Residual Stress Analysis of Aluminum-doped Zinc Oxide Films under

Laser-Induced Recovery Process

Yu-Chen Hsieh, Ching-Ching Yang, Chih-Chung Yang, Yu-Hsuan Lin, Kuo-Cheng Huang

and Wen-Tse Hsiao

Instrument Technology Research Center, National Applied Research Laboratories, 20, R&D Rd. VI. Hsinchu Science Park,

Hsinchu City, Taiwan

Keywords: Ultraviolet Laser System, Low-temperature Annealing, Aluminum Doped Zinc Oxide Films,

Induced-crystalline, Residual Stress Analysis.

Abstract: In this study, a low-temperature annealing technique using an ultraviolet laser was proposed for inducing the

crystallization of transparent conductive aluminum-doped zinc oxide (AZO) films. The technique was used

in conjunction with a galvanometer scanner to adjust the laser energy density and scanning speed, thereby

inducing the amorphous crystallization of thin films. X-ray diffraction was used to analyze the structural

properties of annealed thin films. Analysis with different galvanometer scanning speed during annealing and

laser pulse repetition rates during annealing revealed that the two diffraction peaks (i.e., the (002) and (103)

peaks) of the zinc oxide thin films became more noticeable as the laser pulse repetition rate increased. When

the galvanometer scanning speed during annealing was set to 400 mm/s and 600 mm/s, the full width at half

of the maximum (FWHM) of the AZO thin films decreased while the annealing frequency increased. By

contrast, when the annealing speed was 800 mm/s, increasing the annealing frequency caused the FWHM to

decrease and then increase. An analysis of the residual stress of the annealed thin film confirmed that when

the annealing speed was reduced from 800 mm/s to 400 mm/s, increases in laser pulse repetition rate resulted

in increased residual stress.

1 INTRODUCTION

Regarding the development of materials and

techniques used in manufacturing monitors, the three

major materials used for creating thin-film-transistor

(TFT) components are amorphous-silicon (a-Si) thin

films, poly-silicon thin films, and oxide

semiconductors. To meet the requirements of the

wearable-device and Internet of Things industries,

optoelectronic components should be light, thin,

short, and multifunctional. Additionally, in response

to the advocacy for energy-efficient policies, highly

efficient components with low power consumption

have become increasingly prevalent in electronic

products. The resistivity, crystallization (i.e.,

amorphous, crystalline, and polycrystalline), carrier

concentration, and electron mobility of transparent

conductive thin-film materials can affect the

efficiency and power consumption of a thin-film

device. Recrystallization annealing can be used to

address problems concerning the electron mobility

and off-state current of conventional a-Si TFTs.

Conventional methods for changing the crystalline

state of an amorphous thin film include solid-phase

crystallization, metal-induced crystallization, and

excimer laser crystallization. (Coherent, Inc. 2015)

proposed a technique involving the use of excimer

lasers to perform low-temperature a-Si laser

annealing. This technique can increase monitor

resolution and is applicable to large-scale monitors,

active-matrix liquid-crystal displays, active-matrix

organic light-emitting diodes, organic light-emitting

diode televisions, and flexible electronics. (Zhang et

al. 2012) applied nanosecond and picosecond single-

shot lasers to induce the crystallization of Ge

2

Sb

2

Te

5

thin films and plot a curve representing the

relationship between crystallization temperature and

instantaneous laser energy. This enabled examination

of the ablation threshold, melt threshold, solid-phase

crystallization, and melt recrystallization of thin

films. Their experimental results confirmed that

recrystallization could be achieved under the ablation

threshold of Ge

2

Sb

2

Te

5

by using different values of

laser energy density and exposure time to improve the

134

Hsieh, Y., Yang, C., Yang, C., Lin, Y., Huang, K. and Hsiao, W.

Residual Stress Analysis of Aluminum-doped Zinc Oxide Films under Laser-Induced Recovery Process.

DOI: 10.5220/0007363601340138

In Proceedings of the 7th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2019), pages 134-138

ISBN: 978-989-758-364-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

characteristics of the material. (Huang et al. 2013)

used relevant theories to conduct an experiment in

which a-Si thin films were exposed to a green-light

nanosecond laser at 532 nm; subsequently, a finite

element analysis was conducted to simulate the melt-

recrystallization process and determine the optimal

energy density. Their experimental results revealed

that the recrystallization temperature and melting

depth varied with the laser exposure time.

Specifically, the results of Raman spectroscopy

revealed that optimal crystallization was achieved

when the energy density was 1000 mJ/cm

2

. By using

excimer lasers to induce the recrystallization of a-

Si/SiO

2

/glass thin films, (Kuo et al. 2007)

investigated the effect of excimer laser during the

melting process on silicon recrystallization, film

thickness, and substrate temperature. They observed

notable changes in film thickness when the melting

duration was increased, particularly at high

temperatures. (Emelyanov et al. 2014) used

femtosecond lasers to induce the recrystallization of

a-Si thin films; specifically, the experiment involved

adjusting the energy density of the laser to identify

the parameters affecting the structure and

photoelectrical characteristics of such thin films.

(Cheng et al. 2014) used a high-repetition-rate

femtosecond laser to induce the crystallization of

transparent conductive thin films composed of

amorphous indium tin oxide (ITO). The results

revealed that with the laser energy of 536 mJ,

repetition rate of 0.05 MHz, and scanning speed of

0.25 mm/s, the crystal structure was perpendicular to

the scanning path (E/C). (Lee et al. 2010) used a 248-

nm krypton fluoride excimer laser to anneal

aluminum-doped zinc oxide (AZO) thin films and

analyze their structure, surface morphology, and

photoelectrical characteristics. The laser energy

density and frequency were fixed at 160 mJ/cm

2

and

10 Hz, respectively, and the laser pulse number

ranged between 600 and 3000. The scanning electron

microscopic analysis revealed that during the laser

annealing process, the pore size of the thin film was

reduced, thereby increasing the grain boundary. The

XRD analysis confirmed that when the number of

laser pulses increased, the diffraction peak intensity

also increased, indicating more favorable crystalline

characteristics. (Tsang et al. 2008) adopted the sol-gel

process to prepare AZO thin films, and a krypton

fluoride excimer laser was used at various energy

levels to anneal the thin films. The XRD analysis

revealed that under a fixed laser pulse number,

increasing the laser energy caused the diffraction

peak values to increase. Similarly, increasing the laser

pulse number under fixed laser energy also increased

the diffraction peak values, indicating that both laser

energy and pulse number affected the thin-film

structure. Investigations of the electrical

characteristics of annealed crystalline structures have

revealed that resistivity noticeably decreases in

response to increases in laser energy. This

phenomenon is attributable to the increased electron

mobility caused by crystal defects and reduced grain

boundary density (Tsang et al. 2008). (Chen et al.

2012) (Chen et al. 2011) used laser beam shaping

techniques to anneal transparent conductive ITO thin

films and fluorine-doped tin oxide thin films. Their

results revealed that laser processing parameters (e.g.,

spot shape, energy distribution, spot overlay, and

operating modes) affected the photoelectrical

characteristics of annealed thin films. In the case of

the fluorine-doped tin oxide thin film, its resistivity

decreased from 7.19 ± 0.55 to 6.70 ± 0.20 × 10

−3

Ω-

cm. (Kim et al. 2011) proposed a low-cost annealing

technique applicable to large-scale metal-oxide thin

films that could be used to manufacture TFT liquid-

crystal displays and flexible electronics. They noted

that conventional annealing chambers require an

annealing temperature of >400 °C, which is

unsuitable for processing the substrates of flexible

electronics; hence, they proposed a low-temperature

manufacturing technique (<200 °C) to anneal four

thin-film materials (In

2

O

3

, a-Zn-Sn-O, a-In-Zn-O,

and ITO). (Morimoto et al. 2012) used a 405-nm

gallium nitride laser diode as the light source for

inducing the crystallization of a-Si TFTs, which were

compared with those with crystallization induced

with commercially available 405-nm, 445-nm, and

532-nm light sources. The results confirmed that a-Si

exhibited a greater absorbance coefficient at 405 nm.

Data from the simulation and experiment regarding

the evenness of the resulting crystalline structure and

efficiency of the crystallization process indicated that

the proposed method can be used to recrystallize and

transform a-Si into micro crystalline Si. (Huang et al.

2016) proposed a 532 nm pulse laser to anneal Al-

doped ZnO films on polyethylene terephthalate (PET)

flexible substrate. By using the laser annealing could

greatly enhance grain crystalline. When the

crystalline size increased and avoid damage to the

PET flexible substrates. (Xu et al. 2018) used light

emission based physical approaches to measure the

driving voltage, reverse current versus relative light

intensity. In addition, the spectroscopic information

shown that the electroluminescence (EL) spectrum

has a broad emitting range of 400-900 nm.

Residual Stress Analysis of Aluminum-doped Zinc Oxide Films under Laser-Induced Recovery Process

135

2 THE PROPOSED

LASER-INDUCED RECOVERY

SYSTEM, SAMPLE PREPARED,

AND RESIDUAL STRESS

ANALYSIS

The proposed low-temperature laser annealing

system contains a Nd:YVO

4

laser source,

galvanometer scanning module, and beam delivery

system. The specifications of the proposed system are

as follows: a laser wavelength of 355 nm, maximal

output power of 14 W, spatial mode of TEM

00

,

maximal pulse repetition rate of 300 kHz, and pulse

width of 30 ns. The galvanometer scanning module

consists of a telecentric lens with a focal length of 163

mm, and its scanning range reaches 60 mm × 60 mm,

which is sufficient for covering the entire annealing

area. The transparent conductive AZO thin film was

prepared first by using a sputtering approach to

deposit the film on a Corning Eagle 2000 glass

substrate (Corning Inc., United States) with an

approximate thickness of 200 nm. To avoid damaging

the glass substrate during the annealing process, the

laser energy was maintained at 61.2 μJ, while the

pulse repetition rate was adjusted to 40, 55, and 70

kHz and the scanning speed was adjusted to 400, 600,

and 800 mm/s. In Bragg’s law (1), d denotes lattice

spacing, θ denotes diffraction angle, and λ denotes X-

ray wavelength (0.154 nm). Accordingly, d decreases

when θ increases, indicating a decrease in film stress.

Therefore, a biaxial stress model can be used to

estimate the residual stress of a thin film during

modification (Jun et al. 2012). Film stress can be

estimated using (2) when it is being analyzed in the c-

axis direction using XRD.

nd sin2

(1)

bulk

bulkfilm

film

C

CC

(2)

where C

bulk

is the lattice strain constant (0.2609

nm) of the ZnO thin film. C

film

was estimated by

substituting the lattice parameter of the AZO thin film

that was derived from XRD analysis into (1). The

surface-layer stress of the thin film can be estimated

using (3) (Jo et al. 2018).

filmf

c

cccc

13

121133

2

13

2

2

(3)

where c

ij

is the elastic constant of ZnO. According

to research on elastic constants (Cebulla et al. 1998),

c

11

= 208.8 GPa, c

12

= 119.7 GPa, c

13

= 104.2 GPa,

and c

33

= 213.8 GPa.

3 STRUCTURE ANALYSIS OF

ANNEALED AZO THIN FILMS

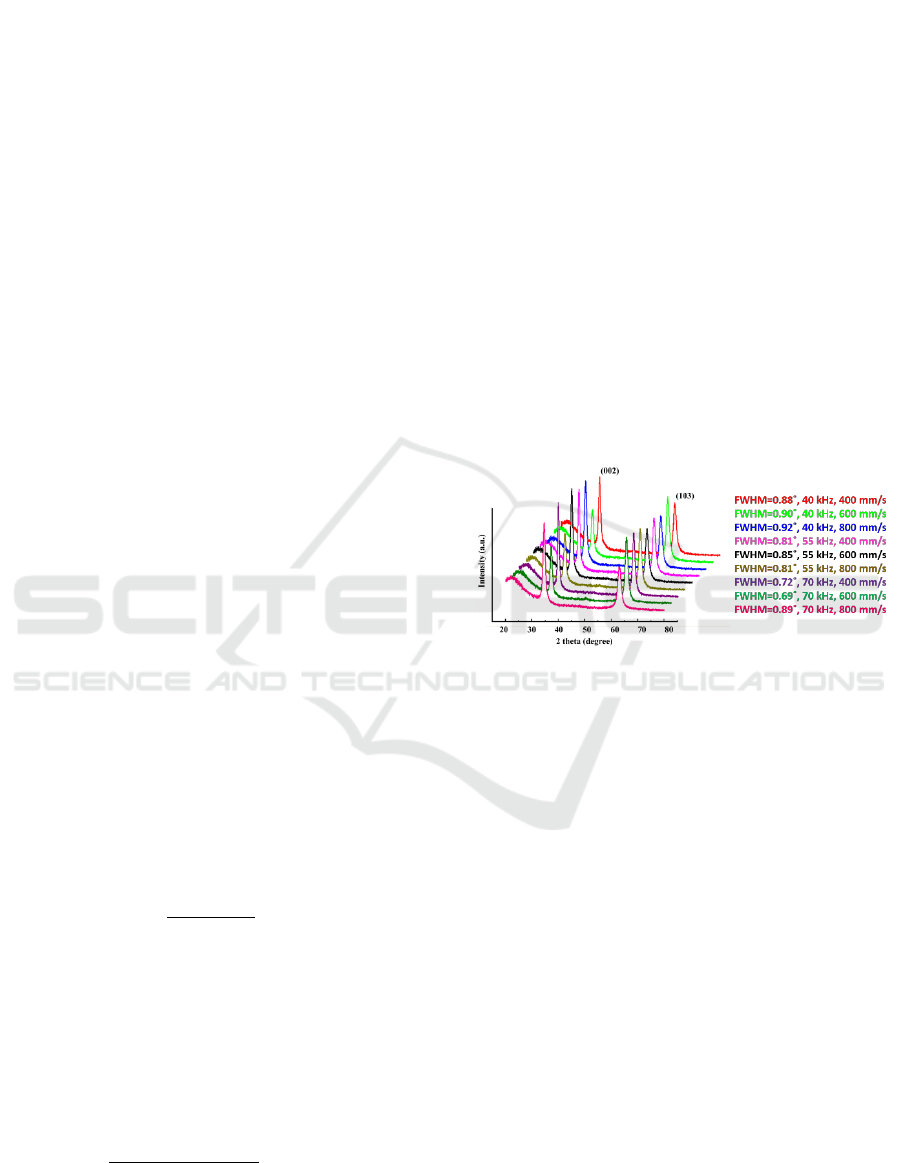

Figure 1 presents the XRD spectra of the AZO thin

films deposited on a Corning Eagle 2000 glass

substrate at different galvanometer scanning speed

during annealing and laser pulse repetition rates (40,

55, and 70 kHz). The spectra exhibited two noticeable

diffraction peaks of the zinc oxide thin films, namely

the (002) and (103) peaks. Increasing the laser pulse

repetition rate caused a substantial increase in the

intensity of the (002) peak. The Scherrer equation is

used for calculating the crystallite size from FWHM

of the (002) peak.

Figure 1: XRD spectrum of AZO films under different

recovery process conditions. (Hsiao et al. 2013).

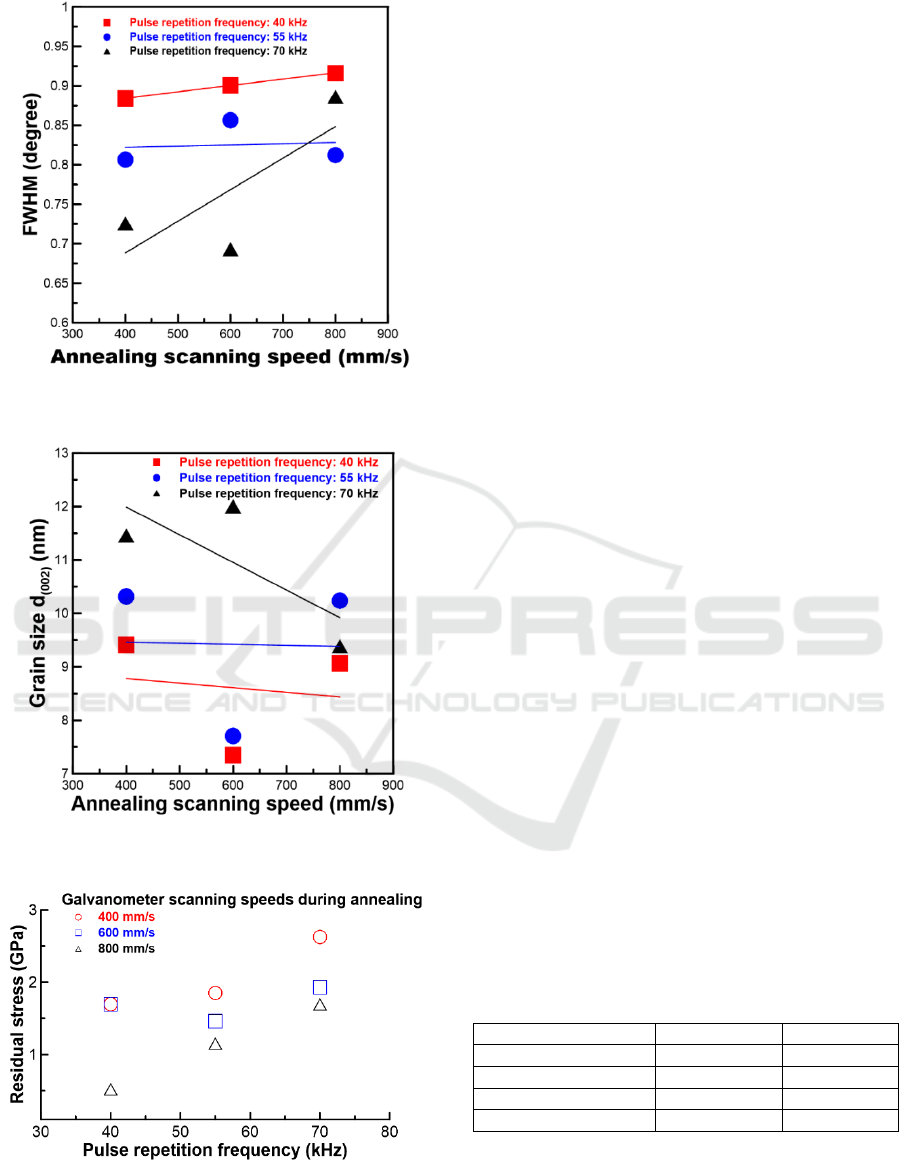

As indicated in Figure 2, when the galvanometer

scanning speed during annealing was set to 400 and

600 mm/s, the FWHM of the annealed AZO thin film

decreased in accordance with the increasing

annealing frequency. When the galvanometer

scanning speed during annealing was set to 800 mm/s,

the increase in annealing frequency caused the

FWHM to decrease and then increase. These findings

indicated that the grain size of the annealed thin film

was affected by the laser pulse repetition rate and

scanning speed.

The results displayed in Figure 3 revealed that

when the galvanometer scanning speed during

annealing was reduced from 800 to 400 mm/s, the

grain size increased from 7.4 nm to 12 mm. Figure 4

presents the residual stress of the annealed AZO thin

films under the laser pulse repetition rates of 40, 55,

and 70 kHz and scanning speeds of 400, 600, and 800

mm/s; residual stress was calculated using (1)–(3).

The results confirmed that the residual stress of the

thin films increased in accordance with increases in

the laser pulse repetition rate. By contrast, the

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

136

Figure 2: Relationship between FWHM versus different

annealing speeds.

Figure 3: Grain size versus annealing speeds under different

pulse repetition frequency.

Figure 4: Residual stress versus pulse repetition frequency

under different speeds.

residual stress decreased with increasing scanning

speeds under a constant laser pulse repetition rate.

This was attributable to both the increases in pulse

energy of the Nd:YVO

4

laser source in accordance

with the increasing repetition rate and the

accumulation of excessive heat on the thin-film

surface as a result of a low scanning speed.

4 CONCLUSIONS

A low-temperature annealing technique using an

ultraviolet laser was proposed in this study for

inducing the crystallization of transparent conductive

AZO thin films. XRD was used to analyze the

structure of annealed thin films. The resulting XRD

spectra exhibited two noticeable diffraction peaks,

(002) and (103), the intensity of which increased with

an increasing laser pulse repetition rate. The FWHM

of the AZO thin film increased in accordance with

decreasing annealing frequency. When the

galvanometer scanning speed during annealing was

800 mm/s, increasing the annealing frequency caused

the FWHM to decrease and then increase. When the

scanning speed during annealing was reduced from

800 to 400 mm/s, increasing the laser pulse repetition

rate increased the residual stress of the thin film.

Under a fixed laser pulse repetition rate, the residual

stress of the thin film decreased with the increasing

scanning speed during annealing. This was

attributable to two phenomena: the pulse energy of

the Nd:YVO

4

laser source increased as a result of an

increasing repetition rate, and excessive heat

accumulated on the thin-film surface because of the

low scanning speed. Table1 summarizes the stress

under different annealing processes of AZO films (Jo

et al. 2018) (Huang et al. 2016) and (Kim et al. 2017).

In this experiment results indicated that the calculated

the stress values in the annealed AZO films were

approximately less than 3 GPa. During the higher

scanning speed of 800 mm/s, the residual stress were

less than 2 GPa.

Table 1: Specification of the picosecond laser scanning

system.

Authors

Methods

Stress (GPa)

(Jo et al. 2018)

UV +RTA

-0.3 ~ 0.7

(Huang et al. 2016)

Green laser

-

(Kim et al. 2017)

UV + RTA

-

Our present

UV laser

< 3

Residual Stress Analysis of Aluminum-doped Zinc Oxide Films under Laser-Induced Recovery Process

137

ACKNOWLEDGEMENTS

This work was supported in part by the Ministry of

Science and Technology, TAIWAN, numbers MOST

106-2221-E-492 -012 and 107-2622-E-492 -009 -

CC3

REFERENCES

COHERENT, Co. Ltd., 2015. White paper: The digital

display revolution: Built on Excimer laser annealing.

Zhang, K., Li, S., Liang, G., Huang, H., Wang, Y., Lai, T.,

Wu, Y., 2012. Different crystallization processes of as-

deposited amorphous Ge

2

Sb

2

Te

5

films on nano-and

picoseconds single laser pulse irradiation. Physica B,

Vol. 407, pp. 2447-2450.

Huang, L., Jina, J., Shia, W., Yuanb, Z., Yanga, W.,

Caoa, Z., Wanga, L., Zhoub, J., Loub, Q., 2013.

Characterization and simulation analysis of laser-

induced crystallization of amorphous silicon thin films.

Mater. Sci. Semicond. Process. Vol. 16, pp. 1982-1987.

Kuo, C.C., Yeh, W.C., Lee, J.F., Jeng, J.Y., 2007. Effects

of Si film thickness and substrate temperature on melt

duration observed in excimer laser-induced

crystallization of amorphous Si thin films using in-situ

transient reflectivity measurements. Thin Solid Films

Vol. 515, pp. 8094-8100.

Emelyanov, A.V., Khenkin, M.V., Kazanskii, A.G., Forsh,

P.A., Kashkarov, P.K., Gecevicius, M., Beresna, M.,

Kazansky, P.G., 2014. Femtosecond laser induced

crystallization of hydrogenated amorphous silicon for

photovoltaic applications. Thin Solid Films Vol. 556,

pp. 410-413.

Cheng, C.W., Lee, I.M., Chen, J.S., 2014. Femtosecond

laser-induced nanoperiodic structures and simultaneous

crystallization in amorphous indium-tin-oxide thin

films. Appl. Surf. Sci. Vol. 316, pp. 9-14.

Lee, S., Seong, J., Kim, D.Y., 2010. Effects of laser-

annealing using a KrF excimer laser on the surface,

structural, optical, and electrical properties of AlZnO

thin films. J. Korean Phys. Soc. Vol. 56, pp. 782-786.

Tsang, W.M., Wong, F.L., Fung, M.K., Chang, J.C., Lee,

C.S., Lee, S.T., 2008. Transparent conducting

aluminum-doped zinc oxide thin films prepared by sol-

gel process followed by laser irradiation treatment. Thin

Solid Films Vol. 517, pp. 891-895.

Chen, M.F., Lin, K.M., Ho, Y.S., 2012. Laser annealing

process of ITO thin films using beam shaping

technology. Opt. Lasers Eng. Vol. 50 pp. 491-495.

Chen, M.F., Lin, K.M., Ho, Y.S., 2011. Effects of laser-

induced recovery process on conductive property of

SnO

2

:F thin films. Mater. Sci. Eng. B Vol. 176, pp. 127-

131.

Kim, M.G., Kanatzidis, M.G., Facchetti, A., Marks, T.J.,

2011. Low-temperature fabrication of high-

performance metal oxide thin-film electronics via

combustion processing. Nat. Mater. Vol. 10, pp. 382-

388.

Morimoto, K., Suzuki, N., Liu, X., Samonji, K., Yamanaka,

K., Yuri, M., 2012. Amorphous Si crystallization by

405 nm GaN laser diodes for high performance TFT

applications: advantages of using 405 nm wavelength.

Proc. of SPIE Vol. 8244, pp. 824407-1.

Jun, M.C., Park, S.U., Koh, J.H., 2012. Comparative

analysis of Al-doped ZnO and Ga-doped ZnO thin

films. Integr. Ferroelectr., Vol. 140, pp. 166-176.

Cebulla, R., Wendt, R., Ellmer, K., 1998. Al-doped zinc

oxide films deposited by simultaneous rf and dc

excitation of a magnetron plasma: relationships

between plasma parameters and structural and electrical

film properties. J. Appl. Phys. Vol. 83, pp. 1087-1095.

Hsiao, W.T., Tseng, S.F., Huang, K.C., Chiang, D., 2013.

Electrode patterning and annealing processes of

aluminum-doped zinc oxide thin films using a UV laser

system. Opt. Laser Eng. Vol. 51, pp. 15-22.

Huang, L.J., Li, B.J., Ren, N.F., 2016. Enhancing optical

and electrical properties of Al-doped ZnO coated

polyethylene terephthalate substrates by laser annealing

using overlap rate controlling strategy. Ceramic

International Vol. 42, pp. 7246-7252.

Jo, G.H., Kim, S.H., Koh, J.H., 2018. Enhanced electrical

and optical properties based on stress reduced graded

structure of Al-doped ZnO thin films. Ceramic

International Vol. 44, 735-741.

Xu, K., Huang, L., Zhang, Z., Zhao, J., Zhang, Z., Snyman,

L.W., Swart, J.W., 2018. Light emission from a poly-

silicon device with carrier injection engineering.

Materials Science & Engineering B Vol. 231, pp. 28-

31.

Kim, J., Ji, J.H., Min, S.W., Jo, G.H., Jung, M.W., Park,

M.J., Lee, S.K., Koh, J.H., 2017. Enhanced

conductance properties of UV laser / RTA annealed Al-

doped ZnO thin films. Ceramic International Vol. 43,

3900-3904.

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

138