Utilization of Alginate Powder Strengthened with Silicon Rubber as

Composite Bolus Material for Radiotherapy 8 Mev Energy

Herty Afrina Sianturi

1

, Juliaster Marbun

1

, Ikhwanuddin

1

, Azhari

1

and Lincewati Sidauruk

2

1

Department of Physics, Universitas Sumatera Utara, Medan, Indonesia

2

Balai Pengamanan Fasilitas Kesehatan, Medan, Indonesia

Keywords: Cancer, Radioteraphy, Composite Bolus, CT scan, RED

Abstract: Cancer is one of the highest causes of death in the world. The incidence is increasing every year. the incidence

of cancer in Indonesia (136.2 / 100,000 population) ranks 8th in Southeast Asia, whereas in Asia ranks 23rd.

Radiotherapy is a cancer treatment method that utilizes ionizing radiation. Research is conducted on the use

of alginate powder which is reinforced with silicon rubber as a composite bolus material for radiotherapy

shield applications at 8 mev energy. bolus composite as a radiotherapy shield using a mixture of silicon rubber,

catalyst and alginate powder in variations (80:18:2)% wt, (80:16:4)% wt, (80:14:6)% wt, (80:12:8)% wt and

(80:10:10)% wt also with bolus thicknesses of 5 mm, 10 mm and 15 mm. A mixture of silicon rubber is one

of the synthetic polymer materials derived from polydimethylsiloxane (PDMS), alginate powder and catalysts

are expected to fill the blanks of bolus made from PDMS so that it has a more even density. Composite boluses

were analyzed using CT-Scan to determine the relative electron density (RED) value, mechanical properties

(tensile strength, and elastic modulus), and absorbed dose analysis using electrons at 8 MeV energy.

1 INTRODUCTION

Cancer is one of the highest causes of death in the

world. the incidence is increasing every year.

According to WHO, cancer is a general term for a

large group of diseases that can affect every part of

the body. Other terms used are malignant tumors and

metastatic neoplasms which are the main causes of

cancer deaths. Based on Globocan data, in 2018 there

were 18.1 million new cases with a mortality rate of

9.6 million deaths from cancer, where one in five men

and one in six women in the world experience cancer.

The data also states that one in eight men and one in

11 women died of cancer. Director General of

Disease Prevention and Control (P2P) Ministry of

Health (Kemenkes) Anung Sugihantono explained

the incidence of cancer in Indonesia (136.2 / 100,000

population ) ranks 8th in Southeast Asia, whereas in

Asia 23

rd

. Seeing a high enough number, the Ministry

of Health is undertaking prevention efforts that go

hand in hand with prevention for cancer sufferers in

Indonesia, namely by optimizing health facilities,

early detection for those who have not been detected

by cancer, and radiotherapy to those affected by

cancer as a step to control cancer. Radiotherapy is a

cancer treatment method that utilizes ionizing

radiation. Linear accelerator (Linac) is a radiotherapy

device that consists of a number of discrete

components. Linac serves to accelerate high-energy

electrons by using RF waves before the electrons

reach the target to produce X-rays. Nowadays linear

accelerators can produce two different energies

namely X-rays and electrons (Chianese and

Chamberlain, 2009)

However, during the process of radiotherapy

using linac, it was found several other problems that

there were some radiation beams which were likely to

affect healthy tissue (normal) so that it could

potentially cause unwanted new cancers. Then, when

treating cancer that is on the surface of the skin

(Superficial), the surface dose resulting from the use

of electron beams has not reached 100%. So as to

overcome these problems a radiotherapy facility

known as a bolus is needed.

Bolus in radiotherapy at this time which has

advantages and disadvantages, but in general to use

boluses, the main thing to note is the flexibility of the

material must be checked, the material must be stable

with temperatures between 4°C to 52°C and

dosimetric properties and electron density must be

equivalent to water. In addition, the bolus to be used

is odorless, non-sticky, and not harmful to the skin

Afrina Sianturi, H., Marbun, J., Ikhwanuddin, ., Azhari, . and Sidauruk, L.

Utilization of Alginate Powder Strenged with Silicon Rubber as Composite Bolus Material for Radiotheraphy 8 Mev Energy.

DOI: 10.5220/0010139200002775

In Proceedings of the 1st International MIPAnet Conference on Science and Mathematics (IMC-SciMath 2019), pages 209-213

ISBN: 978-989-758-556-2

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

209

(Podgosark, 2006). Based on research from Dodi

Junaedi in the manufacture of commercial boluses

from PDMS material, with the title of the analysis of

the use of polydimethyl siloxane as a bolus in

radiotherapy to assess the feasibility of using

polydimethyl siloxane as a material for making

radiotherapy boluses with thickness variations to

determine the value of CT Number and absorption

dose with 8 MeV electrons from the results of the

study found that the nature of polydimethyl siloxane

can increase the surface dose, decrease the dose range

depth and density similar to soft tissue (Junaedi,

2016). Composite is an amalgamation of different

materials whose purpose is to find new materials that

have intermediate properties of the constituent

materials which would not be obtained if the

constituent materials stand alone. The nature resulting

from the incorporation of materials is expected to

improve the weaknesses and weaknesses of the

constituent materials (Rianto, 2011).

Composite material consists of two main

constituents namely matrix and reinforcement /

reinforcement. The matrix is a component forming

and binding in the composite. Some composites have

a combined matrix consisting of two or more layers

with different compositions and arranged alternately

while the filler as a reinforcing material or filler on

the composite (Nayiroh, 2013).

Utilization of silicon rubber in polymer resin as a

matrix phase is an engineering that is carried out to

obtain the elastic characteristics of composite

materials. Considering that silicon rubber is part of a

polymer that has advantages in terms of elasticity, so

mixing the two is identified as being able to provide

better toughness properties (Sujana and Widi, 2014).

Alginate is part of a linear copolymer consisting of

two monomeric units, namely D-mannuronic acid and

L-guluronic acid. One of the most important

properties in the use of sodium alginate, potassium

alginate and magnesium alginate is its ability to form

gels that are adapted to calcium ions. Sources of

calcium are usually in the form of calcium carbonate,

calcium sulphate, calcium chloride, calcium

phosphate and calcium tartrate. Besides having the

ability to form a gel, alginate is also used as a

thickener (water binder), emulsifier, and stabilizer

(Kirk, 1994).

Relative electron density (RED) is used as a tool

to capture images and to test the performance of bolus

radiotherapy by first determining the bolus

tomographic image capture using CT-Scan. The bolus

tomographic image capture method uses axial

scanning method with the tube voltage and current

used at 120 kV and 160 mA. The results of the

tomographic image on the bolus are sent to the

computer so that the CT-Number value can be read in

the treatment planning system (TPS) program. The

relative electron density (RED) value of bolus

silicone rubber without alginate mixture is 1.168

(Mayles et al., 2007).

Based on the description above, a study

was carried out on the use of alginate powder

reinforced with silicon rubber as a composite bolus

material for radiotherapy shielding applications at 8

MeV energy. Composite bolus as a radiotherapy

shield by using a mixture of silicon rubber, catalyst

and alginate powder at variations (80:18:2)% wt,

(80:16:4)% wt, (80:14:6)% wt, (80:12:8)% wt and

(80:10:10)% wt also with bolus thicknesses of 5 mm,

10 mm and 15 mm. A mixture of silicon rubber is one

of the synthetic polymer materials derived from

polydimethylsiloxane (PDMS), alginate powder and

catalysts are expected to fill the blanks of PDMS-

based bolus so that it has a more even density.

Composite boluses were analyzed using CT-Scan to

determine the relative electron density (RED) value,

mechanical properties (tensile strength, and elastic

modulus), and absorbed dose analysis using electrons

at 8 MeV energy.

2 METHODOLOGY

The method used in making bolus material in this

study is the coprecipitation method, which uses a

chemical solution deposition technique that is mixed

with the wet mixing method which is then molded and

cooled.

2.1 Tools and Materials

Digital Balance, 100 mL Plastic Beaker, Bowl,

Mixer, Glass, Spatula, Oven, Caliper, Scissor, Linear

Accelerator (LINAC) brands from Siemens Primus,

Solid Water Phantom, Computed Tomography

Scanner (CT-Scanner) Chamber Plan Parallel

Ultimate Testing Machine, Alginate as filler material

for RTV 52 Silicone rubber as a matrix (adhesive),

bluesil Catalist 60R.

2.2 Research Procedure

The stages of the use of alginate powder reinforced

with silicon rubber as composite bolus material for

radiotherapy shielding applications at 8 mev energy,

namely making bolus using materials: alginate

powder, silicone rubber, bluesil catalyst, testing

mechanical properties (tensile strength, and elastic

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

210

modulus), CT-Scan to determine the relative electron

density (RED) value, and absorbency dose analysis

using electrons at 8 MeV energy.

3 RESULTS AND DISCUSSION

Based on the research that has been done, namely the

use of alginate powder reinforced with silicon rubber

as a composite bolus material for radiotherapy

shielding applications at 8 MeV energy, the results of

the tests performed are mechanical tests (tensile

strength and elastic modulus), analyzed using CT-

Scan to determine the relative electron density (RED)

value, and absorbance dose analysis using electrons

at 8 MeV energy.

3.1 Tensile Strength Test

Tensile strength is a test performed to determine the

ability of radiotherapy bolus in holding a load or a

vertical mechanical force that is given until the

occurrence of broken or broken where tensile strength

testing using Universal Testing Machine (UTM) with

ASTM D 882. From the results of research conducted

using the Strong equation Pull = F / A

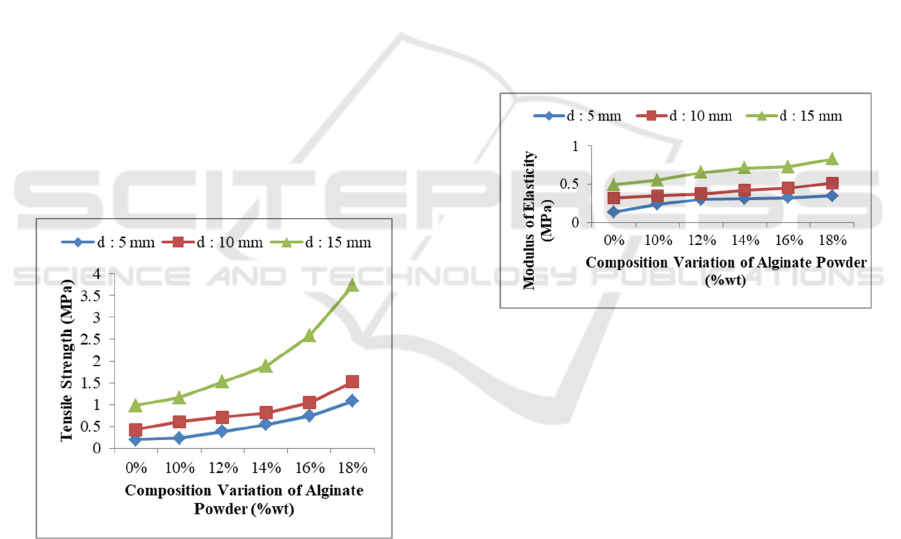

Figure 3.1. Results of Bolus Tensile Strength Test Based on

Alginate Powder and Silicon Rubber in Various

Composition Variations

From observations based on the graph in Figure

3.1. above shows that the value of tensile strength

increases in proportion to the increase in the

composition of the filler (filler), namely alginate

powder. This is shown from the results of the study

that the optimum conditions obtained tensile strength

values in the composition of silicone rubber: alginate

powder (80:20) % wt at a thickness of 15 mm is 3.834

MPa and less optimum conditions in the composition

of silicone rubber: alginate powder (80:12)% wt at a

thickness of 5 mm produces a tensile strength of

0.329 MPa. The value of tensile strength decreases

when the filler mass of alginate powder decreases

causing hydrogen (H

2

) bonds and makes the distance

between the bolus polymer chains more tenuous.

Where the hydrogen bond is a very weak bond,

weaker than the covalent bond which causes an

increase in the speed of viscoelastic response and

molecular mobility of polymer chains in the compiler

of radiotherapy bolus.

3.2 Modulus of Elasticity

Elastic modulus test is a test that aims to find out how

resistant a bolus material experiences strain to elastic

deformation when given vertical outside stress.

Where the elastic modulus testing procedure refers to

ASTM D 882-97 which results in the following

graphic form:

Figure 3.2. Test Results for Young Bolus Modulus Based

on Alginate Powder and Silicon Rubber in Various

Composition Variations

Figure 3.2. shows that the modulus of elasticity

increases in proportion to the addition of alginate

powder composition and bolus thickness. The results

showed that the bolus which had optimum modulus

of elasticity in the composition of silicone rubber:

alginate powder (80:20)% wt at a thickness of 15 mm

was 0.8252 MPa. Whereas the variation condition

which has less optimum modulus of elasticity in the

composition of silicone rubber: alginate powder

(80:12)% wt with a thickness of 5 mm is 0.1321 MPa.

Modulus of elasticity is affected by the addition of

alginate powder and thickness which triggers the

viscoelastic response and mobility of the siloxan

chain molecule (Si-O-Si) formed from silanol (Si-

OH) silicon rubber groups causing the elasticity of the

radius bolus to increase and the stiffness of the bolus

material to decrease. Silicon rubber as a matrix has

properties that can increase the flexibility, elongation

Utilization of Alginate Powder Strenged with Silicon Rubber as Composite Bolus Material for Radiotheraphy 8 Mev Energy

211

and strength of the polymer so that it reduces the

hardness and stiffness of the polymer because it

increases the distance between chains by reducing

bonds between secondary molecules.

3.3 Relative Electron Density (RED)

Bolus radiotherapy based on alginate powder

composite reinforced by silicone rubber scanning

process using CT-Scan to obtain bolus tomographic

images in axial and coronal directions with the aim to

take the CT-Number value. CT-Number that has been

obtained depends on the value of CT-Number

obtained. The relative electron density (RED) value

of pure silicon rubber bolus without mixture is 1.168.

When compared with the RED value of pure silicone

rubber bolus composite with composite bolus of

alginate powder reinforced with silicone rubber.

Where the value of RED bolus has an important

role when the dose distribution calculation process is

performed when the patient uses bolus, so it can be

known how much the estimated radiation dose

received by the patient on the skin surface area and

under the skin surface. To reassure the results of the

compatibility of composite boluses with tissue types,

a calculation based on the composition of the

optimum alginate powder and bolus thickness and

various tissues using the effective atomic number

(EAN) calculation produces the following graphical

form:

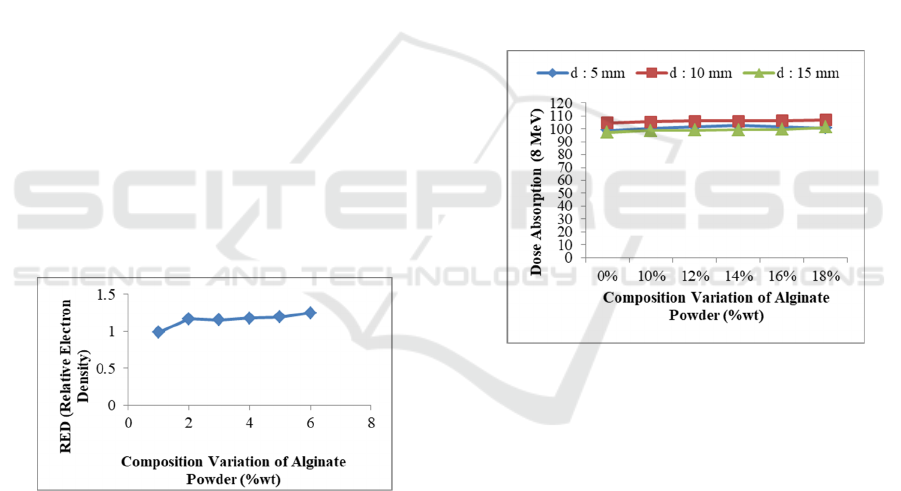

Figure 3.3 Test Results of RED Bolus Radiotherapy Based

on Composite Alginate / Silicon Rubber with CT Scans on

Various Composition

Figure 3.3 shows that the optimum conditions

obtained relative electron density (RED) value from

the CT scan results on the composition of silicone

rubber: alginate powder (80:20)% wt of 1.251 with

CT Number 241.4 HU, while for bad conditions on

the composition of silicon rubber: alginate powder

(80:12)% wt with RED 1.152 with CT Number 414.9

HU. The increase in the RED value is influenced by

the composition of the alginate powder, which is the

bond of inorganic polymers of silicon rubber in the

form of siloxane bonds consisting of silicon (Si) and

oxygen (O) atoms and methyl bonds consisting of

carbon (C) and hydrogen atoms are optimum for bind

the filler alginate powder so that it is denser and

stronger. Where the bolus material density affects the

absorption of material to the x-rays received by the

bolus.

3.4 Percentage of Dose Absorption on

the Surface

Bolus shielding radiotherapy based on alginate

powder composite reinforced by silicone rubber each

tested using LINAC to find out how much percentage

of the surface dose produced in electron beams with

8 MeV energy calculated by the equation D = (dε̄) /

dm. With the same calculation, it can be made a

measurement chart for the absorption dose value on

the surface of the silicone rubber-based bolus material

and alginate powder as follows:

Figure 3.4 Test Results Percentage of 8 MeV Absorbed

Doses in Alginate / Silicon Rubber Composite-Based

Boluses in Various Composition Variations

From the observations above, the graph shows

that the absorbance dose increases in proportion to the

increase in the composition of the alginate powder

and the thickness of the radiotherapy bolus. This is

shown from the results of the study that the optimum

conditions obtained absorbance values at 8 MeV are

good on the composition of silicone rubber: alginate

powder (80:20)% wt at 10 mm thickness of 106.92%

which the absorbent dose without bolus is 93%. This

increase in absorbency dose occurs due to differences

in scattering (scattering) that occurs when electron

particles pass through the medium (solid phantom).

For low-energy electron beams, electrons become

more easily scattered when interacting with a medium

(solid phantom), consequently the electron beam

IMC-SciMath 2019 - The International MIPAnet Conference on Science and Mathematics (IMC-SciMath)

212

fluence becomes more increased because of the

greater scattering angle (ѳ).

This results in the area of build-up that occurs not

too deep after passing through the surface of a solid

phantom, so that the ratio of the surface dose to the

maximum dose becomes smaller in the use of

electrons with low energy. But overall the increase in

the percentage of surface doses in solid phantom has

not reached 100%. To increase the percentage value

of the surface dose, a bolus with a uniform thickness

of 5 mm to 15 mm is used.

4 CONCLUSION

Research on the Utilization of Alginate Powder

Strengthened by Silicon Rubber as a Composite

Bolus Material for Radiotherapy Shielding

Applications at 8 Mev Energy, using a chemical

solution deposition method. In research with

composite bolus material made from alginate powder

reinforced with silicon rubber the following results

were obtained: the optimum composition is a

variation of the composition of silicone rubber:

alginate powder: catalyst (80:18:2)% wt at a thickness

of 15 mm has strong mechanical properties pull of

3.734 MPa, and modulus of elasticity of 0.8252 MPa.

optimum composition variation, namely silicone

rubber: alginate powder (80:18)% wt at 15 mm

thickness has CT number density properties that meet

tissue standards in phantom testing for therapeutic

media with a value of relative electron density (RED)

from the CT Scan results on the composition of 1.251

produced a surface absorbency dose for 8 MeV of

106.92%.

REFERENCES

Chianese J. and F. Chamberlain, Pratical Radiotherapy.

2009.

Hsu S. H., P. L. Roberson, Y. Chen, R. B. Marsh, L. J.

Pierce, and J. M. Moran, “Assessment of skin dose for

breast chest wall radiotherapy as a function of bolus

material,” Phys. Med. Biol., 2008.

Podgorsak E. B., Radiation Oncology Physics: A Handbook

for Teachers and Students. Chapter 6: External Photon

Beams: Physical Aspects. 2006.

Junaedi D, “Analysis penggunaan polydimethyl siloxane

sebagai bolus dalam rdioterapi menggunakan elektron

8 MeV pada linac,” Youngster Phys. J., vol. 5, no. 4, pp.

391–398, 2016.

Rianto Y., “Pengaruh komposisi campuran filler terhadap

kekuatan bending komposit ampas tebu, serbuk kayu

dalam matrik poliester” 2011.

Nayiroh N, “Teknologi Material Kmposi,” 2013. .

Sujana W. and I. K. A. Widi, “Pemanfaatan Silicon Rubber

Untuk Meningkatkan Ketangguhan Produk Otomotif

Buatan Lokal,” J. Energi Dan Manufaktur, vol. 6, no.

1, pp. 37–42, 2014.

Kirk O., Kirk‐Othmer Encyclopedia of Chemical

Technology, Fourth Edi. New York: John Wiley &

Sons, 1994.

P. Mayles, A. Nahum, and J. C. Rosenwald, Handbook of

radiotherapy physics: Theory and practice. 2007.

Utilization of Alginate Powder Strenged with Silicon Rubber as Composite Bolus Material for Radiotheraphy 8 Mev Energy

213