The Effect of Gambir Adhesive Level and Hot Press Temperature on

Physical and Mechanical Properties of Bamboo Particleboard

Tito Sucipto

1

, Ragil Widyorini

2

, Tibertius Agus Prayitno

2

and Ganis Lukmandaru

2

1

Department of Forest Product Technology, Faculty of Forestry, Universitas Sumatera Utara,

Jl. Tri Dharma Ujung No.1 Medan20155, Indonesia

2

Department of Forest Product Technology, Faculty of Forestry, Universitas Gadjah Mada,

Jl. Agro No.1 Yogyakarta55281, Indonesia

Keywords: Gambir, Adhesive, Bamboo, Particleboard, Properties.

Abstract: Gambir is the extract of leaves sap and young twigs of gambir plants, which contains tannin.Gambir-

formaldehyde adhesives have been applied to the particleboards, butsome properties of particleboard

produced did not meetthe standard.In this study, gambir adhesives (without formaldehyde) were applied to

the bamboo particleboard.The dimension of particleboard was 25x25x1 cm, and the board density target was

set at 0.8 g/cm3. Three kinds of adhesive levels (10, 20, 30%) and four kinds of hot-press temperature (160,

180, 200, 220

o

C) were used for particleboard production. The research aimed to investigatethe effect of

gambir adhesive level and hot-press temperature on the physical and mechanical properties of the

bambooparticleboard. The physical and mechanical properties of particleboards were then evaluated and

compared to the JIS A5908-2003 standard.The study showed that adhesive level and hot-press temperature

affected significantly on thickness swelling, water absorption, internal bond, modulus of rupture and modulus

of elasticityof particleboard, while the effect of an adhesive level factor was also significant on density

properties.Interaction between adhesive level and hot-press temperature factor only affected significantly on

water absorption. Particleboards with hot-press temperatures of 200

o

C and 220

o

C have better properties than

others.The high hot-press temperature has exceeded the melting point of the catechin (174-178

o

C),

furthermore, the gambir adhesive becomes hardened and cured. The most optimal bamboo particleboard is

particleboard with 220

o

C hot-press temperature and adhesive level of 30%, based on the best of particleboard

properties compared to JIS A5908-2003.

1 INTRODUCTION

Gambir (Uncariagambir (Hunter) Roxb.) in

Indonesia are mostly found in West Sumatra and Riau

Province (export markets), as well as North Sumatra,

Bengkulu, South Sumatra and Aceh (local markets)

(Sabarni, 2015; Gumbira-Sa’idet al., 2009). In 2012,

gambir commodities in Indonesia with gambir plant

area covering 29,326 ha could produce 20,511 tons of

dried gambir and exported as many as 15,685 tons

worth US$ 34 million(Ministry of Agriculture of

Indonesia, 2013).

Gambir is the extract of leaves sap and young

twigs of gambir plants, which contain tannin

especially tannin from catechins of phenolic groups.

Some gambir extract products are processed by the

community in various gambir production center in

Indonesia. It hasthe catechin content varies from 2.5

to 95% (Amos, 2010).

Many national and global industries need gambir

as the main or additional materials in the production

process. The factories include the chemical industry,

biopharmaceuticals, cosmetics, textiles, leather

processing, food and beverages, biopesticides, and

metal industries (Ministry of Agriculture of

Indonesia, 2013).

The tannins in gambir can also be used as natural

adhesives (Pizzi, 1994; Pizzi, 2008).Gambir

adhesives combined with formaldehyde have been

applied to particleboards from oil palm trunk (Kasim

et al., 2007), empty fruit bunches mixture with acacia

bark (Fathanah and Sofyana, 2013), and empty fruit

bunches (Junaidiet al., 2015).Formaldehyde

functions as a cross-linker or hardener, with additions

of 10% (Kasim et al., 2007; Junaidiet al., 2015) and

362

Sucipto, T., Widyorini, R., Prayitno, T. and Lukmandaru, G.

The Effect of Gambir Adhesive Level and Hot Press Temperature on Physical and Mechanical Properties of Bamboo Particleboard.

DOI: 10.5220/0010182800002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 362-367

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2% (Fathanah and Sofyana, 2013). However, on the

other hand, formaldehyde causes formaldehyde

emissions, that are toxic and can disrupt the

environment and humans (Foyer et al., 2016).

Some physical and mechanical properties of the

produced particleboard (Kasim et al., 2007; Fathanah

and Sofyana, 2013; Junaidiet al., 2015)did not meet

the particleboard standards based on SNI 03-2105-

2006. This is thought to be caused by the weakness of

material preparation, gambir adhesive formulation,

and hot-press process, therefore that the bonding

between adhesive and lignocellulose particles was not

optimal.

The adhesive level and hot-press temperature

affect the quality of the particleboard. As a factor

affecting particle board quality, the levels of gambir-

formaldehyde adhesives that have been used were

16% (Kasim et al., 2007), 12%, 14%, 16% (Junaidiet

al., 2015), and the ratio of gambir to empty fruit

bunches (v/v) 30/70, 40/60, 50/50, 60/40 and 70/30

(Fathanah and Sofyana, 2013). The optimal hot-press

temperature was 150

o

C for 15 min (Kasim et al.,

2007; Junaidiet al., 2015) and 145

o

C for 30 min

(Fathanah and Sofyana, 2013). The particleboard hot-

press temperature was less optimal because it is lower

than the melting point of the catechin as the main

component of the gambir. The melting point of

catechins was 174-178

o

C (Rahmawatiet al., 2012).

This means that the gambir adhesive was thought to

have not melted to subsequently harden when

bonding with lignocellulose particles.

Based on these problems, gambir adhesives

(without formaldehyde) were applied to the bamboo

particleboard by a factor of adhesive level and hot-

press temperature. Betung bamboo wastes from the

industry of roof truss components were used as

particle materials. Particleboards were tested for the

physical and mechanical properties based on JIS

A5908-2003 standards. The study aimedto

investigate the effect of gambir adhesive level and

hot-press temperature on the physical and mechanical

properties of bamboo particleboard.

2 MATERIALS AND METHODS

2.1 Materials

Gambirwas purchased from the traditional market

and sodium hydroxide (97%) was purchased from

Merck. Gambir commonly called gambirbootch,

cylindrical form, and dark brown color were used

without purification. Each gambir and sodium

hydroxide were ground into powder (passes 20-mesh

screen).

Betung bamboo (Dendrocalamus asper) was used

as a particleboard material, originating from the

industrial waste of roof truss component in Sleman

District, Special Region of Yogyakarta. Bamboo chip

wasground into a particle (passes 10-mesh screen)

and dried to air-dry condition.

2.2 Methods

2.2.1 Adhesive Formulation

The gambir adhesives were made by dissolving

gambir powder in distilled water. The concentration

of the solution was adjusted to 45wt%. In each

gambir adhesive formulation, the sodium hydroxide

solution was added until pH 8 was reached (Kasim et

al., 2007).

2.2.2 Particleboard Manufacturing

The particleboard manufacturing consisted of

blending, particles and adhesives mix drying at 80

o

C

for 4 hours, mat-forming, hot-pressing, and

conditioning for one week. The dimension of

particleboard was 25x25x1 cm, and the board density

target was set at 0.8 g/cm

3

. Four kinds of hot-press

temperature (160

o

C, 180

o

C, 200

o

C, 220

o

C) and three

kinds of adhesive levels (10%, 20%, 30%) were used

for particleboard production.

The boards were pressed at four kinds of

temperaturewith a pressure of 3.5 MPa for 10

min.Particleboard pressing used the breathing system

(5-1-5 min). The particleboard was then conditioned

at room temperature for one week. The gambir

adhesives and bamboo particle preparation are

summarized in Table 1.

2.2.3 Particleboards Testing

The particleboards were cut into a sample for physical

and mechanical properties testing. The sample size

used of 5x5 cm (thickness swelling, water absorption,

density, and internal bond testing), and 20x5 cm

(modulus of rupture and modulus of elasticity

testing).

The physical properties of particleboards

(thickness swelling, water absorption, and density)

and mechanical properties (internal bond, modulus of

rupture, and modulus of elasticity) were then

evaluated. The board properties were compared to the

JIS A5908-2003 standard. The effect of adhesive

level and hot-press temperature on the particleboard

properties were tested by statistical variance analysis.

The Effect of Gambir Adhesive Level and Hot Press Temperature on Physical and Mechanical Properties of Bamboo Particleboard

363

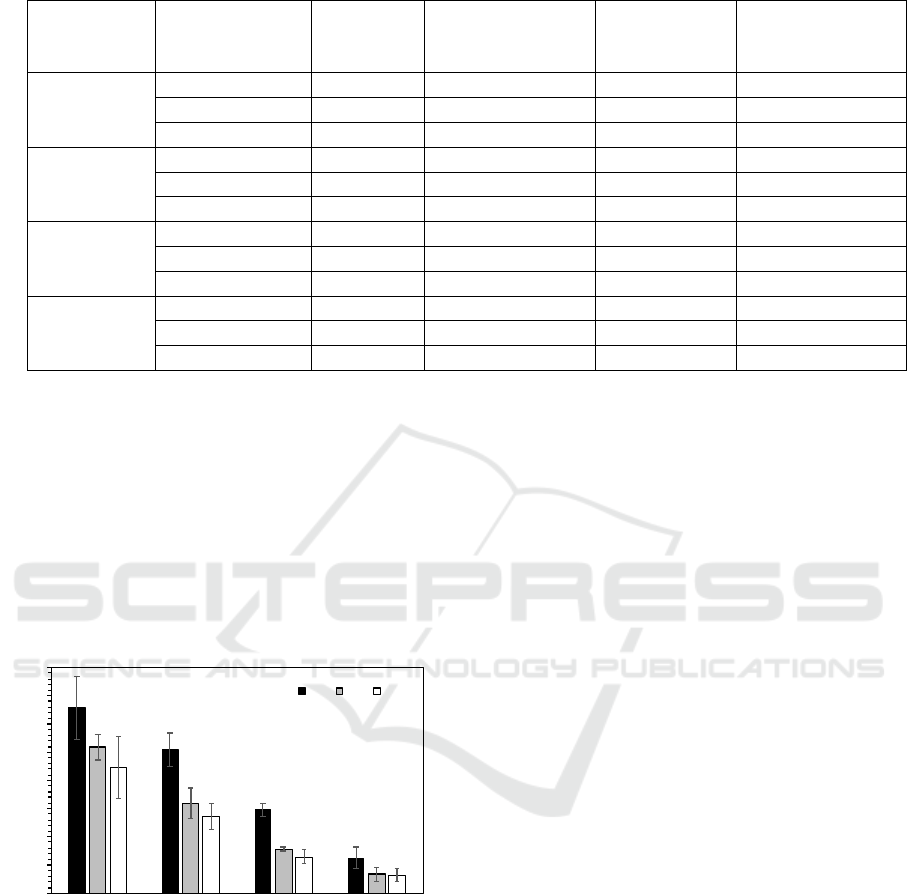

Table 1: Preparation of gambir and bamboo particle.

Hot-press

temperature

(

o

C)

Adhesive level (%) Gambir (g) Distilled water (ml) NaOH 50% (ml) Bamboo particle (g)

160

10 45.45 101.00 8 504.54

20 83.33 185.18 14 462.49

30 115.38 256.40 19 426.93

180

10 45.45 101.00 8 504.54

20 83.33 185.18 14 462.49

30 115.38 256.40 19 426.93

200

10 45.45 101.00 8 504.54

20 83.33 185.18 14 462.49

30 115.38 256.40 19 426.93

220

10 45.45 101.00 8 504.54

20 83.33 185.18 14 462.49

30 115.38 256.40 19 426.93

3 RESULTS AND DISCUSSIONS

3.1 Physical Properties

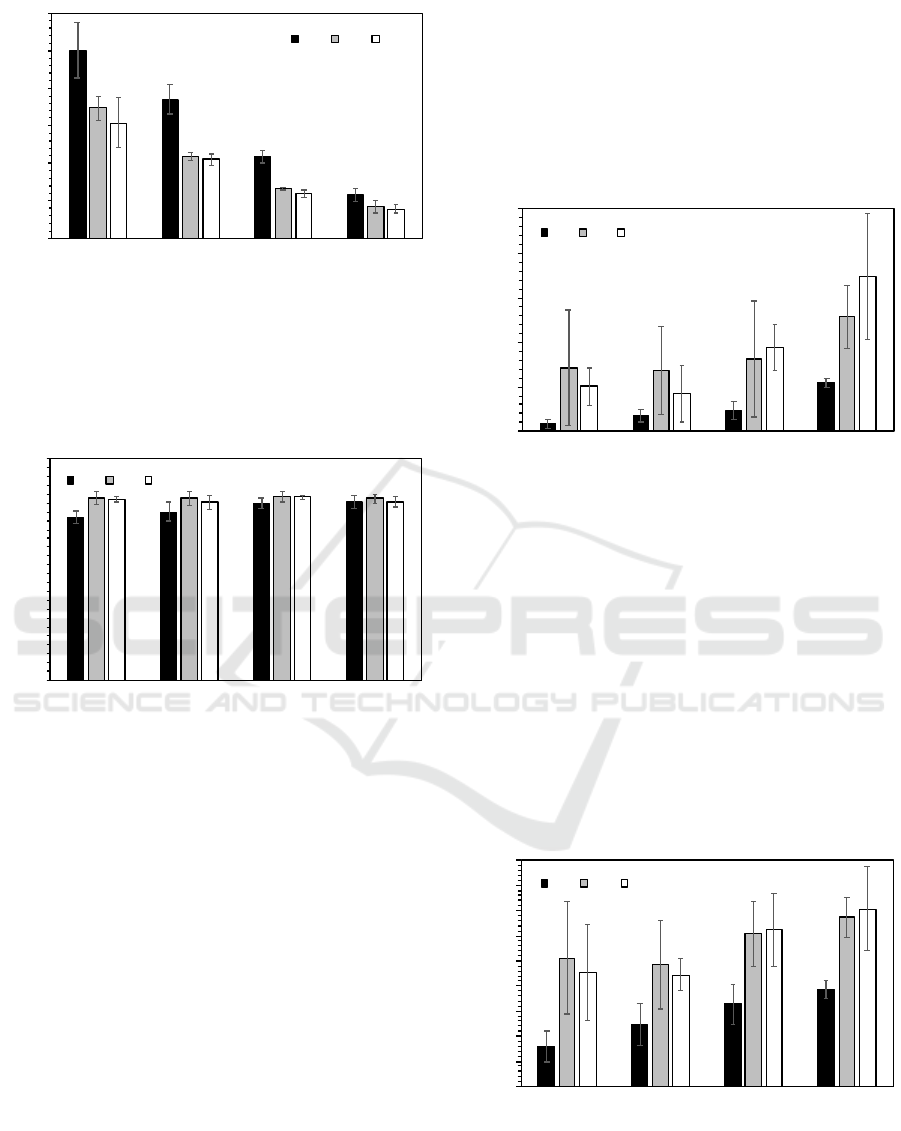

The thickness swelling of bamboo particleboard

ranged from 13.11% to 131.70%. Figure 1 showed

that all the thickness swelling of particleboard did not

meet the requirement of JIS A5908-2003 (≤12% of

thickness swelling).

Figure 1: Thickness swelling of particleboard.

In another study, the thickness swelling of

bamboo binderless particleboard was below than

12%, to meet the requirement of JIS A5908-2003.The

binderless particleboard was hot-pressed on 200

o

C

temperature for 15 min (Widyoriniet al., 2011). It

might be due to the polar characteristic of gambir

tannins (10% to 30%) was applied in this study and a

difference in the target of density (0.8 g/cm

3

vs 0.9

g/cm

3

). It was reported that catechin is the main

chemical component of gambir (Amos, 2010; Hiller

and Melzig, 2007).

The factors of adhesive level and hot-press

temperature significantly affected the board thickness

swelling, while the interaction between two factors

was not significant. The high level ofhot-press

temperature with the high adhesive level formed a

strong bonding between gambir adhesive and bamboo

particles.

The particleboard of oil palm trunk used gambir-

formaldehyde adhesive obtained thickness swelling

properties ranged from 56.98% to 72.63% (Kasim et

al., 2007). Consequently, no formaldehyde addition

as hardener or cross-linker on gambir adhesive.

The average of particleboard water absorption

was 114.34% (Figure 2). Water absorption is usually

in line with the thickness swelling, therefore the lower

of adhesive level and hot-press temperature will

increase the water absorption and thickness swelling

properties.

The water absorption of particleboards that meets

the FAO standard are particleboards with a hot-press

temperature of 220

o

C (all adhesive level) and 200

o

C

hot-press temperature on adhesive level of 20% and

30%. FAO standards require the particleboard water

absorption ranged from 20% to 75%. The factors of

adhesive level and hot-press temperature and

interaction between two factors were significantly

affected on the board water absorption.

0

20

40

60

80

100

120

140

160

160180200220

T hickness swell ing (% )

H ot- pr ess t emper at ur e (

o

C)

10% 20% 30%

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

364

Figure 2: Water absorptionof particleboard.

Figure 3 showed that all the density of

particleboardswere ranged from 0.74 g/cm

3

to 0.83

g/cm

3

(average of 0.80 g/cm

3

), meet the JIS A5908-

2003 requirement.

Figure 3: Density of particleboard.

The particleboard density wasappropriated to the

density target of 0.80 g/cm

3

and classified to the

medium density particleboard group (0.59-0.80

g/cm

3

) (Maloney, 1993). The factors of adhesive level

significantly affected the board density, while hot-

press temperature factor and interaction between two

factors were not significant. Other studies showed

that density of particleboard ranged from 0.60g/cm

3

to 0.75 g/cm

3

(density target of 0.7 g/cm

3

) (Kasim,

2007) and 0.75-0.85 g/cm

3

(density target of

0.9g/cm

3

) (Widyoriniet al., 2011).

3.2 Mechanical Properties

The effect of adhesive level and hot-press

temperature on internal bond, modulus of rupture and

modulus of elasticity of bamboo particleboard are

shown in Figure 4, Figure 5, and Figure 6,

respectively. The internal bond of bamboo

particleboard ranged from 0.03 MPa to 0.70 MPa.

The result showed that the internal bond of

bamboo particleboard waslower than the internal

bond of oil palm trunk particleboard used gambir-

formaldehyde adhesive (0,71-0,81 MPa) (Kasim et

al., 2007). Formaldehyde as a cross-linker on gambir

adhesive could increase the internal bond of

particleboard, even though itcauses toxic emissions

for the environment and humans (Foyer et al., 2016).

Figure 4: Internal bond of particleboard.

The factors of adhesive level and hot-press

temperature significantly affected the board internal

bond, while the interaction between two factors was

not significant. The result showed that internal bond

values meet JIS A5908-2003 requirement for grade 8

types particleboard, on particleboard with the

adhesive level of 20% and 30% (all hot-press

temperature), plus an adhesive level of 10% (220

o

C).

Particleboards with a hot-press temperature of 200

and 220

o

C (adhesive level of 20% and 30%) also meet

JIS A5908-2003 (type 18).

The modulus of rupture of bamboo particleboard

ranged from 3.13MPa to 14.16MPa (Figure 5).

Figure 5: Modulus of rupture of particleboard.

The interaction between two factors was not

significantly affected the board modulus of rupture,

while the factors of adhesive level and hot-press

0

50

100

150

200

250

300

160 180 200 220

Water absorption (% )

H ot-pr ess t emper at ur e (

o

C)

10% 20% 30%

0,0

0,2

0,4

0,6

0,8

1,0

160 180 200 220

Density (g/cm

3

)

H ot-pr ess t emper at ur e (

o

C)

10% 20% 30%

0,0

0,2

0,4

0,6

0,8

1,0

160180200220

Internal bond (MPa)

H ot-pr ess t emper at ur e (

o

C)

10% 20% 30%

0

2

4

6

8

10

12

14

16

18

160 180 200 220

M odulus of rupture (M Pa)

H ot-pr ess t emper at ur e (

o

C)

10% 20% 30%

The Effect of Gambir Adhesive Level and Hot Press Temperature on Physical and Mechanical Properties of Bamboo Particleboard

365

temperature significantly affected the modulus of

rupture properties. Particleboards with all hot-press

temperature (adhesive level of 20% and 30%) were

met JIS A5908-2003 (type 8). Particleboard grade 13

type only fulfilled by particleboards with hot press

temperature of 220

o

C (adhesive level of 20% and

30%).

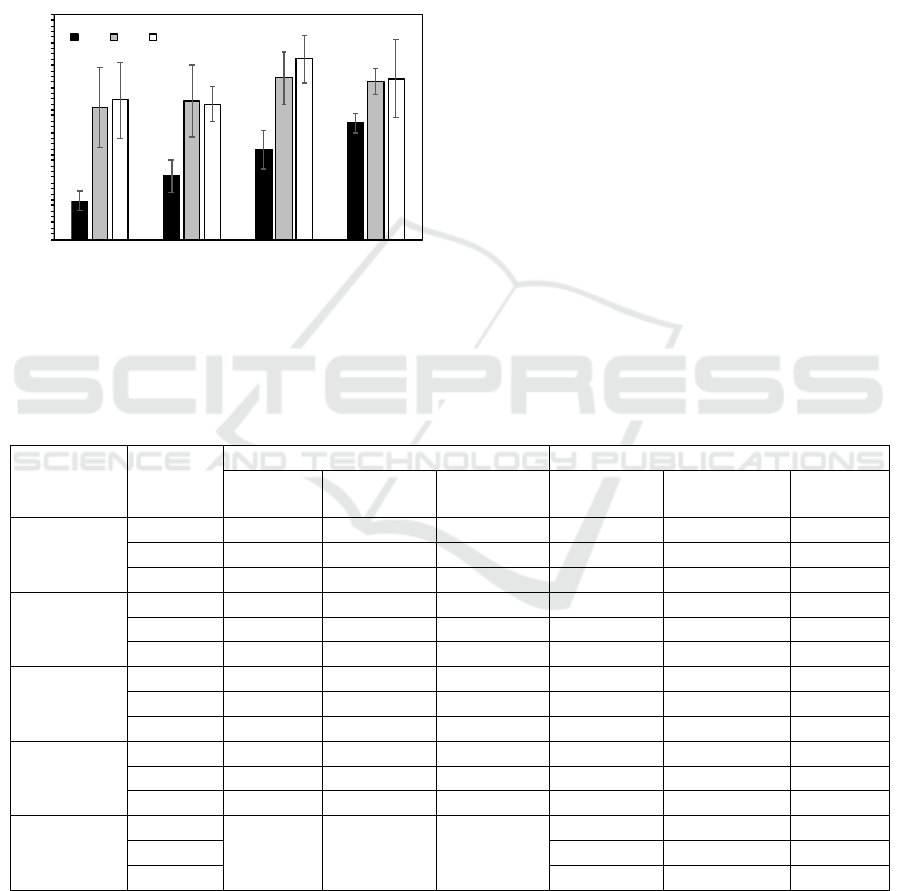

Figure 6 showed that the modulus of elasticity of

bamboo particleboard ranged from 0.68 GPa to 3.21

GPa (average of 2.24 GPa).

Figure 6: Modulus of elasticity of particleboard.

Particleboard that meets JIS A5908-2003 (type 8)

requirement for modulus of elasticity were all

particleboard with the adhesive level of 20% and

30%, plus one particleboard with the adhesive level

of 10% on 220

o

C hot-press temperature.

For JIS A5908-2003 (type 8)fulfilled by

particleboards with a hot-press temperature of 200

and 220

o

C (adhesive level of 20% and 30%).The one

and only particleboard with a hot-press temperature

of 200

o

C on adhesive level of 30%were meet JIS

A5908-2003 (type 18).

The factors of adhesive level and hot-press

temperature significantly affected the board modulus

of elasticity, while the interaction between two

factors was not significant.

3.3 The Optimal Physical and

Mechanical Properties of

Particleboards

The physical and mechanical properties of bamboo

particleboards compared with JIS A5908-2003 and

statistical analysis are summarized in Table 2. The

most optimal bamboo particleboard is particleboard

with 220

o

C hot-press temperature and adhesive level

of 30%, based on the best values of the physical and

mechanical properties of particleboard compared to

JIS A5908-2003.

Table 2: The physical and mechanical properties of particleboards compared with JIS A5908-2003 and statistical analysis.

Hot-press

temperature

(

o

C)

Adhesive

level (%)

Physical properties Mechanical properties

TS (%) WA (%) D (g/cm

3

) IB (MPa) MOR (MPa) MOE (GPa)

160

10 131.70 (a) 250.29 (a) 0.74

)18

(c) 0.03 (d) 3.19 (e) 0.68 (e)

20 103.66 (b) 173.33 (bc) 0.82

)18

(a) 0.28

)13

(bcd) 10.24

)8

(abc) 2.35

)8

(abc)

30 89.10 (b) 154.05 (c) 0.81

)18

(ab) 0.20

)13

(cd) 9.05

)8

(abcd) 2.48

)8

(abc)

180

10 101.79 (b) 184.96 (b) 0.76

)18

(bc) 0.07 (cd) 4.95 (de) 1.12 (de)

20 63.58 (c) 109.40 (d) 0.82

)18

(a) 0.27

)13

(bcd) 9.71

)8

(abcd) 2.47

)8

(abc)

30 54.69 (c) 104.98 (d) 0.80

)18

(ab) 0.17

)8

(cd) 8.88

)8

(abcd) 2.40

)8

(abc)

200

10 59.38 (c) 108.87 (d) 0.80

)18

(ab) 0.09 (cd) 6.55 (cde) 1.60 (cd)

20 31.20 (d) 66.35 (e)

0.83

)18

(a) 0.33

)18

(bcd) 12.17

)8

(ab) 2.87

)13

(ab)

30 25.85 (d) 59.06 (e) 0.83

)18

(a) 0.38

)18

(bc) 12.49

)8

(ab) 3.21

)18

(a)

220

10 24.78 (d) 57.09 (e) 0.80

)18

(ab) 0.22

)13

(bcd) 7.70 (bcde) 2.07

)8

(bc)

20 13.31 (d) 41.36 (e) 0.82

)18

(a) 0.51

)18

(ab) 13.45

)13

(a) 2.81

)13

(ab)

30 13.11 (d) 38.82 (e) 0.80

)18

(ab) 0.70

)18

(a) 14.16

)13

(ab) 2.86

)13

(ab)

JIS A5908-

2003

Type 8

≤12 20-75* 0.4–0.9

≥0.15 ≥8 ≥2

Type 13 ≥0.2 ≥13 ≥2.5

Type 18 ≥0.3 ≥18 ≥3

Description: - *FAO standard.

-

)8

meet JIS A5908-2003 type 8;

)13

meet JIS A5908-2003 type 13;

)18

meet JIS A5908-2003 type 18.

- numbers followed by the same letters (in parentheses) mean that they are not significantly different.

0,0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

4,0

160 180 200 220

M odulus of elasticity (GPa)

Hot-press temperature (

o

C)

10% 20% 30%

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

366

4 CONCLUSIONS

Gambir could be used as the natural adhesive for

particleboard, that can meet most of the JIS

A5908-2003 requirements. Adhesive level and

hot-press temperature factor affected significantly

on thickness swelling, water absorption, internal

bond, modulus of rupture and modulus of

elasticity of particleboard, whilethe effect of an

adhesive level factor was also significant on the

density of particleboard.Interaction between

adhesive level and hot press temperature factor

only affected significantly on water absorption of

particleboard.

Particleboards with hot-press temperatures of

200

o

C and 220

o

C have better properties than

others. Particleboards with the adhesive level of

20% and 30% also have better properties than

10%.The high hot-press temperature has

exceeded the melting point of the catechin (174-

178

o

C), therefore the gambir adhesive becomes

hardened and cured. The most optimal bamboo

particleboard is particleboard with 220

o

C hot-

press temperature and adhesive level of 30%,

based on the best of particleboard properties

compared to JIS A5908-2003.

ACKNOWLEDGMENTS

The authors are grateful for the financial support from

The Indonesia Endowment Fund for Education

(LPDP) and The Ministry of Research, Technology,

and Higher Education of Indonesia.

REFERENCES

Amos. (2010). Kandungankatekingambirsentraproduksi di

Indonesia.JurnalStandardisasi, 12(3), pp. 149-155

(2010).

Fathanah, U., and Sofyana. (2013).

Pembuatanpapanpartikel (particle board)

daritandankosongsawitdenganperekatkulitakasiadanga

mbir. Journal of Chemical Engineering and

Environment, 9(2), pp. 137-143.

Foyer, G., Chanfi, B.H., Virieux, D., David, G., and Caillol,

S. (2016). Aromatic dialdehyde precursors from lignin

derivativesfor the synthesis of formaldehyde-free dan

high char yield phenolic resins. Eur. Polym., J. 77, pp.

65-74.

Gumbira-Sa’id, E., Syamsu K., Mardliyanti E., Heryandie

A., Evalia N.A., Rahayu D.L., Puspitarini, A.A.A.R.,

Ahyarudin, A., and Hadiwijoyo, A. (2009).

Agroindustri danbisnisgambir Indonesia. Bogor: IPB

Press, pp. 63-104.

Hiller, K., and Melzig, M.F. (2007).Die

großeEnzyklopaedie der Arzneipflanzen und Drogen.

Heidelberg: Elsevier Spektrum Verlag, 443 pp.

JIS. (2003).Japanese Industrial Standard A5908-2003:

Particleboards. Japan: Japanese Standards Association,

pp. 1-25.

Junaidi, Kasim, A., and Budiman, D. (2015).

Pengaruhjenisserattandankosongsawit (TKS)

hasildefiberasisecaramekanisdankadarperekatgambirte

rhadapkualitaspapankomposit. In: Seminar

NasionalRekayasaTeknologiIndustridanInformasi ke-

10. Yogyakarta: Sekolah Tinggi TeknologiNasional,

pp. 889-895.

Kasim, A., Yumarni, and Fuadi, A. (2007).

Pengaruhsuhudan lama

pengempaanpadapembuatanpapanpartikeldaribatangke

lapasawit (Elaeisguineensis Jacq.)

denganperekatgambir (UncariagambirRoxb.)

terhadapsifatpapanpartikel. Journal Tropical Wood

Science and Technology, 5(1), pp. 17-21 (2007).

Maloney, T.M. (1993). Modern particleboard dan dry-

process fiberboard manufacturing. San Francisco:

Miller Freeman, 681 pp.

Ministry of Agriculture of Indonesia. (2013). Tree Corp

Estate of Indonesia 2012-2014: Spices and Beverage

Crops. Jakarta: Ministry of Agriculture of Indonesia,

pp. 59-77.

Pizzi, A. (1994). Advance wood adhesives technology. New

York: Marcel Dekker Inc. 289 pp.

Pizzi, A. (2008). Tannins: Major sources, properties, and

applications. In: M.N., Belgacem, and A, Gandini. ed.,

Monomers, polymers and composites from renewable

resources. Amsterdam: Elsevier, pp. 180-194.

Rahmawati, N., Bakhtiar A., and Putra, D.P. (2011).

Optimasimetodaisolasikatekindarigambiruntuksediaan

farmasidansenyawa marker.

JurnalSainsdanTeknologiFarmasi, 16(2), pp. 171-179.

Sabarni.2015. Teknik pembuatangambir

(UncariagambirRoxb) secaratradisional. Elkawnie:

Journal of Islamic Science and Technology, 1(1), pp.

105-112.

SNI.(2006).StandarNasional Indonesia 03-2105-2006:

Papanpartikel. Jakarta: BadanStandardisasiNasional,

pp.1-22.

Widyorini, W., Yudha, A.P., and Prayitno, T.A. (2011).

Some of properties of binderless particleboard

manufactured from bamboo. World Research Journal,

2(2), pp. 89-93.

The Effect of Gambir Adhesive Level and Hot Press Temperature on Physical and Mechanical Properties of Bamboo Particleboard

367