Study on Application of Floating Structure Technology in Indonesia

Christino Boyke

1,a

, Tri Achmadi, Hasan Iqbal Nur

1

Department of Marine Transportation Engineering, Institut Teknologi Sepuluh Nopember, Indonesia

Keywords: Application, Floating Structure, Technology.

Abstract: As the climate and global weather conditions change, the human environment also changes. Rising sea levels

and higher rainfall are driving people to find safer shelter. The increase in population causes the lack of

residential land that can be used as a residence. These problems also occur in Indonesia, the country with the

4th largest population globally and has waters covering 70% of the total area. One potential technology that

can be used to reduce the impact of the problems that have been conveyed is the use of floating structures.

With a large area of water and the number of residential lands is decreasing, this technology offers alternative

solutions to these problems. Floating structures are defined as structures that rely on water's buoyancy force

to support the structure's weight. Some floating technologies that can be utilized for development in Indonesia

include floating houses, floating breakwaters, floating bridges, floating docks, and other infrastructure

facilities. In this research, we will see the advisability of the floating structure technology application in

overcoming some of the problems that occur in Indonesia using comparative analysis. Several literature

reviews were carried out to study the various applications of floating structures in Indonesia. The study results

show that this technology is very likely to be applied and can solve several problems that occur in Indonesia.

1 INTRODUCTION

Infrastructure development in Indonesia continues to

grow to be able to encourage high economic growth.

The increasing level of international trade and the

needs of the maritime industry is promoting sea

reclamation. Without proper implementation and

planning, reclamation can have a negative impact.

Adverse impacts such as the destruction of animals'

living places and coastal plants can cause the balance

of nature to be disturbed. Besides, the seawater

hydrological system on the coast will change from its

natural state.

Maritime infrastructure development is mostly

done conventionally, using land as a foundation that

supports the structure's weight above it. In certain sea

areas, the seabed is very deep, so a deep foundation is

needed. In this condition, water buoyancy can be

utilized to support the weight of the existing structure.

Thus, infrastructure development in areas with deep

seabed can be more effective.

One potential technology that can be used to

reduce the impact of the problems that have been

conveyed is the use of floating structures. Floating

structures are defined as structures that rely on water's

buoyancy force to support the structure's weight.

Under broader conditions, structures that rest on the

soft seabed and use the buoyancy force to reduce the

reaction forces that occur can be categorized as

floating structures (Wang and Wang, 2015).

There have been many studies on the use of

floating structures in solving problems in the world.

Anderson (Anderson, 2014) examined amphibious

architecture, Drieman (Drieman, 2011) also

researched the use of A Floating Breakwater To

Protect a New Artificial Beach In Balchik, Bulgaria.

Research on the use of floating buildings has also

been carried out by Boyke (Boyke et al., 2019) with a

conceptual design of floating houses for disaster

response purposes.

With many uses of this floating technology, this

research seeks to identify what floating technologies

can be used to solve some of the problems that occur

in Indonesia. In this study, floating structures are all

structures that float on water with specific dimensions

that are static and have no movers. Therefore, boats

and ships are not included in the definition in this

study. This study's potential use of floating buildings

is a floating house, road, bridge, breakwaters, jetty,

and other possible functions.

10

Boyke, C., Achmadi, T. and Nur, H.

Study on Application of Floating Structure Technology in Indonesia.

DOI: 10.5220/0010854300003261

In Proceedings of the 4th International Conference on Marine Technology (senta 2019) - Transforming Maritime Technology for Fair and Sustainable Development in the Era of Industrial

Revolution 4.0, pages 10-18

ISBN: 978-989-758-557-9; ISSN: 2795-4579

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 FLOATING STRUCTURE

In the development of floating technology, many

types of materials have been used for this structure.

In offshore buildings, steel structures have been

widely used as the primary material for aggressive

environments. For smaller-scale applications, such as

housing and marinas, concrete floating objects are

used more. The floating structure can be made from

several types of materials, including:

1. Caisson Concrete

2. Concrete tray

3. Steel structure

4. Concrete - EPS

From these various materials, diverse floating

technologies have been developed with several

functions: floating houses, floating bridges, floating

dock, and other public facilities.

2.1 Floating Structure Materials

2.1.1 Caisson Concrete

The term Caisson is French which means large box,

which refers to the Caisson form. The Caisson

structure has been widely used in Civil Engineering

works as pillars of bridges, docks, and tunnels. This

structure can float on water to be carried easily to the

installation location by the sea. After arriving at the

installation location, this structure will be submerged

to build a foundation. At present, the Caisson

concrete system is the most widely used structural

system as a base for floating buildings.

Closed space that contains the air inside the

caisson is the cause of the large caisson buoyancy.

Caisson is made of hefty, reinforced concrete, so this

type of structure has an extensive draft and is suitable

for deep seabed areas.

Advantages:

has been widely used, so that a lot of

experience regarding the design and

implementation.

has excellent stability because of its weight.

has an internal space that can be utilized

relatively inexpensive compared to steel

has good durability, with low maintenance

costs.

Disadvantages:

has a small buoyancy

has a big draft

easy to sink if it leaks

2.1.2 Concrete Tray/Open Caisson

A concrete tray or open caisson is a type of caisson

that does not have a roof covering or is free. This type

has similarities with a boat. This type is widely used

for light construction such as houses.

2.1.3 Steel

The steel structure is a structural system that is widely

used in offshore buildings and ship buildings. Steel

structures can be made in various shapes. The box

pontoon is the most common type used for floating

installations. The steel structure has a thin wall

thickness, so it has a lighter weight and great

buoyancy. But with its lightweight, the steel structure

is more unstable than concrete. But this can be

overcome by using ballast water. The main

disadvantage of steel structures is susceptibility to

corrosion. Thus, routine maintenance is needed on

steel structures, so this type is rarely used for light

installations.

Advantages:

it has been widely used, so that a lot of

experience in designing and implementing it.

has an internal space that can be utilized

has a low draft

has a small weight

Disadvantages:

high maintenance costs

relatively more expensive when compared to

concrete

easy to sink if it leaks

can conduct heat and electricity.

2.1.4 Concrete - EPS

EPS (Expanded Poly Styrene) is a floating building

first introduced by International Marine Floatation

Systems Inc. (IMF) in 1980. This system consists of

a core EPS layer covered by a concrete layer as an

outer protector. EPS material has a specific gravity of

20 kg / m3, about 50 times lighter than water. With

an EPS system, a floating building's weight can be

much lighter compared to conventional Caisson

systems. This is because the plate's dimensions can be

thinner. After all, some EPS supports the inside.

Besides, the inner plate is no longer needed because

its function has been replaced with lightweight EPS.

With the use of EPS, floating objects can have smaller

drafts. Also, the risk of drowning due to leakage can

be reduced because the concrete's cavities are no

longer filled with air but instead contain EPS. The use

of EPS certainly adds to the cost, but this can be

Study on Application of Floating Structure Technology in Indonesia

11

compensated for by the reduced concrete volume and

weight.

Advantages:

EPS structure cannot sink

lightweight, large buoyancy

short draft

cheap maintenance

can be formed in various forms

Disadvantages:

Has no internal space that can be utilized

2.2 Application of Floating Technology

in the World

2.2.1 Floating Houses

The concept of floating housing is not a new thing or

new technology in human life. Floating housing has

become part of human history in the world. For

example, countries that know the floating settlement

culture are Cambodia, Vietnam, Indonesia, Thailand,

China, Peru, and Bolivia. This settlement is used as a

home for aquaculture and fisheries.

Figure 1: Floating city at Sedanau Island, Natuna (Masaul,

2013).

Indonesia itself has several floating villages in

several provinces. The first floating village is in

Torosiaje Village, Popayato District, Gorontalo. Then

there is the Ayapo village located on Lake Sentani's

shores, Jayapura, and the Bajo Village in Sulawesi.

Besides, there are also villages on the Mahakam River

banks, Kalimantan, and the City on Sedanau Island,

Natuna. The towns are a form of local people's

wisdom in adapting to nature where they live.

The more modern floating house was first

introduced in the 80s. Then this concept is widely

applied in several countries, especially those with

large territorial waters. A company called

International Marine Flotation Systems Inc.

developed a floating house which later became a

trend in several countries in Europe. The house was

designed using concrete with EPS (Expanded Poly

Styrene) as the filling (System, 2013). This system

allows the concrete to have a lighter weight to be built

in shallow water areas. This development then

encouraged several companies to make similar

innovations. In the Netherlands, modern floating

homes have been developed as alternative housing for

residents (Figure 2). These floating houses have good

facilities and safety standards, so many people are

interested in using them.

Several other studies on floating houses were

carried out by Ambrica (Ambica, 2015), who

developed house designs in areas with high water

level fluctuations. Also, Muksin (Muchsin,

Fachruddin Purwono and Amiuza, 2011) researched

floating lodging for tourists in Indonesia.

Figure 2: Floating house at the Netherlands (System, 2013).

2.2.2 Floating Bridge

The floating bridge was first made from a series of

boats bound by a wooden frame and anchored to the

seabed. Floating bridges in the past were usually only

used temporarily because they could not last long and

were unable to support heavy loads. The first floating

bridge recorded in history was built by the Persian

King Xerses when he invaded Greece in 480 BC. This

bridge was built in the Strait of Dardenelles, Turkey,

to cross the war troops. This bridge consists of 300

boats tied and anchored at both ends with large

vessels.

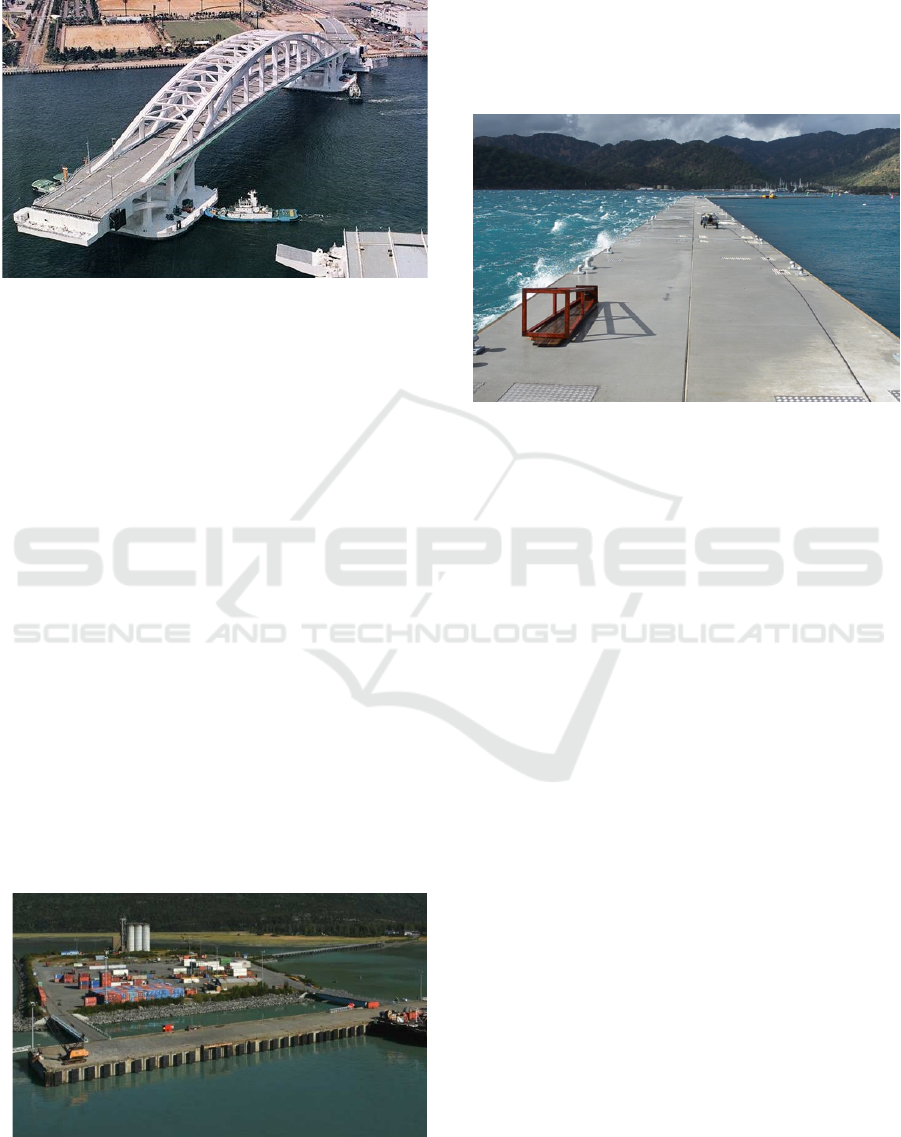

Examples of floating bridges in the modern era are

the Bergsoysund Bridge with a span of 931 m and the

Nordhorland Bridge with 1614 m in Norway. The

largest steel frame floating bridge are located in

Japan, the Yumemai Bridge (Figure 3). This bridge

connects two reclamation islands, where underwater

tunnels and conventional bridges are not feasible.

There is also a floating concrete bridge in Dubai

senta 2019 - The International Conference on Marine Technology (SENTA)

12

which was built in 2007. This bridge connects Bur

Dubai and Deira.

Figure 3: Yumemai Bridge, Japan (Ltd, 2000).

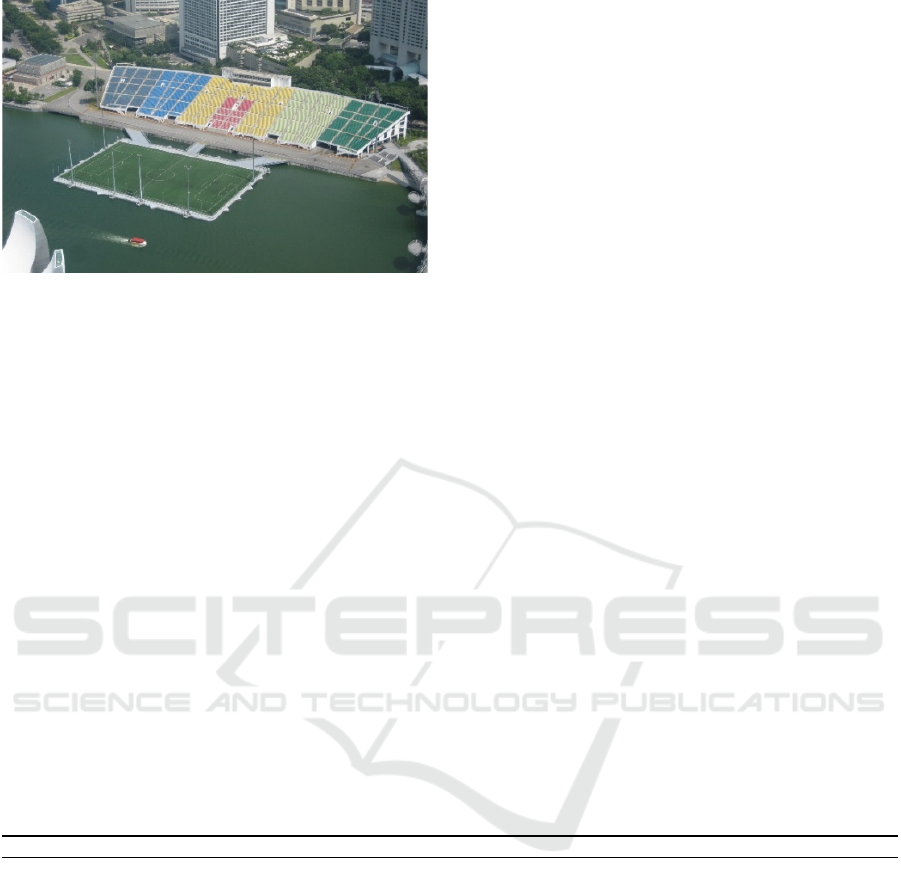

2.2.3 Floating Piers

The floating pier was first used in World War II. At

that time, the construction and repair of conventional

ports became impractical because of the war.

Therefore, it needs a pier that can be dismantled and

moved quickly. Mulberry Harbour is an example of a

type of floating pier that Britain developed in World

War 2. This bridge consists of 3 parts, namely

Breakwater, pier head, and walkway.

A modern floating pier design was built in Alaska

and Japan. The first floating pier with a prestressed

system was constructed in Valdez, Alaska (Figure 4).

This pier opened in 1982 and serves container ships.

This pier has many advantages because of its minimal

maintenance and its ability to work in the deep sea

and follow the tides. In Japan, the floating dock is

located at Ujina Pier in Hiroshima, built-in 1993. This

pier functions as a ferry pier. Because the location has

a very high tidal difference of 4 m, a floating pier is

used to overcome this condition.

2.2.4 Floating Breakwater

Floating Breakwater is an innovation in coastal

engineering. This structure is made of a concrete box

with a hollow in the middle. (Biesheuvel, 2013) This

concrete box is anchored to the seabed to maintain

stability and effectiveness in breaking waves. This

Breakwater is made up of several segments which are

joined together and can be moved easily (Figure 5).

Figure 5: Ingemar Floating Breakwater (Engineering,

2000).

This type of Breakwater is suitable for deepwater

areas because it is not limited to depth and can follow

tides. This structure is not large and massive, so the

manufacturing cost is relatively cheaper than other

types. There are also no environmental problems such

as erosion and sedimentation due to their floating

shape. The upper part of the floating Breakwater can

also be used for various facilities. Every breakwater

segment are connected using special connection that

allows all the units working together (Koekoek,

2013).

2.2.5 Floating Entertainment Facilities

As a supporting facility for residents, various

entertainment facilities are also needed. To overcome

the lack of land and provide a new experience,

floating entertainment facilities have been developed.

Examples are Jumbo Restaurant in Hong Kong and

floating restaurants in Yokohama, Japan. A seven-

story floating hotel has been built in Singapore to be

towed to Australia and established there. The largest

floating entertainment stage in the world is made at

Singapore Marina Bay (Figure 6). This floating

structure is designed as an entertainment stage. The

floating island on the Han River, Korea, is an artificial

floating island that is environmentally friendly.

Figure 4: Floating Container Pier Valdez (Engineering,

2000

)

.

Study on Application of Floating Structure Technology in Indonesia

13

Figure 6: Marina Bay Floating Stage (Wang and Wang,

2015).

2.2.6 Large Floating Storage Facilities

Various structures with storage functions have been

built using floating technology. An example is the

construction of oil storage facilities in Kamigoto and

Shirashima. This storage is intended as oil reserves

when an emergency occurs. Shirashima oil storage

consists of 8 floating steel structures measuring 397 x

82 x 25.4 m. One system can hold 7 million m3 of oil,

equivalent to Japanese oil consumption in 1 day.

Also, Japan has also made a floating solar power plant

in Kagoshima Prefecture. This structure is the largest

solar power plant in Japan.

3 STUDY OF APPLICATIONS IN

INDONESIA

In this section, a comparative analysis between

conventional technology and floating technology will

be performed to overcome some of the problems.

Floating technology that will be used includes

floating houses, a floating pier, and floating

breakwater.

3.1 The Problem of Abrasion on the

Nusa Dua Beach

Nusa Dua beach area with a beach length of ± 4 km

is located in Nusa Dua, Bali. At present, the condition

of the Nusa Dua beach is experiencing severe

abrasion. This can be seen from the reduction in trees

and the shrinking of beach sand eroded by abrasion.

The beach condition, which is eroded by abrasion,

damages Nusa Dua's image as an exclusive tourism

area with golf course facilities, four and 5-star hotels,

and other facilities with international standards.

A breakwater is planned to be built in this area to

reduce the wave pressure that causes abrasion.

Because the seabed in this area has been designated

as a coral reef reserve, the construction of

breakwaters must not damage the coral reefs. The

alternative comparisons used are floating breakwaters

and conventional breakwaters of mountain rocks or

tetrapods.

In conducting a comparative analysis, the first

step compares several criteria between alternatives 1

and 2, as listed in Table 1.

Table 1: Comparison between alternative breakwaters.

Evaluation Aspect Alt.1 Conventional Alt.2 Floating

Effectiveness of wave

attenuation

Able to reduce waves> 2m with attenuation up

to 100%

Able to reduce waves> 2m with attenuation of

50% - 80% de

p

endin

g

on desi

g

n re

q

uirements

Influence/impact on the

Marine Environment

It was causing environmental impacts because

dredging work is needed in coastal areas and

Breakwater's development that can damage

coral reefs

It does not cause environmental impacts

because there is no need for dredging work,

and the construction does not damage the

seabed corals

Construction

Permitting Process

Requires a special permitting process to carry

out dredging and construction that damages

coral reefs

Permitting is more comfortable because it

does not require dredging and does not

dama

g

e the coral reefs

The effective protected

water area

Smaller, because it cannot be installed in deep

waters

More extensive, because it can be installed in

dee

p

waters

Estimated Construction

Costs

Rp. 68.803.377,-/ m Rp.105.851.023, / m

Estimated completion

time

Eight months Ten months

Flexibility Massive and permanent construction (not

flexible to relocate

)

Flexible and can be moved if needed

Value-added Do not have the space that can provide added

value

It has a void space that can be used as a fuel

b

unker/water, restaurant, mini hotel

senta 2019 - The International Conference on Marine Technology (SENTA)

14

Table 2: Comparison value between alternative breakwaters.

Evaluation Aspect Alt.1

Conventional

Alt.2

Floatin

g

Effectiveness of wave

attenuation

100 80

Influence / impact on

the Marine

Environment

50 100

Construction

Permittin

g

Process

60 90

The effective protected

water area

60 100

Estimated Construction

Costs

95 100

Estimated completion

time

100 85

Flexibilit

y

60 100

Value-adde

d

70 100

TOTAL 595 755

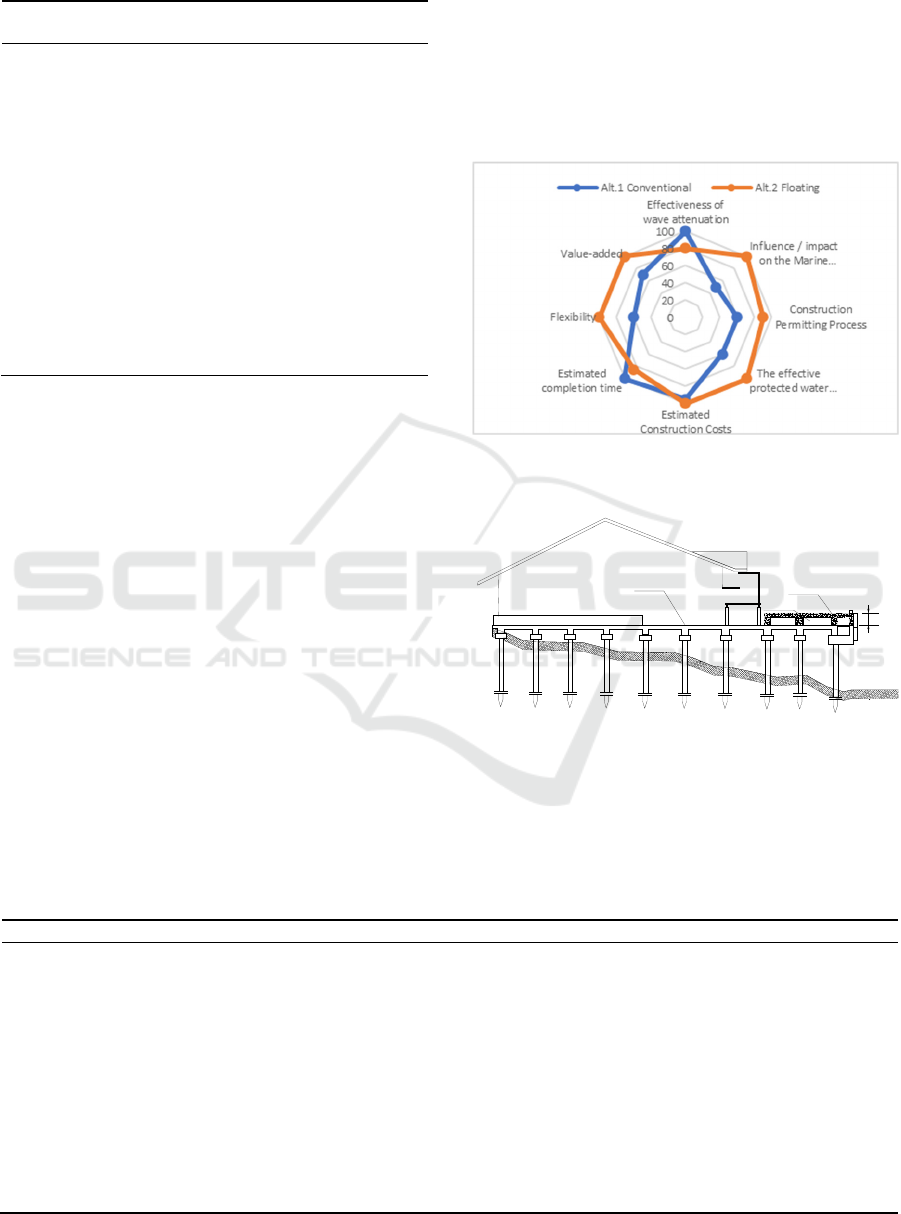

From several comparisons in Table 1, an assessment

of each of the two alternative criteria can be made. The

evaluation is carried out on a scale of 0-100. The results

of the evaluation can be seen in Table 2.

From the results of the comparison in Table 2, it

was found that the greatest benefit obtained from

Alternative 2 (Floating) with a value of 755 is more

significant than Alternative 1 with 595. The results of

the comparison are illustrated in Figure 7.

3.2 Pier Elevation Problems in Port of

Tanjung Emas Semarang

Semarang is one of the industrial cities in Indonesia,

which has a high level of sea traffic. Tanjung Emas

Harbor is the main gate of Semarang City from the

sea. This Port has a typical land that continues to

experience substantial settlement for each year. This

is a significant problem for the Port of Tanjung Emas

because the pier elevation decreases until it reaches

sea level. One solution to the Port's concern is to

elevate the pier elevation by adding a new structure

above the existing structure. As an alternative

solution to these problems, a floating pier can be

made in front of the existing pier. The floating pier

will always move to follow the water level and is not

affected by land subsidence.

Figure 7: Comparison value between alternative

breakwaters.

Figure 8: Alternative 1 (new construction above existing

pier).

In conducting a comparative analysis, the first

step compares several criteria between alternatives 1

1.30

Dermaga

Eksisting

Balok Memanjang

70 x130

Balok Melintang

70 x130

Table 3: Comparison between alternative pier.

Evaluation Aspect Alt.1 Conventional Alt.2 Floating

Effectiveness in

overcoming sea level rise

Ineffective, because it is static, it cannot keep

up with rising water levels.

Practical because the height of the

floating pier can always change

according to sea level.

Influence/impact on

Existing Pier

Significant impact, adding additional burden

to the existing pier. This can cause a decrease

in stren

g

th at the existin

g

Port in the lon

g

run.

No impact because it was built in front of

the existing pier, so it does not directly

b

urden the existin

g

p

ier structure.

The Pier area can be used 10x 100 m2 2 x 10x 100 m2

Estimated Construction

Costs

Rp. 50.000.000, - / m Rp. 150.000.000, -/ m

Estimated completion

time

Nine months 12 months

Flexibility Massive and permanent construction (not

flexible to relocate).

Flexible and can be moved if needed.

Study on Application of Floating Structure Technology in Indonesia

15

and 2, as listed in Table 3. And the second step is to

make a scoring of each of the two options. The

assessment is carried out on a scale of 0-100. The

evaluation result can be seen in Table 4.

Figure 9: Alternative 2 (new construction of floating

structure in front of the existing pier).

Table 4: Comparison value between alternative pier.

Evaluation Aspect Alt.1

Conventional

Alt.2

Floating

Effectiveness in

overcoming sea level

rise

60 100

Influence / impact on

Existin

g

Pie

r

70 100

The Pier area can be

use

d

100 100

Estimated construction

costs

100 30

Estimated completion

time

90 100

Flexibilit

y

60 100

TOTAL 480 530

From the scoring that has been done in Table 4, it

can be concluded that Alternative 1 (Conventional)

and Alternative 2 (Floating) can both be used at

Tanjung Emas Pier. From the assessment results, it

was found that the most significant benefit obtained

from Alternative 2 (Floating) with a value of 530 is

more significant than Alternative 1 with 480. The

results of the comparison are illustrated in Figure 10.

3.3 Temporary Shelters for Earthquake

Victim

When the earthquake strikes, thousands of residents

affected by the earthquake are forced to live in

refugee camps with emergency tents as temporary

shelters. Due to the immensity of the affected area

and the number of damaged roads, the aid that came

can be slow and insufficient. If this happens, refugees

are forced to live in makeshift tents that they made

themselves. Many of these tents are uncomfortable to

live in, causing refugees' physical and mental

conditions to decline. To help disaster victims with

such situations, there must be a temporary shelter that

is habitable, safe, comfortable, and delivery is not

affected by road damage. The floating house can be

used as an alternative solution. A floating home can

be placed on the coast, where most of the affected

victims live. Floating houses can be deployed by sea;

therefore, mobilization is not affected by road

damage. With this floating emergency house,

refugees are expected to live with better quality

housing.

Figure 11: Makeshift tents built by refugees.

Figure 12: Emergency floating house.

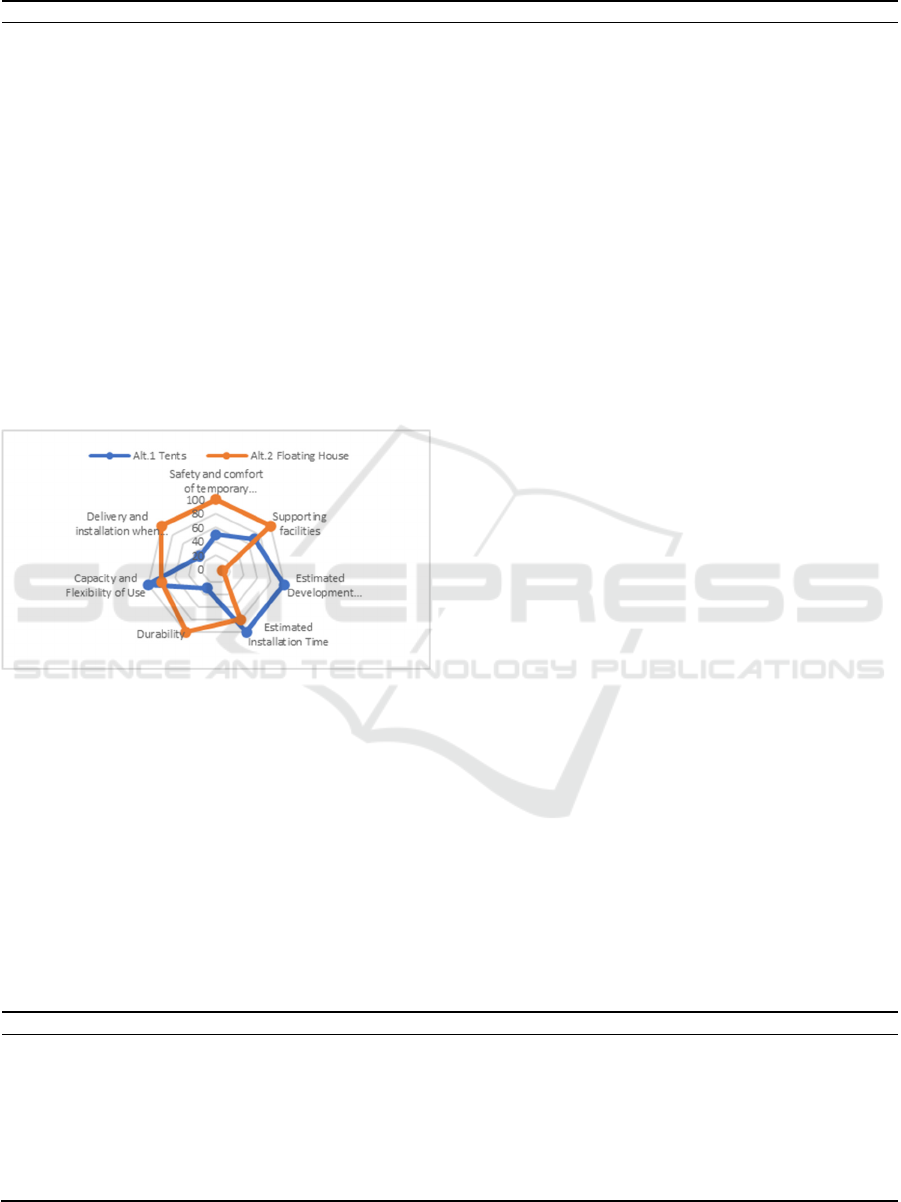

In conducting a comparative analysis, the first

step compares several criteria between alternatives 1

and 2, as listed in Table 5. And the second step is to

make a scoring of each of the two options. The

assessment is carried out on a scale of 0-100. The

results of the evaluation can be seen in Table 6.

Jembatan

Penghub ung

10

2,52,5

Dermaga

Eksisting

Struktur Apung

Beton Bertulang

t=0.5 m

Anchor Chain

Anchor Block

Figure 10: Comparison between alternative piers.

senta 2019 - The International Conference on Marine Technology (SENTA)

16

Table 5: Comparison between alternative temporary shelters.

Evaluation Aspect Alt.1 Tents Alt.2 Floating House

Safety and comfort of

temporary shelters

Unsafe and uncomfortable for refugees if

evacuated for an extended period.

Safer and more comfortable to live in the

long term because there are more

complete supporting facilities.

Supporting facilities Has limited supporting facilities. Have more complete supporting

facilities.

Estimated Development Cost

p

er unit

Rp.10.000.000, - per unit. Rp.100.000.000, - per unit.

Estimated Installation Time 1 hour. 8 hours.

Durability It has low durability, can be damaged at

one-time use onl

y

.

Very durable, can be used many times

durin

g

the buildin

g

p

eriod of 50

y

ears.

Capacity and Flexibility of Use It can accommodate many refugees and can

be demolished/disposed of when not in use.

Accommodate fewer refugees. After not

being used, it must be brought back to the

p

lace of origin to be stored.

Delivery and installation when

land infrastructure is damage

d

Difficult to do because construction and

delivery are mostly done on land.

Can be sent by sea and installed at

sea/beach.

Figure 13: Comparison Between Alternative Temporary

Shelters.

From the assessment conducted in Table 5, it can

be concluded that Type 1 (Conventional Emergency

Tents) and Type 2 (Floating Houses) can both be used

as temporary shelters after an earthquake. From the

evaluation of several criteria in Table 6, it was found

that the most significant benefit was obtained from

Type 2 with a value of 570, more significant than

Type 1 with 480. The results of the comparison are

illustrated in Figure 13.

4 CONCLUSIONS

Some problems in Indonesia require alternative

solutions in the form of the application of floating

technology. Issues that occur include sea-level rise,

land subsidence, increased urbanization to cities, and

a large seabed depth. Applications of floating

technology that can be implemented in Indonesia

include floating breakwaters, floating docks, floating

bridges, floating houses, and other infrastructure that

may be needed. Examples of applying floating

technologies suitable for Indonesia's application are

Floating Breakwater, with a sample of Bali's Nusa

Dua beach; Floating Pier, for example, Pier at

Tanjung Emas Semarang and Floating Houses, with

examples of post-earthquake emergency shelters.

More detailed research is needed to apply the

conceptual design that has been made to be applicable

following existing field conditions in Indonesia.

Table 6: Comparison value between alternative temporary shelters.

Evaluation As

p

ect Alt.1 Tents Alt.2 Floatin

g

House

Safety and comfort of temporary shelters 50 100

Su

pp

ortin

g

facilities 70 100

Estimated Development Cost per unit 100 10

Estimated Installation Time 100 80

Durabilit

y

30 100

Ca

p

acit

y

and Flexibilit

y

of Use 100 80

Delivery and installation when land infrastructure is damage

d

30 100

TOTAL 480 570

Study on Application of Floating Structure Technology in Indonesia

17

REFERENCES

Hydrophilic Floating House for Fluctuating Water Level.

Indian J. Sci. Technol. 8, 1–5.

https://doi.org/10.17485/ijst/2015/v8i32/84304

Anderson, C.H., 2014. Amphibious Architecture Living

with a Rising Bay. Faculty of California Polytechnic

State University, San Louis.

Biesheuvel, C.., 2013. Effectiveness of Floating

Breakwaters Wave Attenuating Floating Structures.

Faculty of Civil Engineering, Technical University of

Delft.

Boyke, C., Achmadi, T., Iqbal, H., 2019. The Conceptual

Design of Floating House for Post-Earthquake

Temporary Shelters in Difficult Land Access Areas in

Indonesia. Int. J. Civ. Eng. Technol. 10, 198-213.

Drieman, R., 2011. Feasibility Study on the use of A

Floating Breakwater To Protect a New Artificial Beach

In Balchik, Bulgaria. Faculty of Civil Engineering,

Technical University of Delft.

Engineering, I.M., 2000. Floating breakwaters [WWW

Document]. URL http://www.ingemar.it/en/products-

services/product/Floating-breakwaters-9

Koekoek, M., 2013. Connecting Modular Floating

Structures A General Survey and Structural Design of a

Modular Pavilion. Faculty of Civil Engineering,

Technical University of Delft.

Ltd, K.D.C., 2000. Movable Floating Bridge (MFB)

[WWW Document]. URL

http://157.205.186.22/en/project/project01_002.html

Masaul, A., 2013. Sungguhan Ada, Ini Kota Terapung di

Indonesia [WWW Document]. Detik.com. URL

https://travel.detik.com/domestic-destination/d-

3809150/sungguhan-ada-ini-kota-terapung-di-

indonesia

Muchsin , Fachruddin Purwono, E.H., Amiuza, C.B., 2011.

Penginapan Terapung Waduk Batujai Sebagai Fasilitas

Penunjang Kegiatan Wisata di Pulau Lombok. Jurusan

Arsitektur Fakultas Teknik Universitas Brawijaya.

System, I.M.F.I., 2013. Technology [WWW Document].

URL

https://www.floatingstructures.com/product/floating-

homes/

Wang, C.., Wang, B.., 2015. Large Floating Structures

Technological Advances. Springler, Singapore.

senta 2019 - The International Conference on Marine Technology (SENTA)

18