Manufacture and Measurement of Graphene-based Supercapasitor

Electrodes and Characterization using Charging-discharging Method

Ivan Anggia Sihotang, Kerista Tarigan and Syahrul Humaidi

Department of Physics, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan, Indonesia

Keywords: Graphene, Activated Carbon, Epoxy Resin, Phosphoric Acid (H

3

PO

4

), Aluminum Plate, Supercapacitor.

Abstract: Supercapacitors or known as EDLCs (Electrochemically double-layer Capacitors) are electric double layers

separated by separators. Supercapacitors provide very high power density values, long repetition cycles and

have a higher repetition efficiency compared to batteries. This study aims to design a supercapacitor with a

material of 0.905 gram graphene powder, 2 gram activated carbon, epoxy resin (3 spoonfuls of spatula),

Phosphoric Acid (H

3

PO

4

) electrolyte solution, and aluminum plate with a size of 8 cm x 8 cm, 6 cm x 6 cm,

and 5 cm x 5 cm as collector media. The research was carried out in four stages, namely mixing graphene

powder and epoxy resin, coating graphene-epoxy resin powder on both plates, sowing activated carbon on

the surface of the plate, and combining the two plates into one supercapacitor section. The test results show

that with the charging-discharging method, the size of 8 cm x 8 cm which is carried out charging for 3

minutes can store a voltage of 1.65 Volt, on the size of 6 cm x 6 cm done charging for 3 minutes can store a

voltage of 1.44 Volt, and at a size of 5 cm x 5 cm by charging for 3 minutes can store a voltage of 1.05 Volt.

So it can be proven that the cross-sectional area of a supercapacitor greatly influences the value of the stored

voltage.

1 INTRODUCTION

The development of advancements in technology

now makes everyone need electronic devices that are

able to support their work to make it easier and more

practical. Therefore these electronic devices must

have a great ability to store energy. Large energy

storage is needed so that these electronic devices are

able to work optimally and are durable in order to

support the work to be more practical and efficient.

One of the energy storage that is commonly used is

the battery, the battery is used because it is more

practical and only disposable, but this is also a

disadvantage because it cannot last long in use, has

no economic value, produces waste that is harmful to

the environment, and the power is also stored tend to

be small. That is why lately people have begun to

turn to supercapacitors.

Supercapacitors or known as EDLCs

(Electrochemically double-layer Capacitors) are

electric double layers separated by separators.

Supercapacitors provide very high power density

values, long repetition cycles and have a higher

repetition efficiency compared to batteries. From a

technical point of view, supercapacitors have a

relatively large number of cycles (> 100000 cycles),

high energy density, large energy saving capacity,

simple principles and easy construction (Hyeok,

2001). Whereas in terms of user friendliness,

supercapacitors increase safety because there are no

corrosive materials and less toxic materials.

Supercapacitors collect the charge from the

absorption of electrostatic ions onto the surface of the

double layer electrode / electrolyte to the conduction

material at a specific surface area in this case,

activated carbon. The electrodes commonly used are

carbon and also metal plates. But what is often used

lately is carbon because metal plates have no

economic value and their ability as an electrode to

store a charge is relatively small. Therefore carbon is

more often used as an electrode in supercapacitors.

To increase the specific surface area, carbon is

activated so that its ability to increase the charge is

better.

Among carbon materials, graphene is the most

promising material as an electrode for energy storage

device applications because it has a high surface

area, is relatively inexpensive, has high electrical

conductivity. This material has an electron mobility

of 15,000 cm

2

/V•s, a thermal conductivity of 5,000

214

Anggia Sitohang, I., Tarigan, K. and Humaidi, S.

Manufacture and Measurement of Graphene-based Supercapasitor Electrodes and Characterization using Charging-discharging Method.

DOI: 10.5220/0010139300002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 214-218

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reser ved

Wm

-1

K

-1

. Graphene is an ideal material for

fabricating supercapacitors because it has a large

surface area of 2630 m

2

/g and intrinsic

electrochemical capacitance of ~ 21 mF/cm

2

. This

value is the maximum value for all carbon-based

materials (K & Carlen, 2000).

In this research, graphene-based supercapacitor

electrodes will be made, where graphene functions as

carbon material used in the process of making

supercapacitor electrodes.

2 MATERIALS AND METHODS

2.1 Material Used in Research

The materials used in this study are graphene

powder, activated carbon, epoxy resin, phosphoric

acid (H

3

PO

4

) electrolyte solution, aluminum plate,

and separator (tissue).

Graphene functions as a cathode electrode and a

double layer super capacitor anode that will receive

electrical energy from the collector and then store the

electric charge while after that the electrical charge is

wasted. In this study graphene powder used was

0.905 grams for each supercapacitor.

Activated carbon is used as an anode and cathode

just like graphene powder, and activated carbon

powder also functions as a store of electric charge

and a second layer after graphene to be given an

electrolyte solution. In this study active carbon

powder was used for 2 grams for each

supercapacitor.

Epoxy resins are used as an adhesive between

graphene powder, activated carbon and laminating

foil. in addition, epoxy resin also serves as a

protector so that the electrolyte liquid cannot touch

the collector laminating foil and also so that there is

no loss of capacitance that will make electrons move

to the collector. In this study epoxy resins used 3

spoonfuls of spatula for each supercapacitor.

Phosphoric Acid (H

3

PO

4

) electrolyte solution

functions as an electrolyte in the supercapacitor to be

dripped into a separator (tissue), where positive and

negative ions will react. Positive and negative ions

will move freely when before being given a voltage

and when given a positive and negative ion will be

attracted to the electrode.

This separator (tissue) functions as a separator

between anode and cathode mixed with an electrolyte

solution and also as a polarity bridge.

The aluminum plate is used as a collector

between the anode and the cathode, which is a double

layer or the right and left side of the supercapacitor

that will receive electrical energy and then be

delivered to the electrodes. The aluminum plate used

has a thickness of 0.2 mm with a size of 8 cm x 8 cm,

6 cm x 6 cm and 5 cm x 5 cm. The surface of the

aluminum plate must be clean so that the graphene

powder and activated carbon can be attached to the

surface of the aluminum plate.

2.2 Overall Research Procedure

This research procedure has several stages. First, the

aluminum plate is divided into two equal parts, each

measuring 8 cm x 8 cm, 6 cm x 6 cm and 5 cm x 5

cm. Then graphene is mixed with epoxy resin

powder with a ratio of 0.905 grams of graphene

powder and 3 tablespoons spatula epoxy resin, after

that it is stirred until evenly distributed. The results

of the mixture of graphene and epoxy resin were

immediately applied to both parts of the aluminum

plate, each of which had a specified size. Let stand

the results for 5 minutes, then sprinkle the activated

carbon powder on top of the aluminum plate evenly,

so that the activated carbon is attached to the

aluminum plate.

Second, unite the two parts of the aluminum plate

by placing a tissue between the two parts of the

aluminum plate while dripping with a solution of

Phosphoric Acid (H

3

PO

4

) electrolytes to the tissue in

an adequate ratio. Then press and clamped both sides

of the aluminum plate that was joined together so

that it sticks. Make a current collector on each part of

the electrode using a crocodile cable / clamp. After

that measured the voltage (V) stored and the length

of time with the charging-discharging method.

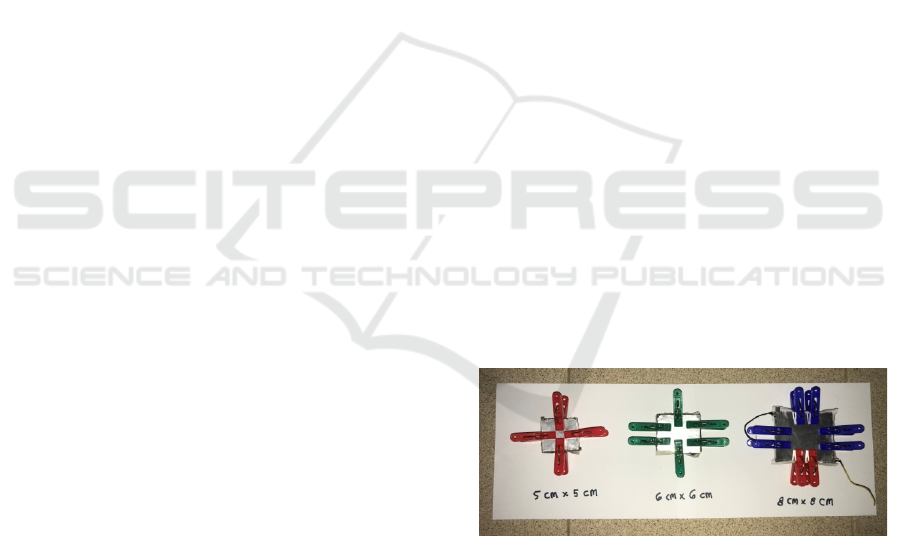

Figure 1: Three supercapacitors designed.

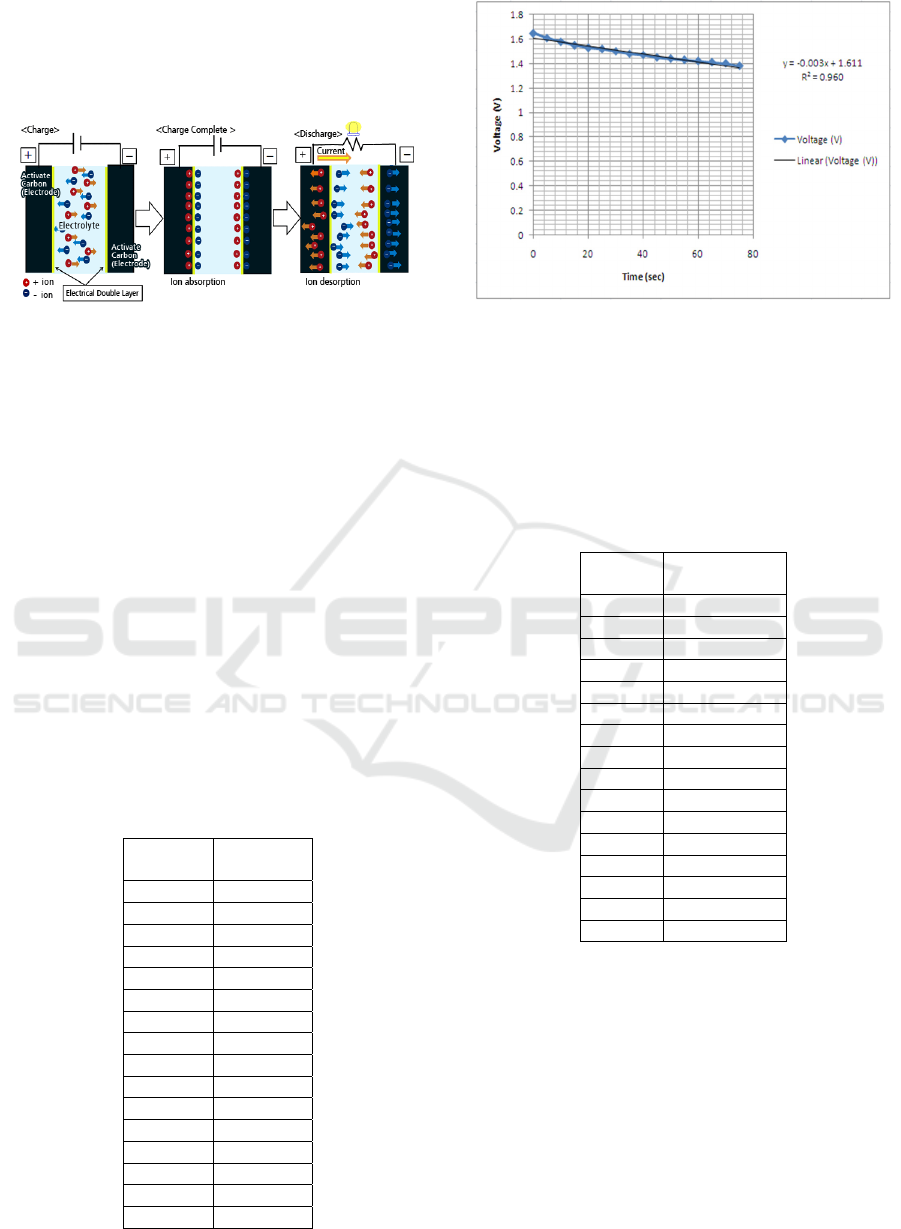

Double-layer electric capacitors or EDLCs are

based on the working principle of the dual electric

layers that form on the inter-surface layer between

activated carbon and electrolytes as dielectric. The

mechanism of absorption and desorption of ions on

both layers of activated carbon electrodes plays a role

in EDLCs charging and emptying. By applying

voltage to the facing electrodes the ions will be

attracted to the surface of the two electrodes and the

charging process will occur. Instead, ions will move

Manufacture and Measurement of Graphene-based Supercapasitor Electrodes and Characterization using Charging-discharging Method

215

away when EDLCs is used or discharging (Murata

America Co. Ltd., 2011). The charging and

discharging process of EDLCs can be seen in Figure

2.

Figure 2: Scheme of charging and discharging process on

EDLCs (Murata co, Ltd, 2011).

3 RESULT AND DISCUSION

3.1 Charging-discharging Method

The results of the research making supercapacitors by

varying the cross-sectional area with a size of 8 cm x

8 cm, 6 cm x 6 cm, and 5 cm x 5 cm. Where in this

test using the charging-discharging method, charging

for 3 minutes with an input voltage (V) of 3 Volt.

3.1.1 Testing on a Supercapacitor with Size

of 8 Cm x 8 Cm

With the charging-discharging method, a storage

voltage of 1.65 Volt is obtained. And the time of

discharge can be seen in the table below.

Table 1: Discharge Time.

Time

(

sec

)

Voltage

(

V

)

0 1.65

5 1.61

10 1.58

15 1.55

20 1.53

25 1.52

30 1.50

35 1.48

40 1.47

45 1.45

50 1.44

55 1.43

60 1.42

65 1.41

70 1.40

75 1.38

Figure 3: Graph of discharge voltage vs time.

3.1.2 Testing on Supercapacitor with a Size

of 6 Cm x 6 Cm

With the charging-discharging method, a storage

voltage of 1.44 Volt is obtained. And the time of

discharge can be seen in the table below.

Table 2: Discharge Time.

Time

(sec)

Voltage

(V)

01.44

51.42

10 1.41

15 1.39

20 1.37

25 1.36

30 1.34

35 1.33

40 1.32

45 1.31

50 1.29

55 1.28

60 1.27

65 1.26

70 1.25

75 1.24

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

216

Figure 4: Graph of discharge voltage vs time.

3.1.3 Testing on Supercapacitors with a Size

of 5 Cm X 5 Cm

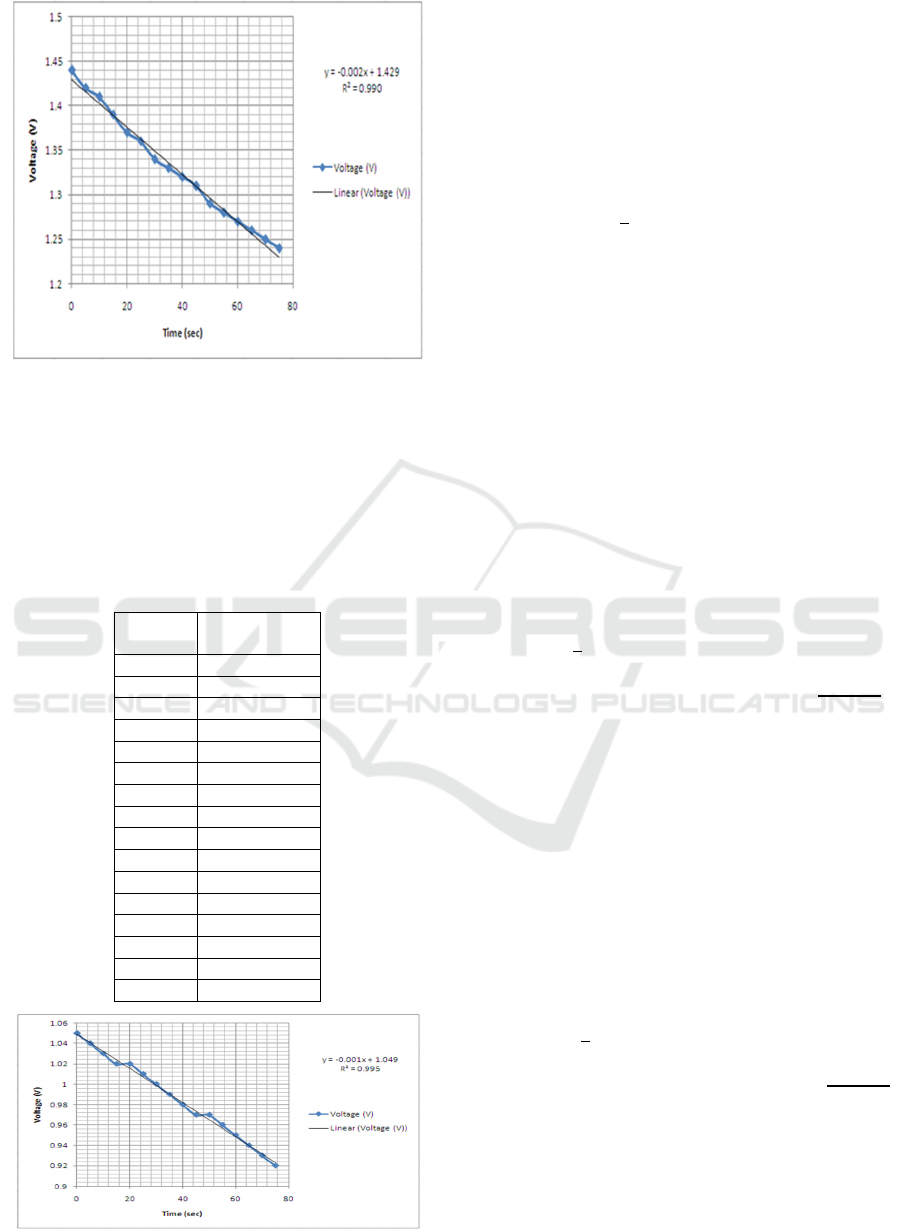

With the charging-discharging method, a storage

voltage of 1.05 Volt is obtained. And the time of

discharge can be seen in the table below.

Table 3: Discharge Time.

Time

(s)

Voltage

(V)

0 1.05

5 1.04

10 1.03

15 1.02

20 1.02

25 1.01

30 1.00

35 0.99

40 0.98

45 0.97

50 0.97

55 0.96

60 0.95

65 0.94

70 0.93

75 0.92

Figure 5: Graph of discharge voltage vs time.

3.2 Capacitance Testing of

Supercapacitor

This test is carried out to find out what is the value of

capacitance in each supercapacitor. Where the plate

cross-sectional area is known, the distance between

the two plates and the dielectric constant value of the

material. By using the equation below.

𝐶 𝜀

o

𝜀

r

(3.1)

3.2.1 Capacitance Testing of Supercapacitors

with a Size of 8 cm x 8 cm

Determine the cross-sectional area of the

supercapsitor using the equation below.

A = s x s (3.2)

Then obtained:

A = 8 cm x 8 cm

A = 64 cm

2

Next determine the capacitance value using equation

3.1. where for the similar

𝜀

r

separator value which is

a polymer material is assumed to be 10,000 through

previous research. So we get the results:

𝐶 𝜀

o

𝜀

r

𝐶

8.854 𝑥 10

𝐹. 𝑚

𝑥 10000 𝑥

64 𝑐𝑚

1 𝑚𝑚

𝐶 0,57 𝑥 10

𝐹

3.2.2 Capacitance Testing on

Supercapacitors with Size 6 cm x 6 cm

Determining the cross-sectional area of the

supercapsitor by using equation 3.2 we get:

A = s x s

A = 6 cm x 6 cm

A = 36 cm

2

Next determine the capacitance value using equation

3.1 so that the results are obtained:

𝐶 𝜀

o

𝜀

r

𝐶

8.854 𝑥 10

𝐹. 𝑚

𝑥 10000 𝑥

36 𝑐𝑚

1 𝑚𝑚

𝐶 0,319 𝑥 10

𝐹

Manufacture and Measurement of Graphene-based Supercapasitor Electrodes and Characterization using Charging-discharging Method

217

3.2.3 Capacitance Testing on

Supercapacitors with a Size of 5 Cm X

5 Cm

Determining the cross-sectional area of the

supercapsitor by using equation 3.2 we get:

A = s x s

A = 5 cm x 5 cm

A = 25 cm

2

Next determine the capacitance value using equation

3.1 so that the results are obtained:

𝐶 𝜀

o

𝜀

r

𝐶

8.854 𝑥 10

𝐹. 𝑚

𝑥 10000 𝑥

25 𝑐𝑚

1 𝑚𝑚

𝐶 0,221 𝑥 10

𝐹

4 CONCLUSIONS

Manufacture and Measurement of Graphene-Based

Supercapasitor Electrodes and Characterization

Using Charging-Discharging Method have been

done. The results show that with the charging-

discharging method, a supercapacitor with a size of 8

cm x 8 cm, 6 cm x 6 cm, and 5 cm x 5 cm after

charging for 3 minutes with a 3 volt input voltage

will obtain the stored voltage in a row of 1.65 volts,

1.44 volts, and 1.05 volts. And by varying the cross-

sectional area of the supercapacitor, the capacitance

value can also be determined using a predetermined

equation. So that it can be proven that the cross-

sectional area of a supercapacitor greatly affects the

value of capacitance and the amount of voltage

stored.

REFERENCES

Hyeok, A. K. (2001). Electrochemical Properties Of High

Power Supercapacitors Using SingleWalled Carbon

nanotube Electrodes. Advanced Functional Materials,

11, 387–392.

K, R., & Carlen, M. (2000). Electrochim. Acta, 45, 2483.

Murata America Co. Ltd. (2011). High Performance

Electrical Double Layer Capacitor. Smyrna: Murata

Electronics.

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

218