Effect of Variation HCl Concentration on Natural Zeolite

Dealumination to The Content of Liquid Smoke Compounds by

Hydrodeoxygenation Process

Saharman Gea

1*

, Andriayani

1

, Agus Haryono

3

, Abdul Malik

1

, Reka Mustika Sari

1

, Junifa Layla

Sihombing

1,2

, Ahmad Nasir Pulungan

1,2

, Rachmad Fauzi

1

and Boy Attaurrazaq

1

1

Department of Chemistry, Universitas Sumatera Utara, Jl. Bioteknologi No. 1, Medan, Indonesia

2

Department of Chemistry, Universitas Negeri Medan, Jl. Willem Iskandar Psr. V Medan, Indonesia

3

Research Centre for Chemistry, Indonesian Institute of Sciences, Banten, Indonesia

{junifalaylasihombing, nasirpl}@unimed.ac.id, {rachmadfauzi8888, boyattaurrazaq37}@gmail.com

Keywords: Dealumination, Hydrodeoxygenation Process, Liquid Smoke, Sarulla Natural Zeolite.

Abstract: Recently, for its direct use as a renewable energy resource of pyrolysis biomass, liquid smoke has received

increased attention. Unfornatunately, the composition of liquid smoke is very complex that cause to obvious

changes in chemical properties of the liquid smoke. Therefore, the hydrodeoxygenation method required to

handle this issue. The Objective of this research was the hydrodeoxygenation of liquid smoke to remove

oxygenated compounds with decreased concentration of ketones and increased phenol concentration using

sarulla natural zeolite dialuminated with 3M, 5M and 7M HCl concentrations at 90°C in the H

2

atmosphere.

Characterization of hydrodeoxygenation product was analyzed content by gas chromatography-mass

spectrometry (GC-MS). The results showed a decrease in phenol content and a rise in carbonyl at 7 M HCl

dealumination while 5 M HCl dealumination increased phenol content and reduced carbonyl compounds.

Treatment with concentration of 5 M HCl results in a better content of liquid smoke.

1 INTRODUCTION

Liquid smoke, a by-product of the charcoal industry,

is high economic in aspects of its discharge into the

atmosphere. Liquid smoke is derived from dew

condensation due to the decay of organic compounds

during pyrolysis. The quantity of liquid pyrolysis

smoke is 90.75% phenol compound, 3.71 %

carbonyl and 1.81% alcohol, an antimicrobial as a

meat preservative (Hadanu & Apituley, 2016).

Liquid smoke produced from pyrolysis has a

higher water and oxygen content and a lower heating

value than fossil fuels, which can be achieved by

upgrading, i.e. hydrodeoxygenation (HDO)

(Bulushev & Ross, 2011). HDO method can reduce

the water and oxygen content and increase the

heating value of biomass (S. P. Zhang et al., 2003).

A catalyst is necessary in the HDO process to

reduce the oxygenate compound content in liquid

smoke. Several studies have used catalysts Pd/C,

Ru/C and Pt/C (300°C, 3 MPa H

2

, 60 minutes) (Oh

et al., 2016) stored (23°C, 20% RH) for 12 weeks)

almost no change in color and physicochemical

properties. The water content changed from 1.3% to

3.4% is still in the dry category (<6%), the acidity

was reduced from 70.2 to 71 mg-KOH/g and HHV

from 762 Da to 867 Da. Likewise for bio oil after

HDO with Pt/Al

2

O

3

, Ni/HY, Pd/C catalyst (260°C,

70 Bar, 2 hours), after 140 hours there was no

change in content except 0.8% to 2.9% aldehyde and

30% phenol to 27% (Alvarez-Galvan et al., 2019;

Liu et al., 2019; Mortensen et al., 2011).

In the other hand, with high temperatures (above

300°C) and high H

2

pressure (2-10 MPa), the

catalyst often becomes inactive due mainly to coke

and water-induced structural changes (Mortensen et

al., 2011). In terms of costs as well as unnecessary

protection. Lercher and Jones show that

cyclohexane-forming phenol hydrodeoxygenation

can be performed at relatively low temperatures

using bi-functional metallic acid catalysts (Mäki-

Arvela & Murzin, 2017; Mo et al., 2018). Therefore

research has carried out the HDO process with

ethanol solvents which act as hydrogen donors and

Gea, S., Andriayani, ., Haryono, A., Malik, A., Mustika Sari, R., Layla Sihombing, J., Nasir Pulungan, A., Fauzi, R. and Attaurrazaq, B.

Effect of Variation HCl Concentration on Natural Zeolite Dealumination to the Content of Liquid Smoke Compounds by Hydrodeoxygenation Process.

DOI: 10.5220/0010152300002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 287-291

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

287

the catalyst used was natural zeolite. This study was

to determine the composition of compounds from

liquid smoke using natural zeolite as a catalyst

without the addition of metals.

2 RESEARCH METHODS

2.1 Materials

In this research using commercial liquid smoke,

natural zeolite purchased at bratachem. Ethanol

(p.a), hydrogen gas and nitrogen gas.

2.2 Activation Natural Zeolite

Zeolite was sieved with the size in 100 mesh and

then washed with distilled water for 24 hours then

filtered and dried at 110°C. The zeolite activation

was carried out by varying the HCl concentrations of

3M, 5M and 7M for 60 minutes at 90°C. After that,

filtered and washed to neutral pH and then dried.

Activated zeolite was calcined at 500°C for 1 hour

while running nitrogen gas 10 mL/min (Sihombing

et al., 2018).

2.3 Pretreatment of Liquid Smoke

Conventional liquid smoke was distilled to separate

water content. Distillation was carried out at 90°C.

After the liquid smoke was water-free, it was

prepared to be used for the cycle of

hydrodeoxygenation.

2.4 Hydrodeoxygenation of Liquid

Smoke

The hydrodeoxygenation process was carried out by

adding natural zeolite to liquid smoke at a ratio of

1% (w / w), then 96% ethanol was added, and

refluxed at 90°C while flowing 10 mL/min hydrogen

gas for 5 hours. After that, GC-MS measured the

components of the compounds.

3 RESULTS AND DISCUSSION

3.1 Identification of Components of

Liquid Smoke Compounds

GC-MS characterization was carried out to

determine the content of compounds in bio-oil. In

accordance with the main purpose of the research

was to vary the catalyst with different concentrations

can affect component compounds in liquid smoke,

i.e increase the content of phenols and reduce the

content of oxygenate compounds. GC-MS results

can be seen in Fig. 1-3.

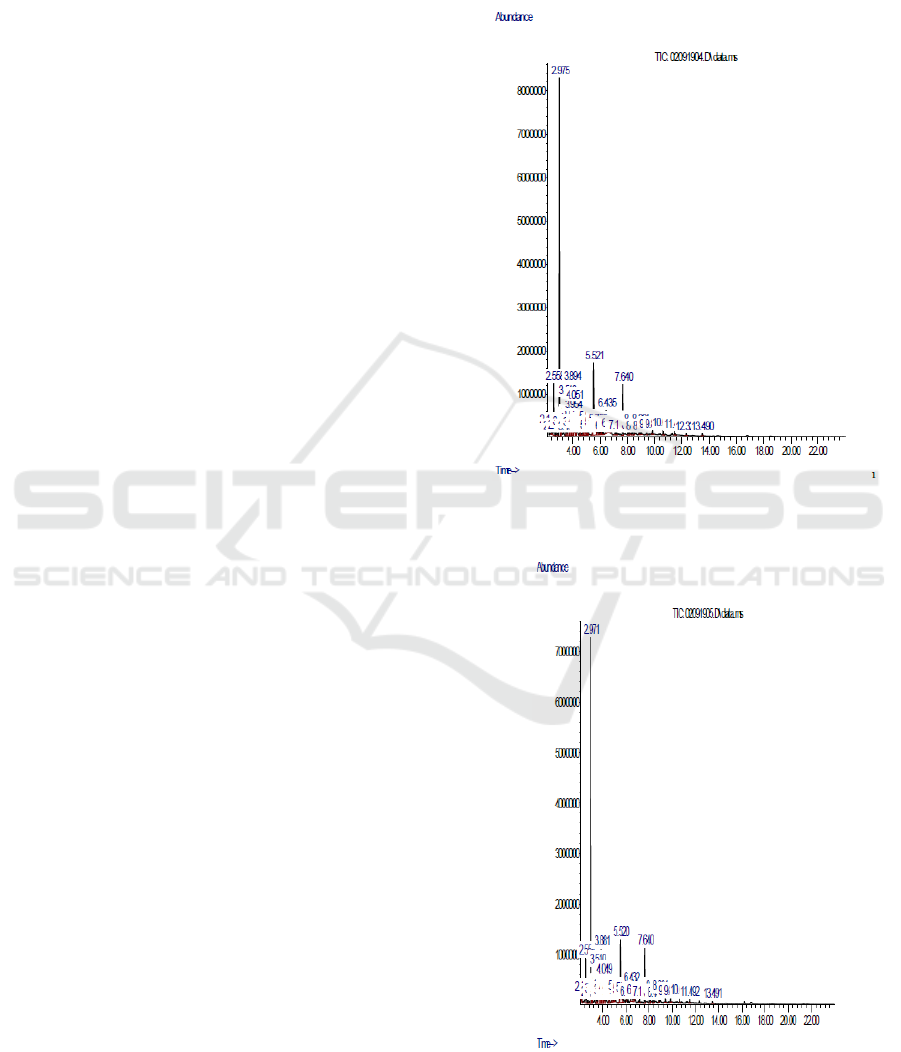

Figure 1: GC-MS chromatogram analysis of liquid smoke

in 3M HCl Zeolite.

Figure 2: GC-MS chromatogram analysis of liquid smoke

in 5M HCl Zeolite.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

288

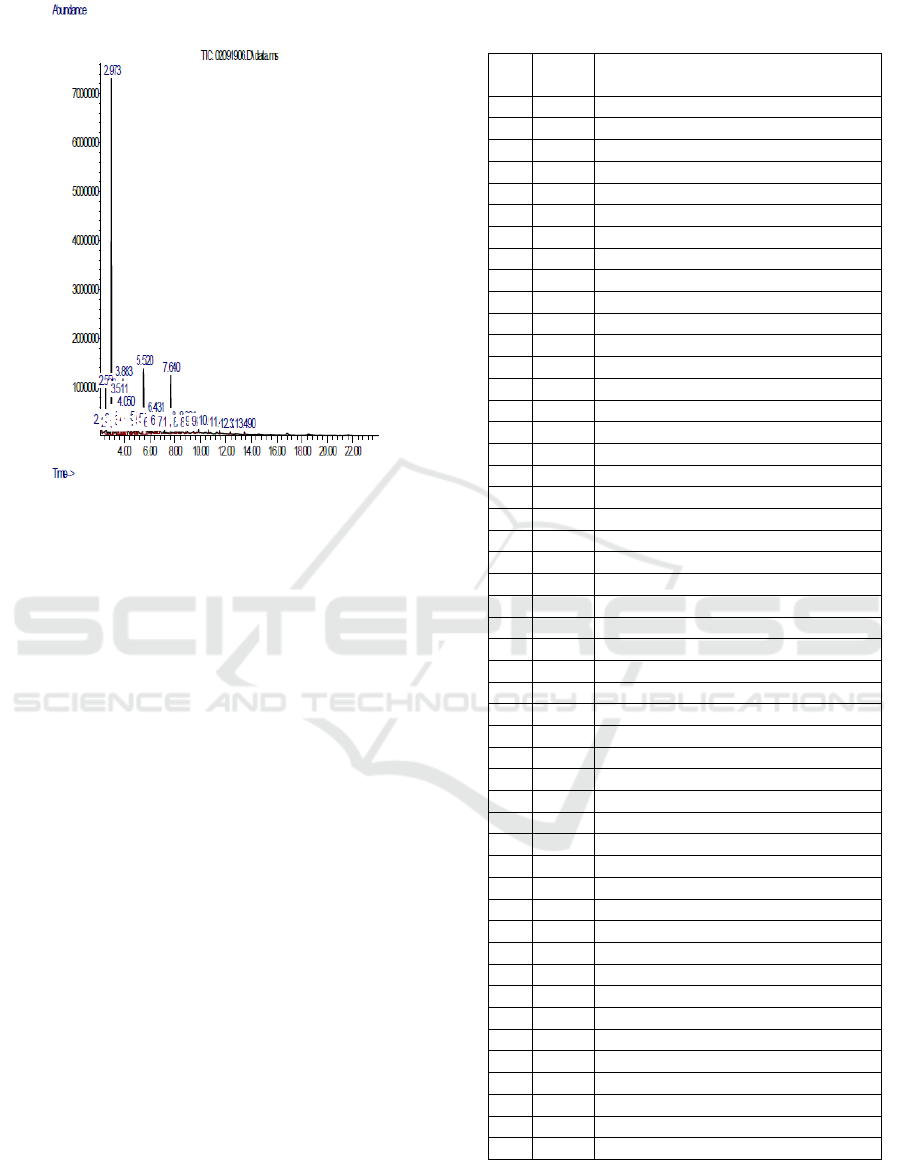

Figure 3: GC-MS chromatogram analysis of liquid smoke

in 7M HCl Zeolite.

There was more than 30 types of compound

components in liquid smoke which are shown in the

Table 1-3.

Table 1: Characterization GC-MS of liquid smoke in 3M

HCl Zeolite.

No

%

Area

Compounds

1 0.28 1,2-Ethanediol

2 0.17 Furan,tetrah

y

dro-2-meth

y

l

3 5.50 Furanone,dihydro

4 0.53 Furanone,5-methyl

5 35.71 Phenol

6 0.81 Phen

y

l alcohol

70.29 2-

p

i

p

eridinone

8 3.28 1,2-c

y

clo

p

entanedion

9 2.23 Pentanoic aci

d

10 1.97 Ethyl,4-hydroxybutanoate

11 0.63 Pentanoic acid,4-oxo,eth

y

l este

r

12 6.05 2-furanmethanol,tetrah

y

dro

13 2.74 Phenol,4-meth

y

l

14 2.64 Tetrahydrofurfurylaceate

15 0.85 Phenol,2-methoxy

16 0.39 3,hydroxy-2-methyl

17 079 2-c

y

clo

p

enten-1-one-3-eth

y

l

18 0.44 3-meth

y

lmor

p

holine

19 0.62 Dih

y

dro-citronella

20 1.13 2-furanone,5-methyl

21 0.38 Methyl este

r

22 1.08 2,2-dimeth

y

,1-one-2-silac

y

clo

23 0.45 Eth

y

l,5-oxohexanone

24 0.71 5-eth

y

ldeh

y

dro

25 13.66 1,2-

b

enzenediol

26 1.46 Cyclopropanecarboxamide

27 0.36 Phenol-d6

28 0.27 Tertrameth

y

l

g

uani

d

29 0.45 2-meth

y

l-3-isothiazolone

30 0.28 2-

p

enten,3-eth

y

l-2-meth

y

l

31 0.32 Phenol,3,4-dimethoxy

32 2.13 3-methyl-1-hexene

33 0.24 3-isobuth

y

ldih

y

dro

py

razin

34 0.67 7,7-dimeth

y

lbic

y

clo

35 0.39 2-n-

p

ro

py

lthiac

y

clohexane

36 0.42 Cyclohexane,ethyl

37 3.95 Phenol,2,6-dimethoxy

38 0.48 1-methoxy-2,6,6-trymethyl

39 0.32 3-

b

uten-2-ol,2-meth

y

l

40 1.00 Benzaldehide,3-h

y

drox

y

41 0.26 Phos

p

honic aci

d

42 0.73 Benzoic acid,4-hydroxy

43 0.42 Methylparaben

44 0.51 Ethanone

45 0.47 7,8-dimeth

y

lbenzoc

y

cloocetene

46 0.57 2,4-dih

y

drox

y

,3-methox

y

47 0.39 Benzaldehyde,4-hydroxy

48 0.24 Ethanone

49 0.24 Aspidinol

Effect of Variation HCl Concentration on Natural Zeolite Dealumination to the Content of Liquid Smoke Compounds by

Hydrodeoxygenation Process

289

Table 2: Characterization GC-MS of liquid smoke in 5M

HCl Zeolite.

No

%

Area

Compunds

1 0.27 Pro

p

anoic aci

d

2 0.63 2-

b

utanone

3 5.37 Furanone-dihydro

4 0.52 Furanone,5-methyl

5 40.02 Phenol

6 0.80 Furanone,3-meth

y

l

7 0.35 2-

p

i

p

eridinone

8 3.45 1,2-c

y

clo

p

entenedione

9 2.26 Pentanoic acid,4-oxo

10 2.08 Ethyl,4-hydroxybutanoate

11 0.55 Pentanoic acid,4-oxo eth

y

l este

r

12 6.09 2-furanmethanol,tetrah

y

dro

13 2.92 Phenol,4-meth

y

l

14 2.31 2-furanmethanol,tetrahidro-acet

15 0.93 Phenol,2-methoxy

16 0.31 3-hydroxy,2=methyl

17 076 2-c

y

clo

p

entene,1-one-3-eth

y

l

18 0.51 2-

p

ro

p

en

y

l,2-eth

y

lbutanone

19 0.83 2-furanone-5-meth

y

l

20 0.50 Ethane,1,1-diethoxy

21 0.69 2,2-dimethyl-1-oxa

22 0.52 2-furanone,dih

y

dro-5-

p

ent

y

l

23 12.87 1,2-

b

enzenediol

24 1.12 2-

p

ro

p

anoic acid,2-meth

y

l-eth

y

l

25 0.13 3-cis-methoxy-5-cus-methyl

26 2.23 Butanoid acid,butyl este

r

27 0.67 2,3-dihydroxy-acetophenone

28 0.39 C

y

clohexane eth

y

l

29 4.64 Phenol,2,6-dimethox

y

30 0.54 2,6-dimeth

y

l-4-oxa

31 0.23 1-hydroxy,2-

p

entanone

32 1.02 Benzaldehide,3-hydroxy

33 0.25 C

y

clo

p

entaneacetic aci

d

34 0.76 Benzoic acid,4-h

y

drox

y

35 0.51 Ethanone

36 0.62 2,3,5-trimethoxytoluene

37 0.48 Ethanone

38 0.44 Benzaldehide,4-hydroxy

39 0.42 As

p

inidiol

Table 3: Characterization GC-MS of liquid smoke in 7M

HCl Zeolite.

No

%

Area

Compounds

10.28 Pro

p

anoic aci

d

20.47 2-et

y

hlbutanal

3 5.31 2-furanone,dihydro

4 0.56 Furanone,5-methyl

5 36.57 Phenol

6 0.83 Phenol

70.39 2-

p

i

p

eridinone

8 3.38 1,2-c

y

clo

p

entanedione

9 2.29 Pentanoic aci

d

10 1.96 Ethyl,4-hydroxybutanoate

11 0.52 Pentanoic acid,4-oxo,eth

y

l

12 5.98 Tetrah

y

drofurfurilalkohol

13 2.66 Phenol,4-meth

y

l

14 2.14 2-furanmethanol

15 0.94 Phenol,2-methoxy

16 0.41 Maltol

17 0.85 2-c

y

clo

p

enten,1-one

18 0.75 4-acet

y

lbutric aci

d

19 1.11 Furanone,5-meth

y

l

20 0.65 Methylester of,4,4-dimethox

y

21 0.99 Methyl-2,3,4-triomethyl

22 0.73 Gamma,hexalactone

23 13.15 1,2-

b

enzenediol

24 1.40 2-

p

ro

p

anoic aci

d

25 0.52 N-methylthiazolone

26 0.39 Methyltriacelatone

27 2.22 Butanoic aci

d

28 0.65 1,4-

b

enzenediol

29 1.25 7,7-dimeth

y

lbic

y

clo

30 0.48 3,6-dih

y

dro-6,6-dimeth

y

l

31 4.55 Phenol,2,6-dimethoxy

32 0.51 Naphtalenone,octahydro

33 0.20 1-h

y

drox

y

-2-

p

entanone

34 0.94 Vanilin

35 0.28 C

y

clo

p

entaneacetic aci

d

36 0.75 Benzoic acid,4-hydroxy

37 0.40 Methylparaben

38 0.41 Ethanone

39 0.54 2,3,5-trimethox

y

toulene

40 0.51 Benzamide,dieth

y

l,4-h

y

drox

y

41 0.45 Benzaldeh

y

de,4-h

y

drox

y

42 0.28 Ethanone

43 0.34 Ethylisovanillymandelate

The high peak indicates a compound most

contained in bio-oil, namely phenol compounds in

the form of syringol and guaiacol. It can be seen

from the three tables above that phenol compounds

and oxygenate compounds are the main components

of bio-oil. Relative to other products, the syringol

compound has the highest and most important

appearance for all bio-oils. There is also a significant

percentage of guaiacol after syringol relative to other

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

290

compounds. Both of these compounds originate

from lignin cracking, while furan, acetate, and

aromatic compounds are derived from degradation

of cellulose and hemicellulose (C. Zhang et al.,

2016).

It appears that phenol compounds, both syringol

and guaiacol, have increased concentrations in this

case characterized by the percentage of the area on

the GC-MS chromatogram. It can be concluded that

the HDO reaction in bio-oil takes place which is

characterized by a decrease in the concentration of

oxygenate compounds such as ketones and an

increase in alcohol concentration in this case

represented by phenols.

But there was a decline in phenol levels at 7 M

zeolite concentration. The possibility of zeolite with

a concentration of 7M has not been able to be a good

catalyst in the HDO process.

4 CONCLUSIONS

Generally, the results showed a decrease in phenol

content and a rise in carbonyl at 7 M HCl

dealumination while 5 M HCl dealumination

increased phenol content and reduced carbonyl

compounds. Treatment with concentration of 5 M

HCl results in a better content of liquid smoke.

ACKNOWLEDGEMENTS

The authors would like to thanks to Universitas

Sumatera utara by TALENTA 2019 scheme.

REFERENCES

Alvarez-Galvan, M. C., Campos-Martin, J. M., & Fierro,

J. L. G. (2019). Transition metal phosphides for the

catalytic hydrodeoxygenation of waste oils into green

diesel. In Catalysts.

https://doi.org/10.3390/catal9030293

Bulushev, D. A., & Ross, J. R. H. (2011). Catalysis for

conversion of biomass to fuels via pyrolysis and

gasification: A review. Catalysis Today.

https://doi.org/10.1016/j.cattod.2011.02.005

Hadanu, R., & Apituley, D. A. N. (2016). Volatile

Compounds Detected in Coconut Shell Liquid Smoke

through Pyrolysis at a Fractioning Temperature of

350-420 C. Makara Journal of Science.

https://doi.org/10.7454/mss.v20i3.6239

Liu, M., Yi, Y., Wang, L., Guo, H., & Bogaerts, A.

(2019). Hydrogenation of carbon dioxide to value-

added chemicals by heterogeneous catalysis and

plasma catalysis. Catalysts.

https://doi.org/10.3390/catal9030275

Mäki-Arvela, P., & Murzin, D. Y. (2017).

Hydrodeoxygenation of lignin-derived phenols: From

fundamental studies towards industrial applications. In

Catalysts. https://doi.org/10.3390/catal7090265

Mo, L., Yu, W., Cai, H., Lou, H., & Zheng, X. (2018).

Hydrodeoxygenation of bio-derived phenol to

cyclohexane fuel catalyzed by bifunctional

mesoporous organic-inorganic hybrids. Frontiers in

Chemistry. https://doi.org/10.3389/fchem.2018.00216

Mortensen, P. M., Grunwaldt, J. D., Jensen, P. A.,

Knudsen, K. G., & Jensen, A. D. (2011). A review of

catalytic upgrading of bio-oil to engine fuels. In

Applied Catalysis A: General.

https://doi.org/10.1016/j.apcata.2011.08.046

Sihombing, J. L., Gea, S., Pulungan, A. N., Agusnar, H.,

Wirjosentono, B., & Hutapea, Y. A. (2018). The

characterization of Sarulla natural zeolite crystal and

its morphological structure. AIP Conference

Proceedings.

Zhang, C., Qi, J., Xing, J., Tang, S. F., Song, L., Sun, Y.,

Zhang, C., Xin, H., & Li, X. (2016). An investigation

on the aqueous-phase hydrodeoxygenation of various

methoxy-substituted lignin monomers on Pd/C and

HZSM-5 catalysts. RSC Advances.

https://doi.org/10.1039/c6ra22492j

Zhang, S. P., Yan, Y. J., Ren, Z., & Li, T. (2003). Study of

hydrodeoxygenation of bio-oil from the fast pyrolysis

of biomass. Energy Sources.

https://doi.org/10.1080/00908310303427

Effect of Variation HCl Concentration on Natural Zeolite Dealumination to the Content of Liquid Smoke Compounds by

Hydrodeoxygenation Process

291