A Textual Thematic Analysis: Tools to Measure the Readiness of

Industry towards the Disruption Era

Pijar Suciati

1

, Mareta Maulidiyanti

1

and Sri Rahayu

2

1

Public Relations Studies, Vocational Education Program, Universitas Indonesia, Depok, West Java, Indonesia

2

Creative Advertising Studies, Vocational Education Program, Universitas Indonesia, Depok, West Java, Indonesia

Keywords: Readiness, Industry 4.0, Thematic Analysis, Textual Analysis

Abstract: This study aims to examine the many tools of readiness measurement of the various Industry to face the

disruption era the industry 4.0. In order to perform this research, a qualitative textual thematic analysis was

used to discover the best-combined way to measure the readiness of the industries facing the era of Artificial

Intelligence and robotics. Themes were found in analysis to show the comprehensive ways in which how to

measure the readiness. The results of this research are the existing models at this time can be used to

measure industry readiness in dealing with industry 4.0 depending on the tendency of the researcher

(tangible, intangible, or combined). Besides, the results of this study can be opened up for other researchers

to develop existing models by adding elements of the dimensions of “psychology” and “environment”. The

finding of this research shall provide input to industries and practitioners which tools to use to analyze their

readiness so that they can prepare and improve their product and services, strategy and organization, and

business model to face the revolutionary industry 4.0. Future studies are needed to elaborate on the result of

this study into a broader scale.

1 INTRODUCTION

Technology can be defined as “the practical

application of knowledge, especially in certain

fields” (Merriam-Webster, 2017). Thus, technology

shows the existence of specific knowledge, as well

as the practical application of that knowledge.

According to this point of view, technology is often

seen as an illustration of science and everyday life

(Bonciu, 2017). The developing technology forces

people to follow developments that are very broad in

all fields and affect their lives and human lifestyles.

One of the most revolutionary technologies in

the history of human life is “the Internet”.

Transformation of the internet is becoming more

complicated because it is developing from Web 1.0

to Web 4.0. Web 1.0 restricts users from only

reading content from the web, while Web 2.0 allows

users to contribute to the web by creating, storing

and sharing content. Web 3.0 is even more advanced

by using semantics, creating better communication

between humans and machines. Web 3.0 moves

from the connection between data and knowledge,

using keywords and tags to connect based on natural

language and intrinsic meaning. This development

can improve information search and data sharing.

Although Web 3.0 is still under development, the era

of Web 4.0 has arrived. Web 4.0 brings connections

to the web anytime and anywhere, personalized

services through data usage and ongoing

connections with other users (Boer, Ajam, Rompay,

2019). This complex and growing web-based

technology create various conveniences. One of

them is making companies more sophisticated,

reliable, and able to improve services to their

stakeholders (Amoroso & Hunsinger, 2009).

Devices with sophisticated technology attract much

attention and also researchers. People began to enjoy

this World Wide Web technology since the late

1990s, and cloud computing began several years ago

(Saariko, Westergren, Blomquist, 2017).

Unnoticed by many people, the 4.0 Industrial

Revolution began to be present in our midst. Based

on the World Economic Forum (WEF), industrial

revolution 4.0, it is hyper automation and

connectivity based on Artificial Intelligence (A.I.),

big data, robots, and the Internet of Things (IoT).

A.I., Big Data, and robotics can increase

productivity and increase industrial production.

Robots that use A.I. can make complicated decisions

404

Suciati, P., Maulidiyanti, M. and Rahayu, S.

A Textual Thematic Analysis: Tools to Measure the Readiness of Industry towards the Disruption Era.

DOI: 10.5220/0010686100002967

In Proceedings of the 4th International Conference of Vocational Higher Education (ICVHE 2019) - Empowering Human Capital Towards Sustainable 4.0 Industry, pages 404-411

ISBN: 978-989-758-530-2; ISSN: 2184-9870

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

on their own like humans. Hyper automation and

hyperconnectivity are increasing not only at the

national level but also globally by using information

and communication technology (ICT). IoT is the

core technology for creating hyperconnectivity in

the Cyber-Physical Systems (CPS) that connects

technology, nature, and humans (Park, 2018).

At the WEF annual Davos meeting from 2016,

the problem of the fourth industrial revolution and

some aspects of this new phase or cycle of industrial

progress were presented by different authors.

According to WEF Chair Klaus Schwab, as the

originator of the term and theme of the fourth

industrial revolution in the Davos debate, the phase

of industrial development begins now, and is

“marked by the ubiquitous and cellular internet,

censors that are smaller, stronger, and cheaper, with

artificial intelligence and machine learning “we can

see its evolution in the world with virtual and

physical systems interrelated in the making, service,

and other human activities (Prisecaru, 2016).

There are opinions similar to the definitions of

WEF regarding the terms “Industry 4.0.” and

“Fourth Industrial Revolution” (FIR), public

institutions (such as the German, US, Italian, French

and Hollande governments), private institutions

(Economic Forum World, Hedge Funds, commercial

banks), from a variety of literature. Industry 4.0

refers to the incomplete transformation of the

production of goods and services produced due to

the adoption of a new wave of technological

innovation: collaborative interconnected robots;

machine learning; Artificial intelligence; 3D printers

connected to digital development software;

interconnected machine simulations; integration of

information flows along the value chain; multi-

directional communication between the

manufacturing process and the product (Internet of

Things) (Caruso, 2018).

In the last ten years, the Internet of Things (IoT)

has influenced organizations and companies to carry

out their daily activities. This is also influenced by

what is called Smart City, when the goal of IoT is to

exploit information and communication technology

(ICT) and support value-added services for the

population, giving companies more opportunities to

innovate through the use of the latest technology.

(Bresciani, Ferraris, Del, 2018). For some, IoT can

be very profitable, but some others feel IoT shifts

the role that was previously performed by humans.

With modern and instant life and technology

compilation making things faster, Internet-of-Things

(IoT) is now more comfortable and more accessible,

allowing companies to take advantage of IoT to

improve their tourism results. IoT allows physical

devices to connect and exchange data through the

internet by gathering strategic information, thus

creating opportunities for companies to be more

efficient and responsive to market changes (Lo &

Campos, 2018).

Another technology used in industry 4.0 is

Artificial Intelligence (A.I.), which, according to

some experts, discusses any device that solves its

environment and takes actions that maximize the

chances of success in several purposes. These

technologies include machine learning, rule-based

systems, supporting natural languages, and the

introduction of acceptance. After completing the rise

and fall in popularity, A.I. technology is now

increasingly difficult to diffuse. In the emergence of

the concept of web 3.0, Internet of Things (IoT),

open innovation, and large and open data, A.I. has

gained momentum as a series of technologies

collected in many fields of Industry, such as finance,

automotive, retail, travel and media (Qian &

Medaglia, 2018). This disruptive era affected the

existing Industry, various industries, as mentioned

earlier, they must be able to keep up with the

technological developments so as not to lag behind

the times. Business organizations continue to look

for ways to benefit from their competitors. Most

companies focus on producing as much as possible

without considering the right request. Recently,

businesses have begun to find more efficient ways to

deal with significant turnover (Erasmus, Rothman,

Eeden, 2011), namely with the technology and

automation offered by the era of the disruption.

Because various industries have successfully

adapted automation, government institutions have

also begun to adopt various Artificial Intelligence

(A.I.) technologies in various domains (e.g. Health,

taxation and education); However, extensive

research is needed to exploit the full potential of A.I.

in the public sector and utilize various A.I.

technologies to address significant problems and

needs. There has been a new approach, as well as an

ICT platform architecture that supports it, for the

continued exploitation of certain A.I. technologies,

namely chatbots, in the public sector to address

critical issues: increasing communication between

government and citizens (who have long been in

trouble) (Androutsopoulou, Karacapilidis, Loukis,

Charalabidis, 2018).

Many researchers have accepted this fact in

various ways. At present, starting to become

unnecessary, especially on raising awareness about

what is the 4.0 trend. This trend, at some point, has

been advancing rapidly in many companies, and

A Textual Thematic Analysis: Tools to Measure the Readiness of Industry towards the Disruption Era

405

furthermore, the dynamics are consistent with the

current high rate of change. Meanwhile, not only in

technological change; they incorporate further

changes, e.g., on demographics and climate. Today’s

question is how quickly trend 4.0 will penetrate into

the daily lives of companies - and into society as a

whole. Various readiness indices and maturity

models can help companies to make easier, faster

decisions about how they should build Industry 4.0,

and at what time. Both of these shows not only the

position of the company but also the position of its

competitors. At present, attention is shifting to tasks

related to implementing the changes needed and

determining expectations in addition to the benefits

associated with their deployment. For example,

achieving the highest possible flexibility and

increasing the availability of products and services,

together with further cost reductions, decreased

resource consumption, and reduced environmental

impact, etc. (Basl & Petr, 2019).

The purpose of this research is to analyze and

summarize the readiness index and maturity model,

compare their essential characteristics, and integrate

them into their groups. These groups set the selected

maturity model and relative readiness index to each

other, then simultaneously identify areas where there

is potential for the basic model in further research.

Finally, the proposed themed group is an essential

guideline for the development of further analysis

from fields such as psychological and environmental

that are predicted to play a significant role in the

level of company preparedness.

2 LITERATURE REVIEW

2.1 Industry 4.0

Hannover Expo 2011 is a new era for the German

Industry because of the debut of Industry 4.0. The

concept of smart factories in the future will produce

smart products for the global market. Deeper

horizontal and vertical integration will result from

each member of the value chain, while collaboration

will move to a service-based model. The physical

and virtual world produces products that become

intelligent and will control production.

Personalization of specially made products will be

produced using sophisticated mass production

technology (Pongrácz, 2016).

Industry 4.0 concept has a characteristic as a

fully automatic and optimal transformation of

production and manufacturing environment.

Production processes vertically and horizontally in

the company system. Sensors, machines, and I.T.

systems are interrelated in the value chain across

corporate boundaries. For this purpose, the Cyber-

Physical System (CPS) is the foundation for smart

factories. New smart factories are still operating in a

geographical environment, and the performance of

these production units is related to the condition of

the community and the region where they are

located. Collaboration between Industry, University

and Local Government is essential because human

factors become essential in innovation to enter the

global competition (Basl & Kopp, 2017).

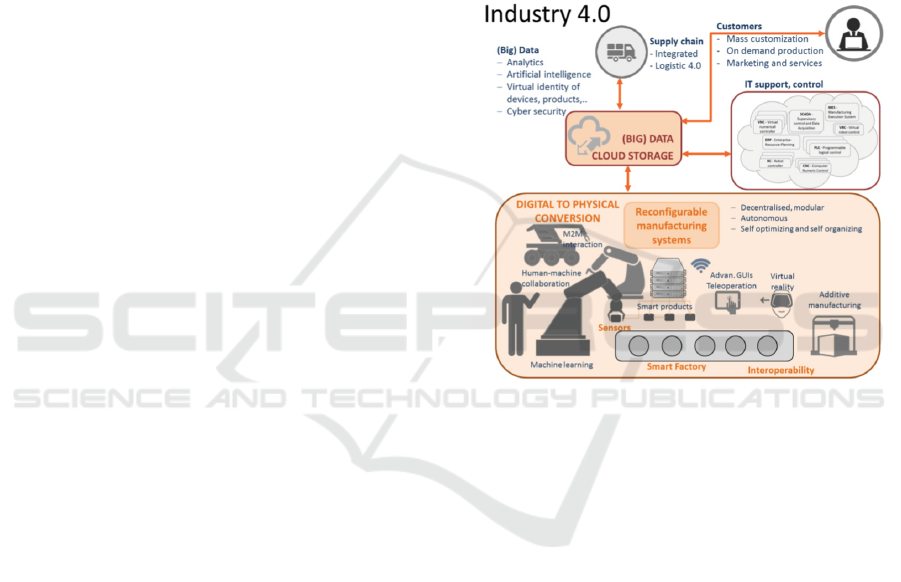

Figure 1: Industry 4.0 Smart Factory [16]

Figure 1 describes the process of how the smart

factory is running. It started from big data that is

converted into physical activities through the I.T.

support and control. In developed countries, Industry

4.0 has been a particular concern for the past few

years. In these countries, national initiatives, projects

or institutions related to Industry 4.0 are being

prepared or supported. For example, Germany offers

a strategic initiative “Industrie 4.0”. France, the

“Industrie du Futur” project is being developed.

Apart from a country, this trend is increasingly in

demand by businesses. (Basl & Kopp, 2017).

Looking at the current condition of Industry 4.0,

it is essential to know the prerequisites that must be

met so that new concepts can be introduced in

industrial manufacturing systems. At least the

following things must be fulfilled:

1. Production stability must be guaranteed

during the transition phase.

2. A gradual investment must be carried out

because most industrial processes cannot

bear a significant investment once.

ICVHE 2019 - The International Conference of Vocational Higher Education (ICVHE) “Empowering Human Capital Towards Sustainable

4.0 Industry”

406

3. Excellent protection is needed. Related to

cybersecurity issues (Rojko, 2017)

The modern concept is not limited to production

systems but also includes a complete chain (from

suppliers to customers) and all company functions

and services. It is not easy to fulfil this criterion

because only a few ‘concepts’ of the Industry 4.0

concept can currently be applied.

2.2 Technology Maturity Index

In general, the term “maturity” refers to a “state of

being complete, perfect, or ready” (The Oxford

English dictionary, 1989) and implies some progress

in the development of a system. Accordingly,

maturing systems (e.g. biological, organizational or

technological) increase their capabilities over time

regarding the achievement of some desirable future

state. Maturity can be captured qualitatively or

quantitatively discretely or continuously (Kohlegger,

Maier, Thalmann, 2009).

A maturity model is used as an instrument to

conceptualize and measure the maturity of the

organization or process in specific target countries.

Then what is labelled synonymously is the readiness

model to capture the starting point and make it

possible to initialize the development process.

Understanding the difference between readiness and

maturity in terms of assessing readiness occurs

before engaging in the maturity process. In contrast,

the maturity assessment aims to capture the

circumstances that occur during the maturity

process, for example in energy and utility

management (Ngai, Chau, Poon, To, 2013), in the

field of manufacturing environmental design or lean

manufacturing (Pigosso, Rozenfeld, McAloone,

2013).

In evaluating at the company level, as in

individual companies, the situation is different from

at the “macro” level. There is no comparison of the

large number of companies involved, but regular

evaluations and self-evaluations to determine the

stage of the company’s maturity. This causes the

maturity model to dominate at this micro-level (in

contrast to the macro level, where the readiness

index dominates).

2.3 Readiness Index

Company will always be in a particular

environment, which requires digitalization and the

ability to innovate. Therefore, we can see company

evaluations not only from a “micro” perspective but

also from the perspective of a broader context. One

of these is the individual dimension of the German

RAMI 4.0 reference model for Industry 4.0, which is

often mentioned by many researchers, also

containing this link in itself (Studie Industrie 4.0,

2014, CSC-Stuie, Industrie 4.0, 2015). Within this

“macro” view, we are viewing the whole of society

or individual nations. Multiple significant readiness

indexes have long existed in this respect, such as:

1. NRI (Networked Readiness Index) (BCG,

2016);

2. GII (Global Innovation Index) (Wang,

Towara, Anderl, 2017);

3. GCI (Global Competitiveness Index) (Suri,

Cadavid, Alferez, Dhouib, Tucci-

Piergiovanni, 2018).

And further

4. OECD scoreboard (Global Information

Technology Report, 2016).

For direct evaluations of Industry 4.0,

meanwhile, this concerns:

5. The Industry 4.0 Readiness Index from

Roland Berger (Dutta, Lanvin, Wunsch-

Vincent, 2018).

Industry 4.0 assessment readiness at the

company level is based on an independent

assessment. Information is collected through internet

surveys or telephone interviews. The initial survey,

targeting general information about awareness,

perceptions, attitudes, etc. Some of them sought

more detailed information about the company,

manufacturing (such as decision-making processes,

smart manufacturing technology, data security) and

branch-specific data (Schwab, 2018). A similar

approach is also observed internationally, (OECD

Science, Technology and Industry Scoreboard 2017)

for the DACH region (Germany, Austria,

Switzerland), and at the global level provides more

descriptive information about the phenomenon

(Siepen, 2015).

3 METHODOLOGY

In order to perform this research, qualitative textual

thematic analysis is used to find the best-combined

way to measure the readiness of the Industry is

facing the era of Artificial Intelligence and robotics.

After the analysis is done, the theme will be found to

show the exact way in which to measure readiness.

The combination method used can produce a full

understanding of this topic. Starting with textual

A Textual Thematic Analysis: Tools to Measure the Readiness of Industry towards the Disruption Era

407

analysis to establish a basic framework than the

thematic analysis that then occurs

3.1 Textual Analysis

Textual analysis is used for content analysis because

nothing can be measured. I need to see the big

picture to get started. The textual analysis allows

texts to be separated and then linked together

(Berger, 1995). Because quantitative content

analysis does not occur, this can be seen as

qualitative content analysis, to some extent, namely

coding. There are no statistical tests on the data

carried out. The texts are seen as a whole and

permitted for more precious comparisons between

them (Berger, 1995).

These journals are analyzed according to their

content and meaning, not their structure (Fairclough,

1992). For this study, the way journals present texts

are not as important as what they say in them. The

textual analysis allows researchers to examine how

words are presented to the reader. Prior (2004) states

that before the research begins, the angle of the text

to be analyzed must be decided. For this research,

the text is examined in a way to measure the

readiness of the Industry to face the industrial era

4.0 (Prior, 2004). The textual analysis in this

research is based on ten published research papers

by a range of 5 years (2015 – 2019).

3.2 Thematic Analysis

The thematic analysis was performed after the

textual analysis in 10 research journals about the

Industry’s readiness to face the Industry 4.0 era that

using different measurement index in the range five

years (2015-2019), they are:

1. A Maturity Model for Assessing Industry

4.0 Readiness and Maturity of

Manufacturing Enterprises by Andreas

Schumacher, Et. al (2016)

2. How to Measure Industry 4.0 Readiness of

Cities by G. Nick, F. Pongrácz (2016)

3. Study of the Readiness of Czech

Companies to the Industry 4.0 by Jakub

Kopp, Josef Basl (2017)

4. Assessing Industry 4.0 Readiness of

Enterprises by Zoltán Rajnai, István Kocsis

(2018)

5. Companies on the Way to Industry 4.0 and

Their Readiness by Josef Basl (2018)

6. Industry 4.0 – Are we ready? by Ślusarczyk

B. (2018)

7. Rapidly Arriving Futures: Future Readiness

for Industry 4.0 by A.P. Botha (2018)

8. A Metamodel for Evaluating Enterprises

Readiness in the Context of Industry 4.0 by

Josef Basl and Petr Doucek (2019)

9. Assessing Industry 4.0 Readiness in

Manufacturing: Evidence for the European

Union by Isabel Castelo-Branco, Et. al.

(2019)

10. Industry 4.0 Readiness in manufacturing

Companies: Challenges and Enablers

Towards Increased Digitalization Carla

Gonçalves Machado, Et. al. (2019)

These themes were extracted from the initial

analysis. “Thematic analysis is the search for themes

that emerge as important for the description of

phenomena” (Fereday, Muir-Cochran, 2006, p. 3).

The phenomenon encountered in this study is the

dimensions and indicators that measure the readiness

of new technologies to come. When conducting a

thematic analysis, the researcher will read and reread

the text carefully; it is essential to reveal the patterns

contained in the data. This enables the emergence of

appropriate analytical categories. For this study, the

researcher categorized into three categories: 1)

Dimensions, 2) Sub Dimension, 3) Leveling

(Fereday, Muir- Cochran, 2006).

After the content is separated into several

categories, the data must be combined and used to fit

the sub-theme. Then from the results of the

discussion, these themes will be justified from the

researchers’ perspective to give the reader a better

understanding of what is pulled from the data that is

considered necessary. All of this lead to how viral

marketing is being used for cyber marketing and

public relations, which was the ultimate goal (Arson,

1994). In this research, the theme is decided into 4,

they are; 1) Tangible Area Domination Models, 2)

Intangible Area Domination Models, 3) Combined

Area Domination Models, 4) Complete Component

Models.

3.3 Limitations

The weakness of textual and thematic analysis is its

subjective nature. Because texts can carry many

meanings, different people can interpret information

in different ways. It is recognized that qualitative

research cannot be generalized, and this applies to

this research. For preliminary work in this field, this

is acceptable. This is the beginning of future

research dealing with the readiness of the Industry to

face industry 4.0 (Stacks, 2002).

ICVHE 2019 - The International Conference of Vocational Higher Education (ICVHE) “Empowering Human Capital Towards Sustainable

4.0 Industry”

408

3.4 Analysis

The guidelines established by the coding sheet guide

the researcher was putting the article into categories

according to the topic. Unlike content analysis, there

is no sum in trend grouping. Articles are read in a

way that looks for where the data is in a predefined

category. By separating articles into trends, thematic

analysis is then produced. The thematic analysis

looks at each broad category defined by textual

analysis, then draws on more specific themes.

Themes will give a better picture of what happens to

readiness measurements. Propositions that are

guided by analysis and repeatedly referred to ensure

that the theory is related to what is being discussed.

The theory is the framework for this entire thesis,

which will show the importance of this research in

an academic and practical perspective.

4 RESULTS AND CONCLUSIONS

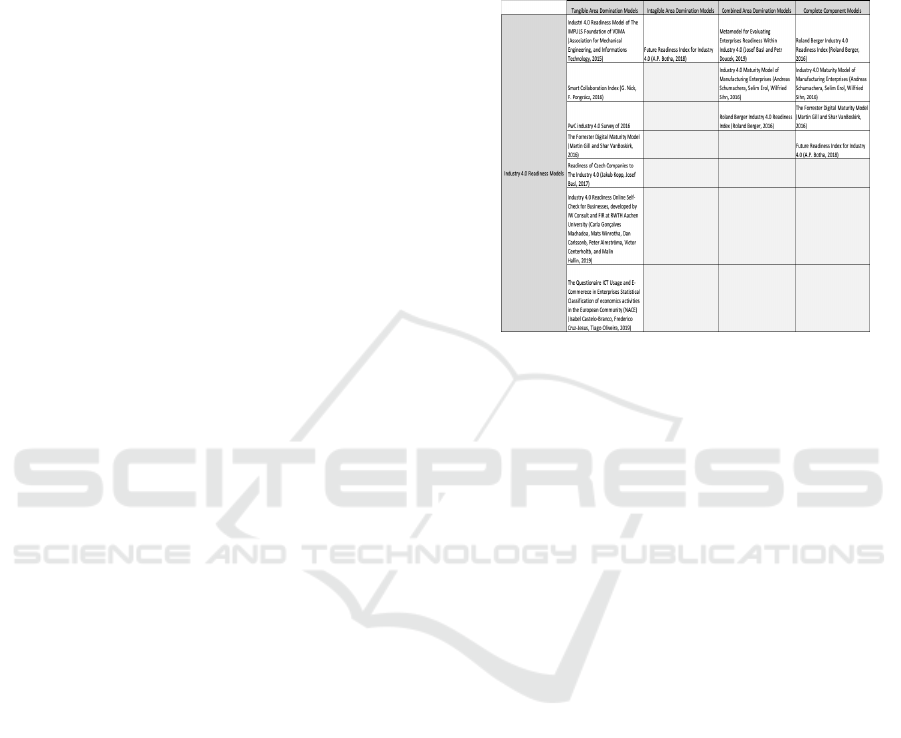

From the thematic textual analysis, it can be

concluded that from the 11 existing models all can

be used to assess industry readiness in a

predominantly substantive area, namely around

products, technology, skills, data, and corporate

strategy in dealing with 4.0. There is a model that is

unexpectedly dominated by assessments of

intangible areas such as value/culture, social,

behaviour, events, etc. If further research wants a

balanced combination of tangible and intangible

areas, a model can be used:

1. Metamodel for Evaluating Enterprises

Readiness Within Industry 4.0 (Josef Basl

and Petr Doucek, 2019)

2. Industry 4.0 Maturity Model of

Manufacturing Enterprises (Andreas

Schumachera, Selim Erol, Wilfried Sihn,

2016)

3. Roland Berger Industry 4.0 Readiness

Index (Roland Berger, 2016)

For researchers who want to use a mature and

complete model (dimensions, sub-dimensions, and

level indexes) can use the following model:

1. Roland Berger Industry 4.0 Readiness

Index (Roland Berger, 2016)

2. Industry 4.0 Maturity Model of

Manufacturing Enterprises (Andreas

Schumachera, Selim Erol, Wilfried Sihn,

2016)

3. The Forrester Digital Maturity Model

(Martin Gill and Shar VanBoskirk, 2016)

4. Future Readiness Index for Industry 4.0

(A.P. Botha, 2018)

Table 1: The Thematic Results Table

Researchers’ findings in the following textual

analysis are; no dimensions or sub-dimensions have

been found that assess and measure the

psychological and mental readiness of workers and

professionals who will face the era of disruptive

industry 4.0. Measurements made are about skills

and abilities in managing, operating, and adapting to

technology 4.0. Also, from the existing model, no

one mentioned the readiness of the Industry in terms

of the environment. Green I.T. is becoming a hot

topic in the world, and it would be nice if the

measurement model of Industry 4.0 readiness also

reviews and measure the environment (recycled tech

waste, green office, etc.).

The conclusion is the existing models at this

time can be used to measure industry readiness in

dealing with industry 4.0 depending on the tendency

of the researcher (tangible, intangible, or combined).

Researchers and industry players can choose models

that suit their needs. In addition, the results of this

study can be opened up for other researchers to

develop existing models by adding elements of the

dimensions of “psychology” and “environment”.

ACKNOWLEDGEMENTS

I’d like to show my gratitude to my co-authors for

sharing their pearls of wisdom and knowledge with

me during the making of this research. I am also

immensely grateful to Program Pendidikan Vokasi

Universitas Indonesia for funding the publication of

A Textual Thematic Analysis: Tools to Measure the Readiness of Industry towards the Disruption Era

409

this research. Any errors and imperfections in this

research are my own and should not tarnish the

reputations of these esteemed persons mentioned.

REFERENCES

Amoroso DL, Hunsinger S., 2009. Measuring the

Acceptance of Internet Technology by Consumers

Measuring the Acceptance of Internet Technology by

Consumers. 3:48–81.

Androutsopoulou A, Karacapilidis N, Loukis E,

Charalabidis Y., 2018. Transforming the

communication between citizens and government

through AI-guided chatbots. Gov Inf Q: 1–10.

https://doi.org/10.1016/j.giq.2018.10.001

Arson, J. ,1994. A Pragmatic View of Thematic Analysis.

The Qualitative Report, 2(1), 1-2

Basl, Josef, 2018. Companies on the Way to Industry 4.0

and their Readiness. Journal of Systems 2018/3. DOI:

10.20470/jsi.v9i3.351

Basl, Josef 1, Petr Doucek. 2019. A Metamodel for

Evaluating Enterprise Readiness in the Context of

Industry 4.0. Information 2019, 10, 89;

doi:10.3390/info10030089

www.mdpi.com/journal/information

Berger, A.A., 1995. Essentials of Mass Communication

Theory. London: SAGE Publications.

Boer PS De, Deursen AJAM Van, Rompay TJL Van,

2019. Telematics and Informatics Accepting the

Internet-of-Things in our homes : The role of user

skills. Telemat Informatics [Internet] ;36(July

2018):147–56. Available from:

https://doi.org/10.1016/j.tele.2018.12.004

Bonciu F, 2017. Evaluation of The Impact of The 4

th

Industrial Revolution in The Labour Market.

Romanian Economic and Business Review, vol. 12,

no. 2, 2017, p. 7

Botha, A.P., 2018. Rapidly Arriving Futures: Future

Readiness For Industry 4.0. South African Journal of

Industrial Engineering November 2018 Vol 29(3)

Special Edition, pp 148-160

Bresciani S, Ferraris A, Del M., 2018. Technological

Forecasting & Social Change The management of

organizational ambidexterity through alliances in a

new context of analysis : Internet of Things ( IoT )

smart city projects. Technol Forecast Soc Chang

[Internet]. Elsevier Inc.; 2018;136:331–8. Available

from: https://doi.org/10.1016/j.techfore.2017.03.002

Castelo-Branco, Isabel, Frederico Cruz-Jesus, Tiago

Oliveira, 2019. Assessing Industry 4.0 readiness in

manufacturing: Evidence for the European Union.

Computers in Industry 107 (2019) 22–32.

https://doi.org/10.1016/j.compind.2019.01.007

Caruso L., 2018. Digital innovation and the fourth

industrial revolution: epochal social changes ? A.I.

Soc. Springer London; 2018;33(3):379–92.

CSC-Stuie „Industrie 4.0, 2015. Ländevergleich DACH.

Dutta, S.; Lanvin, B.; Wunsch-Vincent, S., 2018. Global

Innovation Index 2018 Energizing the World with

Innovation.

https://www.globalinnovationindex.org/gii-2018-

report

Erasmus E, Rothmann S, Eeden C Van, Triangle V, Africa

S, Rothmann S, 2011. A structural model of

technology acceptance. 2011;1–12.

Fairclough, N., 1992. Discourse and Text: Linguistic and

Intertextual Analysis within Discourse Analysis.

Dicourse & Society, 3(2), 193-217.

Fereday, J. and Muir-Cochran, E., 2006. Demonstrating

Rigor Using Thematic Analysis: A Hybrid Approach to

Inductive and Deductive Coding and Theme

Developments. International Journal of Qualitative

Methods, 5(1), 1-13

Global Information Technology Report, 2016. Networked

Readiness Index. http://reports.weforum.org/global-

information-technology-report-2016/networked-

readiness-index/

Kohlegger, M., R. Maier, and S. Thalmann, 2009.

Understanding Maturity Models Results of a

structured Content Analysis. Presented at the I-

KNOW ’09 and I-SEMANTICS ’09, Graz, Austria,

2009.

Kopp, Jakub, Josef Basl, 2017. Study of the Readiness of

Czech Companies to the Industry 4.0. Journal of

System Integration 2017/3. DOI:

10.20470/jsi.v8i2.313

Lo, F, Campos, N, 2018. Technological Forecasting &

Social Change Blending Internet-of-Things ( IoT )

solutions into relationship marketing strategies.

Technol Forecast Soc Chang [Internet]. Elsevier;

2018;137(September):10–8. Available from:

https://doi.org/10.1016/j.techfore.2018.09.029

Machadoa, Carla Gonçalves, Mats Winrotha, Dan

Carlssonb, Peter Almströma, Victor Centerholt, Malin

Hallin. 2019. Industry 4.0 readiness in Manufacturing

Companies: Challenges and Enablers Towards

Increased Digitalization. Procedia CIRP 81 (2019)

1113–1118

Ngai, E. W, D. C. K. Chau, J. K. L. Poon, and C. K. M.

To, 2013. Energy and utility management maturity

model for sustainable manufacturing process.

International Journal of Production Economics, vol.

146, no. 2, pp. 453–464, Dec. 2013.

OECD Science, Technology and Industry Scoreboard,

2017. The Digital Transformation. OECD Publishing:

Paris, France, 2017.

Park SC, 2018. The Fourth Industrial Revolution and

implications for innovative cluster policies. A.I. Soc

[Internet]. Springer London; 2018;33(3):433–45.

Available from: http://dx.doi.org/10.1007/s00146-017-

0777-5

Pigosso, D. C. A., H. Rozenfeld, and T. C. McAloone,

2013. Ecodesign maturity model: a management

framework to support ecodesign implementation into

manufacturing companies. Journal of Cleaner Pro-

duction, vol. 59, pp. 160–173, Nov. 2013.

ICVHE 2019 - The International Conference of Vocational Higher Education (ICVHE) “Empowering Human Capital Towards Sustainable

4.0 Industry”

410

Pongrácz, Nick, F., 2016. How To Measure Industry 4.0

Readiness of Cities. Scientific Proceedings I

International Scientific Conference “Industry 2.4”

2016. ISSN 1310-3946

Prior, L., 2004. Doing Things with Documents. In

Silverman, D. (Ed.), Qualitative Research: Theory,

Method and Practice (2nd ed.) (77-94). London:

SAGE Publications.

Prisecaru P., 2016. Knowledge Horizons - Economics.

8(1):57–62.

Qian T, Medaglia R., 2018. Mapping the challenges of

Artificial Intelligence in the public sector : Evidence

from public healthcare. Gov Inf Q [Internet]. Elsevier;

2018;(June):1–16. Available from:

https://doi.org/10.1016/j.giq.2018.09.008

Rajnai, Zoltán, István Kocsis, 2018. Assessing Industry 4.0

Readiness of Enterprises. SAMI 2018 • IEEE 16th

World Symposium on Applied Machine Intelligence

and Informatics • February 7-10 • Košice, Herl’any,

Slovakia. 978-1-5386-4772-1/18/$31.00 ©2018 IEEE

Rojko, Andreja, 2017. Industry 4.0 Concept: Background

and Overview Industry 4.0.

https://doi.org/10.3991/ijim.v11i5.7072. iJIM ‒ Vol.

11, No. 5, 2017

Saarikko T, Westergren UH, Blomquist T., 2017. The

Internet of Things : Are you ready for what ’ s

coming ? Bus Horiz [Internet]. “Kelley School of

Business, Indiana University”; 2020;60(5):667–76.

Available from:

http://dx.doi.org/10.1016/j.bushor.2017.05.010

Siepen, S., 2015. Industry 4.0: The role of Switzerland

within a European Manufacturing Revolution.

Available online:

https://www.rolandberger.com/en/Publications/Industr

y-4.0-The-role-of-Switzerland. html

Oxford University Press, 1989. The Oxford English

dictionary, 2nd ed. Edited by Simpson, J. A., Weiner,

E. S. C.,. Oxford : Oxford; New York: Clarendon

Press ; Oxford University Press.

Suri, K.; Cadavid, J.; Alferez, M.; Dhouib, S.; Tucci-

Piergiovanni, S., 2018. Modeling Business Motivation

and Underlying Processes for RAMI 4.0-Aligned

Cyber-Physical Production Systems. In Proceedings of

the 22nd IEEE International Conference on Emerging

Technologies and Factory Automation, Limassol,

Cyprus, 12–15 September 2017; IEEE: New York,

NY, USA, 2018.

Schumacher, Andreas, Selim Erol, Wilfried Sihn, 2016. A

maturity model for assessing Industry 4.0 readiness

and maturity of manufacturing enterprises. Procedia

CIRP 52 (2016) 161 – 166

Ślusarczyk B., 2018. Industry 4.0 – Are We Ready?. Polish

Journal of Management Studies 2018. Vol 17 No.1.

Stacks, D.W., 2002. Primer of Public Relations Research.

New York: The Guilford Press.

Studie Industrie 4.0, 2014. Eine Standortbestimmung der

Automobil- und Fertigungsindustrie (MHP,

Gesellschaft für Management- und ITBeratung mbH.

2014.

Schwab, K., 2018. The Global Competitiveness Report

2018; World Economic Forum: Geneva, Switzerland,

2018; Available online:

http://www3.weforum.org/docs/GCR2018/05FullRepo

rt/TheGlobalCompetitivenessReport2018.pdf

The Boston Consulting Group, 2016. Inside OPS – Are

your operations ready for a digital revolution? (BCG.

2016.)

Wang, Y.; Towara, T.; Anderl, R., 2017. Topological

Approach for Mapping Technologies in Reference

Architectural Model Industrie 4.0 (RAMI 4.0). In

Proceedings of the World Congress on Engineering

and Computer Science 2017, San Francisco, CA,

USA, 25–27 October 2017; pp. 982–990.

A Textual Thematic Analysis: Tools to Measure the Readiness of Industry towards the Disruption Era

411