Technical and Economic Analysis Repair of the Wooden Boat using

Fiberglass Laminates on Fishing Boats in Lamongan District

Mohammad Sholikhan Arif

1 a

, Heri Supomo, Hasanuddin, Sri Rejeki Wahyu Pribadi,

Wing Hendro Prasetyo Akbar Putra, Dedi Budi Purwanto, Sufian Imam Wahidi,

Ahmad Nasiruddin, and Chandra Ariesta

1

Department of Naval Architecture, Institut Teknologi Sepuluh Nopember, Indonesia

Keywords: Boat Repair, Fibreglass Laminates, Fishing Boat, Lamongan District, Wooden Boat.

Abstract: In 2016 there are 3,263 vessels fishing boats in Lamongan, and 90 percent uses wood as the primary material

for fishing vessels. The wooden boat repair activities in the Lamongan Regency are very high, considering

the wooden vessels repaired regularly so that the vessels' condition remains suitable for fishing activities in

fishing. At present, repairing wooden vessels still uses conventional methods, such as attaching the skin of

the boat with fiber or cloth axis and replacing damaged wood with new ones. Conventional methods are

inefficient and ineffective because it has checked periodically and it is expensive to buy new wood,

considering the price of wood is increasingly expensive because of the difficulty of finding wood material.

One new method in repairing damage to new boats by using FRP (Fiberglass Reinforced Plastic) lamination.

In this research, tensile testing carried out on several fibreglass layers on wood to obtain the most significant

strength. Furthermore, we have an economic analysis to get the cheapest variations of fibreglass lamination.

1 INTRODUCTION

Lamongan Regency located on 6

o

51 '- 7

o

23' South

Latitude and 112

o

33 '- 112

o

34 East Longitude.

Lamongan Regency has approximately 1,812.8 km2

or ± 3.78% of the total area of East Java Province.

With a length of 47 km, the sea area of Lamongan

Regency is 902.4 km2, if calculated 12 miles from sea

level (Norromadani, 2016).

According to data from the Central Statistics

Agency of Lamongan Regency in 2008, fish

production in Lamongan District amounted to 61,436

tons, Lamongan with the most significant amount of

fish production in East Java, it also had an impact on

the lives of the community, where most of the

Lamongan community utilize resources fisheries as

their livelihood or work as fishermen, both permanent

fishermen. With the most significant amount of fish

production in East Java, resulting in the number of

fishers in Lamongan because of the many fishermen,

Lamongan Regency become the highest number of

fishers (Utami, 2016).

Maintenance of wooden boats used to catch fish is

needed to keep the boat in good condition, and repairs

are needed if damage occurs. In general, a wooden

boat maintenance and repair must be done on regular

basis, and if not done properly and adequately, it will

result in high costs for the boat repair process. (Arif,

2018) The process carried out in repairing the damage

uses several conventional methods, including using

natural fibres and fabric wicks to patch the boundaries

between the wood. From a technical perspective. this

is obviously lacking and needs to be done both

technically and economically. As a result, one method

of repairing a wooden boat using fibreglass

lamination exist.

This study aims to conduct a technical and

economic analysis of wooden boat repairs using

fibreglass laminates application methods on existing

boat objects in the coastal fishing community of

Lamongan. The technical analysis carried out is to

obtain the number of fibreglass layers that will be

applied to the repair of wooden boats that meet the

classification requirements, and economic analysis to

get the cost of repairing wooden boats using

fibreglass laminates.

128

Arif, M., Supomo, H., Hasanuddin, ., Pribadi, S., Putra, W., Purwanto, D., Wahidi, S., Nasiruddin, A. and Ariesta, C.

Technical and Economic Analysis Repair of the Wooden Boat using Fiberglass Laminates on Fishing Boats in Lamongan District.

DOI: 10.5220/0010856000003261

In Proceedings of the 4th International Conference on Marine Technology (senta 2019) - Transforming Maritime Technology for Fair and Sustainable Development in the Era of Industrial

Revolution 4.0, pages 128-135

ISBN: 978-989-758-557-9; ISSN: 2795-4579

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 LITERATURE REVIEW

2.1 Damage to Wooden Boat

There are several types of damage to wooden hulls as

follows:

2.1.1 Marine Growth

Marine growth is a various species of marine

animals/plants that grow and colonize the surface of

buildings/structures in the sea, where temperature,

food/nutrition, pH (acidity) factors, and other

environmental conditions are suitable for their

growth. The growth of marine growth on the surface

of this building may cause various problems. Marine

growth that grows on wooden boats will cause the

boat's weight to increase, causing additional

resistance to the boat. In addition, marine growth on

fishing boats will increase the boat's resistance when

moving because the surface of the boat's skin

becomes rough.

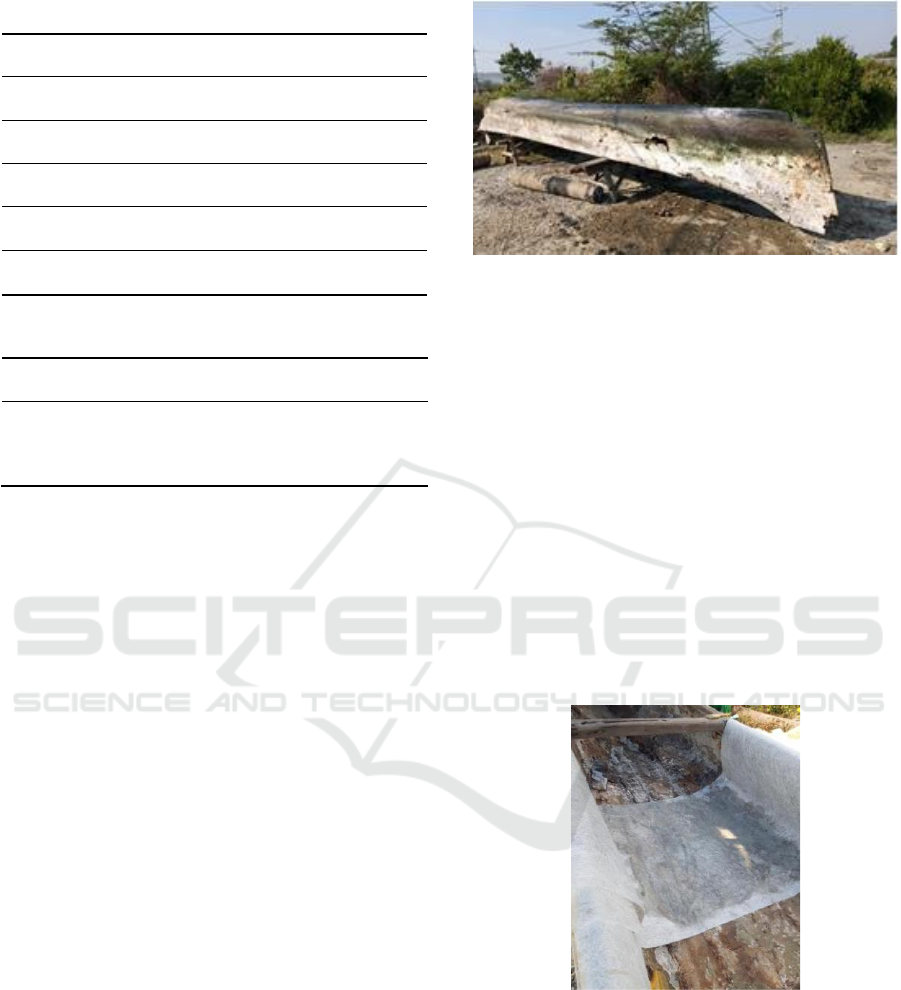

Figure 1: Marine growth.

2.1.2 Wood Weathering

Wood Weathering occurs in the natural process of the

wood itself, also caused by destructive marine

animals such as moulds and barnacles attached to the

body of the boat and microbes in the form of mould

mildew. During this time, the process of

drying/preservation of material carried out at the

Boatyard naturally and takes up to one month, which

will affect the strength of fishing vessels.

Weathering on wooden boats will cause damage

to the boat hull in the form of leakage or reduced

strength of the boat when receiving loads, both

internal and external.

Figure 2: Wood weathering.

2.1.3 Leaks (holes)

Leakage on the hull is one of the results of several

previous events, such as the condition of weathered

wood and the presence of sea animals that enter the

construction of the wooden hull (Greene, 2016).

Figure 3: Leakage because of sea animals.

2.1.4 Crack

Crack damage on wooden boats occurs due to several

possibilities such as collisions with objects, collisions

on the hull of the boat and in the form of collisions

with fellow boats or collisions between boats with

objects in the water such as rocks, buoys, beams, logs,

chunks of ice or collisions with other boats with

objects in the water such as rocks, buoys, beams, logs,

chunks of ice and others.

Collision with objects on the edge of the land,

such as jetty and breakwater, occurs when they jutting

into the water. Another possible cause of cracking is

the damage associated with wave propagation to the

hull of the boat due to the vibration of the propulsion

engine and the other engines as well as the impact of

the waves on the hull of both waves from the outside

and waves that arise due to the spinning of the

propeller engine and the other engines as the impact

Technical and Economic Analysis Repair of the Wooden Boat using Fiberglass Laminates on Fishing Boats in Lamongan District

129

of the waves on the hull of both waves from the

outside and waves that arise due to the spinning of the

propeller engine and the other engines as with the

waters when the boat is operated in the construction

of the boat and damaged due to excessive vibration

caused by faults in the design of construction where

the vibration is not channelled correctly so that the

construction experiences a cracking and release of

welding from certain parts of the construction caused

by defects in the design of construction where the

vibration is not appropriately channelled so that the

construction experiences a cracking and release of

welding from certain parts of the construction due to

other defects in the design of construction where the

vibration is not appropriately channelled. Propeller

leaf damage.

Figure 4: Crack on the wooden boat.

2.2 The Material Used for Wooden

Boat Repair using Fiberglass

Materials used in boat repair using fiberglass

lamination are (Baskoro, 2018):

2.2.1 Resin

Resin is a binder used to support fiberglass so that the

fiberglass stays in place. The resin consists of three

main components, glycol, organic acids, and active

thinners (usually styrene). Resins that used are

polyester resins, vinyl ester resins, and epoxy resins

(Bader, 2002).

2.2.2 CSM (Chopped Strand Mat)

Chopped Strand Mat (CSM) is a type of fiberglass

made of glass fiber placed and arranged randomly

between one another. CSM Fiberglass is

distinguished by weight per square meter. For

example, CSM 300 means that each square meter of

fiberglass weighs 300 grams.

2.2.3 WR (Woven Roving)

Woven Roving (WR) is fiberglass made of glass fiber

woven in two directions continuously at an angle of

90°. Fiberglass WR is the reinforcement material

most often used for the construction of marine

structures.

2.2.4 Catalyst

The catalyst has the function of accelerating the

curing and polymerization between resin and

fiberglass.

2.2.5 Talc

Talc serves as a mixture of fiberglass dough to make

it rigid and somewhat flexible; as the name suggests,

this material is white powder-like sago.

2.2.6 Gelcoat

Gelcoat is a layer made of resin, aerosol, and cobalt

(accelerator). In making Gelcoat, the three materials

mixed evenly. When the gel coat has cured, the gel-

coat will have a shiny and smooth surface. Therefore

the gel coat is generally applied as the outermost layer

of the laminate after the release agent layer.

The method used in this boat repair process is by

direct application (Boat Structure Committee, 1990).

Fiberglass is applied to damaged wooden fishing

boats using the multi-layered (3-layer) method and

then analyse economic feasibility calculations with

the repair method compared to traditional wooden-

boat repair.

3 METHODOLOGY

3.1 Technical Method

The material, tensile, and compressive testing are

carried out to find out the strength of the tensile and

compressive. There are five variations of material to

be used as shown in Table 1.

Table 1: Variations and lamination schedule.

Name Lamination Schedule

1

st

Variation Wood

(

reference material

)

2

nd

Variation Wood + CSM300 +WR600 + CSM300

3

rd

Variation Wood + CSM450 +WR600+ CSM300

4

th

Variation Wood + WR600 + CSM450 +CSM300

5

th

Variation Wood + WR600+ CSM300 + CSM300

senta 2019 - The International Conference on Marine Technology (SENTA)

130

After determining the Variation of material to be

tested, the next step is making the material, while the

stages in making the material are as follows:

• Prepare five pieces of teak wood material with

dimensions of 30 cm x 30 cm x 2 cm.

• Preparing the resin that will be used for the

material and mixed with a catalyst that functions

to dry the resin, the ratio of catalysts and resins is

1: 100.

Figure 5: Wood as a primary material.

• Coating wood with resin and fiberglass fibers by

the lamination schedule using a roll and brush to

avoid air bubbles that enter during the lamination

because it will reduce the laminate's strength.

Figure 6: laminated wood with fiberglass.

Before testing and pulling, the first thing to do is

to prepare the test material. Test materials are

numbered in accordance with variations so that it is

accessible when recording test results. In tensile

testing, the engine used is Universal Testing Machine

MFL/UFD 2.0.

Figure 7: Universal testing machine MFL / UFD 2.0.

The width size for tensile and bending specimens

is determined by the laminated material thickness,

while the length of the specimen is free as long as it

exceeds 20 times the thickness of the material. The

size of tensile and compressed specimens is

determined by the size of fiberglass material

specimens determined in the 2016 Indonesian

Classification Bureau annex, Rules for Fiberglass

Reinforced Plastic Boats.

Figure 8: BKI Tensile Specimen Standard.

Technical and Economic Analysis Repair of the Wooden Boat using Fiberglass Laminates on Fishing Boats in Lamongan District

131

Figure 9: BKI Bending Specimen Standard.

Figure 10: Specimen of tensile and bending test.

Then the test specimen is made following the

provisions of predetermined standards.

3.2 Economic Method

Economic analysis is carried out after technical

analysis. Repair of wooden boats using the fiberglass

lamination method adjusts to technical aspects,

including the number of layers of fiberglass laminate

according to the Variation of specimens that have

been made. The cost components calculated are as

follows:

3.2.1 Material Cost

To calculate the cost of repairing wooden boats using

the fiberglass lamination method, it is necessary to

know the price of the material used in the boat repair

process, including the price of resin, the price of

mat/CSM, catalyst, nails used per m

2

.

3.2.2 Labor Cost

Labour costs are calculated to determine how much

these costs are used to repair wooden boats using the

fiberglass lamination method per m

2

.

3.2.3 Total Cost

The total cost is calculated by adding the material cost

and labour costs together.

4 ANALYSIS OF RESULTS

The results of the tensile test are tabulated in Table 2.

It can be seen that the third variation has the highest

average tensile test results, which are equal to 47.87

MPa. Whereas the results of the compressive test can

be seen in Table 3.

From the bend test results table above, we can see

the most significant buckling test results is the third

Variation that is equal to 4.20 MPa.

For economic analysis, we do the following

calculations. In Table 4 we can see that the material

costs in variations 2 and 5 are the same, Rp 284,537

while variations 3 and 4 have the same material cost,

Rp. 317,056. This difference is due to the different

thickness of the woven roving, and the CSM used.

Meanwhile, the labour cost for each m2 is Rp

208,907, so that we can see economically that

variations 2 and 5 have the advantage of being

cheaper than variations 3 and 4.

Table 2: Tensile strength result and stress calculation.

Code Fu (kN)

Stress

(Mpa)

Average Stress

(M

p

a)

V1.1

14 29.41

27.11

V1.2

13 27.18

V1.3

17 24.75

V2.1

18 34.71

32.99

V2.2

15.5 33.73

V2.3

13.5 30.52

V3.1

21 47.23

47.87

V3.2

23 52.66

V3.3

18 43.71

V4.1

15.5 38.88

39.82

V4.2

15 41.63

V4.3

15 38.94

V5.1

19.5 45.27

44.59

V5.2

17.5 42.14

V5.3

20 46.34

senta 2019 - The International Conference on Marine Technology (SENTA)

132

Table 4: Cost calculation.

Code

Material Cost

(Rp)

Labour Cost

(Rp)

Total Cost

(Rp)

2

nd

Variation

284,537 208,907 493,444

3

rd

Variation

317,056 208,907 525,963

4

th

Variation

317,056 208,907 525,963

5

th

Variation

284,537 208,907 493,444

5 APPLICATION

Fiberglass lamination on a wooden boat is the process

of repairing a wooden boat using fiberglass coating to

a wooden boat by attaching fiberglass fibres to the

damaged or in need of repair part of the boat or the

entire body of the boat. Repair purposes replace the

damaged part of the boat and protect the hull from

leaks and strengthen the hull's construction.

Fiberglass lamination can increase the thickness of

the hull between 0.5-1 centimetre.

The steps in the process of repairing wooden

vessels using fiberglass lamination are explained as

follows:

5.1 Drying the Boat

Wooden vessels to be laminated must be dried before

starting to make repairs. The purpose of this drying is

to avoid water content into the wood, which would

damage the fiberglass layer, which will would

otherwise adhere tightly to the hull of the boat. Resin,

fiberglass, and wood cannot bond effectively if

exposed to water, even in minimal amounts (Sunardi,

2018).

Figure 11: Boat drying process.

5.2 Cleaning the Hull

After the wooden boat underwent a process of drying,

the boat first cleaned all parts using a grinder and

sandpaper. It aims to remove the rest of the paint,

putty or dirt that still attached to the boat's hull and

the remnants of marine plants connected to the boat.

5.3 Installation of Fiberglass

After the boat undergoes a drying and cleaning

process, the next step of the boat is ready to be

repaired by the fiberglass lamination method.

Fiberglass laminates are used in 3 layers (Wood +

CSM450 +WR600+ CSM300). This laminate will

add a thickness of 5-10 mm.

Figure 12: Installation of fiberglass fiber.

The installation of fiberglass lamination will

make the hull of the boat impermeable and not leak

so that the boat will avoid the entry of seawater. Boat

construction will also be stronger, and weathering in

wood, which usually occurs due to seawater, will be

avoided.

Table 3: Bend test result.

Code

Fu (kN)

Deflection

(

mm

)

Stress

(

MPa

)

Average

Stress

(

MPa

)

V1.1

2.6 11 2.74

2.71

V1.2

2.55 12 2.68

V2.1

2.7 13 3.00

2.97

V2.2

2.8 13 2.95

V3.1

4.15 11 4.15

4.20

V3.2

4.25 10 4.25

V4.1

3.6 13 3.79

3.53

V4.2

3.1 13 3.26

V5.1

3 12 3.33

3.28

V5.2

2.9 12 3.22

Technical and Economic Analysis Repair of the Wooden Boat using Fiberglass Laminates on Fishing Boats in Lamongan District

133

5.4 Fiberglass Lamination Nailing

Strengthening of the laminate with anti-rust nails

measuring 3 cm at 20-30 cm. The purpose of nailing

is to strengthen the fiberglass layer attached to the

hull, so there is no possibility of the fiberglass

separated layer from the hull.

Figure 13: Nailing on the fiberglass layer.

5.5 Retardation and Refinement

After the layers have been installed, the heating

process is carried out. The putty used is made up of

talc and resin with a catalyst added. After stirring,

putty is applied to the hull of the boat. Once it has dry,

mashed the putty using sandpaper.

6 PAINTING AND FINISHING

After all the processes are done, the last step is to

apply unique paint with colour pigments. This colour

pigment is mixed with resin and addictive to make the

surface of the boat more glossy and not easy to get

dirty. This paint can also avoid the sticking of sea

animals or dirt that usually attached to the hull of the

boat.

Figure 14: Painting on the hull of a boat.

The economic benefits of fiberglass lamination

for wooden boat repair compared to traditional boat

repair explained as follows:

1. Repair and maintenance with fiberglass

lamination can reduce maintenance in cleaning

marine growth because, in fiberglass, marine

growth cannot eat the fiberglass material

differently.

2. Repair and maintenance in a conventional way

need more time than the fiberglass method,

fiberglass method faster 50% than the

conventional way.

Fiberglass lamination on wooden boat repair will

offer the following benefits:

1. Damages that occur on a wooden boat can be

overcome by doing fiberglass lamination, which

prevent wooden boats leaks.

2. Fiberglass laminated material, which marine

animals and plants do not eat, allows the boat's life

to be longer.

3. Facilitate the cleaning of the hull so that

maintenance costs are lower compared to wooden

boats.

a. Before

b

. Afte

r

Fi

g

ure 15: Boat Re

p

air Before and After Results.

senta 2019 - The International Conference on Marine Technology (SENTA)

134

4. With fiberglass lamination, the boat repair process

will become more comfortable and lighter in

terms of price.

7 CONCLUSIONS

Fiberglass lamination on wooden boat repair can

increase the strength of the hull construction and

prevent leakage in the boat. Repairs using fiberglass

lamination benefit fishers because it can save

maintenance costs and repair boats. The boat's

lifespan is also longer because maintenance can be

more routine.

From the tensile and bending tests that have been

carried out on five variations, with the highest value

is obtained in the 3rd Variation of the tensile strength

of 47.87 MPa and the bending strength of 4.20 MPa.

The cheapest boat repair cost is obtained for

variations 2 and 5, which is Rp.493,444 / m2

ACKNOWLEDGEMENTS

We gratefully thank for Institut Teknologi Sepuluh

Nopember Surabaya for financial support, we thank

to PT. Justus Kimia Raya to support the material of

Fiberglass and Resin. We also thank the reviewer for

the constructive comments and suggestions that

substantially improved the paper.

REFERENCES

Arif, M., Pribadi, S., Prasetyo, W., Purwanto, D.,

Ahadyanti, G., Utama, D., & Ariesta, R. (2020). Design

and Production of FRP Catamaran Boat for Better River

Transportation in Randuboto Village, Sedayu District,

Gresik Regency.

https://doi.org/10.5220/0008375000820086

Bader, S. (2002). Composites Handbook. Wollaston: Scott

Bader Company Ltd.

Baskoro, A. (2018). Analisa Teknis dan Ekonomis

Pembangunan Kapal Ikan Ukuran 10-20GT

Konstruksi Fibreglass Reinforced Plastic (FRP) Sesuai

Standar Biro Klasifikasi Indonesia. Surabaya: ITS.

Greene, E. (2006). Composite Boat Repair: Part One,

Damage Assessment. Maryland: Eric Greene

Associate.

Lamongan, K. (2018, 02 19). Kabupaten Lamongan.

Retrieved from Kabupaten Lamongan:

https://lamongankab.go.id/paciran/potensi-perikanan-

kelautan

Munawaroh, S., Adrianto, A., & Suwarno. (2017). Perahu

Tradisional Ijon-Ijon di Desa Semangkon Lamongan.

Yogyakarta: BPNB.

Norromadani Y, R. (2016). Pemetaan Perikanan Laut

Kabupaten / Kota Jawa Timur dengan Metode Fuzzy K-

Means Clustering. Seminar Nasional Maritim, Sains,

dan Teknologi Terapan , 14-21.

Boat Structure Committee. (1990). Use of Fiber Reinforced

Plastics In The Marine Industry.

Washington DC: Boat Structure Committee.

Sunardi, S. B. (2018). Laminasi Fiberglass untuk

Memperbaiki Kapal Ikan Kayu di Kecamatan Lekok,

Kabupaten Pasuruan, Jawa Timur. Jurnal

Pengabdian Masyarakat J-DINAMIKA, Vol. 3 No. 1,15.

Utami, I. D. (2016). Perkembangan Perikanan Lamongan

Tahun 1998 - 2008. Avatara, e-Journal Pendidikan

Sejarah , 832-842.

Technical and Economic Analysis Repair of the Wooden Boat using Fiberglass Laminates on Fishing Boats in Lamongan District

135