Thermal and Mechanical Properties Analysis of Old Newspaper

Deinked using Ultrasound under Alkaline Conditions

Sri Rahayu, Saharman Gea and Andriayani

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Old News Paper, Deinking, Ultrasound, Alkaline Treatment

Abstract: Old newspaper is one of commonly printed paper media which is published daily in large quantities, so it is

important to be recycled. This study aims to analyse thermal and mechanical properties of deinked paper.

This research used the ultrasound-alkaline method to recycle old newspapers in order to be compared to

paper which was deinked ultrasonication method with a variation time of 30 minutes, 60 minutes and 90

minutes.by using conventional methods. The thermal properties of deinked newspaper were analysed by

using TGA/DTG, and the analysis showed that treated samples with NaOH had 12-13% of mass loss, while

the treatment by using Mg(OH)

2

had mass loss around 20-80%. Samples were also analysed for its

mechanical properties by tensile tests. The results show, deinked old newspaper which is treated in 60

minutes ultrasound had best thermal properties with a tensile strength of around 1834 MPa and a strain of

0.1%.

1 INTRODUCTION

Old newspapers are one of the potential sources of

fibre in the world. It is one of the paper files fibres

that can be recycled. The deinking process is the

most important step in the recycling of used

newspapers to remove contaminants from reusable

paper fibres (Gil, 2013) . Recycling used newspapers

is known can increased the economic value of the

old newspapers. In addition, recycling used

newspaper can also reduce the use of wood and

reduce environmental pollution (Retti, 2004).

Ultrasonic was used to enhance the quality of the

paper fibres collected during the recycling process.

The main advantage of the use of sonication lies in

the fact that studies can be carried out at high

temperatures during the ink pretretment stage,

because its has capacity to decrease the use of

chemicals and enhance the physical and optical

properties of recycled paper (Shutilov, 1988). The

use of ultrasonic pre-treatment can further enhance

the alkaline method (Filson & Dawsonando, 2009).

Ultrasonic pre-treatment can reduces processing

time and amount of alkaline used (Zhang, 2008).

Newspapers that treated with alkali and

ultrasonic pre-treatment showed greater

delignification compared to those who used alkaline

pre-treatment only (Subhedar & Gogate, 2014). He

et al. (2004) reported that the use of alkaline sources,

such as magnesium hydroxide, could improve the

mechanical pulp during bleaching treatment.

(Subhedar & Gogate, 2014) conducted research on

alkaline recycled paper using high-frequency

ultrasound. The results showed that delignification

increased 2-fold compared to alkaline treatments

without ultrasonication. He et al. (2004) reported

that the use of alkaline sources, such as magnesium

hydroxide, mechanical pulp during bleaching can be

more efficient. This study would conduct research

on the removal of ink from the used newspaper with

alkaline-based and ultrasound pre-treatment.

2 MATERIALS AND METHODS

2.1 Materials

The material used in this research was old newspaper,

distilled water, alkaline chemical compounds such as,

NaOH (2% w/v), Mg(OH)

2

2% (w/v), Na

2

SiO

3

(w/v), H

2

O

2

2% (v/v) were purchased from Merck.

252

Rahayu, S., Gea, S. and Andriayani, .

Thermal and Mechanical Properties Analysis of Old Newspaper Deinked using Ultrasound under Alkaline Conditions.

DOI: 10.5220/0010142600002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 252-257

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2.2 Methods

2.2.1 Old Newspaper Pulp Preparation

Old newspapers were cut into small pieces, then the

samples were soaked in tap water at room

temperature for 24 h. After the immersion stage, the

papers were washed 2-3 times and then they were

crushed using a mechanical stirrer. The amount of

pulp was then filtered and dried in an oven at 50°C

(Singh, 2012).

2.2.2 Conventional Ink Removal Process

Deinking proses using conventional method was

done by immersed the pulp with 10% (w/v), NaOH

(2% w/v) in accordance to previous study (Gea,

Andita, et al., 2018; Gea, Panindia, et al., 2018)

Mg(OH)

2

2% (w/v), Na

2

SiO

3

(w/v) and H

2

O

2

2%

(v/v) at 70°C for 2 hours. Then these samples were

cooled and washed with distilled water to reach

neutral pH (Xu, 2011).

2.2.3 Alkaline-Based Ink Removal Process

with Ultrasound Method

a. Ultrasound-NaOH

Deinking proses using ultrasound-NaOH method

was done by soaking the pulp (10% w/v) in distilled

water. Then the pulp was cultivated at 35

o

C with a

variation of time 30 minutes, 60 minutes and 90

minutes, respectively. After that, the cultivated pulp

was added with NaOH (2% w/v), Mg(OH)

2

2%

(w/v), Na

2

SiO

3

(w/v) and H

2

O

2

2% (v/v) at 70°C for

2 hours. Finally, the amount of pulp then was cooled

and washed to reach neutral pH.

b. Ultrasound-Mg(OH)

2

Deinking proses using ultrasound-MgOH method

was done by soaked the pulp (10% w/v) in distilled

water. Then the pulp was cultivated at 35

o

C with a

variation of time 30 minutes, 60 minutes and 90

minutes, respectively. After that the cultivated pulp

was added with NaOH (2% w/v), Mg(OH)

2

2%

(w/v), Na

2

SiO

3

(w/v) and H

2

O

2

2% (v/v) at 70°C for

2 hours. Finally, the pulp was cooled and washed

until the pH reach neutral condition.

c. Paper Sheet Molding

The amount of wet pulps that has been treated with

conventional ink removal and ultrasonication were

placed into an Erlenmeyer then each of them were

stirred to reach homogeneous state. The pulp was

washed with distilled water 5-7 times. Then, ink

particles that float on the surface of the water were

removed by filtering. Furthermore, the washed pulp

was filtered and vacuumed using a Buchner funnel

lined with Whatman’s filter paper. Finally, the wet

pulp was covered with 400 mesh wire on both sides

to be moulded using a hot press and then it was dried

in an oven at 45°C.

3 RESULT AND DISCUSSION

3.1 Thermal Properties

The thermal properties of recycle paper that

produced by conventional and ultrasound-chemical

method was analysed by TGA. The result was

shown on the figure 1 and figure 2. Analysis thermal

properties of conventional paper pulp and

Ultrasound-NaOH paper will be displayed in figure

1.

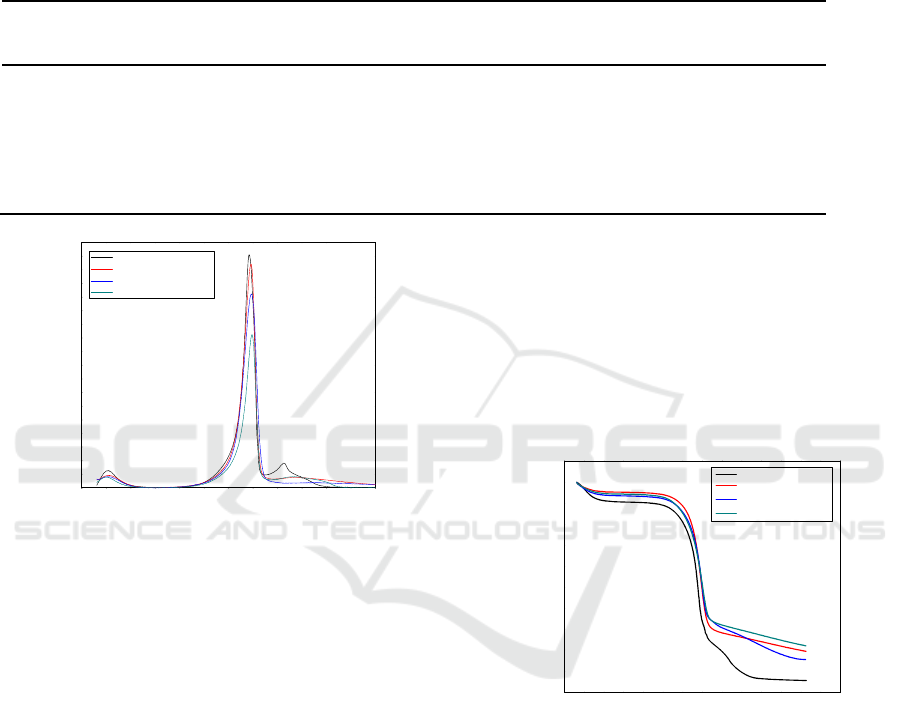

Figure 1: TGA curves of treated conventionally paper pulp

and Ultrasound-NaOH paper.

The thermal stability of conventional and

ultrasound-NaOH paper that was determined by

TGA (Figure 1) and DTG (Figure 2) shows that the

four samples tested provide almost the same curve,

where the thermal degradation that occurs in 3

phases. The curve in Figure 1. shows that the

samples undergo three phases of change during the

heating process in the TGA device. The first phase is

the process of releasing water molecules

(evaporation) in the temperature range of 30-105

o

C

(Singh et al., 2018). The evaporation process causes

a mass loss of 8-10% of the initial mass. The second

phase of change occurring in the range of 105-250

o

C

is a process of dihydroxylation and devolatization

(Singh et al., 2018), and a mass reduction of 69-

73%. The carbonization and decomposition phase of

organic compounds is the third phase that occurs

during the thermal testing process and occurs in the

range 250-600°C. in this phase, conventional and

0 100 200 300 400 500 600 700

0

20

40

60

80

100

Weight Percent (%)

Temperature

0

C

Treated Conventionally

NaOH 30'

NaOH 60'

NaOH 90'

Thermal and Mechanical Properties Analysis of Old Newspaper Deinked using Ultrasound under Alkaline Conditions

253

ultrasound-NaOH paper samples experienced a mass

reduction of 12-13%.

Table 1 shows the data of T

20

, T

80

, T

max

, and the

decomposition rate of paper prepared by

conventional and ultrasound-NaOH methods. T

20

and T

80

values indicated the temperature at the

moment of mass degradation of 20 and 80%, while

T

max

shows the temperature at the time of maximum

degradation obtained. The DTG curve was displayed

in figure 2.

Table 1: T

20

, T

max

, and T

80

data on Conventional and Ultrasound-NaOH paper.

Treated

Conventionall

y

Ultrasoun

d

-NaOH

30 min 60 min 90 min

T

20

302.58°C 314.39°C 318.11°C 312.04°C

T

max

341.6°C 345.6°C 346.6°C 347.5°C

T

80

395.85°C 473.51°C 473.51°C 421.94°C

Decomposition rate 1.71 mg/min 1.64 mg/min 1.42 mg/min 1.125 mg/min

Residual Mass 5.9% 9.5% 16.5% 8.7%

0 100 200 300 400 500 600

0

200

400

600

800

1000

1200

1400

1600

1800

Weight percent (%)

Temperature (

o

C)

Treated Conventionally

NaOH 30'

NaOH 60'

NaOH 90'

Figure 2: DTG curves of treated conventionally and

ultrasound-NaOH paper.

On the DTG curve (Figure 2) and Table 2 shows

the paper decomposition process of conventional

and ultrasonication-NaOH methods occurs one stage

marked by the presence of a peak on the DTG curve.

Paper prepared by conventional methods has a T

max

value at 341°C with a decomposition rate of 1.71

mg/min, while paper with ultrasound-NaOH with 30

minutes has a T

max

value at 345°C with a

decomposition rate of 1.64 mg/min from the TGA

data, paper with ultrasound-NaOH with 60 minutes

has a T

max

value at 346°C with a decomposition rate

of 1.42 mg/min. The ultrasound-NaOH paper with

90 minutes showed the value of T

max

at 347°C with a

decomposition rate of 1.13 mg/min.

Based on table 2, it is clear that increasing the

ultrasonic time during the papermaking process can

improve the thermal properties of the paper. This

can occur because the use of ultrasonic can increase

the purity of the resulting paper pulp so that the

thermal stability is higher. This can be an advantage

for the application of ultrasonication in the industrial

world (Liu et al., 2006).

Analysis of Thermal Properties of Conventional

and with Alkaline Treatment Ultrasound- Mg(OH)

2

Paper.

0 100 200 300 400 500 600 700

0

20

40

60

80

100

Weight Percent (%)

Temperature

o

C

Treated Conventionally

Mg(OH)

2

30'

Mg(OH)

2

60'

Mg(OH)

2

90'

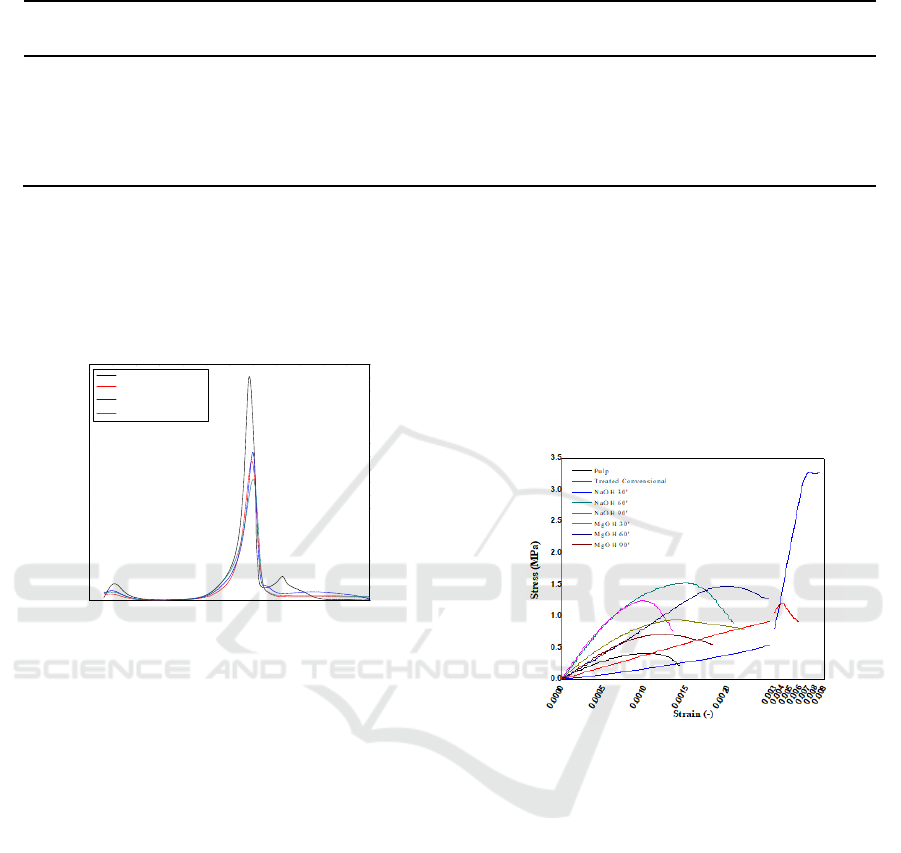

Figure 3: TGA curves of treated conventionally and

ultrasound-Mg(OH)

2

papers.

The curve in Figure 3 shows that all samples

tested provide almost the same curve, where the

thermal degradation that occurs can be 3 parts. Can

be seen in Table 2 below.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

254

Table 2: T

20

, T

max

, dan T

80

data on conventional and Ultrasound-Mg(OH)

2

paper.

Treated

Conventionally

Ultrasoun

d

-M

g(

OH

)

2

30 min 60 min 90 min

T

20

302.58°C 312.36°C 316.91°C 317.13°C

T

Max

341.6°C 346.4°C 349.3°C 350.6°C

T

80

395.85°C 517.38°C 523.66°C >612.7°C

Decomposition rate 1.01 mg/min 1.06 mg/min 1.13 mg/min 1.23 mg/min

Residual Mass 5.9% 21.9% 17.9% 24.7%

While compar to conventionally processed paper,

it can be seen that the thermal properties of

ultrasound paper processed with Mg(OH)

2

are much

better. This can be seen when the paper loses weight

by 20% and 80% increases with increasing

ultrasound time.

Figure 4: DTG Curves of Treated Conventionally and

Ultrasound-Mg(OH)

2

papers.

On the DTG curve, it can be seen that the

decomposition process of all samples takes place in

one stage with the peak of conventional paper

decomposition at 341.6°C in a decomposition rate of

1.71 mg/min, while paper with ultrasound-Mg(OH)

2

with 30 minutes has a decomposition peak

temperature at 346.4°C with a decomposition rate of

1.06 mg/min, paper with ultrasound-Mg(OH)

2

with

60 minutes has a decomposition peak temperature at

349.3°C with a decomposition rate of 1.13 mg/min.

Whereas paper with ultrasonic-Mg(OH)

2

with 90

minutes had a peak decomposition temperature at

350.6°C with a decomposition rate of 0.923 mg/ min.

From the DTG curve it is clearly illustrated that

increasing the time during the ultrasonication pre-

treatment during the papermaking process increases

the thermal properties of the paper. This can be seen

with the increase of T

max

value along with the

increasing time of ultrasonication in paper pulp with

ultrasound-Mg(OH)

2

. This can occur because

physical methods such as ultrasonication are pre-

treatment to reduce the consumption of chemicals on

recycled paper. The increased purity of recycled

paper pulp is known to increase the thermal stability

of recycled paper (Virk et al., 2013).

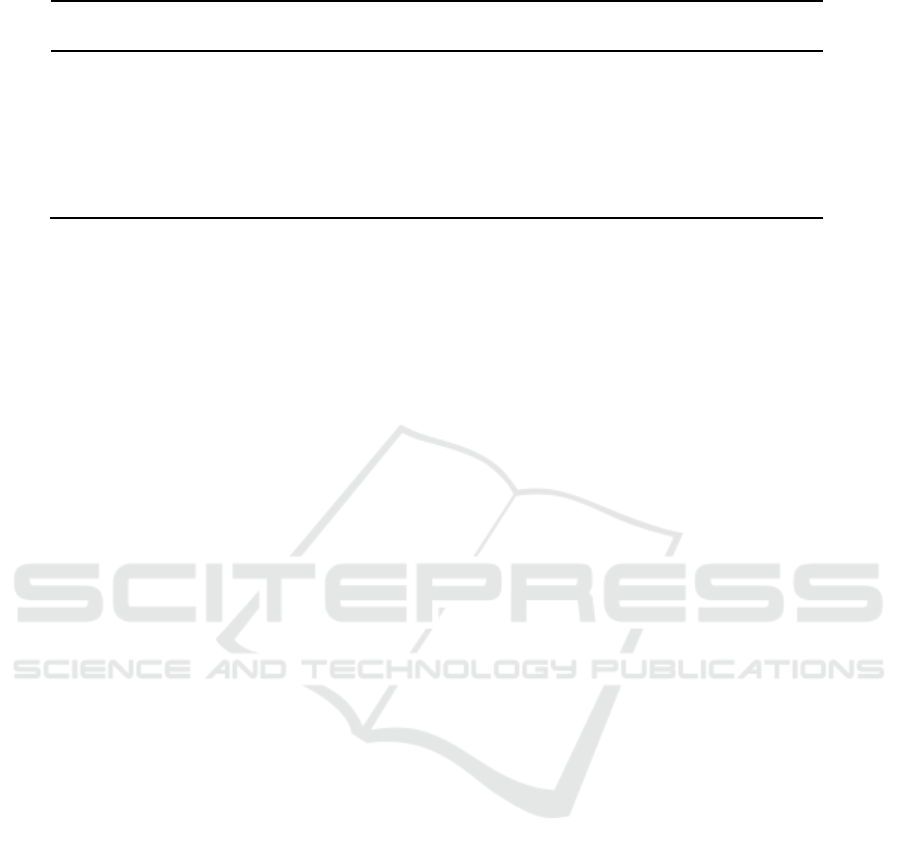

3.2 Mechanical Properties

The mechanical properties of a polymer can be

determined by the strength of a material. The results

sheet of paper was analysed by tensile strength

shown in the figure 5.

Figure 5: Stress-strain curves of Treated Conventionally

and Ultrasound-alkaline papers.

In this study the mechanical properties of paper

with an ultrasound time of 30, 60, and 90 minutes

were tested through tensile tests with an average

thickness of paper produced was 1.05 mm, paper

length 80 mm and width 25 mm. The tensile strength

of each paper can be seen in Table 3.

From Table 3 above it can be seen that the length

of time of ultrasonication and the alkaline solution

used during the deinking process of used newspaper

affect the yield of tensile strength. The highest

modulus young value was found in the Ultrasound-

NaOH treatment for 60 minutes, an increase of 77%

compared to conventional paper, while in the

ultrasound- Mg(OH)

2

treatment for 30 minutes, the

modulus young increased by 62% when compared to

conventional paper. It can be concluded that NaOH

solution is more effective than Mg(OH)

2

solution in

improving the mechanical properties of paper. This

0 100 200 300 400 500 600

0

200

400

600

800

1000

1200

1400

1600

1800

Weight percent (%)

Temperature (

o

C)

Treated Conventionally

Mg(OH)

2

30'

Mg(OH)

2

60'

Mg(OH)

2

90'

Thermal and Mechanical Properties Analysis of Old Newspaper Deinked using Ultrasound under Alkaline Conditions

255

Table 3: Mechanical Properties of Pulp, Conventional and Ultrasound-alkaline.

Sample

Tensile Strength

(MPa)

Elongation at

Break (%)

Young’s Modulus

(GPa)

Pul

p

0.4 0.1 690

Conventional 1.2 0.4 418

NaOH 30 min 3.3 0.7 519

NaOH 60 min 1.5 0.1 1834

NaOH 90 min 1.2 0.1 1752

Mg(OH)

2

30 min 0.9 0.1 1101

M

g(

OH

)

2

60 min 1.5 0.1 795

Mg(OH)

2

90 min 0.7 0.1 970

is due to NaOH having stronger alkaline / alkali

properties compared to Mg(OH)

2

. Paper treatment

in the presence of an alkaline solution shows an

increase in the mechanical strength of the paper.

This is due to the alkali solution can increase the

carboxyl and carbonyl group content by splitting

the ester chain in the fibre. Hydrogen bonds

involving carboxyl and carbonyl groups have

greater strength when compared to hydrogen bonds

which only involve hydroxyl groups (Wistara &

Young, 2000). Hydrogen bonds contained in paper

fibres can improve the mechanical properties or

tensile strength of the paper produced. This data is

supported by the results of the TGA analysis,

where the 30 minutes ultrasound-NaOH paper has

the best residual mass value of 16.5%.

4 CONCLUSION

Deinking prosses trough ultrasound-alkaline

treatment has been successfully carried out based

on TGA and tensile strength data it can be

concluded that paper produced with ultrasound-

alkaline method has better thermal and mechanical

properties compare to paper produced with

conventional method. The mechanical properties

of conventional and ultrasound-alkaline method

are affected by the duration of ultrasound. The

modulus young value increased by 77% (from 418

to 1834 GPa) in the ultrasound-NaOH method for

60 minutes compared to conventional paper. This

data is supported by the results of the TGA

analysis, where the 30 minutes ultrasound-NaOH

paper has the best residual mass value of 16.5%.

While the modulus young value increased by 62%

(from 418 to 1101 GPa) in the ultrasound-

Mg(OH)

2

treatment for 30 minutes. This value is

smaller than the 60-minute ultrasound-NaOH

treatment.

ACKNOWLEDGEMENTS

Authors would like to express a gratitude to the

head of basic science laboratory and basic

chemistry laboratory chemistry laboratory of

Department of Chemistry, Faculty of Mathematics

and Natural Sciences, Universitas Sumatera Utara

for the research facility provided.

REFERENCES

Filson, P., & Dawsonando, B. (2009). Sono-chemical

Preparation of Cellulose Nanocrystals from

Lignocellulose Derived Materials. Bioresource

Technology, 100(7), 2259–2264.

Gea, S., Andita, D., Rahayu, S., Nasution, D. Y.,

Rahayu, S. U., & Piliang, A. F. (2018). Preliminary

study on the fabrication of cellulose nanocomposite

film from oil palm empty fruit bunches partially

solved into licl/dmac with the variation of

dissolution time. Journal of Physics: Conference

Series, 1116(4). https://doi.org/10.1088/1742-

6596/1116/4/042012

Gea, S., Panindia, N., Piliang, A. F., Sembiring, A., &

Hutapea, Y. A. (2018). All-cellulose composite

isolated from oil palm empty fruit bunch. Journal of

Physics: Conference Series, 1116(4), 042013.

https://doi.org/10.1088/1742-6596/1116/4/042013

Gil. (2013). Study of Enzymatic/Neutral Deinking

Process of Waste PhotocopyPpaper. Technical

Article/Peer Review Article. Papel, 74, 61–65.

He, Z., Wekesa, M., & Ni, Y. (2004). Pulp Properties

and Effluent Characteristic from The Mg(OH)2-

Based Peroxide Bleaching Process. Tappi J, 3, 27.

Liu, C. F., Ren, J. L., Xu, F., Liu, J. J., Sun, J. X., &

Sun, R. C. (2006). Isolation and characterization of

cellulose obtained from ultrasonic irradiated

sugarcane bagasse. Journal of Agricultural and Food

Chemistry, 54(16), 5742–5748.

https://doi.org/10.1021/jf060929o

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

256

Retti. (2004). Daur Ulang Kertas HVS Bekas Secara

Kimiawi dan Enzimatik. Jurusan Teknik Kimia

Universitas Katholik Parahyangan Bandung.

Shutilov. (1988). Fisika Fundamental dari Ultrasounds.

In Gordon dan Pelanggaran Sains.

Singh. (2012). An Ecofriendly Cost Effective Enzymatic

Methodology for Deinking of School Waste Paper.

Bioresource Technology, 120, 322–332.

Singh, S. K., Kulkarni, S., Kumar, V., & Vashistha, P.

(2018). Sustainable utilization of deinking paper mill

sludge for the manufacture of building bricks.

Journal of Cleaner Production, 204, 321–333.

https://doi.org/10.1016/j.jclepro.2018.09.028

Subhedar, P. B., & Gogate, P. R. (2014). Alkaline and

ultrasound assisted alkaline pretreatment for

intensification of delignification process from

sustainable raw-material. Ultrasonics

Sonochemistry, 21(1), 216–225.

https://doi.org/10.1016/j.ultsonch.2013.08.001

Virk, A. P., Puri, M., Gupta, V., Capalash, N., &

Sharma, P. (2013). Combined Enzymatic and

Physical Deinking Methodology for Efficient Eco-

Friendly Recycling of Old Newsprint. PLoS ONE,

8(8). https://doi.org/10.1371/journal.pone.0072346

Wistara, N., & Young, R. A. (2000). Properties and

treatments of pulps from recycled paper . Part I .

Physical and chemical properties of pulps. 291–324.

Xu. (2011). Fiber Surface Characterizatition of Old

Newsprint Pulp Deinking By Combining

Hemicellulace with Laccase Mediator System.

Bioresour Technol, 102, 6536–6540.

Zhang, et al. (2008). Enzymatic Hydrolysis of Alkali-

Pretreated rRce Straw by Trichoderma Reesei ZM4-

F3. Biomass Bioenergy, 32, 1130–1135.

Thermal and Mechanical Properties Analysis of Old Newspaper Deinked using Ultrasound under Alkaline Conditions

257