Utilization of Coconut Waste as a Basic Material for Making Carbon

Dots with Acid Oxidation Method

Marpongahtun

1,2

,

Irmayani

1

and Suci A.

1

1

Chemistry Department, Universitas Sumatera Utara, Jalan Bioteknologi No. 1, Medan, Indonesia

2

Laboratorium Penelitian Terpadu Universitas Sumatera Utara, Medan, Indonesia

Keywords: Carbon Dots, Fluorescence, Soot, Acid Oxidation.

Abstract: Utilization of coconut shell soot as raw material for making carbon dots has been successfully carried out.

This study used coconut shell soot with 5 M HNO

3

acid oxidation method which is then the Carbon dots

characteristics were determined using UV light, UV-Vis, TEM analysis, and functional group analysis with

FT-IR. Coconut shell soot is obtained by pyrolysis method. The heating process using a furnace carried out

for 2 hours at 400 °C. Carbon dots produced by heating with 5 M HNO

3

for 12 hours at 100 °C, centrifuged

and dialysis. The yield of carbon dots was 87%. The FT-IR spectrum shows that the Carbon dots formed

produce OH group absorption at 3396 cm

-1

, absorption of C = C at wave number 1637 cm

-1

, absorption of

CO groups, and CH at wave number 1339 cm

-1

, and 835 cm

-1

. Analysis with Transmission Electron

Microscopy shows that carbon dots has an average diameter of 1.50 nm. Absorbance spectrum analysis

(UV-Vis) results in the appearance of new uptake showing the electron transition at a wavelength of 307 nm

and giving green fluorescence under UV light.

1 INTRODUCTION

Fluorescence nanoparticle material is receiving a lot

of attention due to its superiority and wide

application. One of the interesting properties of F-

NPs is the ability to fluency, so it is widely applied

as bioimaging. However, this material involves the

use of heavy metals such as Cd and Pb which are

known to have high toxicity so that their use are

limited. Based on this problem, another alternative is

used to replace the raw material from F-NPs, by

using carbon-based nanoparticles or known as

Carbon dots. Carbon dots is a material that has a

zero dimensional structure and is a product of

carbon nanotubes. Besides has properties that are

almost similar to F-NPs, the ability of fluorescence,

Carbon dots also have high solubility in water,

environmentally friendly, have low toxicity. and low

manufacturing costs (Baker & Baker, 2010). Carbon

sources that can be used as starting material for C-

dots include soot from burning candles (Liu et al.,

2007), nanocrystal cellulose (Marpongahtun et al.,

2018), burning plants (Tan et al., 2013) and coal (Ye

et al., 2013). Carbon dots can also be synthesized

from organic materials such as citric acid (Qu et al.,

2012) and ascorbic acid (Nisa, 2014).

Coconut shell is one of the materials that can be

used as charcoal, the residue produced when burning

charcoal is smoke. The process of the smoke taking

place in the combustion chamber is caused by the

fuel droplets collected into soot because the heating

is too large so that decomposition occurs.

Decomposition will cause carbon solid (soot)

(Arismunndar, 2002). Soot can be made by direct or

indirect heating in the pile or by the pyrolysis

method (Oladeji, 2010).

Various methods for the synthesis of Carbon dots

have been developed by scientists. In general, the

methods for carbon nanoparticle synthesis are based

on 2 approaches, the top-down and bottom-up

approaches. Bottom-up approach includes

electrothermal synthesis, microgear or ultrasonic,

hydrothermal, and acid oxidation (Li et al., 2012).

Carbon dots synthesis in this study uses a bottom-up

approach, through the HNO

3

acid oxidation method.

In addition to acid treatment by HNO

3

, the carbon

dots synthesis is also carried out by the purification

process by centrifugation, dialysis, and other

separation techniques (Li et al., 2012). All of these

processes are to obtain Carbon dots from a carbon

soot combustion. Based on the description above,

the author will conduct research on "Synthesis of

232

Marpongahtun, ., Irmayani, . and A., S.

Utilization of Coconut Waste as a Basic Material for Making Carbon Dots with Acid Oxidation Method.

DOI: 10.5220/0010139700002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 232-236

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Carbon dots from coconut shell soot by acid

oxidation methods".

2 RESEARCH METHODS

2.1 Tools

The tools used in this study are glassware, FT-IR,

FE-SEM, TEM, UV lamps, UV-Visible spectra,

pyrolysis, and centrifugation.

2.2 Material

The materials used in this study are NaOH, HNO

3

(p), distilled water, Coconut Shell, and Dialysis

Membrane.

2.3 Research Procedure

2.3.1 Preparation of Coconut Shell

Coconut shell waste is cleaned from the remaining

coconut husks that still attached, cut into small

pieces and dried in the sun until the weight remains.

2.3.2 Making Soot from Coconut Shell

The dried coconut shell waste is put into a porcelain

cup, then heated using a furnace at 400 °C for 2

hours. The resulting soot was then analyzed by FE-

SEM.

2.3.2 Synthesis of Carbon Dots

Soot of carbon that has been obtained weighed as

much as 500 mg, put in a three neck flask. The

reflux assembly is arranged and a magnetic stir bar

is inserted. Then 100 mL of 5N HNO

3

was added

and refluxed at 100 °C for 12 hours. The result of

reflux is cooled at room temperature, after that it is

messed up using centrifugation at a speed of 4500

rpm for 30 minutes, then from the process will be

obtained 2 phases, the brown supernatant phase and

the solid phase in the form of black deposits, then

the two phases are separated and neutralized with

NaOH 5M (Li et al., 2012).

The neutralization is carried out until pH = 7,

after that the neutralization results are filtered using

filter paper and then dialyzed using a dialysis

membrane for 24 hours by continuing to replace the

aquadest water for 30 minutes 5 times at the

beginning of dialysis.

Dry carbon dots are characterized by UV lamps,

UV-Vis spectros, TEM, FE-SEM, and FT-IR.

3 RESULTS AND DISCUSSION

3.1 Results of Sample Preparation for

Coconut Shell Soot

The soot preparation is carried out using a furnace

tool. This preparation was carried out at 400 °C for 2

hours. The results of soot preparation can be seen in

Figure 1.

Figure 1: Results of coconut shell soot.

From 30 grams of coconut shell used will

obtained 5 grams of black carbon, 16.6% of the

initial weight of the coconut shell. Obtained Carbon

soot then analyzed using FT-IR to determine the

functional groups contained in coconut shell soot

and morphological analysis using FE-SEM.

3.2 Surface Analysis of Soot with

FE-SEM

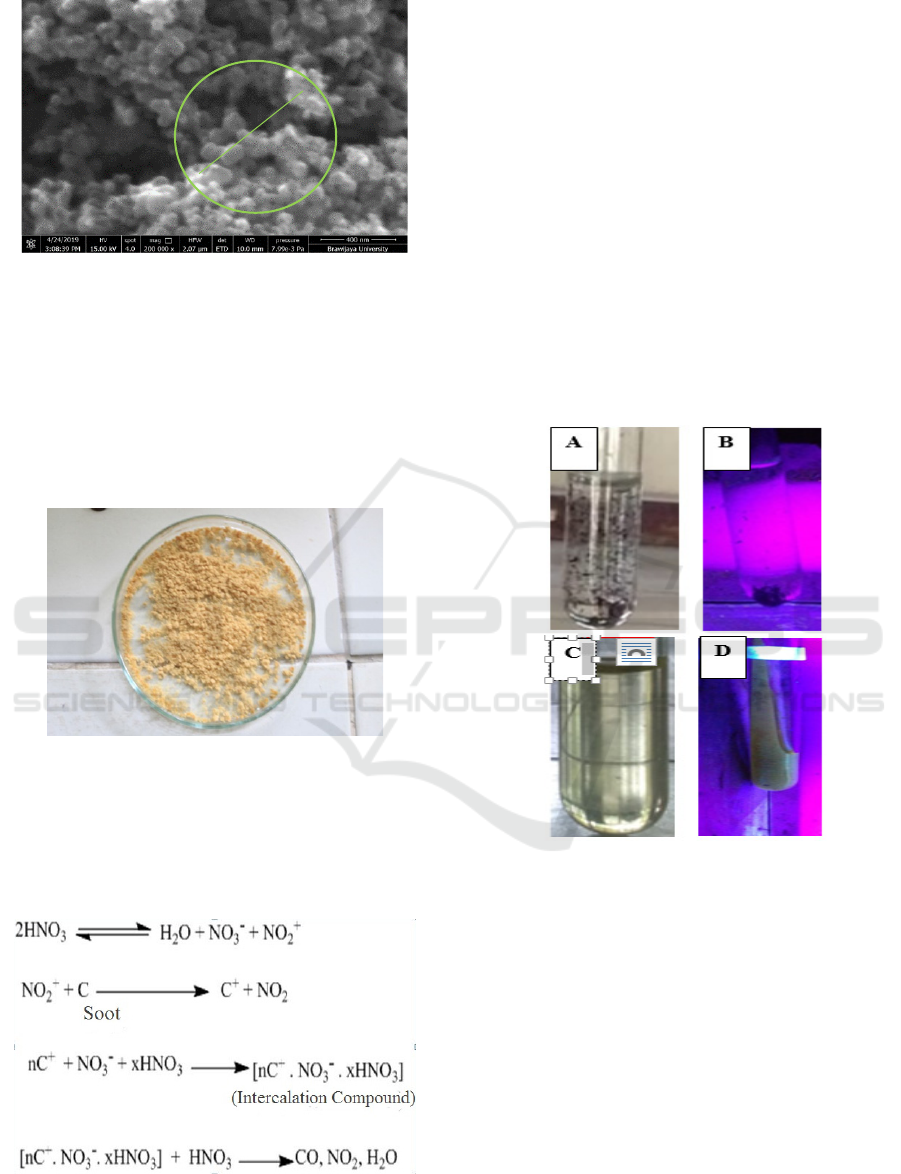

Surface analysis of coconut shell soot using FE-

SEM can be seen in Figure 2.

The results shown in Figure 2 are the results of

coconut shell soot with a heating of 400 °C for 2

hours where the resulting soot has an average

surface diameter of 138.04 µm and appears to be

random piles.

Utilization of Coconut Waste as a Basic Material for Making Carbon Dots with Acid Oxidation Method

233

Figure 2: Results of morphological analysis of coconut

shell soot with enlargement 400 times.

3.3 Soot Carbon dots from Coconut

Shell with Acid Oxidation Method

Carbon dots solution obtained from the coconut shell

in the previous stage placed into a beaker glass then

evaporated to dry in an oven at 90 °C for 12 hours.

The C-dot results obtained can be seen in Figure 3.

Figure 3: Carbon dots from coconut shell soot.

From 0.5 grams of coconut shell soot 0.48 grams

of Carbon dots was obtained equal to 87% of the

initial weight of soot. Carbon dots from coconut

shell soot produce a yellowish brown color. The

oxidation reaction scheme can be seen in Figure 4.

Figure 4: Oxidation reaction scheme.

The addition of HNO

3

aims to disperse by

oxidizing molecules that have undergone

agglomeration. The reaction between carbon from

soot and 𝑁𝑂

ions causing electrons displacement

by the formation of complex compounds produced

Carbon dots are different from the base material.

Further interaction of complex compounds with

HNO

3

forms intercalation compounds (Savitskii,

2017).

3.4 Characterization

3.4.1 Analysis with UV Lamps

Fluorescence testing is carried out physically

through observation under a UV lamp. Carbon dots

produced through the acid oxidation method produce

flourescence under UV light as shown in Figure 5.

Figure 5: Carbon dots irridiation with UV lamps results:

(a) Negative control of coconut shell soot in visible light;

(b) Negative control of coconut shell soot under UV light;

(c) Carbon dots in visible light; (d) Carbon dots under UV

light.

The success of Carbon dots synthesis can be seen

from the fluorescence analysis using UV lamps.

Irradiation is carried out on a Carbon dots solution

with a concentration of 1000 ppm which can be seen

in Figure 5. These results show a green glow and in

accordance with the results reported by Ray et al.

(2009). Fluorescence occurs when electrons move

from the valence band to thes conduction band after

being excited by the excitation source in this case

UV light. Besides having good fluorescence

intensity, Carbon dots also have high solubility in

water (Liu et al., 2007). Figure 5 also shows that

138

,

04

µ

m

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

234

Carbon dots from coconut shell soot have higher

solubility compared to negative control. The

negative control made from a soot solution of pure

coconut shell before oxidation, dissolved in water at

concentration of 1000 ppm. The high solubility point

of Carbon dots is due to the successful functioning

of the Carbon dots surface. The functionalization

process will bring up functional groups such as

hydroxyl and carboxyl which will cause the surface

of Carbon dots to be negatively charged, so that

Carbon dots will be hydrophilic (Liu et al., 2007).

3.4.2 Absorbance Spectrum Analysis with

UV-Vis Spectrophotometry

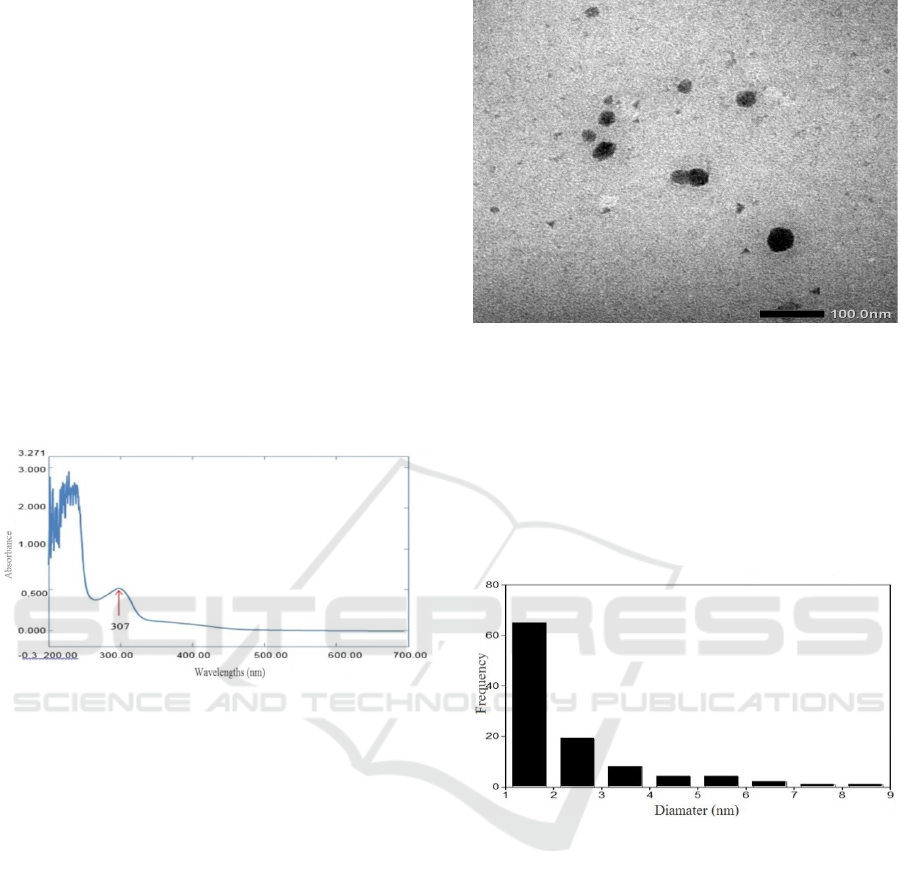

The synthesis results of Carbon dots obtained were

then characterized using UV-Vis spectrophotometry.

Measurements were made at a wavelength of 200-

700 nm with wavelength interval of 100 nm.

Figure 6: Absorbance curve with wavelengths from

coconut shell soot carbon dots.

Spectrum of the negative control Carbon dots of

coconut shell soot does not produce new absorption

at certain wavelengths (Figure 6), different from the

results of the Carbon dots spectrum of coconut shell

soot that produce new absorption at wavelengths of

307 nm with absorbance of 0.5040.

3.4.3 Analysis of C-dot Average Diameter by

using TEM

TEM analysis is used to find the average diameter of

the surface and to magnification of objects in a small

size. Carbon dots shaped like a ball in the form of

dots.

Figure 7: Results of TEM carbon dots with a dispersion of

400000 times.

Carbon dots is a new class of carbon

nanomaterials under 10 nm in size (Baker & Baker,

2010) based on the calculation of Carbon dots

diameter measurements that have been carried out

using the Image J application, obtained the average

diameter of C-dot soot in coconut shell is 1.50 nm.

The particle size distribution illustrated in Figure 8.

Figure 8: Result average diameter.

3.4.4 Analysis of the Function Group with

using FT-IR

Functional group analysis is performed using Opus

Alpha's Bruker FT-IR. Wave numbers obtained from

coconut shell soot and Carbon dots can be seen in

Figure 9.

Utilization of Coconut Waste as a Basic Material for Making Carbon Dots with Acid Oxidation Method

235

Figure 9: Wave numbers of coconut shell soot and C-dots

obtained using FT-IR.

In addition to measurements taken for Carbon

Dots samples, FT-IR measurements were also carried

out for samples of coconut shell soot. This can be

seen in Figure 9, and the interpretation of functional

groups seen in the picture explain that there are

differences in the absorption peaks between Carbon

dots samples and soot of coconut shells. Coconut

shell soot does not produce peak O-H absorption.

Carbon dots of coconut shell soot produce peak O-H

at wave number 3396 cm

-1

. These results explain that

in the structure of Carbon dots that have been

synthesized there are carboxylic functional groups.

This is consistent with the results on Carbon dots

coconut shell soot. Based on experiments reported by

Hu et al. (2014), coal also has a C = C uptake at a

wavelength of 1585 cm

-1

. These results are in

accordance with the Carbon dots that have been

synthesized, although experiencing a shift that is at

wave number 1637 cm

-1

and at wave number 1339

cm

-1

for C-O and 835 cm

-1

for C-H uptake.

4 CONCLUSIONS

Carbon dots can be made from coconut sheell soot

with acid oxidation method. The yield of Carbon

dots obtained was 87% of the initial weight of the

soot. The FT-IR spectrum shows that the Carbon

dots formed produce OH group absorption at 3396

cm

-1

, absorption of C = C at wave number 1637 cm

-

1

, absorption of CO groups, and CH at wave number

1339 cm

-1

, and 835 cm

-1

. Analysis with

Transmission Electron Microscopy shows that

carbon dots has an average diameter of 1.50 nm.

Absorbance spectrum analysis (UV-Vis) results in

the appearance of new uptake showing the electron

transition at a wavelength of 307 nm and giving

green fluorescence under UV light.

REFERENCES

Arismunndar, W. (2002). Motor Bakar Torak (5th ed.).

Institut Teknologi Bandung.

Baker, S. N., & Baker, G. A. (2010). Luminescent Carbon

Nanodots: Emergent Nanolights. Angewandte Chemie

International Edition, 49, 44. https://doi.org/10 .1002 /

anie. 200906623

Hu, C., Yu, C., Li, M. Y., Wang, X., Yang, J., Zhao, Z.,

Eychmuller, A., Sun, Y. P., & Qiu, J. (2014).

Chemically tailoring coal to fluorescent carbon dots

with tuned size and their capacity for Cu(II) detection.

Small, 10(23), 4926–4933.

Li, H., Kang, Z., Liu, Y., & Lee, S. T. (2012). Carbon

nanodots: synthesis, properties and applications.

https://doi.org/doi:10.1039/c2jm34690g

Liu, H., Ye, T., & Mao, C. (2007). Preparation Of

Flourescent Carbon Nanoparticles From Candle Soot.

Angewandte Chemie International Edition, 46, 6473–

6475. https://doi.org/10.1002/ anie.200701271

Marpongahtun, Gea, S., Muis, Y., Andriayani, Novita, T.,

& Piliang, A. F. (2018). Synthesis of Carbon Nanodots

from Cellulose Nanocrystals Oil Palm Empty Fruit by

Pyrolysis Method. Journal of Physics: Conference

Series, 1120(1), 1–6. https://doi.org/10.1088/1742-

6596/1120/1/012071

Nisa, A. K. (IPB). (2014). Sintesis nanopartikel karbon

berfluoresens.

Oladeji, J. (2010). Fuel characterization of briquettes

produced from corncob and rice husk resides. Pacific

Journal of Science and Technology, 11(1), 101–106.

Qu, S. G., Wang, X., Lu, Q., Lie, X., & Wang, L. (2012).

A Biocompatible Fluorescent Ink Based on Water-

Soluble Luminescent Carbon Nanodots. Angewandte

Chemie, 124, 1–5.

https://doi.org/10.1002/amge.201206791

Ray, S. C., Saha, A., Jana, N. R., & Sarkar, R. (2009).

Fluorescent Carbon Nanoparticle: Synthesis,

Characterization, and Bioimaging Application. J Phys

C, 113(43), 18548–18551.

https://doi.org/10.1021/jp905912n

Savitskii, D. P. (2017). Preparation and characterization of

colloidal dispersions of graphene-like structures from

different ranks of coals. In Ranliao Huaxue

Xuebao/Journal of Fuel Chemistry and Technology

(Vol. 45, Issue 8, pp. 897–907).

Tan, M., Zhang, L., Tang, R., Song, X., Li, Y., Wu, H.,

Wang, Y., Lv, G., Liu, W., & Ma, X. (2013).

Enhanced Photoluminescence and Characterization of

Multicolor Carbon Dots Using Plants Soot as a Carbon

Source. Talanta, 115, 950–956.

Ye, R., Xiang, C., Lin, J., Peng, Z., Huang, K., Yan, Z.,

Cook, N. P., Samuel, E. L. G., Hwang, C. C., Ruan,

G., Ceriotti, G., Raji, A. R. O., Martí, A. A., & Tour,

J. M. (2013). Coal as an abundant source of graphene

quantum dots. Nature Communications,

4, 1–7.

https://doi.org/10.1038/ncomms3943

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

236