Training of Fiberglass Boat Repair for Gresik’s Fisherman to

Improve Fiberglass Boat Quality of Boat Construction following the

Indonesian Classification Regulations

Dedi Budi Purwanto

1

, Mohammad Sholikhan Arif

1

and Nurul Hidayati

2

1

Institute Teknologi Sepuluh Nopember (ITS), ITS Sukolilo Campus, ITS Raya Street, Sukolilo,

Surabaya, East Java 60111, Indonesia

2

Department of Naval Architecture and Shipbuilding Engineering, Indonesia

Keywords: Fiberglass, Damage, Classification, Training.

Abstract: There are several types of damage to the fiberglass boat, including holes, cracks, and deformation on the

fiberglass boat hull. At this time, fiberglass boat’s damages are repaired by fishermen with their knowledge

without considering classification regulations. Therefore this paper will explain training on repairing

fiberglass damage using a syllabus and methods by Indonesian classification bureau (BKI) regulations.

1 INTRODUCTION

Gresik Regency is between 7 degrees and 8 degrees

south latitude and between 112 degrees and 113

degrees east longitude. Most of the area is lowland

with an altitude between 0-12 meters above sea

level, except a small part in the north (Panceng

District) has a height of up to 25 meters above sea

level. The Java Sea borders the northern part of the

Gresik Regency; the Madura Strait and Surabaya

City-bound the eastern part; the southern part is

bordered by Sidoarjo Regency and Mojokerto

Regency, while Lamongan Regency borders the

western region.

Gresik Regency has an archipelago of Bawean

Island and several smaller islands around it. The

total area of Gresik is 1,192.25 km2 consisting of

996.14 km2 land area plus 196,11 km2 area of

Bawean Island while the area of the waters is

5,773.80 km2 which is very potential from the

marine fisheries subsector.

Gresik Regency is one of the buffer cities of

Surabaya. Where the city of Surabaya is the capital

and economic center of East Java and East Indonesia.

Nearly one-third of the Gresik Regency is a coastal

area. As a coastal area that has also been facilitated by

a large port, Gresik Regency has access to regional,

national, and even international trade.

The mapping of the marine fisheries sector in

Gresik has the second-highest potential of marine

fisheries from the mapping of the marine fisheries

sector in East Java with the acquisition of catches of

362,624 tons per year with this development the

movement of the economic industry of the Gresik

district community leading to the fisheries sector is

also increasing (Norromadani Y, 2016).

With the use of boat for fishing activities, some

damages caused by collisions or the age of the boat,

so the boat needs to get maintenance and repairs. In

general, repairs activities are replace the entire

damaged part, but it will take a long time by

reviewing the damages for hull repairs effectively.

Repairing fiberglass boats usually still traditional

way based on limited knowledge about fiberglass

boat repair. Therefore, as an institution engaged in

maritime, ITS is doing community service to

develop and improve the welfare of the community

with a form of training support for maintenance and

repair of ships following the standards used by the

Indonesian Classification Bureau for resistance to

fiberglass ship structures.

2 LITERATURE REVIEW

2.1 Fiberglass Boat

FRP ships are generally made of fiberglass or glass

fiber. This is because fiberglass is relatively cheaper

when compared to other reinforcing materials.

Purwanto, D., Arif, M. and Hidayati, N.

Training of Fiberglass Boat Repair for Gresik’s Fisherman to Improve Fiberglass Boat Quality of Boat Construction following the Indonesian Classification Regulations.

DOI: 10.5220/0010141502310235

In Proceedings of the 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management (ISOCEEN 2019), pages 231-235

ISBN: 978-989-758-516-6

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

231

Fiberglass also has a relatively strong strength with a

light weight. Additionally fiberglass has chemical

resistance and is easy to process. However, the strong

tensile strength of this fiberglass decreases when it

receives a continuous load over a long period of time.

Table 1: Composition of E-Glass and S-Glass per unit

weight.

Composition E-Glass S-Glass

Silicone Dioxide 52-56 %

64-66

%

Calcium Dioxide 16-25 % 0-0,3 %

Aluminium Oxide 12-16%

24-26

%

Boron Oxide 5-10 % -

Sodium Oxide & Potassium

Oxide 0-2 % 0-0,3 %

Magnesium Oxide 0-5 % 9-11 %

Iron Oxide 0,05-0,4 % 0-0,3 %

Titanium Oxide 0-0,8 % -

Fluorides 0-1 % -

The table 1 shows the ratio of E-glass and S-glass

composition by weight. In marine use applications, E-

glass (lime aluminum borosilicate) is the most

commonly used reinforcement material because it has

good tensile strength, is resistant to water degradation,

and is cheap. S-glass (silicon dioxide, aluminum, and

magnesium oxides) has 33.33% better tensile strength

and generally has more resistance to fatigue. (Ship

Structure Committee, 1990).

Reinforcement fiberglass material is divided into

several types, namely Chopped Strand Mat (CSM),

Woven Roving (WR), and Multiaxial:

• Chopped Strand Mat (CSM)

Chopped Strand Mat (CSM) is a type of fiberglass

made of glass fibers that are placed and arranged

randomly between one another, as in Figure 2.4. A

comparison of the use of resin against fiberglass

Chopped Strand Mat is 2.5 ~ 3 Resin: 1 CSM.

CSM Fiberglass is generally distinguished by

weight per square meter. For example, CSM 300

means that each square meter of fiberglass weighs

300 grams.

• Woven Roving (WR)

Woven Roving (WR) is fiberglass made of glass

fiber that is woven in two directions continuously

at an angle of 90 °. Fiberglass WR is the

reinforcement material most often used for the

construction of marine structures. It is because WR

fiberglass is available in quite a significant weight

(24 ounces per square yard or around 800 grams

per square meter is the most commonly used

weight) so that the thickness of the structure can be

met quickly. Besides fiberglass, WR also has

resistance to impact because the material is woven.

• Multiaxial

Multiaxial fibers consist of two or more layers of

fibers with different direction orientations (0 °; 90

°; 45 °; -45 °), each report is sewn with fine

polymer yarn. Multiaxial fibers can be combined

with Chopped Strand Mat (CSM) and Woven

Roving (WR). Multiaxial fiber is usually applied

to wind turbines, fast boats, recreational products,

racing cars, aerospace and defense system (defense

equipment). (Baskoro, 2018)

2.2 Types of Fiberglass Boat Damage

Various reasons can cause damage caused to

fiberglass vessels. Based on Greg Davis's survey in

1996, from 3000 respondents 61% damage to

fiberglass boats owned by respondents occurred due

to exposure to foreign objects submerged in the sea,

17% occurred due to collisions, 14% occurred due to

lack of ship maintenance, 5% occurred due to

aground and 3 % occurred due to manufacturing

problems. Following are the types of damage that

can occur to fiberglass vessels. (Greene, 2006)

a. Tear on Boat Skin

Tear damage generally occurs when a ship

collides with another boat or foreign object

when the boat is at sea or the dock. Grounding

or aground of the boat can also be a cause of

this type of damage. This type of damage needs

to do a visual inspection to find out how severe

the injury and delamination that occurs. Tear

damage was initially inspected visually. After

the investigation carried out and the need for

repairs is made, holes are built around the area

of damage. The hole is what will be re-

laminated during the repair process.

b. Delamination

Delamination is damage that occurs when the

loss of bond between the lamination of the skin

of the ship and its core material. Delamination

damage generally cannot be identified visually.

To determine this damage, ultrasonic evaluation

or tap testing is necessary. In the tap testing

evaluation, a part of the delamination is

suspected to be knocked using a metal or plastic

hammer and listen to the sound it makes. Areas

that occur delaminated will cause a higher tone.

c. Cracks on the Gelcoat Layer

These cracks only occur on the surface of the

gel coat layer, and rarely this damage causes

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

232

structural failure. However, cracks in the gel coat

layer can cause water to seep into the fiberglass

laminate layer. To detect, it can be done the

visual evaluation and dye penetrant test.

2.3 Indonesian Classification Bureau

Regulations

In Indonesia, the bereau that regulates fiberglass

ship regulation is the Indonesian Classification

Bureau (BKI). BKI published two regulations about

fiberglass ships, namely BKI 2016, Rules for

Fiberglass Reinforced Plastic Ships, and BKI 2014,

Rules for Non-Metallic Material. BKI in 2016

regulates the calculations performed on the

construction of fiberglass ships while BKI in 2014

regulates the manufacturing process, inspection, and

repair of fiberglass vessels.

The rules used as a reference for the repair of

FRP ships are the 2014 edition of the Indonesian

Classification Bureau (BKI), Rules for Non-Metallic

Material. According to (BKI, 2014), there are

several conditions for repairing FRP vessels. Some

of them are:

• The reparation process should only be carried

out by personnel who have sufficient

experience in this field, generally carried out

by staff who have training certificates.

• The resin used for the repair process must be

the same as the resin used in the production

process. This is done to prevent residual

stresses in the repair area.

• The reinforcement materials used are the same

as those in the production process.

3 METHOD

Stages that need to be done in community service

begins with communicating with fiberglass boat

builders in the Lumpur Village, Gresik District,

Gresik Regency. Next, a visit to the location of the

people's boat port and fiberglass shipbuilding was

made.

The meeting held with the fiberglass shipbuilders

produced several things that needed to be used as

information and input for community activities.

Some of these include a) Obtained the location of

community service for the repair of fiberglass

vessels, namely at the community port of the

Lumpur Village, Gresik District, Gresik Regency. b)

The shape of the ship that is commonly used in the

Lumpur area, ship construction, and the type of

fiberglass material used. c) The process of

maintaining fiberglass fishing boats. d) Damages

that occur as well as the location of damage to the

ship. e) Plan for the operation of ship repair.

The method offered in this community service is

to provide information transfer and training on

fiberglass ship repair by the Indonesian

Classification Bureau standards. The activity is

carried out by providing material and interactive

discussions so that the trainees can understand and

facilitate the understanding of the content provided.

Evaluation of the implementation of the activities

carried out after the ship repair training event is

completed. Matters evaluated include a) The method

of preparing the ship before repairs are made. b)

Methods for preparing tools and materials for ship

repair c) Methods for repairing vessels that are good

and right. As for the analysis of the data used to assess

the success of the training through a descriptive study

based on participant responses to the process and

results of the training activities carried out.

4 RESULTS AND DISCUSSION

Community service activities related to the

maintenance and repair of fiberglass fishing vessels

by following the regulations of the Indonesian

Classification Bureau in the context of increasing the

strength of the structure of fishing vessels in Gresik

Regency are carried out through the following stages:

4.1 Preparation

The implementation of the training program was

initiated by coordinating with the chief fisherman

members in the Lumpur harbor area of the Lumpur

Village to inform the members of the fishermen's

association that there would be a training activity to

repair fiberglass fishing boats.

Figure 1: Discussion with the chief fisherman.

Training of Fiberglass Boat Repair for Gresik’s Fisherman to Improve Fiberglass Boat Quality of Boat Construction following the

Indonesian Classification Regulations

233

4.2 Training Implementation

After purchasing materials that will be used in

fiberglass boat training activities, the next event is to

carry out fiberglass boat repair training. Fifteen

participants were attending the training activities

from fishers who participated in the activities of the

local community. The ship used in training is also

one of the training participants. During the training,

participants were guided directly to carry out the

stages in the fiberglass boat repair process.

Before the ship repair work is carried out, the

ITS team briefs and explains the reparation process

and stages that will be carried out. The trainees were

divided into three groups to simplify and share the

work to be done to save repair time. The first group

was tasked with cleaning all ships to be given layers

of fiber using a grinder. The second group is in

charge of preparing the fibers that will be used. The

fibers used are WR 600, CSM 350, and CSM 450.

The third group is tasked with developing putty,

which will be used to patch the hole in the ship and

also to prepare the resin mixture to be used.

Figure 2: Briefing of participants before the repair process.

Figure 3: Cleaning of the hull before the repair process.

Figure 4: Provision of resin on the surface of the boat.

Figure 5: Installation of WR 600 at keel of the boat.

Figure 6: Photo group after the training.

ISOCEEN 2019 - The 7th International Seminar on Ocean and Coastal Engineering, Environmental and Natural Disaster Management

234

4.3 Training Evaluation

Evaluation is carried out during the process and at

the end of the activity. During the ship repair

training process, participants were able to see

extraordinary enthusiasm.

Before getting this training, they did not know

how to mix resins and catalysts properly, did not

know what percentage of catalysts had to be given

and how to process the coating between fiberglass

and resin properly. After attending this training, they

can carry out the above work well.

Many participants held discussions with

presenters while the training was taking place to

solve problems they found during the ship repair

training process. The results of an evaluation of 15

participants in the repair of fiberglass fishing vessels

on a scale of 1 to 5 can be presented as follows:

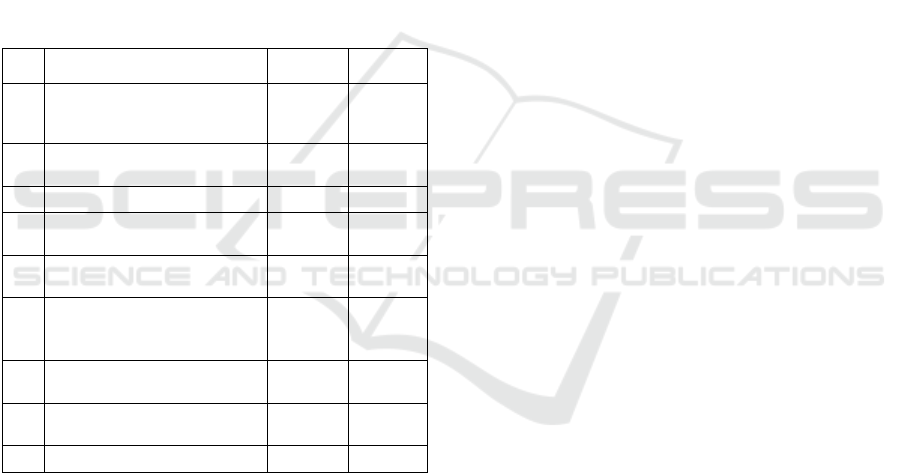

Table 2: Evaluation table for training implementation.

No Questions Average Criteria

1 Material given is needed by

participants

4.53 Good

2 Achieve the objectives of

the training program

4.00 Good

3 Ship repair methods used 4.66 Good

4 The ability of the speaker in

delivering material

4.66 Good

5 Participation of participants

in fish boat repair training

4.00 Good

6 Ship repair training

materials can be applied for

further improvements

4.86 Good

7 Adequate training facilities

(tools and materials, places)

4.33 Good

8 Benefits of training for

participants

4.80 Good

Average 4.48 Good

5 CONCLUSIONS

The fiberglass fish boat repair training in the

Lumpur Village, Gresik District, was well

implemented, and the participants who attended the

training showed high satisfaction. This activity can

also improve the abilities and skills of fishers in the

process of repairing their vessels when damaged.

Participants’ responses to training activities

based on the results of quantitative evaluations are in

the outstanding category with an average rating of

4.48 seen from the aspects of the material needed by

the participants, program objectives, improvement

methods, ability of speakers, facilities, and benefits

for participants.

The results of the evaluation indicate that

fiberglass fishing boat repair training activities are

needed by the fishermen so that later, they can be

used as a provision for boat repair knowledge if

there is damage to their boat.

REFERENCES

Baskoro, A., 2018. Analisa Teknis dan Ekonomis

Pembangunan Kapal Ikan Ukuran 10-20GT

Konstruksi Fibreglass Reinforced Plastic (FRP)

Sesuai Standar Biro Klasifikasi Indonesia. Surabaya.

ITS.

BKI. 2014. Volume XIV, Rules for Non-Metallic

Materials. Jakarta. Biro Klasifikasi Indonesia.

Greene, E., 2006. Composite Boat Repair: Part One,

Damage Assessment. Maryland. Eric Greene

Associate.

Norromadani Y, R., 2016. Pemetaan Perikanan Laut

Kabupaten / Kota Jawa Timur dengan Metode Fuzzy

K-Means Clustering. Seminar Nasional Maritim,

Sains, dan Teknologi Terapan. 14-21.

Ship Structure Comitee., 1990. Use of Fiber Reinforced

Plastics In The Marine Industry. Washington DC.

Ship Structure Comitee.

Training of Fiberglass Boat Repair for Gresik’s Fisherman to Improve Fiberglass Boat Quality of Boat Construction following the

Indonesian Classification Regulations

235