Morphological and Mechanical Properties of Old Newspaper Deinked

with Cellulase and Laccase Combination

Noni Oktari

1

, Saharman Gea

2*

, Andriayani

2

, Sri Rahayu

1

, Reka Mustika Sari

1

and Khatarina

Meldawati Pasaribu

1

1

Postgraduate Chemistry Study Programme, Universitas Sumatera Utara, Jl. Bioteknologi No. 1, Medan, Indonesia

2

Department of Chemistry, Universitas Sumatera Utara, Jl. Bioteknologi No. 1, Medan, Indonesia

Keywords: Cellulase, Deinking, Laccase, Old Newspaper.

Abstract: The utilization of enzyme in deinking process of recycle paper is still in development phase since it was

known that conventional deinking use large amount of chemicals such as sodium hydroxide, sodium

silicate, and hydrogen peroxide which are environmentally damaging. In the present study, cellulase

combined with laccase was used for deinking process of old newspaper pulp. The first step was repulping

the old newspaper, and then the pulp slurry at 10% consistensy was treated with cellulase and laccase with

different concentration from 0-2%. After washing process, the pulp was reforming in to the handsheet. The

tensile strength of the handsheet was tested and the morphological changes was analyzed using scanning

electron microscopy (SEM). The result showed that handsheet treated with 1% cellulase and 1% laccase had

the highest tensile strength (2.1 MPa) with 1493 MPa Young’s modulus. From the images of SEM, showed

that fiber surface pulp turned rough and microfibril also appeared on the fiber surface after enzymatic

treatment with cellulase and laccase, which indicated delignification process and facilitated the release of

ink particle entrapped.

1 INTRODUCTION

Paper is one of important materials which is

inseparable from human life and used for various

purposes in life. Based on survey conducted at 2014,

the global production of paper was 407 million

metric tons (Pandharipande & Ingle, 2018). The

demand of paper is continuously increase year by

year. This causes high demand of green plant as a

basic raw material for paper production. Recycling

of waste paper is an alternative process to preserve

the green plant. Old newspaper is one of waste paper

that has a potential amount especially in urban area

in Indonesia, because it was produced and consumed

every day (Saputra & Sagala, 2017).

Recycling of waste paper requires the removal of

ink from the paper by a process called deinking (A.

Singh et al., 2012). Deinking process involves ink

particle dislodgement from the fiber surface and the

separation of dispersed ink from fiber suspensions

(Muryeti et al., 2015). During chemical deinking or

also called conventional deinking, large quantities of

chemicals such as sodium hydroxide, sodium silicate

and hydrogen peroxide were used, which are not

environmentally friendly (Bajpai, 2014; K. C. Lee et

al., 2016; Liu et al., 2017). On the other hand,

enzyme mediated technologies are getting vast

popularity due to their potential to replace the use of

chemicals and also limit the wastage of water, save

energy and result helps to improve the product

quality (G. Singh & Arya, 2019).

Many researchers have reported the studies on

deinking process using various enzymes. As

compared to the conventional deinking, pulp treated

with enzymes reduce the load on waste water

treatment system due to reduced use of chemicals.

Enzymatic deinking has high efficiency and low

environmental impact. Moreover, enzymatically

deinked pulp also displays improved drainage, lower

residual ink, higher brighness and superior physical

properties (Saxena & Chauhan, 2016). Cellulase-free

xylanase preparation of Aspergillus niger DX-23

could cause efficient deinking of old newspaper pulp

and considerably reduce the use of chemicals (Desai

& Iyer, 2016). The use of cellulases and

hemicellulases mixtures has been described to be

able to deink high quality waste paper (C. K. Lee et

Oktari, N., Gea, S., Andriayani, ., Rahayu, S., Mustika Sari, R. and Meldawati Pasaribu, K.

Morphological and Mechanical Properties of Old Newspaper Deinked with Cellulase and Laccase Combination.

DOI: 10.5220/0010152100002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 273-278

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

273

al., 2013). Treatment with laccase indicates several

characterictic and prominent changes including

degradation of the guaiacyl group and a high degree

of deformation of methyl group in lignin (Shankar et

al., 2018). Combining hemicellulase with laccase

mediator system on old newsprint deinking process

shows that surface coverage lignin of pulp is lower

than the control (Xu et al., 2011). Laccase is capable

to deink old newspaper where the mechanical pulp

contains a huge of lignin (Saxena & Chauhan,

2016). Waste paper pulp was deinked effectively

using laccase and xylanase without mediator

supplementation for laccase activity. It was the first

report on deinking of old newspaper pulp using a

bacterial laccase without the need of mediator,

resulting the process cost effective (Virk et al.,

2013).

This study was carried out to deink old

newspaper pulp using combination between

cellulase and laccase without any mediator.

Conventional deinking method was also done as the

comparison. The morphological and physical

properties of enzymatically and conventionally

deinked pulp were investigated.

2 MATERIALS AND METHODS

2.1 Materials

Cellulase from Aspergillus sp. (Carezyme 1000 L)

with an activity of 1000 S-CEVU/g and laccase from

Aspergillus sp. (Novozym 51003) with an activity

1000 LAMU/g were purchased from Sigma Aldrich.

All the reagents used are analytical grade chemical.

The old newspaper used was collected from the

same publisher by a local supplier.

2.2 Methods

This study consists of 3 main stages, which are

repulping, deinking and reforming process.

2.2.1 Old Newspaper Pulp Preparation

The old newspapers were manually cut into length

size 2-3 cm

2

and then soaked overnight in distilled

water at room temperature. After that, the soaked

newspapers were washed and then disintegrated

using a mechanical stirrer until pulp slurry obtained.

The pulp slurry then squeezed to remove absorbed

water and after that oven dried at 50ºC. The dried

pulp was used for further experiments.

2.2.2 Chemical Deinking

The amount of 15 g dried old newspaper pulp was

soaked in 150 mL distilled water for 30 minutes to

obtain pulp with 10% (w/v) consistency. After that,

pulp was added with 2% NaOH, 2% Na

2

SiO

3

and

2% H

2

O

2

. The treatment was carried out at 70ºC for

2 h. The treated pulp was then washed with distilled

water until the pH to be neutral.

2.2.3 Enzymatic Deinking

The amount of 15 g dried old newspaper pulp was

soaked in 150 mL phosphate buffer (pH 7.5) for 30

minutes to obtain pulp with 10% (w/v) consistency.

Cellulase was added to the pulp and incubated at

40ºC for 30 minutes in inkubator shaker with 150

rpm. After 30 minutes reaction, laccase was added

and allowed to react for 30 minutes at 30ºC with 150

rpm in inkubator shaker. The enzymes were

inactivated by placing the pulp in a boiling water

bath for 15 minutes. The treated pulp was then

washed with distilled water until the pH to be

neutral. Cellulase and laccase enzymes used with 5

different variations of concentration (0%; 0.5%; 1%;

1.5% and 2% of dry weight old newspaper pulp).

2.2.4 Handsheet Formation

The treated pulp (chemically and enzimatically

treated) were suspended in distilled water in an

erlenmeyer flask, mixed and filtered using buchner

funnel under suction using whatman filter paper.

Pulp was recovered using 200 mesh wire and

pressed between two plates using napkin to remove

extra water and then oven dried at 50ºC.

2.2.5 Handsheet Characterization

The handsheets obtained were analyzed for

morphological properties using scanning electron

microscopy (SEM) (ZEISS) at an accelerating

voltage EHT of 20.00 kV, probe = 101 Pa and signal

A = SE1.

Mechanical properties was carried out using a

tensile test tool GOTECH AL-7000M under ambient

temperature and humidity (25ºC, 65 RH) with a

tensile speed 5 mm/min and 1 kN load.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

274

3 RESULTS AND DISCUSSIONS

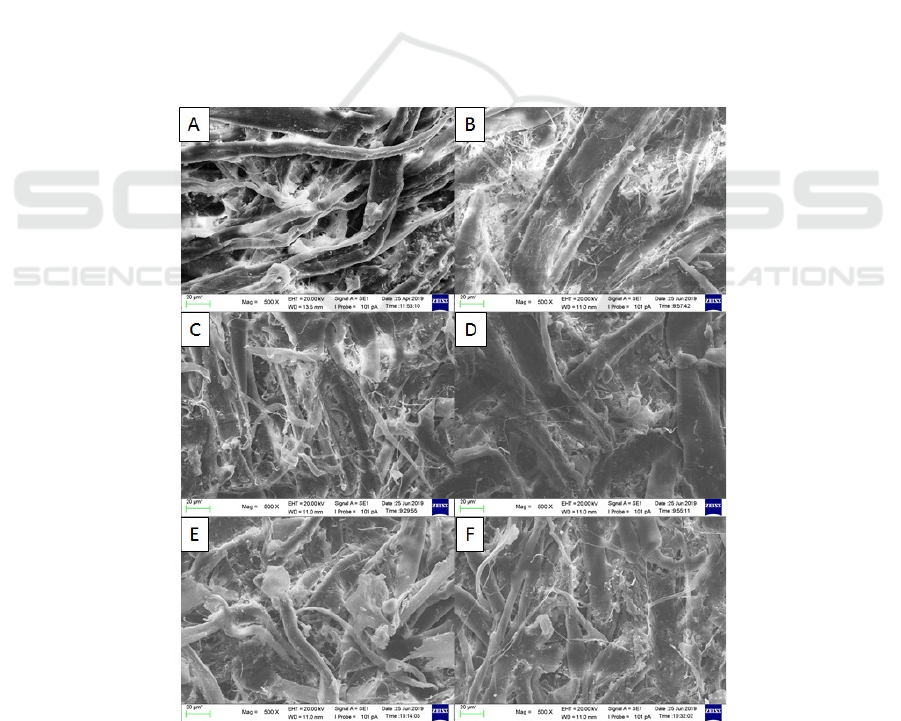

3.1 Scanning Electron Microscopy

Analysis

The analysis on newspaper pulp using SEM was

carried out to analyze the surface morphology of

untreated, enzimatically and chemically treated

newspaper pulp.

Surface morphology of handsheet on 500x

magnification can be seen in Figure 1, it shows that

the fiber surface was significantly changed after

enzymatic deinking process.

The smooth fiber surface was observed on

untreated newspaper pulp (A). On contrary, fiber

surface on enzymatically treated pulp was turned to

be rough. As can be observed, more fibrillation was

appeared on fiber surface, which indicating

delignification process was occured (Xu et al.,

2011). This fiber surface change which facilitated

the release of high amount of lignin molecules and

the ink particles entrapped (Kumar et al., 2019).

Moreover, the change of the fiber surface had a

significant role increasing the strength of the

recycled pulp. Deinking process using cellulase

resulted two types of changes in pulp surface, it was

modification on internal structure and surface

roughening (Efrati et al., 2013). Laccase treatment

alone did not generated in rupturing of the fibers and

deform the structure of the cellulose fibers (Shankar

et al., 2018).

Fiber surface of chemically deinked pulp

(conventional deinking) can be seen in Figure 2, it

shows rupturing after the deinking process. The

rupturing increase with increasing the concentration

of the chemicals, which indicated that high

concentration on chemical deinking deforms the

structural integrity of the cellulose fibers (Shankar et

al., 2018). On the other hand, combine enzimatically

deiked pulp did not show any rupturing. It is clearly

observed that the detachment of the ink particles

from the surface of the fibers was more prominent in

case of pulp treated with cellulase and laccase

combination as compared to conventional deinking.

Figure 1: Scanning Electron Micrographs of A) Untreated newspaper pulp B) Laccase 2% C) Cellulase 0.5%; laccase 1.5%

D) Cellulase 1%; laccase 1% E) Cellulase 1.5%; laccase 0.5% and F) Cellulase 2%.

Morphological and Mechanical Properties of Old Newspaper Deinked with Cellulase and Laccase Combination

275

Figure 2: Scanning Electron Micrographs of A) Chemically deinked pulp and B) Combined cellulase and laccase deinked

pulp.

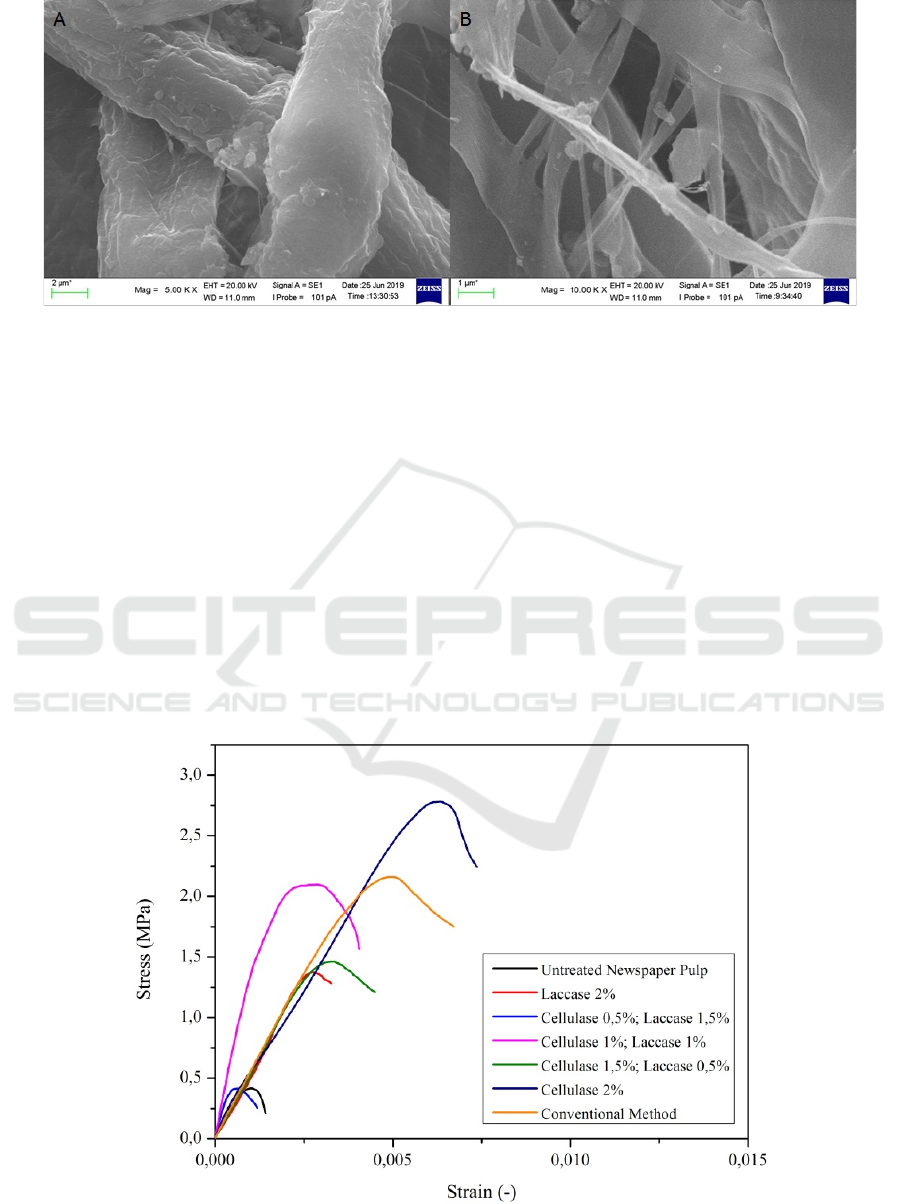

3.2 Mechanical Properties Analysis

In this study, the mechanical properties of recycled

paper was analyzed. The specimen was cut into 80 x

25 mm

2

and then test with tensile test tensometer.

Stress (MPa) vs strain change curve can be seen in

Figure 3.

Tensile strength (MPa), elongation at break (%)

and Young’s modulus (MPa) of untreated and reated

newspaper pulp are shown in Table 1. As can be

seen, tensile strength increased significantly for

enzymatic treated pulp. Tensile strength for

untreated pulp was 0.42 MPa with Young’s modulus

714 MPa, whereas the highest tensile strength was

2.78 MPa with Young’s modulus 743 MPa which

obtained in 2% cellulase treated. Young’s modulus

is the ratio between stress and strain.

Pulp given an enzymatic treatment with 1%

cellulase and 1% laccase combination had the

highest Young’a modulus, it was 1493 MPa with 2.1

MPa tensile strength value. This indicated that there

was a synergestic deinking effect between cellulase

and laccase.

While compare with conventional deinking,

enzymatic deinking had a better tensile strength with

a significant difference. This results are in

accordance with the use of chemical that caused

damage during the deinking process which can also

observed from the morphology of pulp fibers.

Conventional

deinking method even decreases the

Figure 3: Stress-strain curve of untreated and treated handsheets of newspaper pulp.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

276

Table 1: The Mechanical properties of untreated and treated newspaper pulp.

No Treatment

Tensile

Strength

(MPa)

Elongation at

Break (%)

Young’s

Modulus

(MPa)

1 Untreated News

p

a

p

er Pul

p

0.42 0.1 714

2 Laccase 2% 1.38 0.3 572

3 Cellulase 0.5%; Laccase 1.5% 0.41 0.07 1041

4 Cellulase 1%; Laccase 1% 2.1 0.3 1493

5 Cellulase 1.5%; Laccase 0.5% 1.46 0.3 523

6 Cellulase 2% 2.78 0.6 743

7 Conventional Metho

d

13 0.4 459

Young’s modulus compared to untreated newspaper

pulp. This study also in accordance with Shankar et

al. (2018) who reported the increasing of chemical

concentration caused substantial decrease in tensile

strength. The use of large concentration of chemical

may have reduced the tensile strength owing to high

degree of depolymerization of cellulose content of

the fibers (Shankar et al., 2018).

4 CONCLUSIONS

Cellulase combining with laccase effectively

deinked old newspaper pulps without mediator

supplementation for laccase activity. Morphological

properties of enzymatic treated pulp show that the

detachment of the ink particles from the surface of

the fibers is more prominent in case of pulp treated

with cellulase and laccase combination as compared

to conventional deinking. Tensile test observed pulp

treated with cellulase 1% and laccase 1% has the

highest mechanical properties with 1493 MPa

Young’s modulus and 2.1 MPa tensile strength.

ACKNOWLEDGEMENTS

Author would like to express a gratitude to the head

of Material and Polymer Reseach Unit Postgraduate

and Basic Science Laboratory Universitas Sumatera

Utara for the research facility provided.

REFERENCES

Bajpai, P. (2014). Deinking with Enzymes. Recycling and

Deinking of Recovered Paper, 2006, 139–153.

https://doi.org/10.1016/b978-0-12-416998-2.00008-8

Desai, D. I., & Iyer, B. D. (2016). Biodeinking of old

newspaper pulp using a cellulase-free xylanase

preparation of Aspergillus niger DX-23. Biocatalysis

and Agricultural Biotechnology, 5, 78–85.

https://doi.org/10.1016/j.bcab.2015.11.001

Efrati, Z., Talaeipour, M., Khakifirouz, A., & Bazyar, B.

(2013). Impact of cellulose enzyme treatment on

strength, morphology and crystallinity of deinked

pulp. Cellulose Chemicstry and Technology, 47(7–8),

547–551.

Kumar, N. V., Rani, M. E., Centre, R., Nadu, T., & Nadu,

T. (2019). Microbial enzymes in paper and pulp

industries for bioleaching application. Research

Trends of Microbiology.

Lee, C. K., Ibrahim, D., & Che Omar, I. (2013).

Enzymatic deinking of various types of waste paper:

Efficiency and characteristics. Process Biochemistry,

48(2), 299–305.

https://doi.org/10.1016/j.procbio.2012.12.015

Lee, K. C., Tong, W. Y., Ibrahim, D., Arai, T., Murata, Y.,

Mori, Y., & Kosugi, A. (2016). Evaluation of

Enzymatic Deinking of Non-impact Ink Laser-Printed

Paper Using Crude Enzyme from Penicillium rolfsii

c3-2(1) IBRL. Applied Biochemistry and

Biotechnology, 181(1), 451–463.

https://doi.org/10.1007/s12010-016-2223-4

Liu, M., Yang, S., Long, L., Wu, S., & Ding, S. (2017).

The enzymatic deinking of waste papers by engineered

bifunctional chimeric neutral Lipase - Endoglucanase.

BioResources, 12(3), 6812–6831.

https://doi.org/10.15376/biores.12.3.6812-6831

Muryeti, Mulyani, E. B., & Sinurat, E. (2015). Adsorption

of Carbon Black Using Chitosan in the Deinking

Process. Procedia Chemistry, 17, 106–110.

https://doi.org/10.1016/j.proche.2015.12.117

Pandharipande, S., & Ingle, A. P. (2018). Novel Use of

Wheat Grass Extract in Enzymatic Deinking of Printed

Paper. 3549–3558.

https://doi.org/10.15680/IJIRSET.2018.0704048

Saputra, A. A., & Sagala, R. (2017). Limbah Koran

Sebagai Bahan Campuran. 16(1), 77–84.

Saxena, A., & Chauhan, P. S. (2016). Critical Reviews in

Biotechnology Role of various enzymes for deinking

paper : a review. 8551(July).

https://doi.org/10.1080/07388551.2016.1207594

Shankar, S., Shikha, Bhan, C., Chandra, R., & Tyagi, S.

(2018). Laccase based de-inking of mixed office waste

and evaluation of its impact on physico-optical

properties of recycled fiber. Environmental

Morphological and Mechanical Properties of Old Newspaper Deinked with Cellulase and Laccase Combination

277

Sustainability, 1(3), 233–244.

https://doi.org/10.1007/s42398-018-0021-3

Singh, A., Dutt, R., Kaur, A., & Mahajan, R. (2012). An

ecofriendly cost effective enzymatic methodology for

deinking of school waste paper. Bioresource

Technology, 120, 322–327.

https://doi.org/10.1016/j.biortech.2012.06.050

Singh, G., & Arya, S. K. (2019). Utility of laccase in pulp

and paper industry: A progressive step towards the

green technology. International Journal of Biological

Macromolecules, 134, 1070–1084.

https://doi.org/10.1016/j.ijbiomac.2019.05.168

Virk, A. P., Puri, M., Gupta, V., Capalash, N., & Sharma,

P. (2013). Combined Enzymatic and Physical

Deinking Methodology for Efficient Eco-Friendly

Recycling of Old Newsprint. PLoS ONE, 8(8).

https://doi.org/10.1371/journal.pone.0072346

Xu, Q. H., Wang, Y. P., Qin, M. H., Fu, Y. J., Li, Z. Q.,

Zhang, F. S., & Li, J. H. (2011). Fiber surface

characterization of old newsprint pulp deinked by

combining hemicellulase with laccase-mediator

system. Bioresource Technology, 102(11), 6536–6540.

https://doi.org/10.1016/j.biortech.2011.03.051

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

278