Modeling and Analysis of Double Layer Motheye Anti Reflective

Coatings on Organic Light Emitting Diode

Chaya B. M.

a

, Sharon Prarthna C., Vinith Kumar G. P. and Narayan K.

b

Sai Vidya Institute of Technology, Visvesvaraya Technological University, Rajanukunte, Bangalore, India

Keywords: Anti-reflective Coatings, Finite Difference Time Domain, Biomimic Structures, Organic Light Emitting

Diode.

Abstract: In this work modeling of double layer motheye anti-reflective coating (DLAR) on organic light emitting diode

(OLED) is presented. Finite difference time domain method (FDTD) and Fresnel reflection theory is used to

study the reflection and transmission of light of Organic Light Emitting Diode (OLED) using Anti-reflective

coatings (ARC). The double layer motheye anti-reflective coatings are incorporated on the surface of glass

substrate of an OLED. This is done to reduce the losses existing in OLEDs substrate-air interface. The

refractive index (RI) of the top and bottom layer of ARC is engineered and the thickness of the top and bottom

layer anti-reflective coatings is modelled using Fresnel’s reflection theory. The effect of double layer motheye

ARC on OLED for enhanced far field intensity is analysed. It is found that the far field electric intensity of

DLAR based OLED has a significant enhancement compared to OLED with Single layer Antireflective

coatings on the glass substrate.

1 INTRODUCTION

The OLED is formed by the arrangement of metal-

organic emissive layer in a specific order. Light is

emitted when DC voltage source is applied across the

anode and cathode of the OLED (Tang and Vanslyke,

1987 and Tang, 1989). Due to the applied voltage, the

population of the excitons are increased to produce

light by radiative decay. (Macleod, 2010 and Lee,

2003). The emission wavelength of the OLED device

can be chosen by using appropriate organic dopants

for the fluorescent-based device (Wasey et.al, 2000).

When the voltage is applied, a singlet excitons are

produced to emit Fluorescent light with internal

quantum efficiency (IQE) is 25 %. The external

quantum efficiency is limited to 20% for the

conventional OLED device (Wasey et.al, 2000). The

formation of light takes place in the emissive layer of

the device. When the device is excited with the

source, it undergoes radiative decay to emit the

maximum number of excitons. The emitting of the

light from the device can be either top emitting or

bottom emitting depending on the design structure

(Kim.et.al, 2016). The application of OLEDs based

a

https://orcid.org/0000-1111-2222-3333

b

https://orcid.org/1111-2222-3333-4444

on the Anti-reflective coatings is emerging in in

display technology, photo detectors etc., (Sharma

et.al, 2017). The Anti-reflective coating are made of

nanostructures. These are placed on the devices such

as OLEDs, solar cells etc. to reduce the reflection

losses that exist at the glass substrate interfaces.

These tapered Nanostructures are placed in the

coating layer above glass substrate. The sub

wavelength Nanostructures are created using various

materials to reduce the reflection losses. The DLAR

concept was used on solar cells to improve the

efficiency as in (Dhungel et.al, 2006).

Many experiments have been carried out in the

literature using photonic crystals, micro lenses,

patterned substrates, dielectric nanoparticles in

display and other applications to improve the light out

coupling efficiencies (tan et.al, 2017).

In the recent years, a technique to reduce losses is

done by adopting periodic nanostructures such as bio

mimicking motheye. This is an efficient technique to

incorporate on the surface of the glass substrate of the

OLED. There are various types of anti-reflection

coatings such as single layer Anti-reflective coatings,

double layer anti-reflective coatings etc. The effects

190

M., C., C., S., P., V. and K., N.

Modeling and Analysis of Double Layer Motheye Anti Reflective Coatings on Organic Light Emitting Diode.

DOI: 10.5220/0007385201900195

In Proceedings of the 7th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2019), pages 190-195

ISBN: 978-989-758-364-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

of SLAR are studied in (Keshavarz Hedayati et.al,

2016) showing a significant improvement in the light

coupling efficacy when compared to Photonic

crystals. In this work the effects of double layer anti-

reflective coatings on OLED are investigated. The

thickness, height and pitch are parameters that define

the response of the system and can be designed to

tailor this response.

2 DESIGN OF DLAR BASED

OLED

This section describes the modelling of parabolic

shaped Double layer Anti-reflective coating (DLAR)

and modelling of DLAR on OLED.

2.1 Modeling of Double Layer Motheye

Anti Reflective Coating

The Double layer motheye Anti-reflective coating

(DLAR) was investigated on solar cells, which

showed a significant enhancement due to coverage of

broad band solar spectrum. In this work, the DLAR is

placed on OLED as there is a limited number of

adjustable parameters in single layer motheye Anti-

reflective coatings (SLAR).

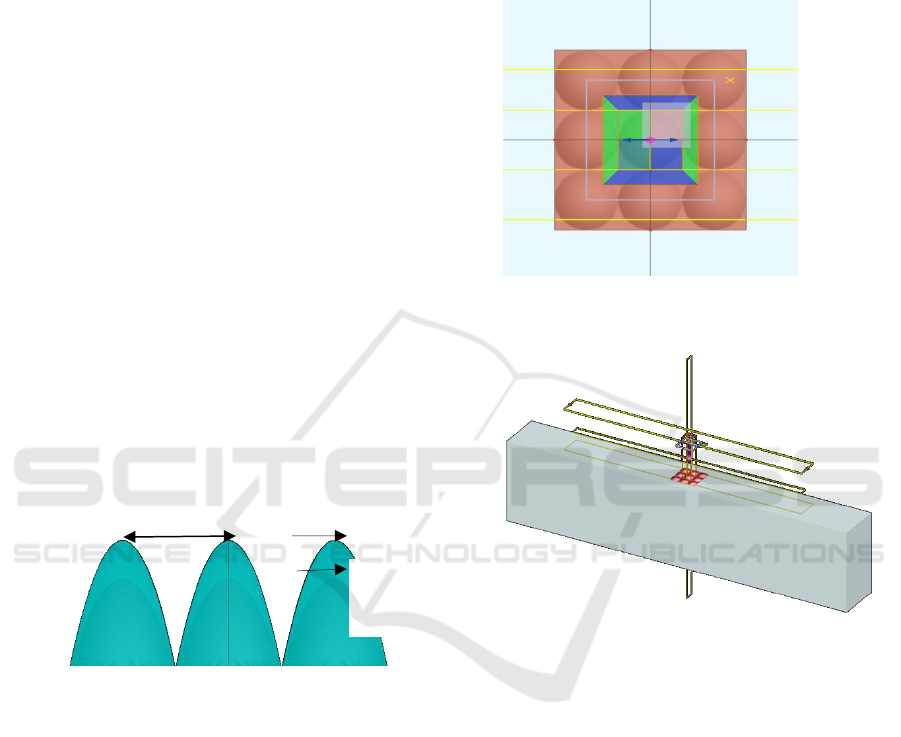

Figure 1: Parabolic shaped Double layer ARC.

In Figure 1, the parabolic shaped double layer

motheye anti-reflectors are shown. The pitch of both

the layers are carefully tailored in order to reduce the

reflection losses. The dimension of double layer

motheye Antireflective coatings such as thickness,

pitch and height are tailored from the Fresnel’s

reflection theory.

Figure 2 and Figure 3 shows the modelling of Double

layer ARC placed on the glass substrate which is

periodic in nature and are tapered at the sides of the

structure. This simulation is carried out to get the

insight of absorption and transmission in the DLAR.

The following boundary conditions are used to model

the DLAR: x (maximum) = anti symmetric and y

(maximum) = symmetric. Also two monitors are

placed to get the reflection analysis behind the source

and other monitors amount of transmission. The plane

wave is chosen to get the effects of ARCs with

Bloch/periodic wave type. The transmission,

reflection and absorption plots are extracted from the

above simulation set up. The modeling is done using

a commercially available Lumerical FDTD software.

Figure 2: Modelled Double layer Anti-Reflective coatings

(XY view).

Figure 3: Perspective View of DLAR.

In DLAR, two reflectance’s are considered so that

maximum reflection is supressed by undergoing

destructive interferences at two interfaces. One at top

layer and bottom layer ARC interface and another at

bottom layer and glass substrate interface.

Figure 3, shows following layers: Glass substrate,

Bottom layer ARC, Top layer ARC and air medium.

The multilayer stack layers are chosen at different

refractive indices that satisfies following condition.

n

0

< n

top

< n

bottom

< n

substrate

where, n

0

= Refractive index of the air ,

n

top

=

Refractive index of top layer Anti-reflective coating

n

bottom

= Refractive index of Bottom layer Anti-

reflective coating, n

substrate

= Refractive index of the

substrate.

The anti-reflection stack is designed for a particular

wave length of 540nm to emit green fluorescent light.

Top Layer

ARC

Bottom

layer ARC

Pitch

Modeling and Analysis of Double Layer Motheye Anti Reflective Coatings on Organic Light Emitting Diode

191

In this simulation, the reflection and transmission

spectra are obtained. The reflection is almost

supressed compared to SLAR. The DLAR coatings

are also called as V-coatings, since the spectral

patterns are obtained is V-shaped, due to quarter –

quarter coatings or thickness relationship. These V-

shaped coatings are perfectly suitable for the point of

care applications as discussed in (Lee et.al. 2016) and

in OLED based bio sensors as in (Krujatz et.al. 2016).

2.2 Design of DLAR based OLED

This section describes the design and modelling of

Double layer Anti-reflective coating (DLAR) based

OLED.

2.2.1 Design of Fluorescent OLED

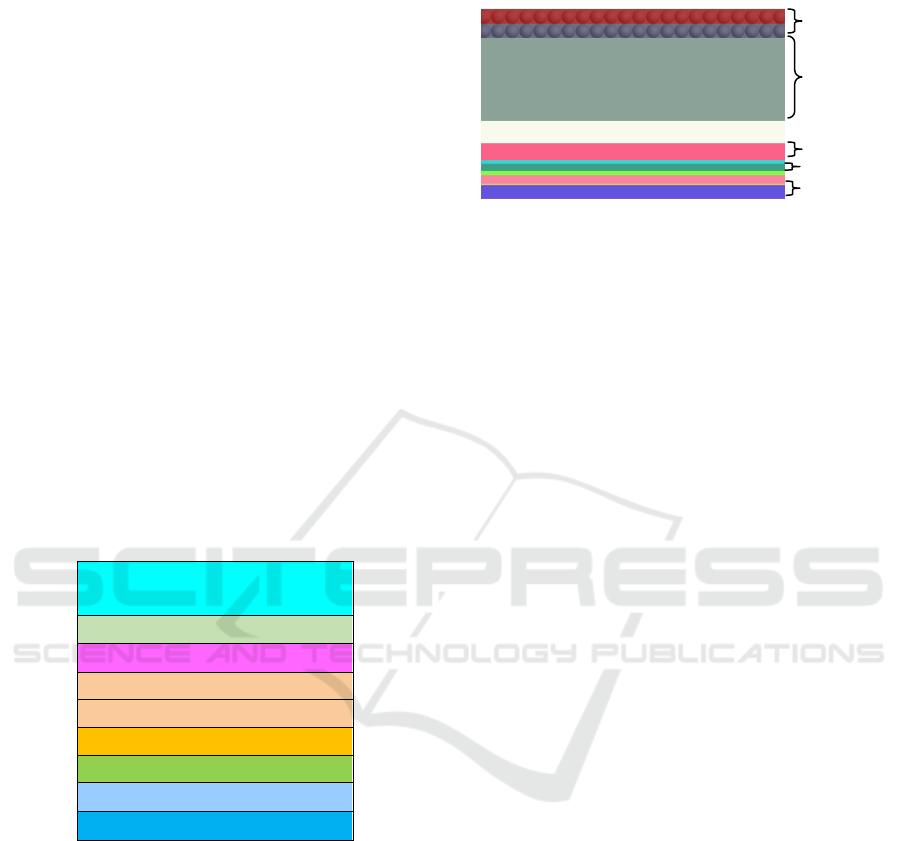

The DLAR based Fluorescent OLED shown in the

Figure 4. It contains multi-layer stack with Alq3-Tris

(8-hydroxyquinoline) aluminum as an Organic layer

placed in between anode and cathode. The Alq3 is

chosen in order to emit green light at an operating

wavelength of 540nm. The work function of the

various layers used in the proposed OLED structure

is chosen from (Novotny et al., 2006).

Double layer Anti-

reflective coatings

Glass Substrate

Anode-ITO-120nm

HIL=CuPc=15 to 30nm

HTL=TPD=40nm

NDP=30nm

Alq3=60nm

HBL=BCP=30nm

Cathode=Al=100nm

Figure 4: DLAR based Fluorescent OLED.

The refractive index of the materials and the structure

of the OLED used in the present work is referred from

the literature (Chaya et al., 2018). The DLAR is

placed on the surface of the substrate to avoid the light

trapped inside the layer. The maximum light is

coupled out to supress the losses due to reflections.

The simulation of the DLAR based OLED is carried

out using Lumerical FDTD.

Figure 5, shows the modeled double layer motheye

Anti-reflective coatings based OLED for the structure

shown in Figure 4. To obtain Fluorescent based

OLED device, the Alq3 organic material is used that

operates at 540nm. This layer is placed in emissive

layer.

Figure 5: Modelling of OLED using DLAR (XY View).

The double layer moth-eye Anti-reflective coatings

are made of top layer and bottom layer. The

Magnesium Fluoride and Mesoporous silica are used

as top and bottom layers of DLAR respectively.

These layers are placed on surface of the glass

substrate of the OLED to suppress reflections that

exist on the substrate-air interface. The materials used

in DLAR based OLED device are detailed as follows,

Indium Tin oxide as anode, Aluminum as Cathode,

BCP-(2, 9 Dimethyl-4, 7-diphenyl-1 as Hole

Blocking Layer (HBL), CuPC- (Copper (II)

phthalocyanine) as Hole Injection layer(HIL), (N, N’-

Bis (3-methylphenyl)-N,N’-diphenyl benzidine) as

Hole Transport layer(HTL)-TPD, Tris(8-

hydroxyquinoline) aluminum (Alq3) as emissive

layer, Double layer Motheye Anti-Reflective

Coatings (pitch=300nm, radius=100nm), Glass

Substrate with 1.52 refractive index is chosen in the

present work.

3 METHODOLOGY

The Fresnel’s Reflection theory is used in this work

to model the double layer motheye Anti-reflective

coatings. The reduction in reflectance from the glass-

air interface is achieved by optimising the thickness

of the double layer Anti reflection coatings. By

tailoring the thickness of the Anti-reflective coatings

destructive interferences is achieved to supress

reflection. As discussed in (Lee et.al, 2000), the two

quarter wavelength coatings, the Optimum refractive

index is determined by the equation (1) and (2),

glassairtop

nnn

23

(1)

23

glassairbottom

nnn

(2)

Where, n

top

= Refractive index of top layer Anti-

reflective coating, n

bottom

= Refractive index of bottom

Glass

Substrate

Anode

Organic Layer

Cathode

DLAR

coatings

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

192

layer ARC, n

air

=Refractive index of air, n

glass

=

Refractive index of glass substrate.

Where, n

top

= Refractive index of top layer Anti-

reflective coating, n

bottom

= Refractive index of bottom

layer ARC, n

air

=Refractive index of air, n

glass

=

Refractive index of glass substrate.

4 RESULTS AND DISCUSSION

4.1 Transmission and Reflectance

Patterns of DLAR

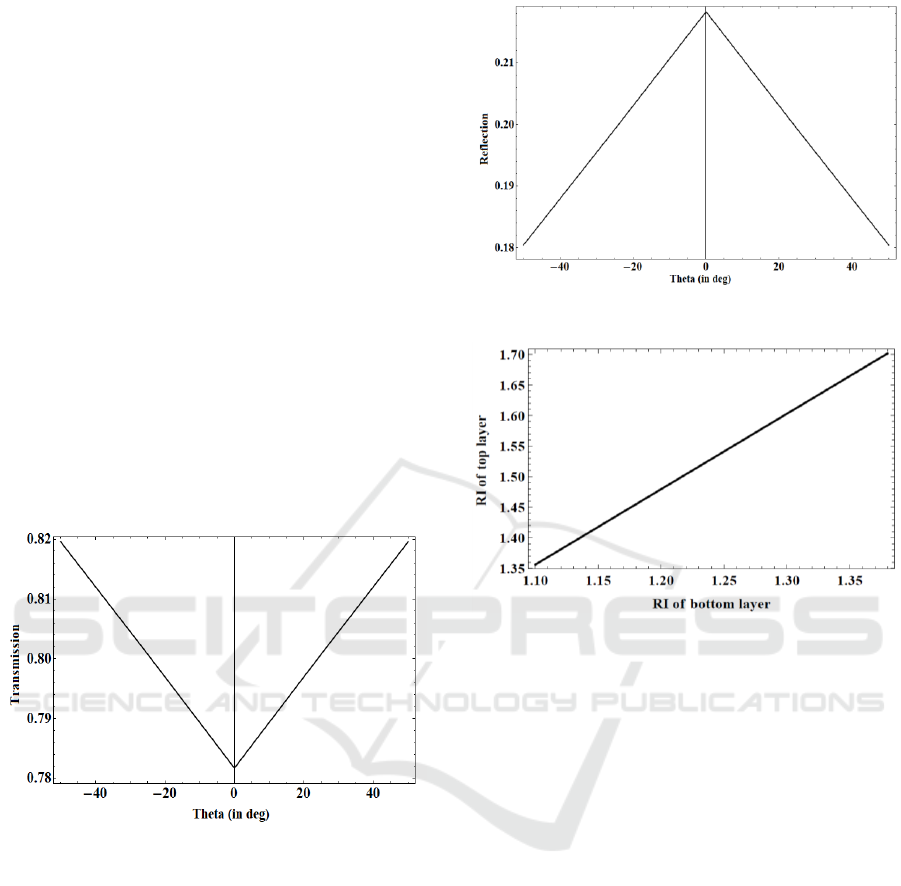

Figure 6 and 7, shows the transmission and

reflectance patterns of the double layer Anti-

reflective coatings with respect to viewing angle. The

transmission and reflectance patterns are obtained at

an operating wavelength of 540nm. Theta in the

graphs represent the angle at which the light transmits

and reflects normal to the surface.

It is observed from the Figure 6, that the transmission

of DLAR is greatly enhanced.

Figure 6: Transmission Spectra of DLAR.

Also in Figure 7, the reflection is almost suppressed

to zero, helps to reduce the glass substrate-air

interface losses, when this DLAR is placed on OLED.

4.2 Refractive Indices of Top and

Bottom Layer ARC

Figure 8, shows the Refractive index (RI) of Top

layer versus RI of bottom layer of ARC curve. For

different top layer RI values the RI of the bottom layer

ARC varies. Based on this analysis the coating

materials are chosen which is to be placed on the

OLED glass substrate.

Figure 7: Reflection Spectra of DLAR.

Figure 8: RI of Top and bottom coating layers.

4.3 Thickness of Top and Bottom

Layer ARC

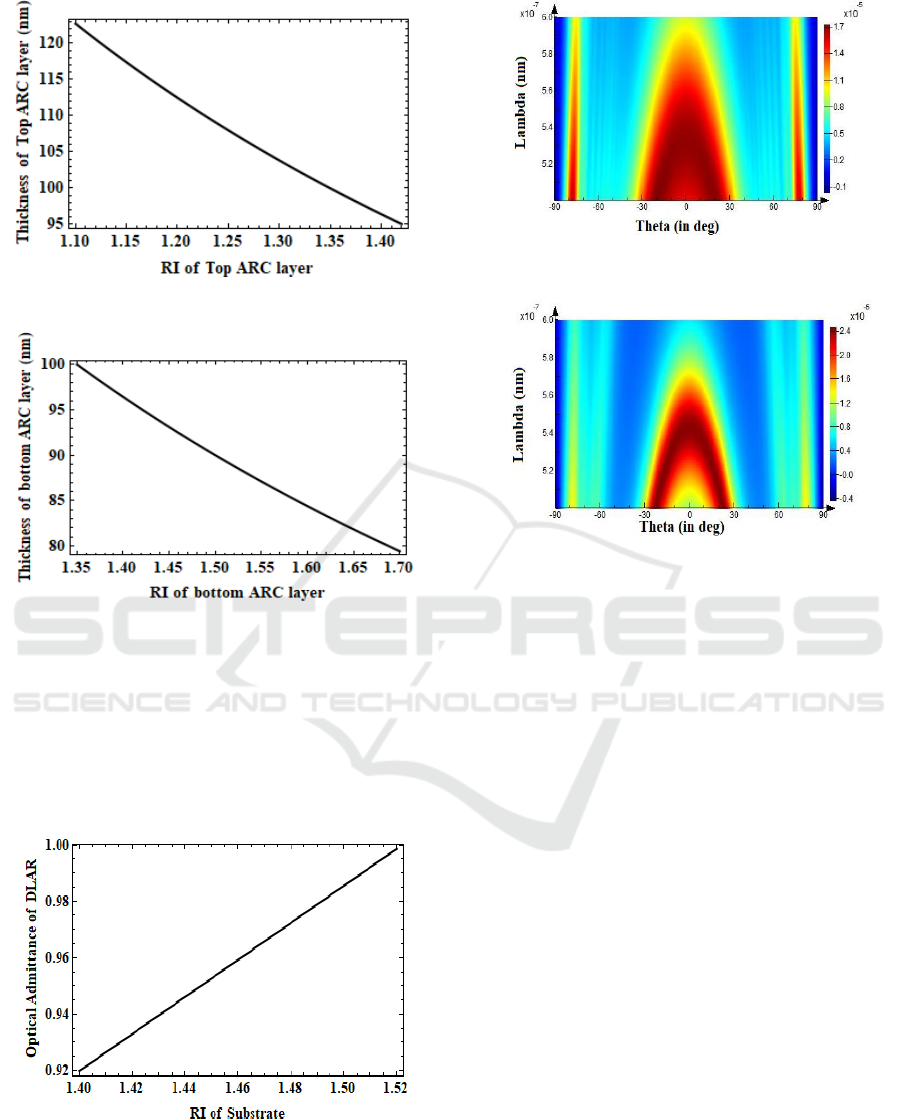

Figure 9 shows the thickness of the top layer ARC

calculated for coating materials of different RI of Top

ARC layer.

The curve shows that the thickness varies from 95 to

125 nm for coating materials of RI values ranging

from 1.10 to 1.42. Therefore, this curve ensures that

the ARC thickness is chosen appropriately for a

particular coating material.

Figure 10 shows the thickness of the bottom layer

ARC calculated for coating material for different

bottom layer ARC. The curve shows that the

thickness varies from 80nm to 100 nm for coating

materials of RI values ranging from 1.35 to 1.70.

Modeling and Analysis of Double Layer Motheye Anti Reflective Coatings on Organic Light Emitting Diode

193

Figure 9: Thickness of Top ARC layer.

Figure 10: Thickness of Bottom ARC layer.

4.4 Optical Admittance and Far Field

Profile of OLED

Figure 11 shows the optical admittance of the double

layer motheye anti-reflective coatings. The curve

shows the optical admittance of the substrate coated

with a quarter wave optical thickness of the DLAR.

Figure 11: Optical Admittance of DLAR.

Figure 12 (a): Far field intensity of Single layer ARC.

Figure 12 (b): Far field intensity of Double layer ARC.

The Far field intensity of the Single layer Anti-

Reflective coating on the surface of the substrate of

the OLED is shown. The materials chosen for the

coatings is Mesoporous silica with refractive index of

1.1.

The far field intensity achieved is about 1.7x10

-5

V/m

as shown in Figure 12 (a). When double layer

coatings of Magnesium Fluoride (MgF

2

) (top layer

ARC)

/ Mesoporous silica (bottom layer ARC) is

coated on the surface of the glass substrate of the

OLED.

The maximum reflection is supressed and far field

electric intensity is achieved of about 2.4 x 10

-5

V/m

compared to single layer ARC placed on OLED as

shown in Figure 12(b). It is observed that, the DLAR

based OLED performance enhances the far field

electric intensity compared to conventional OLED

devices.

5 CONCLUSIONS

In this work, the effects of reflectance and

transmittance of double layer motheye Anti-reflective

coatings are investigated. The thickness of the two

layer ARC are modelled using Fresnel’s theory. This

is done to reduce maximum reflections that imposes

losses on the substrate-air interface. Comparative

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

194

study is carried out for both DLAR and SLAR placed

on OLED. The enhancement in the far field intensity

is achieved with DLAR based OLED is 2.4 x 10

-5

V/m

in greater in comparison with single layer ARC

placed on OLED of about 1.7x10

-5

V/m. Based on

these simulations the reflection losses are reduced at

the glass-air interface of an OLED. Such DLAR

based OLED can be prepared to effectively use in

display and lab-on a chip applications.

ACKNOWLEDGEMENTS

The authors would like to thank Science and

Engineering Research Board, Department of Science

and Technology (DST-SERB) Government of India

for funding this research work.

File No. YSS/2015/000382

REFERENCES

Tang,C.W. and VanSlyke, S.A., 1987. Organic

electroluminescent diodes. Applied physics letters,

51(12), pp.913-915.

Tang, C.W., VanSlyke, S.A. and Chen, C.H., 1989.

Electroluminescence of doped organic thin films.

Journal of Applied Physics, 65(9), pp.3610-3616.

Shockley, W. and Read Jr, W.T., 1952. Statistics of the

recombinations of holes and electrons. Physical review,

87(5), p.835.

Macleod, H.A. and Macleod, H.A., 2010. Thin-film optical

filters. CRC press.

Lee, Y.J., Kim, S.H., Huh, J., Kim, G.H., Lee, Y.H., Cho,

S.H., Kim, Y.C. and Do, Y.R., 2003. A high-extraction-

efficiency nanopatterned organic light-emitting diode.

Applied Physics Letters, 82(21), pp.3779-3781.

Wasey, J.A.E. and Barnes, W.L., 2000. Efficiency of

spontaneous emission from planar microcavities.

Journal of Modern Optics, 47(4), pp.725-741.

Kim, K.H. and Park, S.Y., 2016. Enhancing light-extraction

efficiency of OLEDs with high-and low-refractive-

index organic–inorganic hybrid materials. Organic

Electronics, 36, pp.103-112.

Sharma, R., Amit, G. and Ajit, V., 2017. Effect of single

and double layer antireflection coating to enhance

photovoltaic efficiency of silicon solar.

Dhungel, S.K., Yoo, J., Kim, K., Jung, S., Ghosh, S. and Yi,

J., 2006. Double-layer antireflection coating of

MgF2/SiN x for crystalline silicon solar cells. Journal

of the Korean Physical Society, 49(3), pp.885-889.

Tan, G., Lee, J.H., Lan, Y.H., Wei, M.K., Peng, L.H.,

Cheng, I.C. and Wu, S.T., 2017. Broadband

antireflection film with moth-eye-like structure for

flexible display applications. Optica, 4(7), pp.678-683.

Keshavarz Hedayati, M. and Elbahri, M., 2016.

Antireflective coatings: Conventional stacking layers

and ultrathin plasmonic metasurfaces, a mini-review.

Materials, 9(6), p.497.

Katchman, B.A., Smith, J.T., Obahiagbon, U., Kesiraju, S.,

Lee, S.E., Choi, S.W. and Yi, J., 2000. Double-layer

anti-reflection coating using MgF2 and CeO2 films on

a crystalline silicon substrate. Thin Solid Films, 376(1-

2), pp.208-213.

Lee, Y.K., O’Brien, B., Kaftanoglu, K., Christen, J.B. and

Anderson, K.S., 2016. Application of flat panel OLED

display technology for the point-of-care detection of

circulating cancer biomarkers. Scientific reports, 6,

p.29057.

Krujatz, F., Hild, O., Fehse, K., Jahnel, M. and Werner, A.,

2016. Exploiting the potential of OLED-based photo-

organic sensors for biotechnological applications.

Chem Sci J, 7, p.134.

Chaya B M, et al. FDTD Modeling and Simulation of

Organic Light Emitting Diode with Improved

Extraction Efficiency using Moth-eye Anti-Reflective

Coatings, Proceedings of the 6th International

Conference on Photonics, Optics and Laser Technology

(PHOTOPTICS 2018), pages 266-272.

Novotny, L. and Hecht, B.2006. Principles of Nano-

Optics, Cambridge, Cambridge University Press

Modeling and Analysis of Double Layer Motheye Anti Reflective Coatings on Organic Light Emitting Diode

195