Enlarge Bacterial Cellulose Pore by Adding Aloe Vera Extract as

Potential Material for Skin Tissue Engineering

Khatarina Meldawati Pasaribu

1

, Saharman Gea

1

, Tamrin

1

, Safruddin Ilyas

2

, I Putu Mahendra

1

and

Appealwan Altruistis Sarumaha

1

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1, Medan 20155, Indonesia

2

Department of Biology, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1, Medan 20155, Indonesia

Keywords: Bacterial cellulose (BC), Aloe vera, BC/Aloe, Biocomposite, Scaffold.

Abstract: Bacterial cellulose (BC) is a abundant natural biopolymer which due to its biocompatibility, it has a big

potential to be used in biomedical material applications such as a scaffolding for skin tissue engineering.

But, pristine BC still has some lacks desired properties, which limits its uses as a scaffolding or a template

for growing fibroblast cell. Therefore its properties need to be boosted up to formed a better material that

allow cellular penetration and several key requirement for tissue engineering. Here in this study a

biocomposite was produce by loaded aloe vera extract in to medium in static culture during cellulose fiber

biosynthesis using strain bacteria Acetobacter xylinum. BC/aloe biocomposite were characterized using

FTIR and SEM analyses. Interaction between BC fibers and aloe vera extract was proved by peak in region

1643 cm-1 which is implied the intermolecular interaction of BC and the amino groups of aloe vera gel in

FTIR. It is also supported by SEM analysis that showed Aloe vera extract was covered the BC fiber.

Additionally, due to its biocompatibility BC/aloe composite was potentially using as scaffold material for

skin tissue engineering.

1 INTRODUCTION

Bacterial cellulose (BC) is an abundantly available

biopolymer and has been shown to be biocompatible

with living tissues. BC is also considered suitable for

biomedical applications such as wound dressing, due

to its mechanical characteristics and porous

structure. The three dimension fibers structure of

bacterial cellulose was identical can mimic the skin

extracellular matrix when dried with a freeze dryer

(Gea et al., 2018). Furthermore, it may also

impregnated with other modifiers such drugs to

modulate its properties through enhancing BC

properties such as antimicrobial properties, which is

low for pristine BC. Never dries and high

hydrophilic properties of BC, also become the

desired property to aplicate BC as wound dressing,

because it has been shown that when the wound is

continuously moisturised, wounds heal better and

faster. This feature of BC means that it can act as a

wound dressing and skin tissue scaffold successfully

(Kucińska-Lipka, Carayon and Janik, 2015).

Unfortunately, these features alone do not allow

BC to fulfill the require to be a good wound dressing

or skin-tissue replacement, as wound dressing must

also mimic the wound bed extracellular matrices

(ECM), decrease scar formation and increase wound

healing (Meng et al., 2019). BC also has some

disadvantages to be incorporated as a scaffold, due

to biodegradability and inadequate pore diameters.

Two different approaches were used in BC-based

composite production to obtain the desired

properties as a scaffolding material: in situ (inside

medium culture during BC synthesis) and ex situ

(outside medium culture after BC gels harvested)

modifications. BC properties, such as antimicrobial,

biodegradability or antioxidant activity, reported can

be improved by modifying or adding various

compounds into the BC fibers (Keskin, Urkmez and

Hames, 2017).

Biopolymer-based scaffold materials such as

proteins, (gelatin, fibrin and collagen) and

polysaccharides, (chitosan, hyaluronic acid, dextran,

248

Meldawati Pasaribu, K., Gea, S., Tamrin, ., Ilyas, S., Mahendra, I. and Altruistis Sarumaha, A.

Enlarge Bacterial Cellulose Pore by Adding Aloe Vera Extract as Potential Mater ial for Skin Tissue Engineering Khatarina.

DOI: 10.5220/0010142500002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 248-251

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

alginate, cellulose and aloe vera) were used to

improve BC properties mimic to ECM.

For regenerative medicine, composite based on

BC can be used to restore and rebuild hard and soft

tissues, such as vascular tissues, bone, skin and

cartilage (Dutta, Patel and Lim, 2019). Aloe vera is a

succulent plant, also known as Aloe barbadensis

Miller that is commonly used for cosmetic,

pharmaceutical and biomedical uses. Aloe vera gel

known consists of acetylated glucomannan

polysaccharides that form in a long chain, a complex

of amino acids and other carbohydrates. It also

contains ascorbic acid, 99 percent of water, salicylic

acids, antioxidant (vitamin E and vitamin A)

(Venugopal and Mary, 2014).

Because of its low toxicity, biocompatibility and

biodegradability characteristic, aloe vera gained

significant attention in tissue engineering. There have

been significant recent advances in the development

of aloe vera for tissue engineering applications. Aloe

Vera has been revealed to possess many biologically

active elements. Bioactive components in aloe vera

have effective antibacterial, antioxidant, immune-

modulatory and anti-inflammatory properties that

supported growth cell and tissue regeneration

(Rahman, Carter and Bhattarai, 2017). Gel inside

aloe vera leaf as an abudant natural material is known

suitable to be impregnated with other biomaterials in

tissue engineering in aims to improve scaffold

biological, porosity and biodegradability properties

for support the cell growth of new tissue implanted in

the human body (Tran, Hamid and Cheong2, 2018).

But, pure aloe vera is not suitable for becoming a

material for scaffolding because it has not become a

template for growth cells. In order to make it a

scaffold material, it is important to combine aloe vera

with other polymers such as cellulose. In this

research, we concentrated on the in situ

manufacturing of BC-Aloe composite and

characterization of BC-Aloe potential as a skin tissue

engineering scaffolding material.

2 METHOD

2.1 Production of Pristine BC and in

situ BC-Aloe Composite

Acetobacter xylinum, the bacterial strain that used

for the production of BC gels in this study was

obtained from the Material and Polimer

Postgraduate Labolatorium of Universitas Sumatera

Utara, Indonesia. Ekstrak aloe vera was purchased

from PT. Bali Extract Utama. For in situ production,

pure Aloe Vera (1% w/v) was added to Hestrin &

Schramm (HS) medium that contain 20 g/L glucose,

2.7 g/L disodium hydrogen phosphate, 5 g/L

peptone, 1.15 g/L citric acid and 5 g/L yeast extract.

Then starter of Acetobacter xylinum was inoculated

in the HS medium at a concentration of 1 % v/v. It

left for inoculation at 30 ° C for 14 days in static

condition. After completion of the inoculation

process, composite BC-Aloe gels were harvested

from the medium surface. After that, composites

were purified in a solution of 2.5 M NaOH and wash

with distilled water until reach neutral pH. The same

procedure was follow to produce pristine BC

without adding aloe vera into the medium. Then

pristine BC, BC-aloe dried using freeze dryer.

2.2 Characterization of Prinstine BC

and BC-Aloe Composite

Fourier transform infrared (FTIR): FT-IR

spectroscopy of BC and BC-Aloe composite were

characterized using a Fourier transform infrared

spectrophotometer in the frequency range of 400 to

4,000 cm−1 (FTIR 8400S, Shimadzu, Tokyo,

Japan). Scanning electron microscope (SEM): SEM

EDX EVO 10 car MA Zeiss Bruker operated at 20

kV was used to analyse the surface morphology of

Pristine BC and BC-Aloe composite.

3 RESULT AND DISCUSSION

3.1 FTIR Analysis

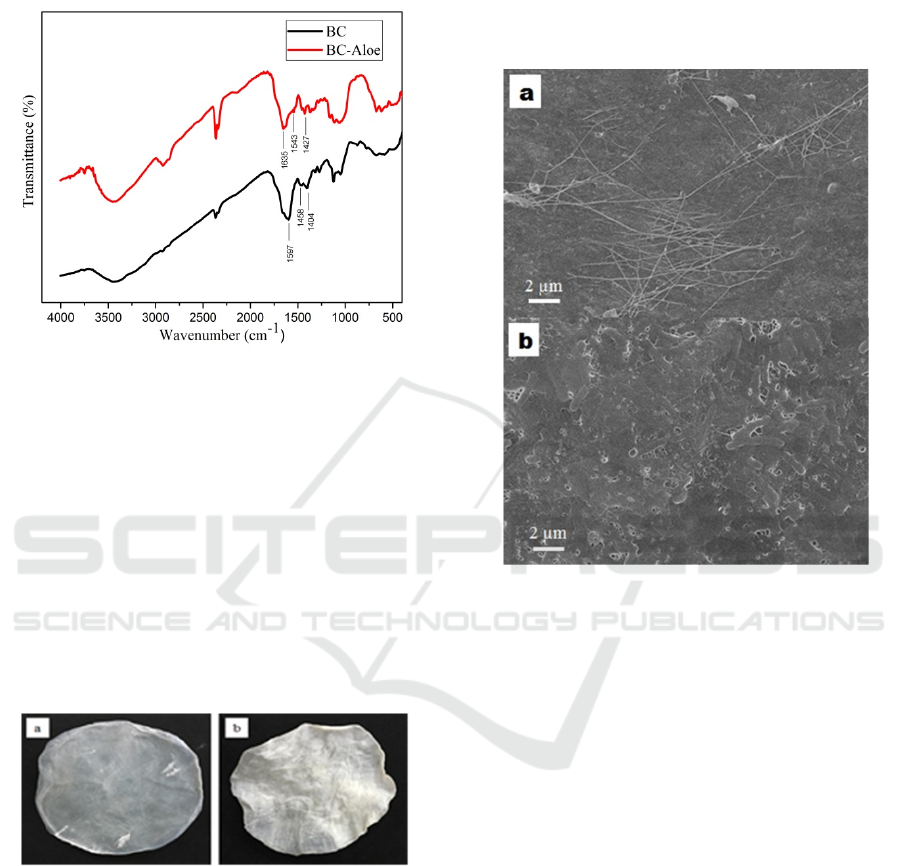

In order to analyse the emergence of any peak

changes or new peaks or that could be due to

interactions between aloe vera gel and cellulose

Fourier transform infrared (FTIR) spectroscopy of

the BC and BC-Aloe composite was performed. The

FTIR spectra of all samples were displayed in Figure

1. The BC FTIR spectrum show that the intense

absorption was in the region band at 1642.9 cm

-1

,

which has been assigned to carbonyl groups

(Amaturrahim, S.A; Gea, 2018), while the band at

1635 cm-1 was observed as the characteristic band

for the absorption of aloe vera. C-O stretching was

assigned to the bands at 1543–1635 cm

-1

which

overlap with NH bending. In addition the absorption

band of NH deformation was at 1565–1540 cm

-1

. In

Figure 1 the BC-Aloe presents a new peak of 1543

cm-1 in FTIR spectra. The new peak suggested there

are intermolecular interaction among the cellulose

chain of the BC and the amino groups in the aloe

vera gel. This accepted that aloe vera gel have

Enlarge Bacterial Cellulose Pore by Adding Aloe Vera Extract as Potential Material for Skin Tissue Engineering Khatarina

249

intermolecular bonding with cellulose fibril as

supported in SEM study (Saibuatong and

Phisalaphong, 2010).

Figure 1: The FTIR Spectra of BC and BC-Aloe

Composite.

3.2 Surface Morphology

Figure 2 shows the difference between (a) BC

pristine film and (b) dried BC-Aloe composite film.

From the picture it can be seen that the BC pristine

film looks more transparent than the BC-Aloe

composite film. This can occur due to the addition of

aloe into the medim culture or the manufacture of

composites in situ making aloe vera extract trapped

in the bacterial cellulose fibers during the

inoculation process. This is also supported by the

SEM results shown in Figure 3.

Figure 2: Photos of dried (a) Pristine BC and (b)

BC-Aloe Composites.

SEM images in Figure 3 illustrate that there are

differences in the surface morphology of Pristine BC

and BC-Aloe composite at magnification 5000 X.

The results of SEM analysis shows that in Pristine

BC, BC fibers are still visible on the surface of the

film but the addition of aloe vera into the culture

medium during the process of inoculation and

synthesis of BC by Acetobacter xylinum makes aloe

vera trapped in BC fibers and covers the surface of

BC. So that in Figure 3 (b) the BC fibers are no

longer visible. Through SEM image also seen. The

entrapment of aloe vera extract in BC can make BC

pores get bigger. This is in accordance with previous

research which states the addition of aloe vera gel

can disrupt the structure of BC and enlarge pores

(Saibuatong and Phisalaphong, 2010).

Figure 3: SEM images of surface morphology of (a)

Pristine BC and (b) BC-Aloe.

4 CONCLUSIONS

Research shows that the use of Acetobacter xylinum

strain bacteria to produce BC then modify the film

by adding aloe vera gel to the culture medium during

BC biosynthesis has improved and provided many

beneficial effects for BC/Aloe composite. FTIR

spectra of BC/Aloe shows that there are interaction

between BC intermolecular with the amino groups

of aloe vera ekstract. SEM image also showed that

morphologically BC-Aloe composite was

successfully produced. The BC-Aloe composite is

expected to be used in a wide range of medical

applications. Another supported characterization to

proven BC-Aloe was potential material for tissue

engineering is on progress

ACKNOWLEDGEMENTS

Authors gratefully acknowledge this study fully

funded by the Ministry of Science, Technology, and

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

250

Higher Education (KEMENRISTEK DIKTI) via

PMDSU 2018 scheme.

REFERENCES

Amaturrahim, S.A; Gea, S. N. D. Y. and H. Y. A. (2018)

‘Preparation of Graphene Oxide/Bacterial Cellulose

Nanocomposite via in situ Process in Agitated

Culture’, Asian Journal of Chemistry, 27(9), pp. 3188–

3196.

Dutta, S. D., Patel, D. K. and Lim, K. T. (2019)

‘Functional cellulose-based hydrogels as extracellular

matrices for tissue engineering’, Journal of Biological

Engineering. Journal of Biological Engineering, 13(1),

pp. 1–19. doi: 10.1186/s13036-019-0177-0.

Gea, S. et al. (2018) ‘Enhancing the quality of nata de

coco starter by channeling the oxygen into the

bioreactor through agitation method’, in AIP

Conference Proceedings. doi: 10.1063/1.5082469.

Keskin, Z., Urkmez, A. S. and Hames, E. E. (2017) ‘Novel

keratin modified bacterial cellulose nanocomposite

production and characterization for skin tissue

engineering’, Materials Science & Engineering C.

Elsevier B.V, S0928-4931(16), pp. 31711–8. doi:

10.1016/j.msec.2017.03.035.

Kucińska-Lipka, J., Carayon, I. and Janik, H. (2015)

‘Bacterial cellulose in the field of wound healing and

regenerative medicine of skin: recent trends and future

prospectives’, POLYMER BULLETIN, 72(9), pp.

2399–2419.

Meng, E. et al. (2019) ‘Bioapplications of bacterial

cellulose polymers conjugated with resveratrol for

epithelial defect regeneration’, Polymers, 11(6). doi:

10.3390/polym11061048.

Rahman, S., Carter, P. and Bhattarai, N. (2017) ‘Aloe

Vera for Tissue Engineering Applications’. doi:

10.3390/jfb8010006.

Saibuatong, O. ard and Phisalaphong, M. (2010) ‘Novo

aloe vera-bacterial cellulose composite film from

biosynthesis’, Carbohydrate Polymers. Elsevier Ltd,

79(2), pp. 455–460. doi:

10.1016/j.carbpol.2009.08.039.

Tran, T. T., Hamid, Z. A. and Cheong2, K. Y. (2018) ‘A

Review of Mechanical Properties of Scaffold in Tissue

Engineering : Aloe Vera Composites A Review of

Mechanical Properties of Scaffold in Tissue

Engineering : Aloe Vera Composites’, IOP Conf.

Series: Journal of Physics, 1082, p. 012080. doi:

10.1088/1742-6596/1082/1/012080.

Venugopal, S. S. J. and Mary, S. A. (2014) ‘Aloe vera

incorporated biomimetic nanofibrous scaffold : a

regenerative approach for skin tissue engineering’, pp.

237–248. doi: 10.1007/s13726-013-0219-2.

Enlarge Bacterial Cellulose Pore by Adding Aloe Vera Extract as Potential Material for Skin Tissue Engineering Khatarina

251