated that in vitro

recapitulation of physiological tissue topography and

rigidity will enable clinical translation of cell-based

therapies.

Figure 1: Substrate rigidity and surface topography as

external cues for stem cell differentiation.

4 METHODOLOGY

4.1 Film Preparation

Absorbable polyesters made from different

combination of monomers, such as lactic acid,

glycolic acid, trimethylene carbonate, dioxanone & β-

caprolactone, were selected for their physico-

chemical intrinsic properties. Even though the

selected polymers have similar chemistry they show

different mechanical and degradation properties

(Figure 2).

Polymeric films were produced by compression

moulding using a thermal presser Carver 3856 CE.

The presser was heated close to the polymer melting

temperature. The polymer was placed between Teflon

sheets and metal sheets inside the presser for 5

minutes. Then the system was placed under pressure.

The sample was removed after gradually cooling

down the system.

Figure 2: Monomers selected (Glycolide, Lactide;

Dioxanone, Ɛ-Caprolactone and Trimethylene Carbonate

(TMC)) and the representation of their intrinsic properties.

4.2 Chemical Characterization

NMR technique monitors the residual solvent

concentration in films and the monomer content. The

samples were prepared by dissolving the polymers in

CDCL3 or TFA deuterated. 1H NMR spectra were

obtained at 400 MHz. Measurements were performed

on a Fourier 300 Bruker spectrometer.

Differential Scanning Calorimetry (DSC)

technique was used to assess the glass transition (Tg)

and melting temperature (Tm), variation of enthalpy

of the polymeric films, as well as the crystallinity

content.

The DSC equipment used, a DSC 1 Star System,

Mettler Toledo, was programmed to perform two

heating curves, with a cooling intermediated step. The

temperatures used for each condition were optimized.

The mass of the analysed sample was between 5 and

6 mg. The second heating curve was the reference for

determining the Tg temperature, Tm and percentage

of crystallinity.

FTIR measurements were obtained using ATR

technique with a Spectrum 100 FT-IR Spectrometer,

Perkin Elmer by averaging 32 scans over the range of

4000 cm-1 to 800 cm-1.

The wettability of the samples was characterized

by static water contact angle measurements using a

sessile drop method with an OCA15+ goniometer

(DataPhysics, Germany) under ambient conditions at

room temperature. A 3 µL drop of distilled water and

diiodomethane (CH2I2) were dropped via a motor-

driven syringe. The data presented was calculated

using the final averaged values. The values for

polarity of the surface and the surface tension were

obtained by the Owens-Wendt method.

Design and Characterization of Synthetic Biodegradable Films for Soft Tissue Engineering

29

4.3 Mechanical Properties

4.3.1 Dynamic Mechanical Analysis (DMA)

The viscoelastic measurements were performed using

a DMA Q800 from TA Instruments. The

measurements were carried out at 37ºC in wet

conditions. Samples were cut in rectangular shapes

with about 14.5 x 5.3 mm (l,w) and 0.2 mm thickness

and clamped in the DMA apparatus. The sample was

deformed at constant stress-amplitude (25 µm) over 3

different frequencies (0.1, 1 and 10 Hz).

4.3.2 Tensile Tests

Mechanical properties were assessed under uniaxial

tension, using a Zwick/Roell (Leominster,

Herefordshire, UK) Z005 testing machine, loaded

with a 10 N load cell, as has been described

previously.

The samples were pre-cut into a dog-bone shape,

as per ASTM D882−2010 guidelines. Prior to testing,

all samples were incubated overnight at room

temperature in PBS and tissue paper was used to

remove excess PBS. The samples thickness was

measured using digital callipers (Scienceware, Digi-

Max, Sigma-Aldrich, Ireland). The samples were

hand-tightened between the vertical grips, which

were set at 50 mm gauge length. Scaffolds that broke

at contact points with the grips were rejected from the

analysis. The extension rate was set at 5 mm/min. The

following definitions were used to calculate

mechanical data: stress at break was defined as the

load at failure divided by the original cross-sectional

area (engineering stress), strain at break was defined

as the increase in scaffold length required to cause

failure divided by the original length, and modulus

was defined as the linear region of the stress-strain

curve using a stress at 0.02 strain divided by 0.02.

4.4 Degradation Studies

Films were incubated at 37°C in PBS for up to three

months. After predetermined periods of time samples

were removed from the solution, rinsed with distilled

water and dried at 37°C for 48 hours. Membrane mass

was weighted, and the percentage of weight loss was

calculated following equation 1:

% weight loss = (m

i

– m

f

)/m

i

X 100

(1)

Where m

i

and m

f

are the initial and final mass of

the sample, respectively.

4.5 In Vitro Assessment

4.5.1 Human Bone Marrow Stem Cells

(hBMSCs) Isolation and Culture

BMSCs were isolated according to standard

protocols. Briefly, bone marrow was flushed from

femurs and the flush-out solution was thoroughly

resuspended in complete basal medium and passed

through a 70 µm cell strainer. Cells were washed in

PBS- and were subsequently plated in complete basal

medium. After 2 days in culture non-adherent cells

were removed by several washes in PBS- and

cultured to near confluence (approx. 80%). Cells were

trypsinised, pooled, and re-plated (passage 0). Cells

were subsequently passaged at approximately 70-

80% confluency and were never allowed to reach full

confluency. Cells at passage 2 to 4 were used for all

experiments.

4.5.2 hBMSCs Seeding on Polymeric Films

Prior to cell culture studies, the films were sterilized

by ethylene oxide. hBMSCs at passages 3–4 were

harvested from culture flasks using trypLE Express

(Thermo Fisher, USA). Cells were washed with PBS

and centrifuged at 1200 rpm for 5 minutes. The cell

pellet was resuspended in α-minimal essential

medium (αMEM) supplemented with 10% fetal

bovine serum (FBS) and 2mM GlutaMAX and the

cells were seeded at different concentrations

described below onto the polymeric films, previously

placed into wells of a 24 well plate. The cells were

then cultured at 37 °C in a humidified atmosphere of

5% CO

2

. Subsequently, a drop of 100 μl of the cell

solution was seeded on top of the films and the cells

were allowed to attach at 37 °C, 5% CO2, 90%

humidity for 2,5 h prior to adding 900 μl complete

basal medium. The medium was changed every other

day.

4.5.3 Cell Adhesion

To evaluate the influence of the substrate stiffness in

cell morphology, 500 cell/cm

2

were seeded into the

polymeric films and incubated for 6 and 24 hours.

hBMSCs morphology was assessed by F-actin and

DAPI staining. Cells were fixed using a 10% formalin

solution for 30 minutes at 4°C. The samples were then

washed with PBS. For cell permeabilization it was

used a solution of 2% BSA in PBS. 4′,6-Diamidino-

2-phenylindole dihydrochloride (DAPI) and

Rhodamine B isothiocyanate were used to stain the

cell nuclei and F-actin filaments, respectively. The

samples were incubated with 1 mL of PBS containing

DCBIOSTEC 2019 - Doctoral Consortium on Biomedical Engineering Systems and Technologies

30

5 µL of Rhodamine for 20 minutes at room

temperature and protected from light. After extensive

washing, samples were stained with 1µL or DAPI in

1 mL of PBS for 20 minutes at room temperature in

the dark. After staining the samples these were

washed again with PBS. The cells were visualized

using a fluorescence microscope.

4.5.4 Cell Proliferation

After each time point, the metabolic activity was

assessed by Alamarblue® assay. The samples were

placed in a new well-plate with 0.1M phosphate

buffer saline solution (PBS). 1 mL of 10%

Alamarblue® solution in PBS was added and a

negative control of Alamarblue® at 10% alone. The

cell culture plates were incubated for 3 hours at 37°C

at 5% CO2. A microplate read (Bio-Tek, USA) was

used to read the Optical Density (OD). Three

replicates of each condition were analysed.

To assess the hBMSCs proliferation seeded on

polymeric films and coverslips as control samples, a

fluorometric double-strand DNA quantification kit

(PicoGreen, Molecular Probes, Invitrogen) was used.

For this purpose, cell lysates were collected at 7, 14

and 21 days by transferring the samples into 1.5 mL

microtubes containing 1 mL of ultrapure water. The

samples were incubated for 1h at 37 °C in a water

bath, and next stored at -80 °C. Cell lysates and

standards (ranging from 0 to 2 mg mL-1) were

prepared and mixed with a PicoGreen solution in a

200:1 ratio and placed in an opaque 96-well plate.

The plate was incubated for 10 min in the dark, and

fluorescence was measured on a microplate ELISA

reader (Synergy HT, BioTek, USA) with excitation at

485/20 nm and emission at 528/20 nm. The DNA

values were calculated using a calibration curve.

4.5.5 Differentiation

For assessing the in vitro differentiation capacity,

cells were seeded onto polymeric films, as described

above, and were kept in complete basal medium for

48 h. Subsequently, the samples were placed in

appropriate differentiation media. The trilineage

differentiation capacity was confirmed after 21 days

in culture by and semi-quantitative qPCR.

4.6 Imprinting

Si master moulds with grooved topography (2x2 µm)

were fabricated via a photolithography process,

followed by reactive ion etching (RIE). Silicon

wafers (3.0 _3.0 cm

2

) were spin-coated with a

positive photoresist (S1813 PR, Shipley) and then

exposed using OAI Mask Aligner (Model MBA800).

Following photoresist development, the master

mould was etched by RIE (Oxford ICP etcher) using

CHF3 + SF6 ionised gas. The moulds were silanised

with 5 mM octadecyltrichlorosilane (OTS, Sigma

Aldrich, Ireland) solution to enable imprint release. A

thermal imprinting process was used to transfer the

master pattern into the polymeric films using a

nanoimprinter at optimized temperatures and

pressures. The imprinted gratings on polymer were

subsequently analysed by SEM and AFM. Non-

imprinted substrates were used as isotropic control

substrates.

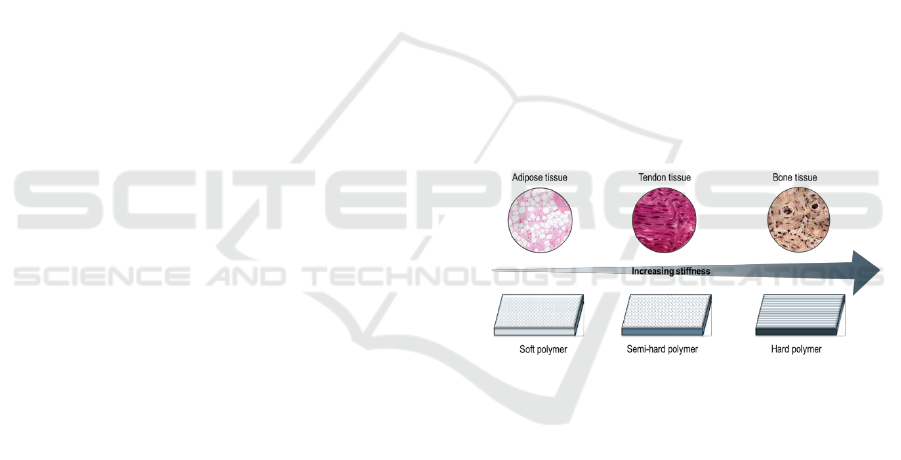

5 EXPECTED OUTCOME

It is expected to obtain polyester films with a range of

mechanical properties that will mimic the intrinsic

mechanical properties of the native tissue, such as

adipose, tenogenic and osteogenic tissue (Figure 3).

Chemical characterization and degradation studies

will provide information about the polyester prolife.

In vitro studies will shed some light on the impact of

the film’s stiffness to the cell fate.

Figure 3: Polyester films with increasing stiffness in order

to mimic adipose, tendon and bone tissue.

6 STAGE OF THE RESEARCH

It was possible to successfully produce polymeric

films using a large range of polyesters using a thermal

presser. Chemical analysis was used to trace the

chemical profile for each polymer. The selection

performed lead to materials with very distinct

profiles, regarding their crystallinity content and

degradation rate.

The mechanical properties of the materials were

analysed regarding at their macro level by DMA at

37°C in a PBS bath. The results show that the

developed films have a storage modulus ranging from

0.1 up to 2.6 GPa.

Design and Characterization of Synthetic Biodegradable Films for Soft Tissue Engineering

31

Biological assays showed good cell adhesion, cell

proliferation and cell viability. Cell morphology and

cluster formation were very different from one to

another polymer. The focal adhesion pattern has been

analysed as well, which means that the behaviour of

cells was strongly influenced by the nature of the

polymer and its associated stiffness, while other

parameters remained equal.

In the future, the combined effect of stiffness and

topography will be assessed on cell phenotype

maintenance.

This project is entering its final stage and is set to

finish in May 2019. As a disclosure, results cannot be

presented in details since 2 papers are under

preparation. In addition to this work, I co-authored

two book chapters and an additional review paper is

under preparation.

The results have been orally communicated at

these conventions: European Orthopaedic Research

Society, November 2018, Galway, Ireland; 4th

International Conference on Biomedical Polymers &

Polymeric Biomaterials, July 2018, Krakow, Poland;

and Future Investigators of Regenerative Medicine

(FIRM) Meeting, September 2017, Girona, Spain.

This work received funding from H2020-MSCA-

ITN-2015, Tendon Therapy Train Project (Grant

Agreement Number: 676338).

REFERENCES

Abbah, S. A., et al. 2014. Assessment of stem cell carriers

for tendon tissue engineering in pre-clinical models.

Stem Cell Research & Therapy. 5. 38.

Engler, A. J., et al. 2006. Matrix Elasticity Directs Stem

Cell Lineage Specification. Cell. 126. 677-689.

Gomes, M. E., et al. 2017. Tissue Engineering and

Regenerative Medicine: New Trends and Directions-A

Year in Review. Tissue Engineering Part B: Reviews.

23(3). 211-224.

Jin, G., et al. 2018. Electrospun three-dimensional aligned

nanofibrous scaffolds for tissue engineering. Materials

Science & Engineering C. 92. 995-1005.

Li, Z., et al. 2013. Differential regulation of stiffness,

topography, and dimension of substrates in rat

mesenchymal stem cells. Biomaterials. 34. 7616-7625.

Lv, H., et al. 2015. Mechanism of regulation of stem cell

differentiation by matrix stiffness. Stem Cell Research

& Therapy. 6:103.

Vermeulen, S., et al. 2019. Identification of topographical

architectures supporting the phenotype of rat tenocytes.

Acta Biomaterialia. 83. 277-290.

Zeugolis D.I., et al. 2011. Xenogenic tissues and

biomaterials for the skeletal system. In Comprehensive

Biomaterials. Volume 2. Oxford. Elsevier. 387–404.

Zeugolis D.I., Chan, J.C.Y., Pandit, A. 2011. Tendons:

engineering of functional tissues. In Tissue

Engineering. Berlin. Springer. 537–572.

DCBIOSTEC 2019 - Doctoral Consortium on Biomedical Engineering Systems and Technologies

32