Designing a Flexible Supply Chain Network with Autonomous Agents

Takaki Matsune and Katsuhide Fujita

Tokyo University of Agriculture and Technology, Koganei, Tokyo, Japan

Keywords:

Supply Chain Network Design, Multi-agent System, Automated Negotiation.

Abstract:

This paper proposes a supply chain model that enables companies with a software agent to construct a flexible

supply chain network automatically, assuming the network is composed of many competitors. Unlike the

traditional supply chain model including agents, it is impossible to manage the behavior of all companies

directly in the structure of the supply chain network. Each company can handle only its own strategy or

planning. We also propose a simple strategy for manufacturing agents focusing on individual profit. Our

experimental results demonstrate that our agents can make a supply chain network structure that produces

profits in the small-to-medium-scale scenario under some sample models of various scales.

1 INTRODUCTION

Today, companies are required to produce and sup-

ply resources at low cost without delivery delays. A

supply chain, which is a network between material

suppliers, manufacturers, and consumers, produces

products and distributes them. Subsequently, supply

chain management, which is a method to predict fu-

ture demand for products and optimizing the produc-

tion plan, is used to prevent excessive production and

the occurrence of excess inventory. It is studied in

both academic theory and within the practical use of

corporate management.(Lambert and Cooper, 2000)

At a manufacturing echelon for materials in a sup-

ply chain, it is uncommon to complete all processes

within a single company. Therefore, companies need

to procure resources from other companies for pro-

duction after bargaining for price, deadline, and so

forth with them, except cases where all companies in

a supply chain network can be controlled like the Toy-

ota production system. When a supply chain network

contains many competitors, they may not have infor-

mation about the competition companies’ plans or op-

timize their behavior.

This paper proposes a supply chain model includ-

ing agents that dynamically constructs its network ac-

cording to the behavior of the manufacturers. Com-

panies have information on the bills of materials and

templates of manufacturing plants. And they can de-

cide their role (e.g., processing raw materials and as-

sembling parts) in the network by building factory fa-

cilities. We also proposed the protocols of commu-

nication and negotiation to buy and sell the resources

needed to operate factory facilities within the manu-

facturer’s plant from competitors.

By using this model, we can (1) propose a strat-

egy of a company to fully automatize-from the con-

struction of manufacturing factories to the sale of re-

sources, (2) analyze changes in profits of companies

within the manufacturing process, and (3) analyze

the influence on the network that contains a company

with non-rational behavior.

The rest of the paper is organized as follows. In

section 2, we describe related work. In section 3,

we propose a supply chain model that enables com-

panies to autonomously form a flexible supply chain

network, assuming the network will be composed of

many competitors. In section 4, we propose a strategy

for manufacturing companies. In section 5, we con-

duct experiments to evaluate the supply chain model

with our simulator. Finally, we present conclusions

and recommendations for future work.

2 RELATED WORK

Many studies (Chen et al., 1999; Xue et al., 2005)

which introduce automated negotiation into supply

chain management, do not assume abandonment of

contracts after negotiation. If there is a possibility that

resources needed by a manufacturer can be obtained

from other companies than currently negotiating with

an opponent, and for that reason it might be worth

negotiating with those companies. Especially, in real-

194

Matsune, T. and Fujita, K.

Designing a Flexible Supply Chain Network with Autonomous Agents.

DOI: 10.5220/0007392401940201

In Proceedings of the 11th International Conference on Agents and Artificial Intelligence (ICAART 2019), pages 194-201

ISBN: 978-989-758-350-6

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

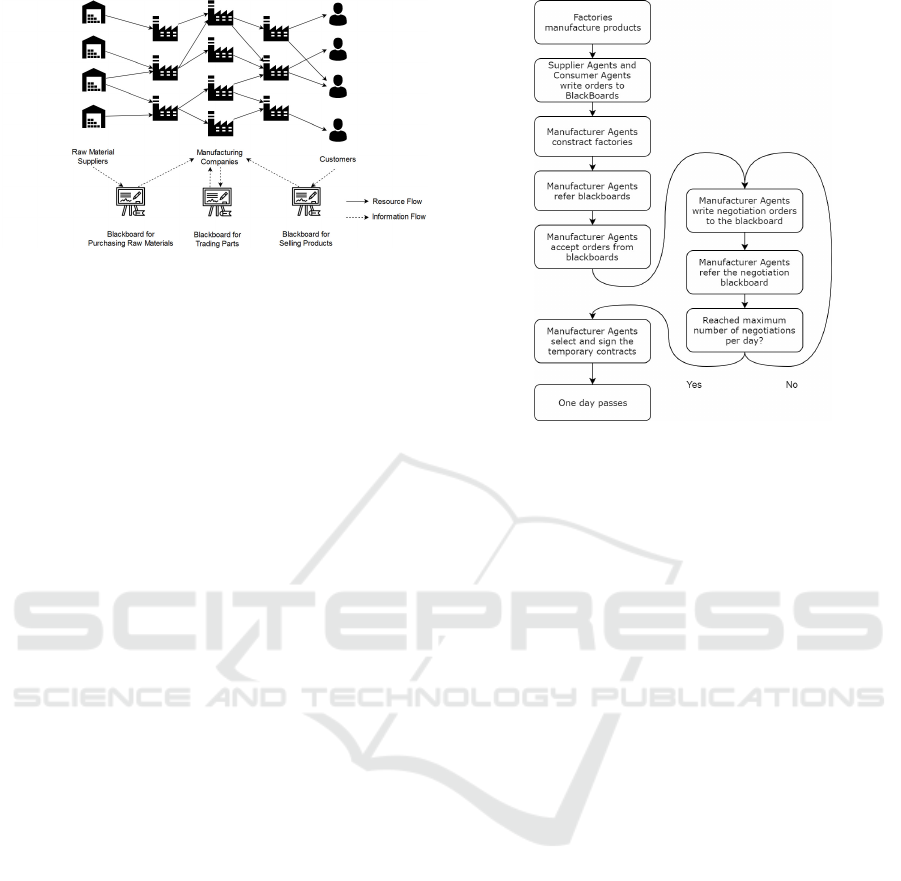

Figure 1: The detail of our proposed supply chain model.

istic inter-company negotiations, after estimating by

negotiating with a plurality of companies, it is often

the case to contract with the current company (or dis-

carding the pending contract).

Recently, some research (Ivanov et al., 2016;

Radziwon et al., 2014) has attempted to make the

supply chain network more flexible. Industry 4.0 is

a manufacturing digitization project promoted by the

German government, and one of its goals is to realize

the implementation of a “smart factory.” In Smart Fac-

tory, by connecting numerous sensors from factories

to the network and collecting the operation informa-

tion, it is possible to detect and automatically repair

the malfunction of equipment by using AI technology.

In addition, in the conventional supply chain, com-

panies responsible for specific processes of product

manufacturing are fixed. In a smart factory, however,

the role of the factory can be automatically and flex-

ibly changed, as they are connected not only within

a single factory but also on the market with the net-

work. Therefore, such a system is expected to be

able to quickly deal with sudden changes of suppli-

ers due to bankruptcy or other reasons and to realize

individually customized products rapidly. Compared

with Industry 4.0, the focus of our research is similar.

However, it differs in that our study tries to automate

processes from the construction of the factories to the

delivery to consumers via agents.

3 FLEXIBLE SUPPLY CHAIN

MODEL

In this section, we propose a supply chain model that

enables manufacturing companies to form a flexible

supply chain network. This model makes it easier for

manufacturers to build factories, find opponents and

negotiate with them to secure resources, and to close

deals with suppliers or consumers.

An overview of the model is shown in Figure 1,

and Figure 2 depicts the flow of the day in the model.

Figure 2: One day flow in our model.

There are three blackboards for transacting resources

between companies in addition to three types of com-

panies. These blackboards make it easier to negoti-

ate resources between suppliers and a manufacturer or

manufacturers, or a manufacturer and consumers. In

order to prevent the problem from becoming too com-

plicated due to the wide range of actions the manufac-

turers can take, the functions of manufacturing, distri-

bution, wholesale and retail sales are consolidated in

the manufacturer, while a typical supply chain model

has several kinds of echelons. Furthermore, to make

it easier to describe the model, we roughly divided

the components of the supply chain into three kinds

of agents and seven models.

3.1 Supplier Agent

Supplier Agents produce and selling raw materials

to manufacturing agents. They can take three ac-

tions: securing raw materials, writing on a blackboard

for selling, and selling raw materials to manufactur-

ing agents. Each supplier agent has a single supply

model.

Securing Raw Materials. Each agent procures raw

materials each Interval of days, which is defined

in a supply model.

Writing on a Blackboard. After procuring raw ma-

terials, the agent writes an order on the black-

board immediately to indicate sales information

to manufacturing agents. If any manufacturing

agent does not receive the order within a certain

number of days, the order will be withdrawn au-

tomatically.

Designing a Flexible Supply Chain Network with Autonomous Agents

195

Table 1: Example part of a recipe.

Unique name Deliverable Quantity to be produced Items to be processed Quantity required

Assemble1 Product1 1 Part2 4

Assemble1 Product1 1 Part3 8

Selling Raw Materials to Manufacturing Agents.

When a manufacturing agent receives a supply

order, the supply agent initiates it to prepare for

shipment immediately. As soon as it is ready

for shipment, it sells the raw materials to the

manufacturing agent. Since it is assumed that

any accidents will not occur, supplier agents are

assumed to be able to deliver materials on time.

3.2 Manufacturing Agent

Manufacturing Agent processes raw materials and

parts. They can take these actions: building facto-

ries, writing on or referring to blackboards, negotiat-

ing with other companies, and so on. Details of these

actions are explained below.

Building Factories. Manufacturing agents can build

factories by selecting from predefined factory

models. In addition, when building factories,

agents can utilize their strategy by referring to

BOM models and blackboards.

Referring or Writing on Blackboards. Agents can

refer blackboards to improve production plan,

purchase raw materials or parts, negotiate with

other manufacturing agents for trading every day.

Besides, agents can write buy (or sell) orders on

blackboards if necessary.

Negotiating and Selecting Temporary Agreements.

When agents initiate negotiation, they follow the

negotiation protocol defined in Section 3.10. Af-

ter the negotiation is successful, the negotiation

result can be put on hold temporarily, and as long

as during the day, a temporary contract can be ac-

cumulated by negotiating with other agents. After

that, the agent on the side who started the negoti-

ation can sign the contract by selecting one of the

negotiation results accumulated at the end of its

turn.

3.3 Consumer Agent

Consumer Agents purchase products from manufac-

turing agents. They can take two actions: write on a

blackboard to deal with purchasing products, and buy

products from manufacturing agents. Each consumer

agent has a single demand model.

Writing on a Blackboard for Purchasing Products.

Each consumer agent writes an order on the black-

board every Interval day, which is defined in a de-

mand model, to indicate purchase information for

manufacturing agents. If no manufacturing agents

receive the order within a certain number of days,

the consumer agent’s order is withdrawn automat-

ically.

Buying Products from Manufacturing Agents.

When a manufacturing agent receives an order,

it waits until the deadline for products to be de-

livered from the manufacturer. This agent pays

a commission to the manufacturing agent if the

products are delivered on time; otherwise it is pe-

nalized.

3.4 Bill of Materials Model

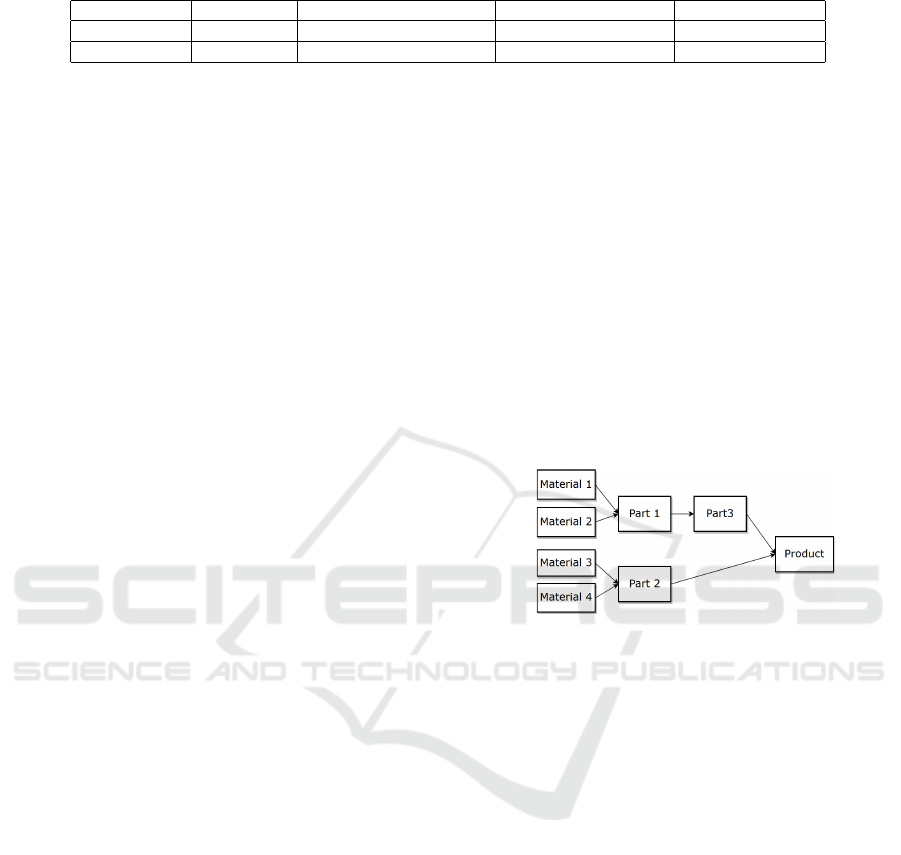

Figure 3: An example of bills of materials (BOM).

The bill of materials (BOM) model defines items

(i.e., raw materials, parts, products) and recipes for

manufacturing a product. The details of this process

are as follows:

Item: Item name, Item type (material, part, product)

Recipe: Recipe name, Deliverables, Quantity to pro-

duce, Items to be processed, Quantity required

Table 1 shows an example part of recipe, and Figure

3 indicates the set of recipes.

3.5 Factory Model

Factory model defines a factory that manufacturing

agents can build. The detail of attributes are as fol-

lows: ItemRecipe indicates a recipe to be processed

by the factory. FactoryName is a unique name of

this model. ConstractionTime is days needed to build

a factory. ConstractionCost indicates an initial cost

to build a factory. CostPerUnit stands for the cost

to manufacture an item. ProductionRate is a quan-

tity that this factory can manufacture per day, which

follows a Gaussian distribution with a standard devi-

ation of stddevProductionRate. MaintenanceCost is

the cost per day.

ICAART 2019 - 11th International Conference on Agents and Artificial Intelligence

196

3.6 Decision-making Model

Decision-making model describes manufacturing and

negotiating strategies of manufacturing agents, which

precepts of the environment, judgments regarding be-

havior, and instructs regarding actions required of the

agent. We propose a detailed strategy for agents in

Section 4.

3.7 Demand Model

Demand Model defines the demand for products, and

it is used by the consumer’s agent. The detail of these

attributes is as follows: ModelName is a unique name

of the demand model. Item with Amount and Price

are items that are required by the consumer’s agents.

Deadline is the number of days until hitting the dead-

line received from manufacturing agents that has an

accepted order to fulfill delivery. Deadline follows a

Gaussian distribution with a standard deviation of std-

devDeadline. Interval is an average interval of days

between the time the item is delivered and the time the

next demand for an item occurs that follows a expo-

nential distribution. Penalty is the penalty price when

manufacturing agent does not deliver the products by

the deadline.

3.8 Supply Model

A supply model describes the supply of raw materi-

als provided by supply agents. The detail of these

attributes is as follows: ModelName is a unique name

of this model. Item with Amount and Price is an item

that will be supplied by consumer agents. Delivery-

Date is a day needed to deliver raw materials, and this

value follows a Gaussian distribution with a standard

deviation of stddevDeliveryDate. Interval is an av-

erage interval of days between the time the materi-

als are delivered, and the time that the next supply

need occurs, and this follows an exponential distribu-

tion. There is no penalty included because the supply

model assumes that delivery delays will not occur.

3.9 Blackboard Model

Blackboard Model defines communication protocols

that enable agents to trade resources or initiate nego-

tiations. To make it easier for agents to find nego-

tiating opponents, this paper uses a Blackboard sys-

tem (Sadeh et al., 2001), which is widely used in

the multi-agent research field. Bulletin board trading

(Kikuchi, 2006) is an example in which a model simi-

lar to the Blackboard system is used, and it is used by

Table 2: An example order for negotiation.

Attribute Example value

From ManufacturerAgent1

Type BUY

Item Part1

Since 20

Japan Electric Power Exchange (JEPE), which pro-

vides power trading in Japan.

As shown in Figure 1, There are three kinds of

blackboards in the supply chain model, and each one

has a different function.

Blackboard for Purchasing Raw Materials. This

blackboard is used to trade raw materials between

a supplier’s agent and a manufacturer’s. The

details of an order written by supply agents are as

follows: Supplier is the name of the person who

wrote the order, and SupplyModelName is the

name of the model described in Supply Model.

The attribute Since is the day when the order was

placed.

Blackboard for Trading Parts. This blackboard is

used to trade items between manufacturing

agents. When a manufacturing agent needs to se-

cure parts from other companies or wants to sell

parts to others, it writes an order as described in

Table 2. The attribute From is the name of the

agent who wrote the order. Type indicates whether

the agent wants to buy or sell. Item is the item the

agent wants to trade. The attribute Since is the day

when the order was written. Other agents can re-

fer the blackboard every day, and they can initiate

negotiations with the agent who posted the entry.

Once the negotiation is started, the entry is deleted

so other agents cannot reference it.

Blackboard for Selling Products. This blackboard

is used to place an order for products by con-

sumer agents. When product demand occurs, they

write orders on the blackboard to purchase prod-

ucts from manufacturing agents. The order con-

tains three attributes: Consumer is the name of

the person who placed the order, DemandModel-

Name is the name of Demand Model, and Since is

the day when the order was placed.

3.10 Negotiation Model

Figure 4: Alternating Offers Protocol.

Designing a Flexible Supply Chain Network with Autonomous Agents

197

The negotiation model defines the negotiation pro-

tocol that is used by manufacturing agents. Alternat-

ing offers (Rubinstein, 1982), a bilateral negotiation

protocol, is used for this protocol. The flow of alter-

nating offers is shown in Figure 4. We consider the

case in which agents A and B conduct negotiations.

In the beginning, agent A makes a proposal to agent

B. Next. Agent B takes one of the following actions

with respect to agent A:

• Offer: Rejecting the previous proposal and

proposing a new one.

• Accept: Accepting the previous proposal.

• EndNegotiation: Ending the negotiation without

agreement before the deadline reaches.

Afterwards, agent A takes come up with a new action

for agent B, In alternating offers, negotiations will be

continued until the following conditions are satisfied:

• One agent accepts the proposal.

• The negotiation deadline passes before an agree-

ment was reached.

• One agent terminates the negotiation by selecting

EndNegotiation.

4 STRATEGIES FOR

MANUFACTURING AGENT

In this section, we propose six kinds of strategies for

manufacturing agents to focus on individual profit as

follows: building factories, receiving demand orders,

receiving supply orders, writing orders on a black-

board, selecting negotiation opponents, and negotia-

tion.

Building Factories. While manufacturing agents

can freely build factories, construction of un-

planned factories can cause losses due to running

costs up. This strategy described in Algorithm 1

prevents agents from building the same factory

that other companies built. Building factories

are continued until the maximum construction

quantity is satisfied.

Receiving Demand Orders. This strategy described

in Algorithm 2 prevents that agents receive an or-

der for products that their factories cannot pro-

duce. In addition, this strategy also prevents ex-

cessive orders.

Receiving Supply Orders. Algorithm 3 makes

agents to purchase only the resources required

by their factories and prevent holding too many

resources.

Algorithm 1: Building Factories.

Require: maximum number of facilities F

max

1: p ⇐ a random value in (0, 1)

2: if current number of factories = F

max

then

3: do nothing

4: end if

5: if p < 0.3 then

6: do nothing

7: else if p < 0.6 then

8: choose and build a factory randomly from factory templates

9: else

10: refer the blackboards to confirm current demands

11: select a factory which satisfies the demand from the templates and

build it.

12: end if

Algorithm 2: Receiving Demand Orders.

Require: current number of factories n, types of items that currently owned

factory can produce I

1: if n = 0 or the size of demandboard = 0 then

2: do nothing

3: else

4: extract only the demand that needs I and receive one of them.

5: end if

Algorithm 3: Receiving Supply Orders.

Require: current number of factories n, types of items that currently owned

factory requires to manufacture items I

1: if n = 0 or the size of supplyboard = 0 then

2: do nothing

3: else

4: L ⇐ extract only the supply that supplies I

5: K ⇐ extract from L what currently owned amount does not exceed

twice the amount necessary to manufacture.

6: receive an order randomly from K

7: end if

Writing Orders on the Blackboard. Algorithm 4

describes the strategy that permits agents to sell

the parts manufactured to other manufacturing

agents by writing it on the negotiation blackboard.

Selecting Negotiation Opponents. Algorithm 5 al-

lows the agent select an opponent who wants re-

sources that the agent owns. Also, in order to re-

duce the number of negotiations, we adjusted the

probability of negotiation.

Negotiation. In this strategy (Algorithm 6), the agent

negotiates with the opponent about the price.

First, when the agent is a seller, they propose a

price 1 to 2 times the price required for manu-

facturing parts. After that, it decides whether to

accept or reject it based on the proposed price.

ICAART 2019 - 11th International Conference on Agents and Artificial Intelligence

198

Algorithm 4: Writing Orders on the Blackboard.

Require: current number of factories n, types of items that currently owned

factory requires to manufacture items I = {i

1

,i

2

,...,i

k

}

1: if n = 0 then

2: do nothing

3: end if

4: for j = 0 to k do

5: if the currency amount of i

j

> 2∗ the amount i

j

owned factory re-

quires then

6: add i

j

to list L

7: end if

8: select one from L randomly and write a request on the blackboard

9: i ← i + 1

10: end for

Algorithm 5: Selecting Negotiation Opponents.

Require: current number of factories n, types of items that currently owned

factory can produce I

1: if n = 0 or the size of negotiation blackboard = 0 then

2: do nothing

3: else

4: L ⇐ refer to the negotiation blackboard and extract the entry that

including I.

5: select one of L and initiate negotiation with 10% chance

6: end if

Algorithm 6: Negotiation Strategy.

Require: current number of factories n, types of items that the currently

owned factory can produce I, last received proposal from opponent lbid,

price from lbid l pr, penalty from lbid l pe function to offer a pro-

posal O f f er(amount, price,deadline, penalty), function to accept the

proposal Accept(proposal), function rand(x, y) returns the uniformly

distributed random number on (x,y), N = 5, D = 15

1: while negotiation continues do

2: if sel f is a buyer then

3: if lbid is not exist then

4: O f f er(N, 0.0,D,0)

5: else

6: O f f er(N, (1 − rand(0,1)/4)∗lpr,D,3/4 ∗lpe)

7: end if

8: else

9: U

p

⇐ calculate unit costs needed to produce an item currently

being negotiating for.

10: if lbid is not exist then

11: O f f er(N,2 ∗U

p

∗ N, D,U

p

/3)

12: else

13: if lbid > N ∗U

p

∗ 1.3 then

14: Accept(lbid)

15: else

16: O f f er(N,U

p

∗ (1 + rand(0,1))∗ N, D,U

p

/3)

17: end if

18: end if

19: end if

20: end while

5 EXPERIMENTS

For evaluating the proposed supply chain model and

agent, we implemented a simulator in Java. Al-

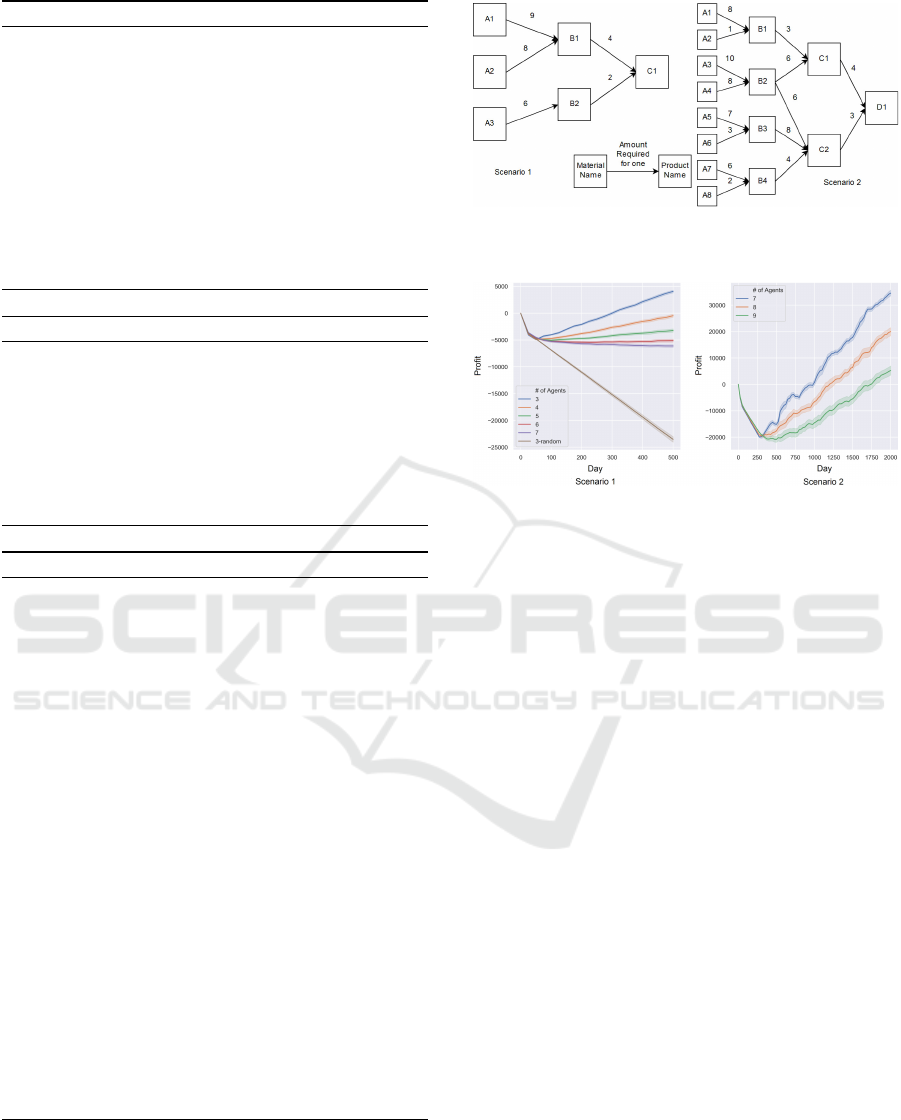

Figure 5: Overview of Scenario 1 and 2.

Figure 6: Average profits in Agents (Scenario 1 and 2) with

95% confidence bands.

though there are datasets for evaluating a supply chain

model(Georgiadis et al., 2011), these datasets can-

not be applied to our model due to the fact that

they lack some necessary data needed to simulate our

model. Therefore, two sample scenarios are gener-

ated to evaluate by random parameters. An overview

for these scenarios is depicted in Figure 5. (see Ap-

pendix for details) To evaluate our proposed strategy,

we prepared a “Random Agent,” which all behaviors

(such as building factories, selecting a negotiations

opponent, and so on) are random.

5.1 Experimental Settings

This experiment was carried out to clarify that man-

ufacturer strategies affect its profit. We have used

two kinds of agents (our proposed agent and Random

Agent) for the experiment. The following are the de-

tails of the experimental settings:

• # of manufacturing agents in the supply chain: 3

to 7 for Scenario 1, 7 to 9 for Scenario 2

• Factories can be built per agent: 1

• Maximum number of negotiations per day: 3

• Maximum contracts can be made per day: 1

• Maximum rounds per negotiation: 1000

• Simulation days: 500 for Scenario 1, 2000 for

Scenario 2

• # of simulations: 100

Designing a Flexible Supply Chain Network with Autonomous Agents

199

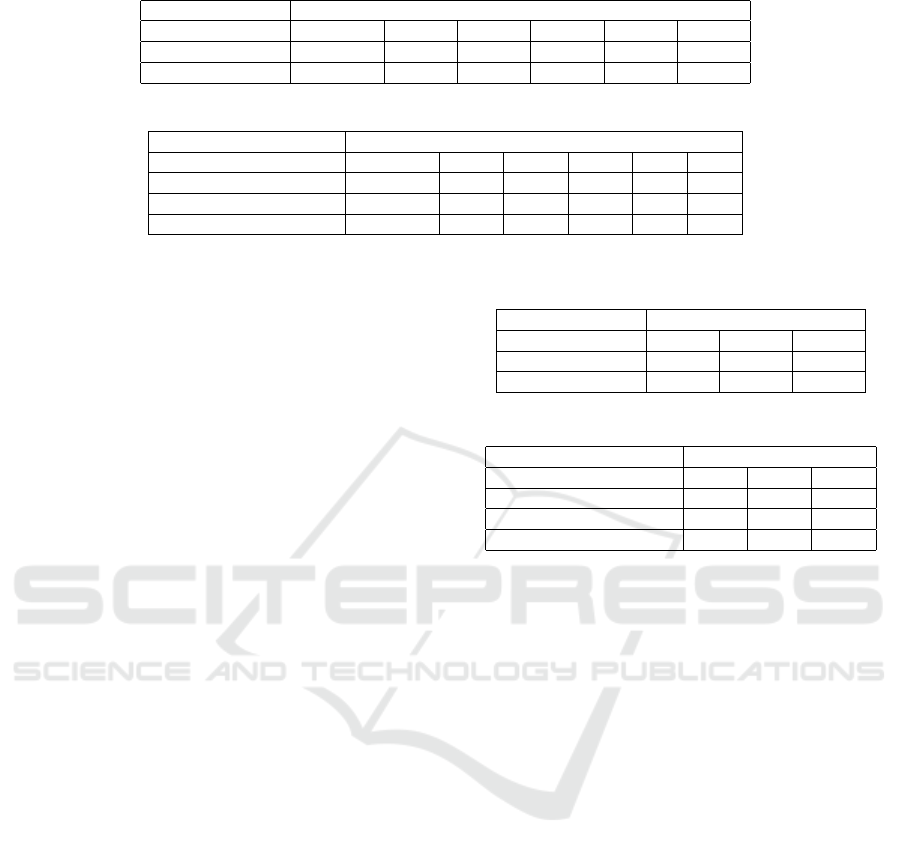

Table 3: Average materials supplied and product offered (Scenario 1).

# of agents

3-random 3 4 5 6 7

Material supplied 38.55 130.11 134.61 137.93 141.22 145.16

Product offered 0 43.08 42.99 42.45 41.90 42.03

Table 4: Average negotiation contracts (Scenario 1).

# of agents

3-random 3 4 5 6 7

Penalties imposed 458.84 1.84 3.15 4.06 4.77 5.14

Successfully transacted 26.51 18.40 14.11 11.40 9.61 8.35

Transaction success rate 0.054 0.90 0.81 0.73 0.66 0.61

5.2 Experimental Results

5.2.1 Scenario 1

Figure 6 shows average profits. Comparing the result

of two agents, while the Random Agent continued to

earn large losses, our proposed agent made a profit fi-

nally, although it experienced a loss in the early stages

of the simulation. Thus, the random agent may have

caused the funds to flow out to the supplier or to the

consumer. In addition, it can be said that as the num-

ber of agents decreases, the overall profit increases.

Table 3 and Table 4 show the statistics on contract

statuses at the end of simulation. Table 3 indicates

that our proposed agent ordered more from the sup-

plier than the random agent. In addition, while the

random agent does not correspond to consumer de-

mand, our agent has never failed to deliver because it

receives only demand orders that are already in inven-

tory. These results imply that the main reason why the

random agent loses is by paying the penalty for con-

sumers. Table 4 indicates that the random agent has

succeeded in transacting with a probability of 5.4%,

on the other hand, our proposed agent has 90% suc-

cessful rate. Therefore, our agent can avoid unreason-

able contracts. However, the result also indicates that

as the number of agents increases, the transaction suc-

cess rate diminishes. This is because our agent signed

many contracts without considering other agents, and

could not produce products on time.

5.2.2 Scenario 2

We conducted additional experiments to clarify that

the shortage of suppliers and the high cost of sales ra-

tio are the cause of losses. The experimental settings

of scenario 2 are the same as scenario 1, except that

the cost percentage is reduced from 50% to 33.3% and

that the number of suppliers per a supply model is

doubled. The results are shown in Figure 6, Table 5,

and Table 6. Although we cannot show the experi-

mental results when the cost percentage and the num-

Table 5: Average materials supplied and product offered

(Scenario 2).

# of agents

7 8 9

Material supplied 828.19 830.93 833.56

Product offered 16.87 16.22 15.10

Table 6: Average negotiation contracts (Scenario 2).

# of agents

7 8 9

Penalties imposed 14.91 14.45 14.06

Successfully transacted 57.84 50.43 44.69

Transaction success rate 0.80 0.77 0.76

ber of suppliers per a supply model are same as sce-

nario 1 due to space limitations, we see that the num-

ber of suppliers of raw materials and the number of

times they provided final products increased. In addi-

tion, a profit is made by lowering the cost percentage

and increasing the number of times of providing the

final products. Therefore, these results showed that

securing a large number of raw materials and lower-

ing the cost percentage are necessary for profit in a

complex supply chain model.

6 CONCLUSIONS AND FUTURE

WORK

This paper focused on a modeling supply chain net-

work which is composed of many competing compa-

nies. We proposed a supply chain model that enables

companies to autonomously form a supply chain net-

work flexibly. Our model assumes that manufacturing

companies can construct factory facilities, secure nec-

essary resources by negotiating, and writing orders

on blackboards freely. We also proposed a strategy

for manufacturing agents that focuses on individual

profit by selling at a higher price than the purchase

price. The experimental results demonstrated that our

supply chain model shows the best performance when

the number of agents is equal to the number of manu-

ICAART 2019 - 11th International Conference on Agents and Artificial Intelligence

200

facturing processes.

One possible future study would be to improve the

current model by employing a more realistic situa-

tion. It is difficult to approach realistic situations in

this model compared to typical supply chain models,

but it can be realized by improving the agent’s strat-

egy such as predicting demand.

ACKNOWLEDGEMENTS

This work was supported by JST CREST Grant Num-

ber JPMJCR15E1, Japan.

REFERENCES

Chen, Y., Peng, Y., Finin, T., Labrou, Y., Chu, B., Yao,

J., Sun, R., Willhelm, B., and Cost, S. (1999). A

negotiation-based multi-agent system for supply chain

management. In In Proceedings of Agents 99 Work-

shop on Agent Based Decision-Support for Managing

the Internet-Enabled Supply-Chain, pages 15–20.

Georgiadis, M. C., Tsiakis, P., Longinidis, P., and

Sofioglou, M. K. (2011). Optimal design of supply

chain networks under uncertain transient demand vari-

ations. Omega, 39(3):254 – 272.

Ivanov, D., Dolgui, A., Sokolov, B., Werner, F., and

Ivanova, M. (2016). A dynamic model and an algo-

rithm for short-term supply chain scheduling in the

smart factory industry 4.0. International Journal of

Production Research, 54(2):386–402.

Kikuchi, H. (2006). The subject of physical distribution

service industry training in an scm. Journal of Japan

Logistics Society, 2006(14):237–244.

Lambert, D. M. and Cooper, M. C. (2000). Issues in sup-

ply chain management. Industrial Marketing Man-

agement, 29(1):65 – 83.

Radziwon, A., Bilberg, A., Bogers, M., and Madsen, E. S.

(2014). The smart factory: Exploring adaptive and

flexible manufacturing solutions. Procedia Engineer-

ing, 69:1184 – 1190. 24th DAAAM International

Symposium on Intelligent Manufacturing and Au-

tomation, 2013.

Rubinstein, A. (1982). Perfect equilibrium in a bargaining

model. Econometrica, 50(1):97–109.

Sadeh, N., Hildum, D., Kjenstad, D., and Tseng, A. (2001).

Mascot: An agent-based architecture for dynamic

supply chain creation and coordination in the internet

economy. 12:212–223.

Xue, X., Li, X., Shen, Q., and Wang, Y. (2005). An agent-

based framework for supply chain coordination in

construction. Automation in Construction, 14(3):413

– 430. International Conference for Construction In-

formation Technology 2004.

APPENDIX

Scenarios used in experiments. For convenience,

we assume rand(x,y) is the uniformly distributed

random number on (x,y) and randi(x,y) is the

uniformly distributed random integer on [x,y].

Common settings. Common model settings in all

scenarios are shown in Table 7, Table 8, and Table

9.

Table 7: Factory Model.

Attribute Parameter

ConstractionTime randi(3,20)

ConstractionCost randi(1000,5000)

CostPerUnit randi(5,20)

ProductionRate randi(5,30)

stddevProductionRate rand(0,3)

MaintenanceCost randi(10,30)

Table 8: Supply Model.

Attribute Parameter

Amount randi(20,50)

Price randi(5,30) per item

DeliveryDate randi(5, 15)

stddevDeliveryDate randi(0,3)

avgInterval randi(5, 15)

Table 9: Demand Model.

Attribute Parameter

Amount 1

Price 2.0 ∗ rawmaterialcost

Deadline randi(3,20)

stddevDeadline rand(0,3)

Interval randi(5,20)

PenaltyPrice rawmaterialcost/3.0

Scenario 1

• BOM Model : 3 raw material, 1 final product

with 3 manufacturing processes. (see Figure 5)

• # of Suppliers : 6 (2 for each supply model)

• # of Consumers : 2 (2 for each demand model)

Scenario 2

• BOM Model : 8 raw material, 1 final product

with 7 manufacturing processes. (see Figure 5)

• # of Suppliers : 32 (4 for each supply model)

• # of Consumers : 2 (2 for each demand model)

• Price in Demand Model : 3.0∗rawmaterialcost

(33.3% cost percentage)

Designing a Flexible Supply Chain Network with Autonomous Agents

201